-

Posts

311 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Tomculb

-

-

Very nice work.

Like you, I found the upper gun port lids to be unacceptable as supplied and therefore made my own. And my kit was missing the photo-etched hinges, had insufficient chainplates, didn't have the very thin wire and included that odd decal! I asked MS to send me hinges and additional chainplates, and I only got the latter.

I really like the way you did the hinges. I don't know whether painting them white would make them more historically accurate, but leaving them black makes them more noticeable in a very credible way.

-

I bought them a few months ago and generally found them to be a mixed bag. Assuming you have wood strips cut in fractions of an inch rather than millimetres, you'll find them a lot easier to work with if you have a strip where the US measurement is close to a metric one. I was lucky in that regard for most of what I needed them for. In that case they work very well. Much harder to keep the strip centered if it has a lot of room to move back and forth within the slot in the tool, but maybe you can make some shims to create a good fit.

-

Your attention to detail is amazing. Keep up the good work.

-

Thanks Jon (I hope I'm remembering your name correctly). I'm pretty happy with my build so far, but it pales in comparison to the masterful job you're doing on your Connie. I enjoyed the recent discussion about coppering. As mentioned before in this blog, I have avoided copper plating because most approaches I have seen simply don't look realistic; more "impressionable" approaches discussed in your blog may change my mind. But maybe the real problem for me is having to overcome laziness. I doubt that I'll ever have the patience you have to devote so many years to one model (5 so far by my count, plus 22 pages of blogging, and you're still working on the hull!!). Kudos to you.

I'm very fortunate that my lower back journey has been much less arduous than yours. I started having issues about 25 years ago, but PT, stretching, lots of exercise, injections, etc. all helped keep symptoms very manageable and avoided any surgery. But loss of strength in one leg detected last fall led a few days ago to the removal of a little bone and a lot of arthritis; fortunately no fusion or artificial parts. With some luck, you'll finish your Connie before I need surgery again. Biggest challenge in my recovery now is tempering my annoyance when my wife admonishes me about bending, twisting and sitting too long. 😀

-

A milestone of sorts . . . I have stepped the mast.

I have mentioned previously that I enlarged the mast hole a bit in each deck so that there would be some wiggle room with which to assure that the mast would be vertical crosswise and would have the correct amount of rake. Good thing I did that because the resulting wiggle room was minimal, leaving little “wiggle” with which to make adjustments.

As it leaned naturally the mast had too much rake and leaned a bit to starboard. I spent quite a bit of time making the determination that if I pulled the mast as far forward and as far to port as possible, I was comfortable it was truly vertical athwartship and had close to the requisite 3 ½ degrees of mast rake. But making that determination was not simple, because I could not assume that i) the tops of the bulwarks were parallel to each other and to the water line, ii) the painted waterline was truly horizontal, or iii) the top of the work bench is level in all respects. I had a bit of a lightbulb-in-the-brain moment one morning when I walked into my work room, my first cup of coffee in hand. Looking at the model head on from maybe 20 feet away, the mast leaning naturally, I could not remember, and I could not tell, whether it was leaning to port or to starboard. Maybe, just maybe, I had been overthinking things.

To eliminate the wiggle and bring the mast forward and to port, I put a drop or two of glue on the bottom of the spar deck mast surround, and positioned it such that the mast was where I wanted it. I let the glue set a little and pulled the mast out (a tighter fit now) and let the glue dry firmly. I then did the same with the berthing and orlop deck surrounds. The gun deck surround was a little more problematic, as it was a very tight fit getting it in place with the guns and pumps and such, and once it was in place, I didn’t feel like pulling it back out to apply some glue. So that surround is not glued in place . . . nor does it need to be.

So now I have some mandatory time away from the shipyard, recovering from lower spinal surgery earlier this week. No bending, twisting or prolonged sitting for several weeks I’m told. Not what I wanted to hear, but the good news is I can walk as much as I feel like, and with a pretty minimal amount of pain meds I’m walking just fine. So life is good. 😀

- NavyShooter, CiscoH, Gregory and 2 others

-

5

5

-

The fighting top has ten precisely laser cut oblong holes, five each port and starboard, for securing the topmast shroud deadeyes along the upper side of the fighting top. Attached to the lower side of each hole is a ring to which the upper end of each futtock shroud will be hooked. The instructions have you use blackened brass wire to wrap around the deadeyes and then pass through the holes to form the ring below. As best as I can tell looking at the real ship, the deadeyes are secured with heavy rope, not with a metal ring, and I prefer working with thread rather than wire. But the ring below is metal, so I had to figure out a way to attach darkened brass eyebolts to the thread tied around the deadeyes. I tried any of a number different approaches that didn’t work. I think I spent as much time getting the first assembly put together as I did working on the other nine total.

Here is what finally seemed to work. First I took some .020” thread, wrapped it around the deadeye, and secured it with a square knot. Then I took an eyebolt, cut a very short piece off the end of the stem, and wrapped the remaining stem around to form a loop.

I passed the two ends of the thread through the hole in the fighting top, then passed one end through the loop I made in the eyebolt. I then passed that end back up through the hole in the fighting top (having previously hardened that end with a drop of CA glue), then used that end to pull the loop end of the eyebolt up into the hole. I then applied a drop of thin CA glue to the bundle of thread in the hole, thinking diluted white glue might not be strong enough. Then to add a belt to the suspenders, after trimming the loose ends, I stuck a small dab of thick CA glue into the bottom of each hole. It all seems pretty secure.

The instructions have you add two eyebolts (also seen in the plans) to each trestle tree, which I did. They also call for six eyebolts to the bottom of the front edge of the fighting top. There are conveniently six pre-drilled holes running along that front edge, but strangely the photos in the instructions clearly show the eyebolts between, not in, those holes. Looking at the plans it does not appear that any of these eyebolts will be used to secure anything, and looking at the real ship, no such eyebolts appear. I chose to leave them off my model.

Next up are what the instructions refer to as bobstay collars. The bobstays are standing rigging which runs from the deck up through bullseyes affixed to the aft side of the main mast then on up to the forward side of the mizzen mast. Of course they do not appear at all on this model, since there is no mizzen mast, but the bullseyes they run through do appear. The three sets of chocks attached to the mast earlier support the bullseyes at the appropriate height.

The bullseyes are seized onto the collar (.020” thread) which runs part way around each side of the mast, where a loop is seized at each end. The loops are pulled tightly together by a thinner line, or lanyard, that comes around the front end of the mast. More easily understood when looking at the pictures below or those in the instructions.

I assembled a jig similar to the one in the instructions, only I used only T-pins rather than a mix of T-pins and brass tubes as the instructions suggest. After wrapping the collar/thread around the pins, I seized a loop at each end, seized on either side of the center pin, and seized the throat at the end opposite the bullseye seizing. Since I am not very adept at seizing, this took quite a bit of time. Don’t tell anyone, but instead of seizing line the old fashioned way as I would have if I were working with a real piece of rope (too difficult to describe here), most of my seizing consists of a row of half hitches. With the very thin fly tying thread I use, you can’t tell the difference.

Not mentioned by the instructions, but the portion of the mast where the lower collar is affixed has a smaller diameter than the upper two, since the chafing protector is smaller lower down. The jig had to be adjusted accordingly to get the proper length. There is a fourth bobstay collar that is to be installed later on the upper, square section of the lower mast, but I left that for a later day, as do the instructions. I’ll have to keep in mind, though, that the upper section of mast has an even smaller diameter than the lower one and the jig will need to be adjusted again.

Once each assembly was secured with diluted white glue and all the loose ends were cut, I removed it from the jig and made the lanyards. I took some dark brown sewing thread and first threading it through each loop of the collar. I then tied an overhand knot as tightly as I could, then tied the other half of a square knot around the other part of the lanyard. A few drops of diluted white glue and the bobstay collars were secure.

-

Mr. BlueJacket kindly messaged me to point out that the trestle trees in the last two photos above are backwards; that is, the port one is on the starboard side and vice versa. The sheaves should be outboard, not inboard. Fortunately they are only dry fit in place to be photographed and not glued.

-

Assembling the fighting top is pretty straightforward. The laser cut floor and a small frame around the perimeter fit together precisely. The center cutout in the floor has a center mark, which greatly facilitates gluing the timbers in place. I drew the various lines running outward from that center mark. The instructions suggest determining the location of the aft timbers directly from the plans rather than using the center mark, but I don’t know why. The timbers overlap the frame forward, and cutting the notches to accommodate them turned out to be easier than I expected. And consistent with expectations, the laser cut upper crosstrees fit precisely.

There are also four laser cut cleats which can be seen in the second picture below. After gluing them in place I saw in the instructions quite a few pages ahead that at least a couple of them will be used to secure some lower yard rigging, and I have some concern that they may be too flimsy for the job. A challenge for another day . . .

The underside of the fighting top is as straightforward as the top side. The laser cut lower crosstrees and trestle trees fit precisely as expected. Same with what are referred to as the “thumb cleats” and their cast metal sheaves. I painted the sheaves black, I guess out of a tendency to leave no metal piece untreated, but so painted they become almost invisible. The instructions have you glue one trestle tree in place (3/16” off the center line) and leave the other one unglued, presumably to allow for a tight fit when it's time to glue the fighting top to the mast. I preferred to leave both trestle trees unglued.

Next I painted the whole thing white, then mixed up some light gray to paint the upper side of the deck. Finally I painted white half (horizontally) a 1/8 x 1/32 strip, and after soaking it, and with the help of an old iron, carefully wrapped and glued it around the front and sides of the fighting top.

A few eyebolts and some deadeyes will finish this stage of the fighting top. The instructions have you build and install the guard rail much later in the build.

Note added two months later -- part of a caption to a photo on page 56 of the instructions says "18 eyebolts added to various locations." Those eyebolts are not mentioned in the instruction text, and I completely overlooked that photo caption. Ten of those eyebolts are supposed to be added to the top of the fighting top, just inboard of where the deadeyes will be installed, and those ten eyebolts will eventually anchor the royal and topgallant shrouds. Easier to add them at this point in the build than where I am now (with deadeyes in and fighting top installed on the mast), but fortunately I have not yet installed the topsail shrouds, which would have made the job almost impossible.

- usedtosail, BobG, sirdrake and 3 others

-

6

6

-

I continue to be in awe of your kit bashing. It took me weeks to get up the courage to remove one side of the spar deck planking and frames to make the cannons below visible.

At the rate you're going you'll pass me in the not too distant future, and I'll have the benefit of following behind your build log. I look forward to that.

-

Phil, I am delighted to see another Connie Cross build log. You have obviously done a lot more historical research, and have been more willing to add to and vary from the kit, than I have. That is fun to see. I will be following your log closely.

One comment on the instructions. They are generally very good and certainly quite detailed, but sometimes they have errors so it is important to also take a look at the plans nearby when reading them. You have probably noticed that.

I look forward to watching your build.

-

Well do I feel stupid (not the first time). I wrote and posted that last entry while away from my model desk for a couple of days, and now upon re-examining the plans and instructions on my return, I see that the “mistakes” I said I made were not mistakes at all. I don’t know how I got that idea into my head! Two weeks prior I had tested positive for Covid, with very minor symptoms, and maybe I did not recognize the Covid fog. In any event, the plans, and at least one of the instructions’ photos, do show a gap between the bottom of the chafing protector (makes more sense to me than “fish”) and the mast surround, and the chafing protector does in fact wrap around the front of the mast and not the back. I edited my post accordingly.

-

From the square cut section down to the deck, the aft portion of the mast has wrapped around it what the instructions refer to as a “chafing fish”, a term I have never heard before and can’t find in any online nautical dictionary. In any event, it consists of additional planking, presumably to absorb chafing from running rigging. On the model, it is made from nine 1/16” x 1/8” strips, the middle three of which are to be cut to a length of 8-7/8” and the outer three on each side to 4-5/16”. The middle three cut to that length run all the way from the square portion of the mast down to the deck, which won’t work since it leaves no room for the spar deck mast surround. I cut them shorter allowing for the mast surround and an additional ⅛” gap between the chafing fish and the surround.

As instructed, I beveled the edges of each strip so that each one meets flush with the adjoining one, but I apparently did not bevel them sufficiently, as there were some small gaps at the surface.. The gaps were easily remedied with some wood filler, but the “fish” ends up wrapping a little farther around the mast than shown on the plans. I found myself thinking I should have used 1/16” x 3/32” instead of 1/16” x 1/8” strips, but better to have done a better job of bevelling the adjoining edges of each strip.

The instructions have you install the lower mast cheeks at this time, carefully sanding/grinding away portions of the chafing fish so that the cheeks can be tangent with the surface of the mast itself. Since the cheeks help support the fighting top and should therefore be glued to its underside without any gap or misalignment, I decided to delay this until the fighting top is assembled and ready to be installed. That project will be made a little more challenging by the fact that the fighting top will be horizontal, parallel with the water line, and not perpendicular to the mast, given the latter’s rake (at least I assume that’s correct, and that appears to be the case on the plans).

Next up . . . mast bands, which wrap between the edges of the chafing fish and all the way around the mast where it is squared for a few inches at the top. The kit supplies 1/64 x 1/16 brass for this purpose. While thinking about how best to put a waterline on my previous build (Joshua Slocumb’s Spray), I learned on these forums about a product called Chartpak, which is vinyl tape in a variety of widths and colors. In addition to a roll of black I purchased for the waterline, I purchased a roll of 1/16” wide white to make a mast band for that model. Voila! It worked like a charm on Connie’s main mast. It cuts easily with scissors and it is easy to trim if the first cut is a little long. And it wraps around the mast perfectly conforming to the curve with virtually no effort or tools, certainly without anything like needle nose pliers or wire cutters. It’s only shortcoming is that the adhesive on the back of the tape doesn’t adhere to anything for very long, so I had to add a little bit of glue. I completed all the bands in no time, and the end result looks pretty good.After adding laser cut chocks and a fairlead, I gave the whole thing a couple of coats of white paint (without any special priming of the mast bands needed!). I have to say I’m pretty pleased with the result.

- unixguy, schooner and usedtosail

-

3

3

-

After a little travel and some other head-clearing distractions I’m ready to tackle the mast. The initial part of the mast work doesn't lend itself to meaningful photography, so this post will be a lot of text and only a couple of photos.

For the lower mast the kit supplies a 16” x 7/16” dowel (identified by those dimensions in the parts list). The first thing we’re to do with that dowel, according to the instructions, is “cut [it] to the length of 16-3/8” long.” If anyone knows how to cut a 16” dowel to 16-3/8” please let me know; knowing how to do so would save a lot of time wasted measuring twice. 😀

Fortunately most of the missing ⅜” the instructions think you can produce consists of a knob at that bottom designed to fit into the mast foot created (in my case) close to a year ago. Again in my case, that knob is unnecessary to secure the mast, as I will use the mast surrounds to securely hold the mast vertical crosswise and with the desired amount of rake. And once all the barrels are in place down there, the interface between the mast bottom and the mast step won't be visible.

Speaking of mast rake . . . I enlarged each of the deck mast holes as I went along to allow for some final adjustment before securing the surrounds, but I think I need to pull the mast just a little bit farther forward than the holes allow to avoid too much rake. The instructions suggest tapering the below decks part of the mast, which I did, but I tapered only the aft half so the above decks part can be brought farther forward. The plans show a mast rake of 3 ½ degrees relative to the waterline, and I think that’s about what I get if I pull the mast forward as far as it goes. I'll try precision before gluing anything in place.

The mast above the deck also is tapered to 3/8”. For that, I first tried using a small plane, but I found it difficult to control, and make somewhat consistent, the amount I shaved off. Trying a different approach, I wrapped some tape around the lower end of the dowel and was able (barely) to wedge it into the chuck of my drill. With a sanding pad and the drill running at a fairly high speed I was able to get much better results.

The top 3-1/8th” is cut square. For that I pulled out a Dremel beveling table I bought years ago and rarely used since because its grip on the Dremel drill was too flimsy. I confirmed that it hasn’t gotten any stiffer over the years, and the flattened sides that resulted were not as flat as they needed to be, but for the most part the flaws disappeared with some sanding. A 1/16th chamfer is then cut into each corner. . . I used a sanding block for that.

Finally, the top 1/4” is cut to a square tenon, to accept the mast cap (which is made from two identical 1/8” thick laser cut pieces). Here, I made a mistake, as the plans appeared to show the mast extending about a 1/16” above the cap, as I would expect, rather than having it end flush with the upper surface of the cap. So I cut the tenon to a length of 5/16”. Turns out the mast does end flush with the upper surface of the cap, and what appeared to be an extension of the mast above it is actually two 1/16” square, so-called “spacers” , shown 15 pages later in the instructions. Fortunately a minor mistake.

- usedtosail and BobG

-

2

2

-

Many thanks Jon for all the pictures and information; thanks to you too Nic. Hard to believe I started this hobby before we had this wonderful community of generous builders.

-

Thank you Tom. That photo will be a big help. I have occassionally been looking at these forums while taking some time away from the build, and I'm surprised I didn't see your post from a month ago, thus the delayed response.

Another question for you or anyone else. . . The instructions refer to four heavy lines (your picture shows 2 of them) which end in thimbles, which are attached to nothing. They just hang there. The instructions refer to them as pendants. Any idea what they are or why they are there? I'm inclined to leave them off my model for fear it will look like I failed to complete something.

Just getting started on the mast. I imagine I'll be posting on progress in a week or so.

-

Well I think I can now declare the hull FINISHED!

With a couple of caveats. First, as mentioned in a previous post, I’m doing the tedious job of securing the netting for the hammock rails in stages, and I am not gluing them in place on the bulwarks until the end of the build. Similarly I’m also leaving one gangway headboard on each side for the end of the build, since it needs to be glued on end with nothing to support it, and I don’t want to snag them either while rigging the mast.

I did manage to finish the other side of the hammock netting, so I am halfway through that job. Hard to see in the photo, but I think I did a better job this time cutting the netting so as not to leave ends sticking up in mid air.

One gangway headboard on each side is glued to the end of the bulwark. That was easy. Also easy . . . a few eyebots and thread, and I had a handrail to go with the sea steps previously installed. In the photo you can see where the other headboard is to be installed and how fragile an installation that will be. I’ll probably pin it to make it a little more secure.

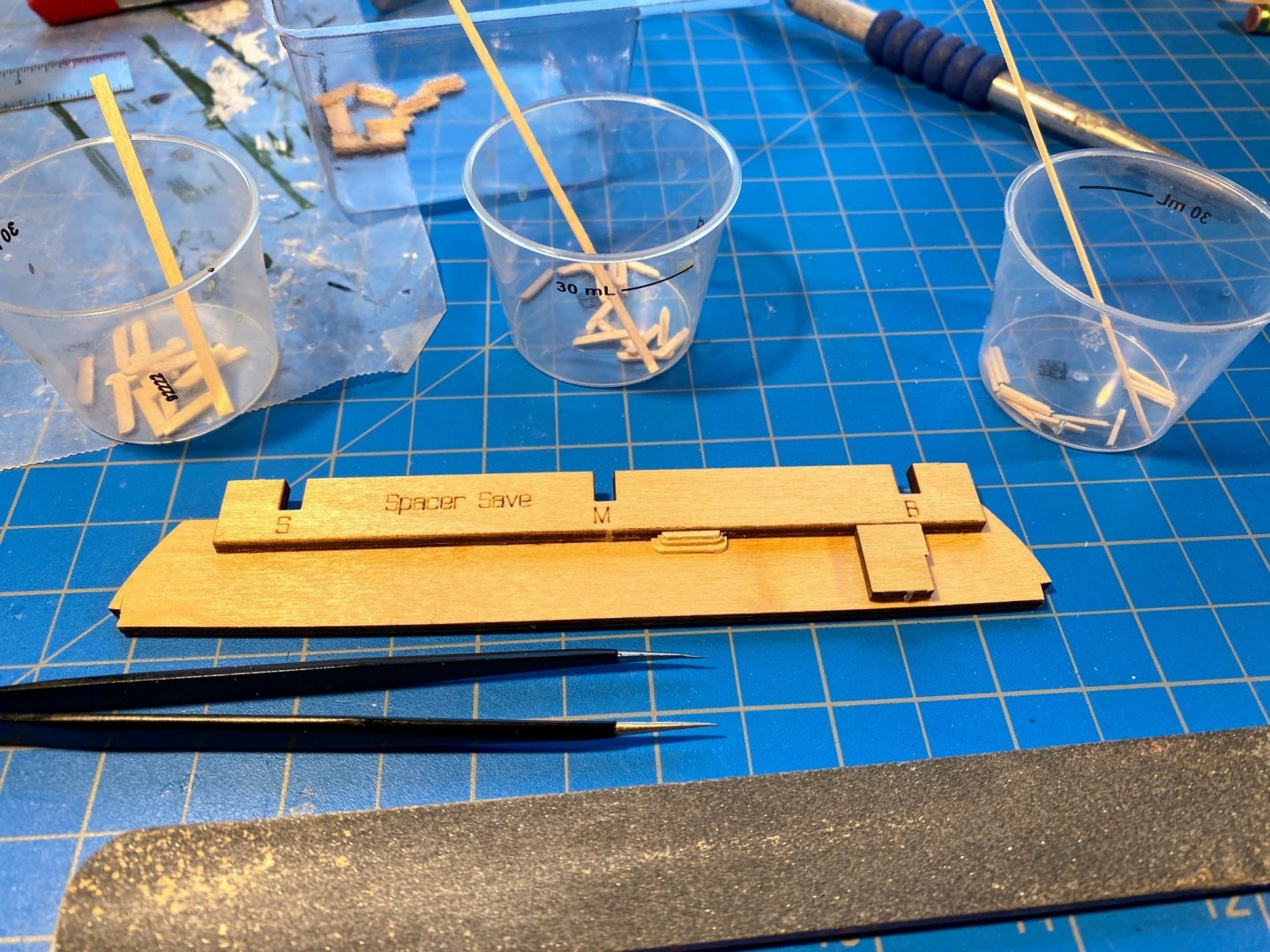

In the picture below you can also see the trim I molded and glued in place. The mold shaping tool I mentioned previously worked very well, and was easier to use than last time because the American dimensioned trim pieces were very close to a metric dimension used by the tool.

One more incomplete project . . . in the process of turning everything upside down and planking the hull I managed to dislodge a few of the teeth in Connie’s grin (ie some barrels). I haven’t gotten around to gluing them back in yet, and I will probably wait until I have installed the mast, so I can look inside and see where its bottom meets the mast step.

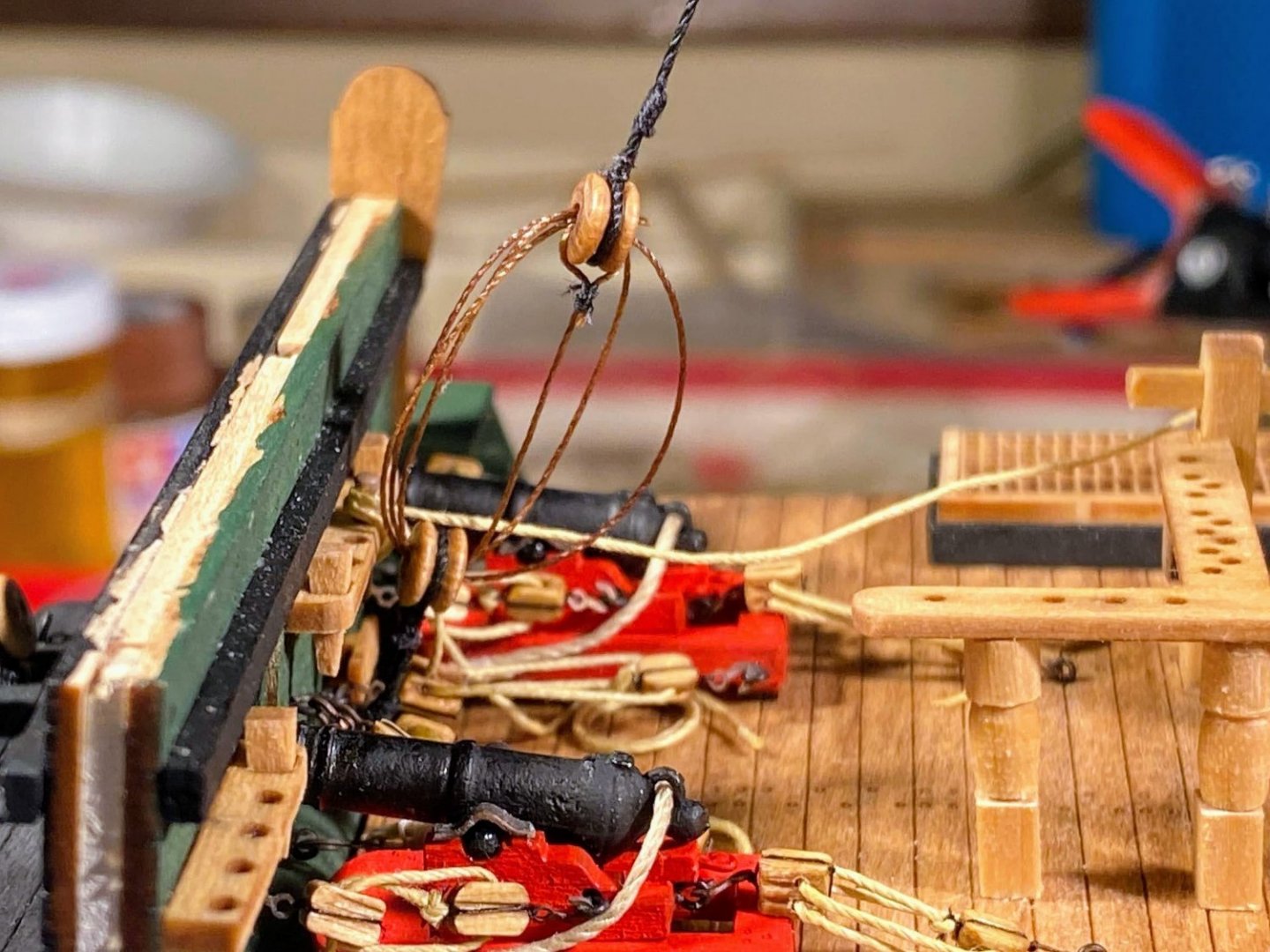

Finally, I realized that the bentinck shrouds will one day be secured to eyebolts installed months ago in the middle of the spar deck waterways. Installed before the cannons were tied in place and became all but completely hidden from view. Obviously hooking the shrouds to those eyebolts isn’t going to get any easier, so I better do it now. The shroud is seized to a bullseye, which is lashed (with a lanyard) to another bullseye which is seized to a hook. Sounds easy enough, but I discovered that my seizing skills are a bit rusty (“skill” being not necessarily the right word in my case), and there was more than one do over along the way but I eventually got it done. I left the lanyard untied, since I assume that is what I will adjust someday to get the shroud appropriately taut.

Hooking the shroud assembly to the eyebolt was not as difficult as I feared; got it done on about the third or fourth try. But once I took a look at how it will eventually look I decided was not happy with the running rigging thread I had used for the lanyard . . . too thick and seemed too light in color.

I mentioned previously that I have been taking a few looks at UsedToSail’s build log of the full ship Constitution, and in it there is a interesting discussion about the lanyards used with deadeyes and bullseyes. They are basically part of the standing rigging, but they are intended to be adjusted occasionally, certainly not frequently. Adjustable standing rigging. On the current ship, the deadeyes, the bullseyes and the lanyards are all black, but as mentioned previously I subconsciously decided to leave my deadeyes natural (dark brown). Someone in that discussion suggested making the lanyards dark brown and mentioned having used dark stain to color lighter thread for that purpose. Not having any dark brown thread, I decided to give that a try . . . another do over. I found some thread of a more acceptable thickness, but after staining it’s a little shiny, which I don’t like (not as bad though as in the pictures below). So in my mind the jury is still out on what thread I will use for lanyards (maybe just black). I may make a trip to a fabric store one day to find some thread that is manufactured in a color I like. In any event, I think yet another do over is called for. At least I’m finding hooking it to the eyebolt to be easier than I feared.

Finally I decided to coil the end of one of the cannon tackles and hang it from the nearby pinrail. And just for fun I hung another coil on the opposite side, where there are no cannons.

So on to the mast, which looks like quite a project. I have decided to take a bit of a break before moving on, probably a few weeks worth, as I spend some time on other things that need to be done and study ahead in the instructions to familiarize myself with the upcoming build. One thing that has me perplexed already is how the other end of the bentinck shrouds are secured to the futtock shrouds . . . . I'm having difficulty understanding the written instructions and something about the pictures just doesn't look right.

-

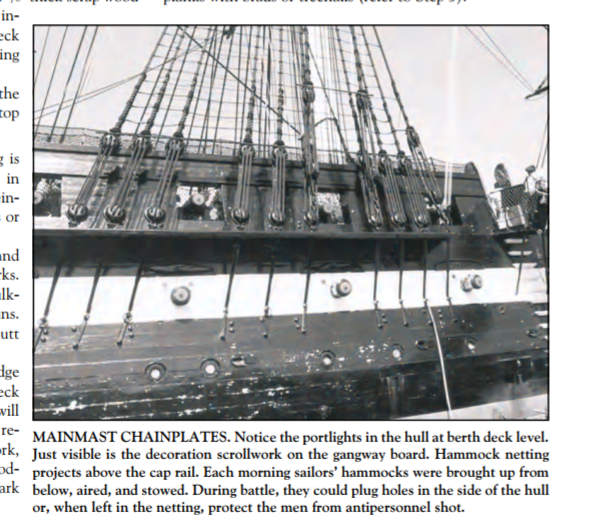

More on whether the chainplates should be perpendicular or run with the shouds to which they are attached . . .

One thing I like about Model Shipways is you can download instructions to any of their kits free of charge. Some time ago I downloaded the instructions to their full-ship Constitution, and I refer to it from time to time when the cross-section instructions leave me with a question or two. I was doing that earlier today with a different question in mind and stumbled upon this old picture of the real ship. Apparently the chainplates were not always perpendicular but did at one time follow the line of the shrouds. In restoring/rebuilding an historic ship to turn it into a museum, that strikes me as an odd thing to change. Anyone have any insight on that?

-

Back to Tom . . . I too used to sail, including a Hobie 16, and occassionally I still get the opportunity (most recently a friend's Hobie 16 on Lake Couer d'Alene). I lived in Hawaii for 18 years as a young adult, and after crewing for others on ocean racers for several years, I raced a Fireball for a while, and then got into Hobie Cats, mostly 16s and then 18s. The 18 was my favorite. . . the dagger boards helped with tacking and the roller furling jib was a plus. As much as I enjoy the moutains and lakes of the Inland Northwest, I miss those days.

-

Different subject as I finish up some details on the hull and look ahead to the mast and rigging . . . The instructions have you finish the shrouds and ratlines before doing any of the running rigging. The running rigging seems to all tie off to the fife rail and a couple of the rails on the inside of the bulwarks. But doing the rigging from the outside in like that, isn't the standing rigging going to get in the way when trying to tie off the running rigging? Wouldn't it be easier to do the running rigging first? Any thoughts??

-

Thanks for your observations Tom. I actually gave that issue some thought, because my initial assumption was, as you say, that the chain plates should be in line with the shrouds. I'm no engineer, but intuatively that seems like the best way to run them from a structural point of view. And that's how they are shown on the plans.

However in the pictures in the instructions, especially the picture on page 93, they appear to run straight up and down and parallel to each other, except on either side of one of the gun ports. And looking at the Google Maps tour of the real ship (picture below) they all look parallel. Parallel seemed easier to do than trying to run them in line with where I think (or hope) the shrouds will run, when they won't be installed until sometime later. So I decided to take the easy approach and make them parallel. I also figured that trying to line them up with the shrouds and missing the mark would probably look worse than parallel albeit inaccurate.

Incidentally, your post led me to go back to look at your Connie build log, which to my recollection I had not seen before. What a magnificent job. Your log will now be one of my go-to sources when I have a question on how to proceed (which seems to happen a lot). Several times during this build (most recently the chain plates) I have marvelled at the patience it must take to build a model of the entire ship, and I have found myself grateful that I am tackling only a cross section. Also . . . the Beagle is on my list (probably the Occre kit), and I'll be looking at your build log when I get to that one.

Thanks again for dropping by.

- schooner and usedtosail

-

2

2

-

The channels are laser cut from a 3/32” sheet. There are six chain plates on each side (5 attached to deadeyes; 1 attached to a small ring), and it appears that MS is having some difficulty in their counting department. The channels have only 5 notches for chain plates (a fault easily remedied by cutting another notch), and the supplied photo-etched sheet of chain plates contains only 10 of them. Fortunately MS has a reputation for great service when parts are missing or broken (a well deserved reputation in my experience), and they sent me a second sheet of chain plates, so now I have extras.

The plans show the channels tapering toward the outer edges, as one would expect as the ship’s designers would probably want to reduce weight on anything extending beyond the walls of the hull. I tapered them from 3/32” to 1/16”, glued a 1/16” square strip along the outer edge, and sanded it round. The instructions suggest a more elaborate molding along the outer edge using the molding shaper discussed in my previous post, but with only 1/16” to work with, and painted black no less, I decided that would not be worth the effort.

The instructions suggest using wire to strop the deadeyes to the top of the chainplates, but I have always found rigging thread easier to work with than wire. Getting the chain plates bent just right took some trial and error, differences of fraction of a millimeter being quite apparent when installed on the hull, so once I got it right on the first one, I reproduced it on paper and tried to bend all the others accordingly. As the instructions mention, they are also a little to long and need to be cut shorter.

Then I simply took .021” black thread, wrapped it around the deadeye, tied half of a square knot tightly, loosely tied a second half of the knot, slipped the bent hook of the chain plate between the two halves, tightened everything up, bent the hook tightly against the knot, and added a large drop of diluted white glue for additional security. The deadeye that emerged once everything dried looked so happy I almost hesitated to cut his arm’s off. 🤪

The instructions show the deadeyes left natural, but the real ship has them painted black, and before I got to this stage, I gave a fair amount of thought as to how I wanted to do mine. But when it came time to tie the first one to the chain plate, I was so focused on that project that I didn’t even think about painting it. Apparently my subconscious brain made the decision for me.

As can be seen above, the chain plates actually come in two pieces, a longer one running from the channel down to the hull (referred to as the “strap” in the instructions) and a shorter one attached to the bottom of the strap, running down flush with the hull (referred to as the “link”). Installing them would probably have been a lot easier had they been provided as one long piece. In any event, I dropped the chain plate/dead eye assembly through the notch in the channel, then brought the lower end of the chain plate to the surface of the hull, and drilled a hole, trying to keep each chain plate perpendicular to the waterline and parallel to the adjacent chain plate. I had previously enlarged the holes in the strap and link parts of the chainplates (as I did with the hammock stanchions discussed in my previous post), as they come supplied with holes too tiny to get much of anything through them.

On alternate chain plates, the instructions (and the real ship) have an eyebolt with a ring hanging from it where the strap and link meet. I’m not sure what function these rings serve, but I suppose they could be used when a small boat ties up along side or when the ship is tied to a dock. On the alternate chain plates the pictures in the instructions show nothing in the holes where these pieces meet nor at the bottom of any of the links. On the ship obviously the chain plates would be secured in these places with large thorough-the-hull bolts, as this is what holds the masts up, and some sort of pin in each of these places on the model would help help assure the chain plates stay in place when the ratlines are firmly tied on. So I dug through my leftover materials from other builds, found some brass wire the same thickness as the wire eyebolts, and pinned the pieces of the chain plates in place with 1/8" lengths of wire, secured with a drop of medium CA glue. Doing this was quite a bit more difficult than it sounds, as anyone working with tiny pieces of photo-etched brass knows that those pieces generally ignore all the rules of gravity, aerodynamics and Newtonian physics. But while it took some effort (and dexterity which seems harder to come by as the years go by), I eventually finished the starboard side, and the port side is now maybe 75% finished. A tiny drop of flat black paint applied to each pin hid the brass, and created something that might look like a bolt head but at this scale too small to really see. I did make the mistake of looking at a couple of them through a magnifying glass, but I don’t think I’ll do that again. 😃 Fortunately the links in person look darker than they do in the picture below.

As mentioned (and can be seen) above, the sixth chain plate on each side is attached to a ring rather than to a deadeye. Here I took a wire eye bolt, bent the stem 90 degrees to the eye, and glued the stem to the underside of the channel with a few dabs of medium CA. The hole in the channel was large enough to accommodate both the stem and the chain plate, and I secured both in place with another dab of CA.

-

Progress both quick and slow . . .

The gun port lids on the port side are displayed open. Putting them together was straightforward and relatively quick. I realized later that I had not put the photo etched brass hinges on the lids on either side, probably in part because they were missing from my kit. I don’t think they will be missed, and who knows, maybe I'll add them later.

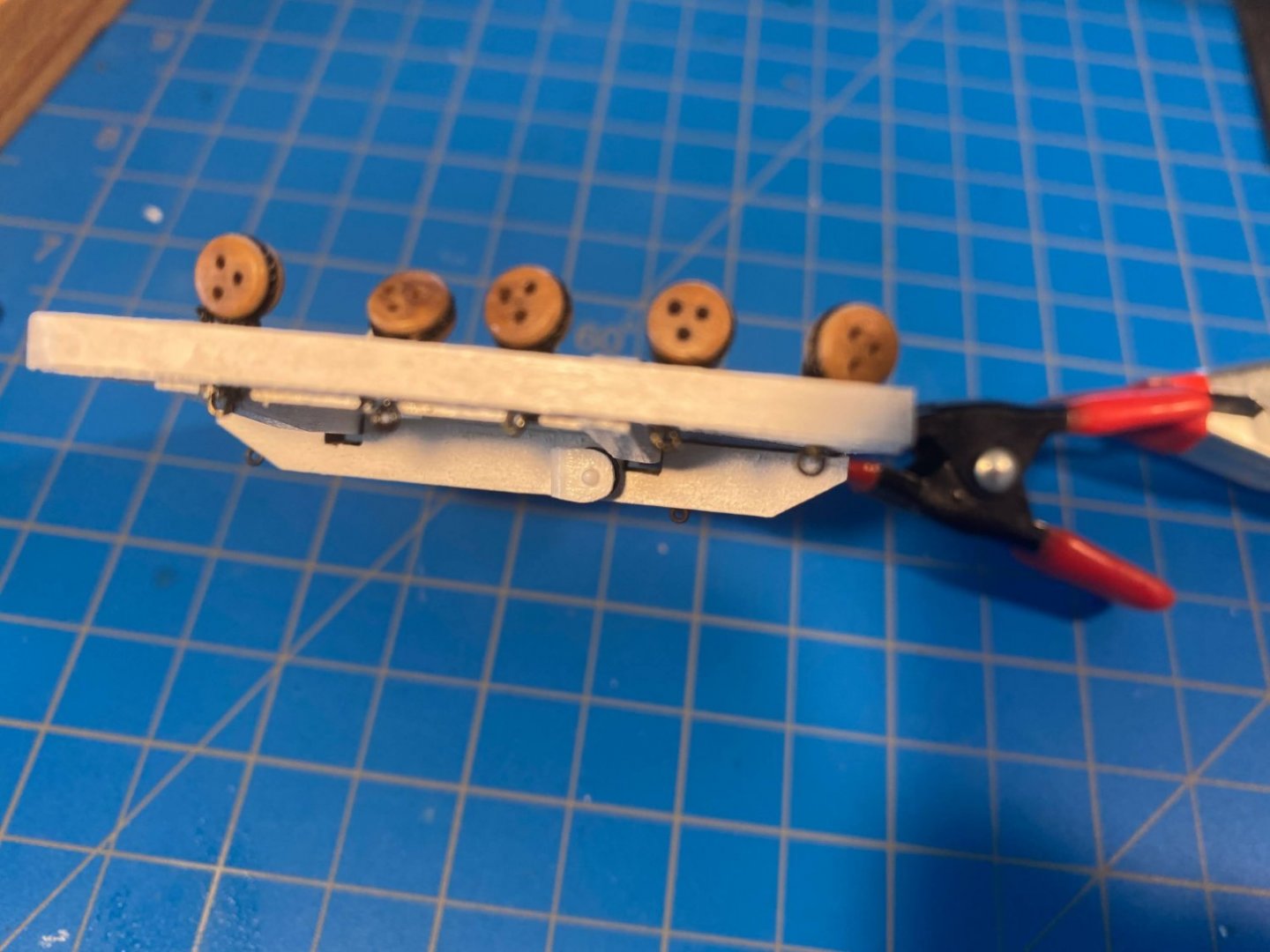

Next I decided to do the cap rails and hammock stanchions & netting. The cap rails are made from ¼’” x ⅛” strips. The outside edge of each is to be shaped with double half round molding, and the instructions suggest using a molding cutter for that purpose (and a picture of such a cutter is shown several pages later in the instructions, with regard to the channels). The only cutters I could find are made by Artisanea Latina. I purchased a set and gave it a try. Unfortunately they are all made for metric sized wood strips, and keeping a US measured strip centered in the desired form was a bit of a challenge. But it worked pretty well, but a bit out of focus in the photo below.

Installing the stanchions on the caprials was pretty straightforward. Fortunately as described further below, I had the foresight to enlarge the holes in them before gluing them onto the cap rail.

The netting was next, and it was anything but straightforward. I looked at logs of a few whole-ship Constitution builds, and discovered others found the netting to be challenging (including GrandpaPhil, an occasional visitor here, on his Victory). After consuming many more hours than it should have, I completed one of four sides of netting, and I’m not entirely satisfied with the result.

Here are a few things I learned or figured out in this effort, which may be helpful to others:

-

The instructions suggest using 34 gauge wire to simulate the rope which links the stanchions together, but none of the supplied wire or wire I already had was thin enough to get through the holes even after enlarging. And using wire to simulate rope seems kind of counterintuitive anyway.

-

I used a 76 gauge drill bit to enlarge the holes in the stanchions, the smallest bit I had that resulted in a hole large enough to get thread through. The drilling had to be done manually with a pin vise and done very carefully to avoid having the bit get stuck and twist the top of the stanchion off.

-

The instructions have you do the netting after gluing the cap rails (with stanchions) to the top of the bulwarks, but I assumed correctly that I would need to approach this task from a lot of different angles, and that wouldn’t be possible once the cap rails were glued in place. I also decided that I won’t glue the cap rails in place until late in the build, after most of the rigging is done, to avoid constantly snagging the rigging on the cap rail/hammock assemblies.

-

The instructions have you glue the netting to the wire (or in my case thread) with tiny drops of CA glue. In my experience even the tiniest drop of CA spreads all over the place and tends to make a mess. Furthermore, it’s usually quite visible after it dries. I much prefer diluted white school glue, because although it too spreads all over, it’s virtually invisible after it’s dry. The downside is that it’s nowhere near as strong as CA, and I doubt that using it to try to glue netting to wire or thread would be sufficient. I thus tried to weave the thread through the diamonds in the net.

-

Putting something white behind what I was doing helped immensely in being able to better see the thread and netting.

-

I used a metal ruler and a knife with a new blade to cut the netting, but I wasn’t careful enough to avoid leaving bare ends of netting (rather than cutting right at the top of each diamond), which are like fishhooks in terms of their ability to snag both the thread and other parts of the netting.

-

As the result of snagging, on my first attempt to thread the thread through the netting, it became unraveled and frayed. On my second attempt, I first ran the length of thread through some diluted white glue, which helped quite a bit. I also dipped the first half inch or so in thin CA glue, to make it like a needle passing through the holes in the stanchions and in the netting.

-

Despite what I thought was extreme care in measuring the height of the strip of net, I cut this one a little too small. Next time I may cut it a little too large, and fold the excess in along the top of the cap rail.

-

The instructions suggest running the forward end of the wire (or thread) into holes drilled in the gangway trail board. This isn’t done on the real ship; instead of attaching the rope somehow to the trail board, the rope ends at the forward stanchion, which is a few inches away from the trailboard. I decided I would do the same with my model.

-

I haven’t figured out why the thread gravitates toward the left and right points of each diamond rather than the top or bottom (as the case may be) of each diamond.

Having completed one of four sides of netting, I have decided to set it aside, and every month or so while working on the mast, take a few hours break and work on one of the other three sides. With enough practice maybe I’ll get good enough, and have developed the patience, to remove my first effort and redo it with a more satisfactory result. In the photo below I have put the partially completed project in place, but without glue.

I'm working now on the channels and chainplates.

-

-

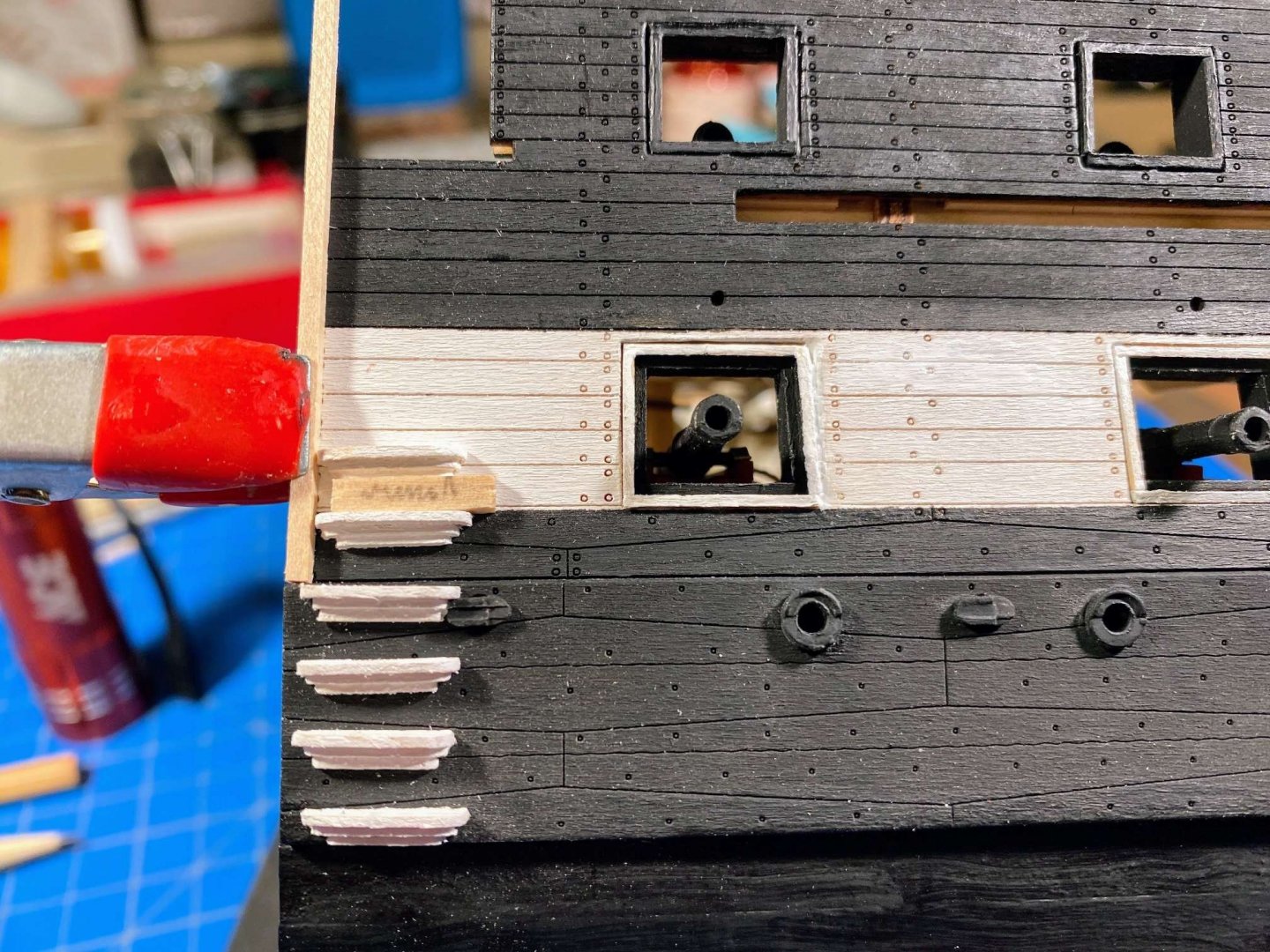

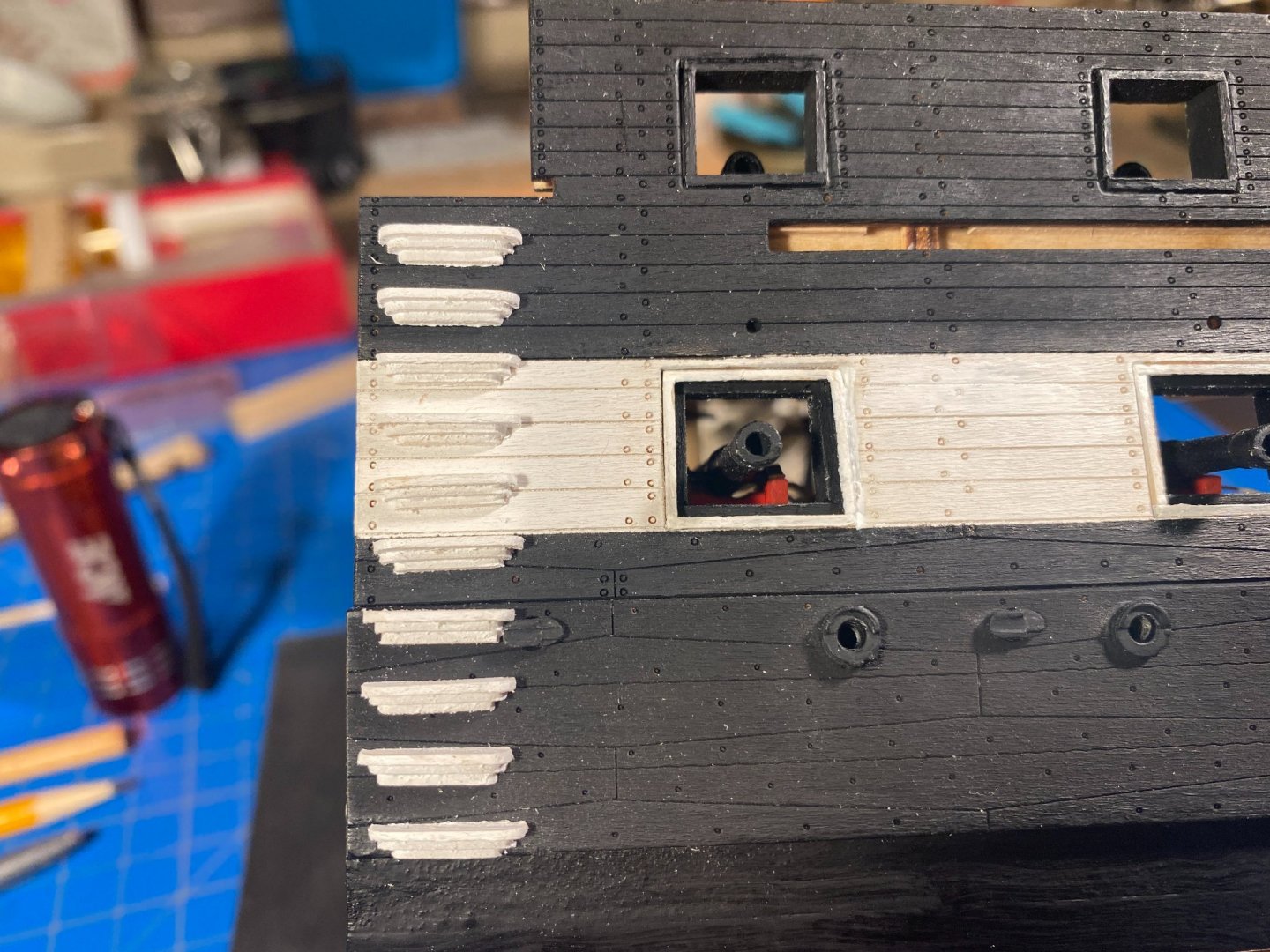

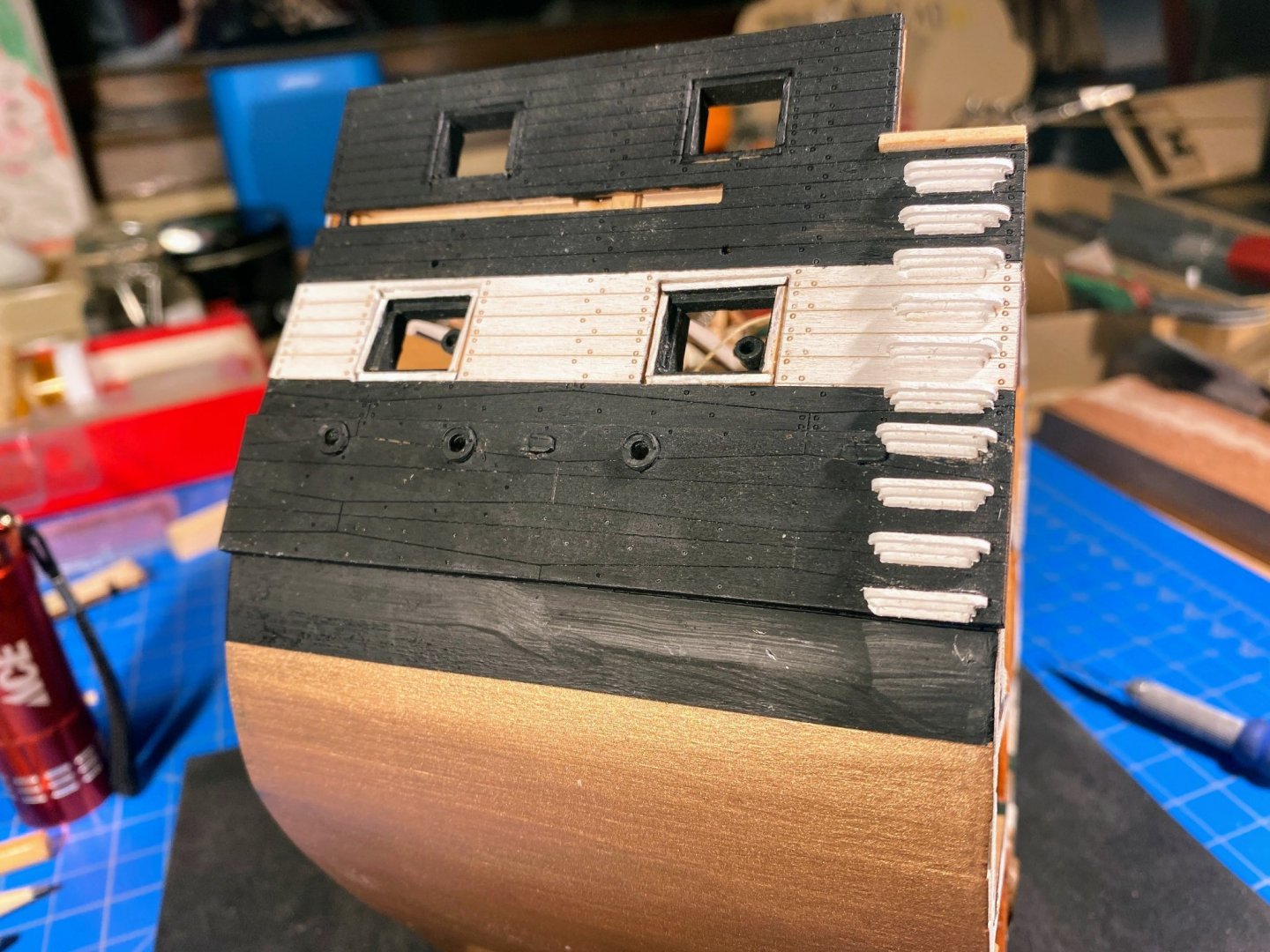

I actually had a good start on the gun port lids (or hatches) when I wrote that last post, and the guest room wasn’t needed until a day later than I had planned on, so this post comes along sooner than I expected.

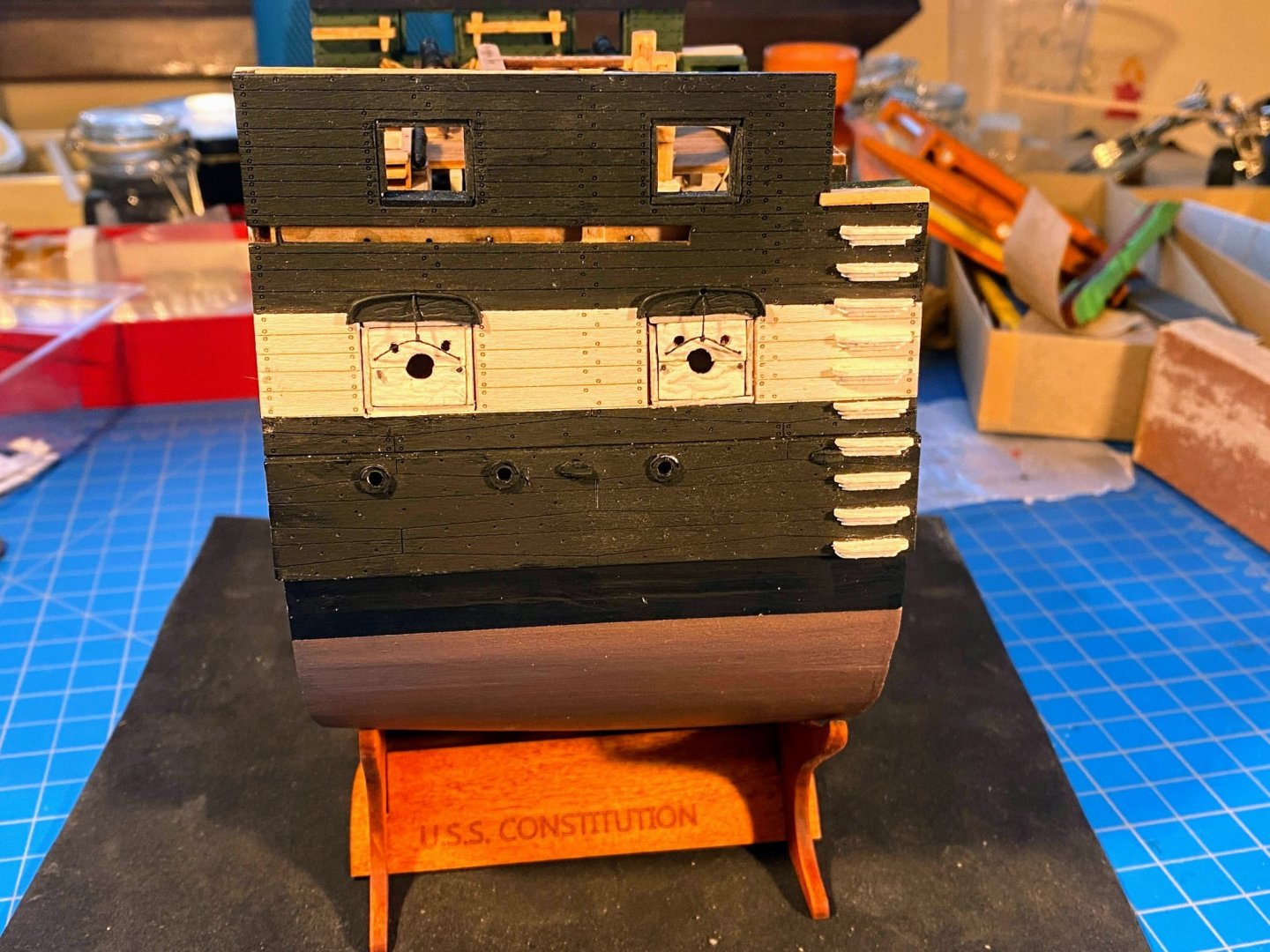

I decided to start with the starboard side ports. Recall my major kit-bashing . . . cutting a hole in the spar deck on that side to open up visibility to the long guns and other details below, and installing those cannons in recoil position with the result that their port lids could be displayed closed.

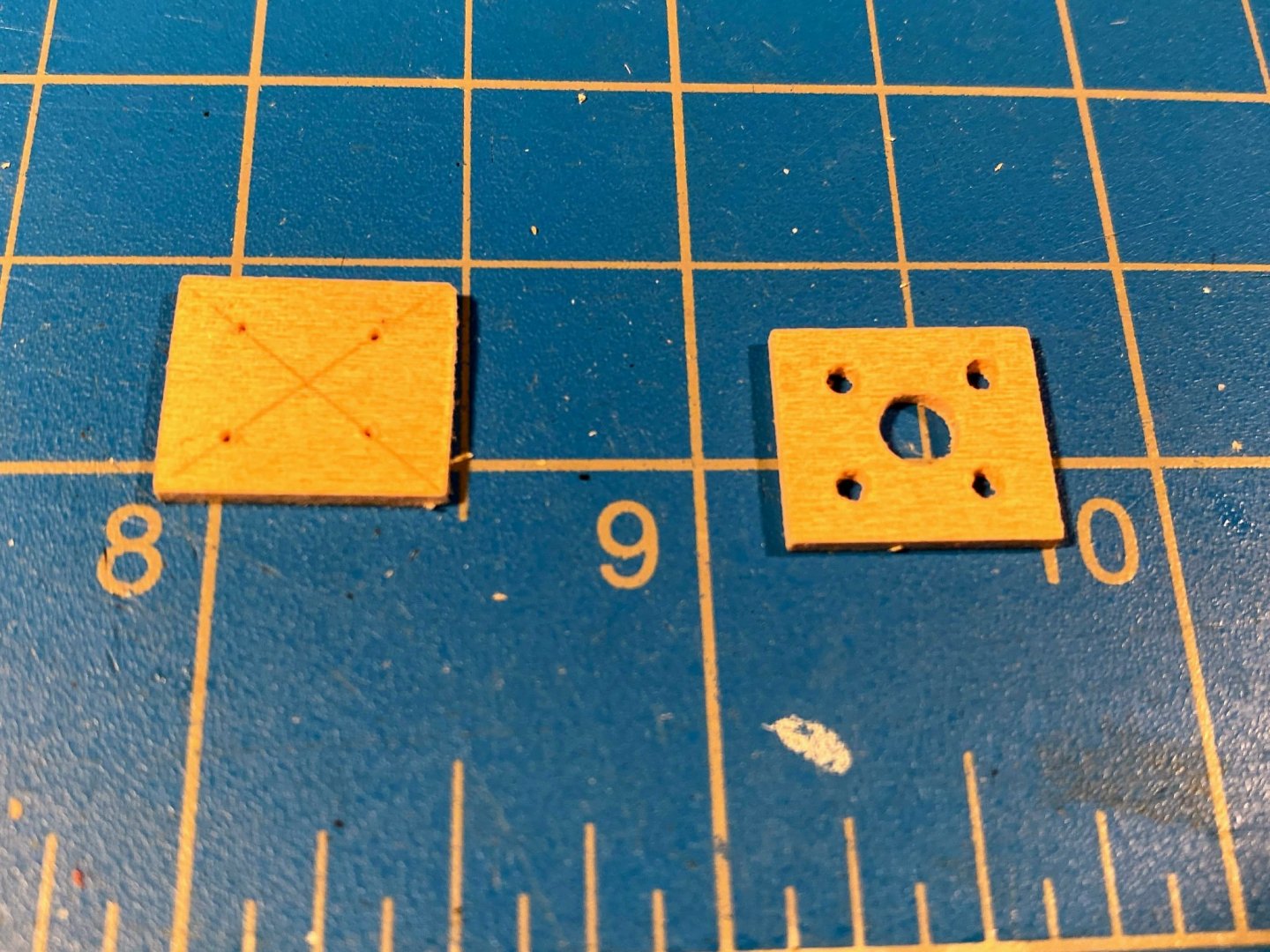

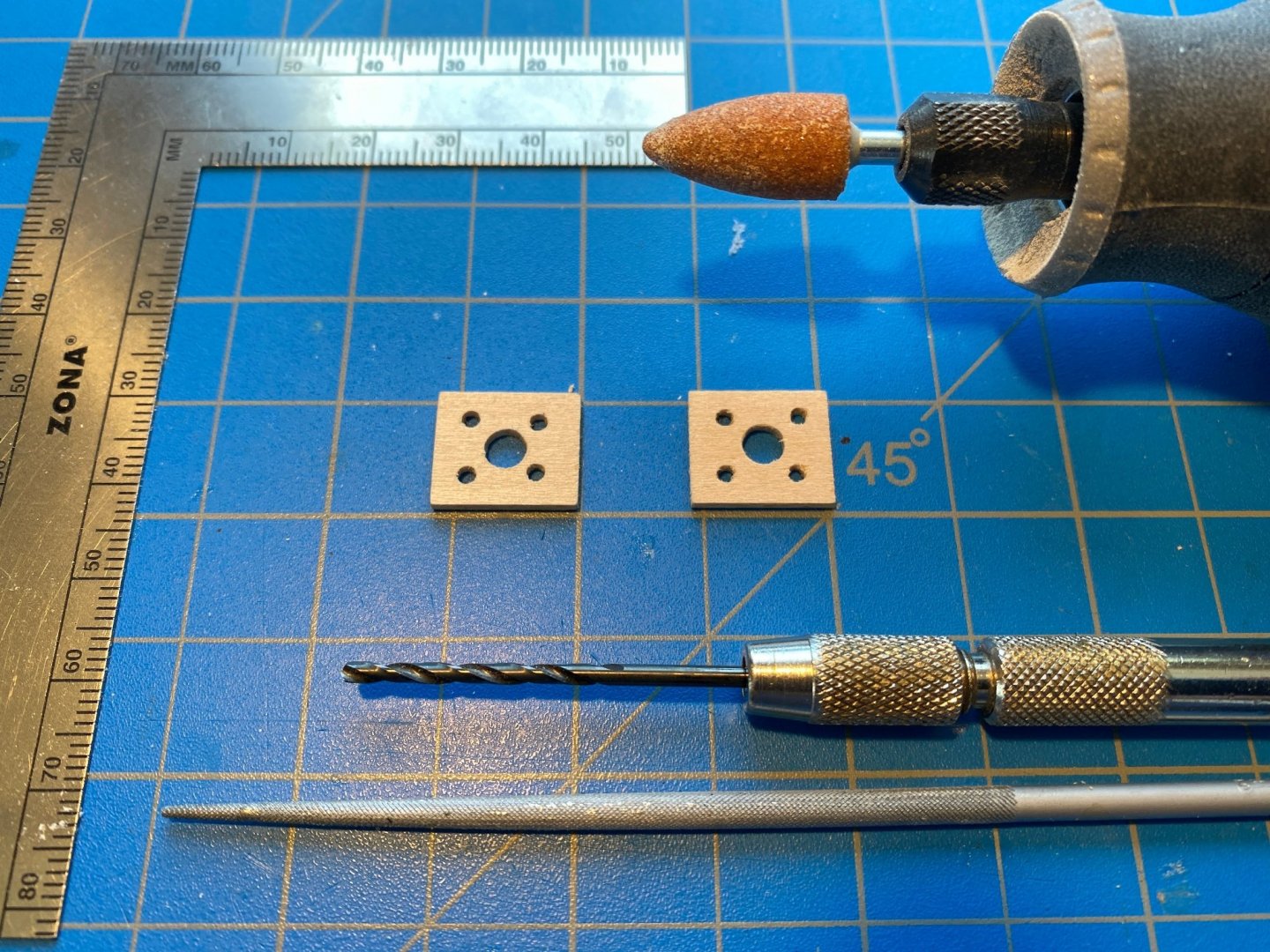

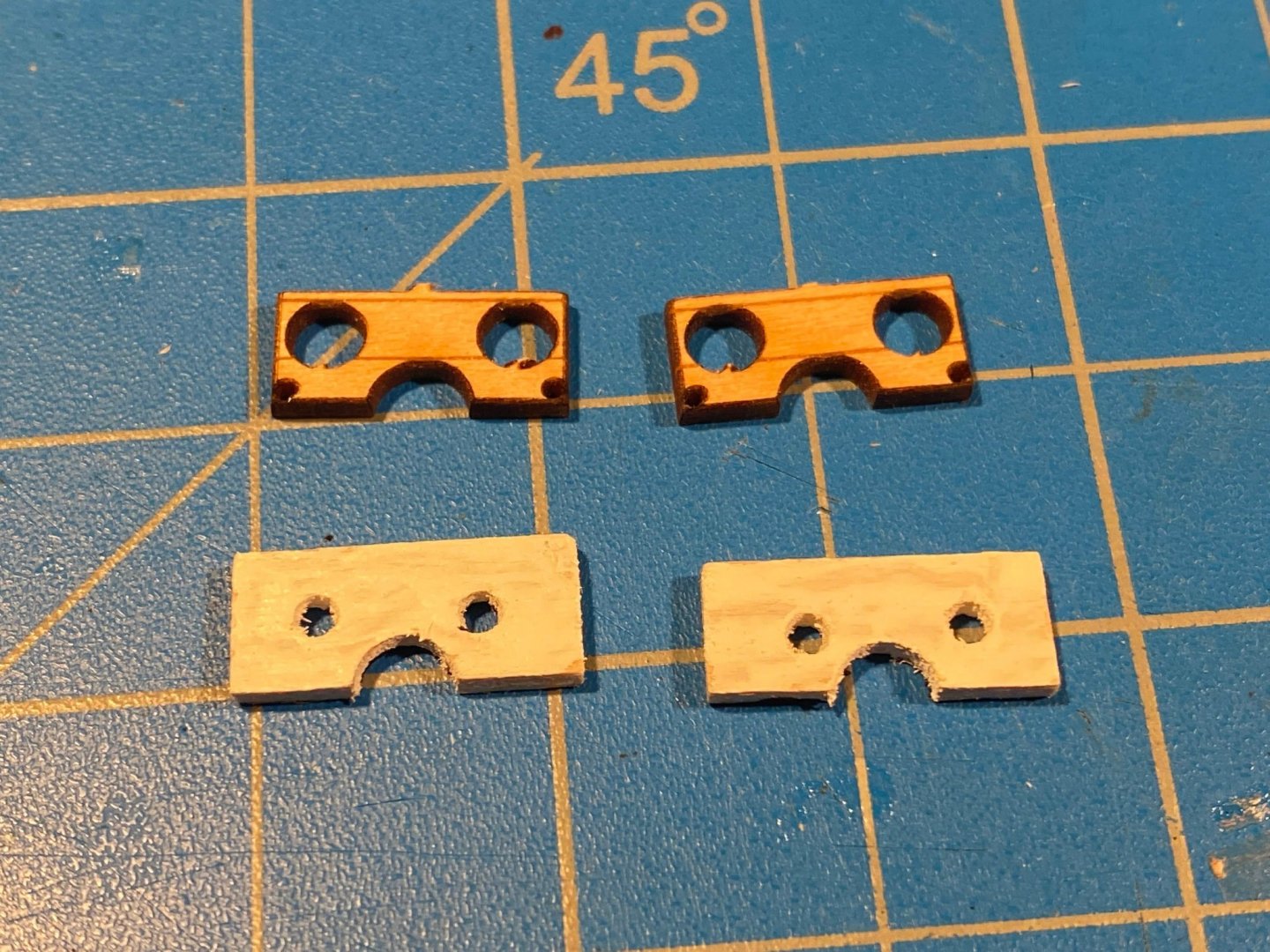

Each pair of lids forms a hole through which the gun barrel can poke through. Each upper lid has an additional pair of holes, which I assume were there for ventilation. In the laser-cut upper lids, these additional holes are almost as large as the cannon barrel hole, which just doesn’t look right. Looking at pictures of the real ship in Boston and various models of the entire ship (including the one developed by MS), the vent holes should be much smaller.

This bothered me enough that I cut out my own upper lids with much smaller vent holes. I drilled holes for two lids in 1/16” stock, then split the stock in half to separate the two. The gun barrel hole had to be 11/64” in diameter to match the lower lid, and drilling the hole proved problematic. Even when drilled by using a handful of successively larger bits, the wood split in two well before I could get the hole as large as 11/64”. I then used a pin vice to get the holes to about 1/16”, then used a conical shaped sander on my Dremel to finish the job. All of that took a while, but it worked.

Once drilled, I painted the outsides of each lid white and the insides black, consistent with what I saw in photos of the real ship and other models (but not the photos in the instructions which show both sides white).

I had made the upper lids intentionally about a millimeter large in both dimensions, just to be safe, so some trimming and sanding was necessary to get them to size, particularly in the case of the port on the right in the pictures.

Both lids have rigging to assist in opening and closing them. The instructions would have you make the rigging out of 34 gauge (.006”), but wire that thin is not supplied in the kit. The photos in the instructions (especially the one on page 49) use wire that looks thicker, and which to my eye looks too thick and stiff. I assume this was rope that was belayed on a cleat and or maybe wound around a small winch; in either case it had to be something flexible. I used some of the .008” black rigging line which came with the kit, which looked much better to me. I dipped the ends of it in diluted white glue to make it stiff enough to pass it through the hole in the eyebrow and the tiny holes in the corners of the lids. On the lower lid I knotted a short piece of rigging line, tied a knot in it, ran the line through the hole, soaked it with more diluted white glue, and cut the ends of the knot (on the outside) and the bare line (on the inside).

Starboard lids completed, the guests are arriving, and I’ll get to the port side later next week.

- usedtosail, yvesvidal, schooner and 2 others

-

5

5

-

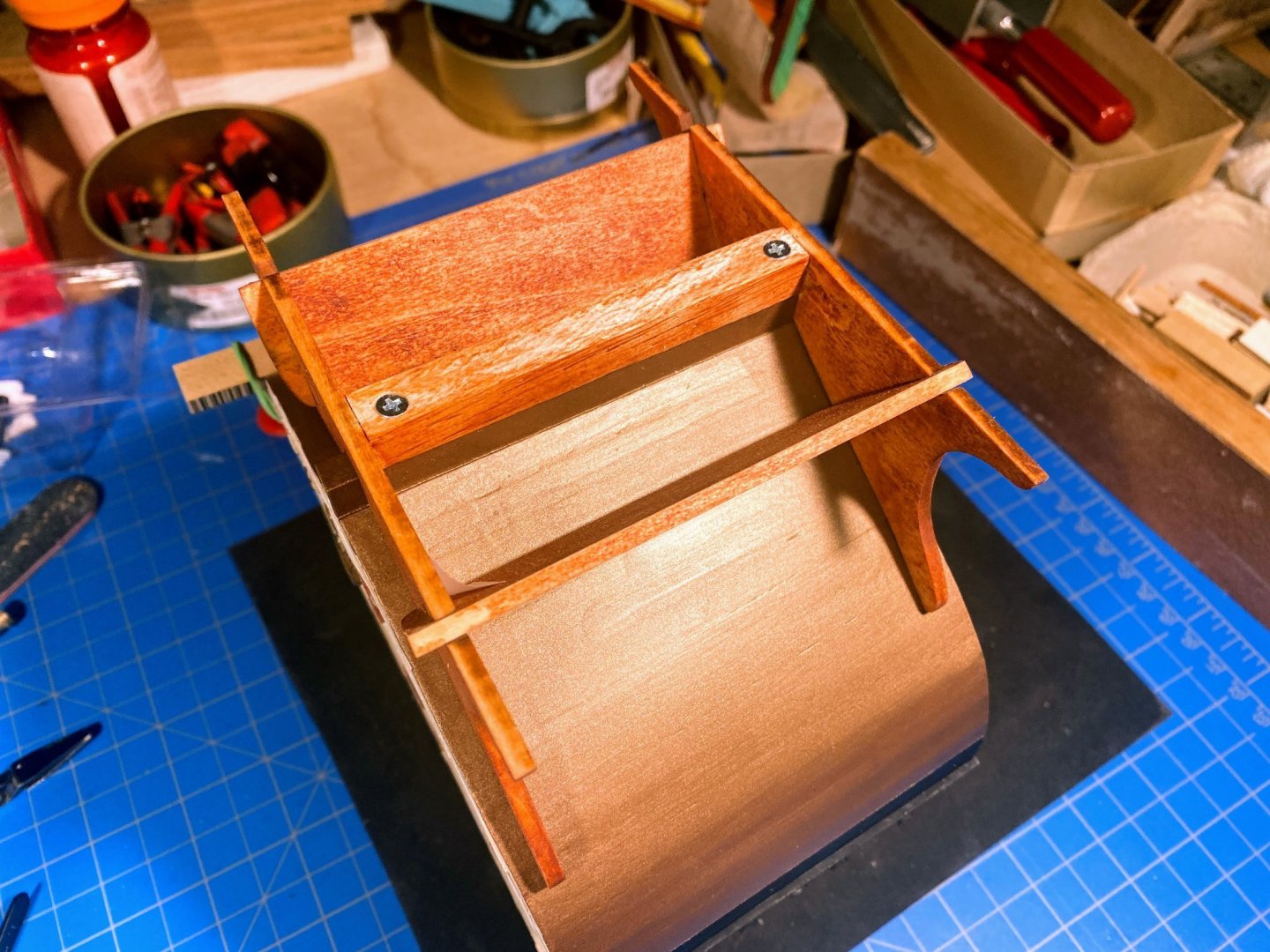

With the hull painted it was time to turn it back right side up. I feel like I’m coming around the final bend and headed for the finish line . . . as to the hull, that is. Major projects between here and there appear to be the boarding (or sea) steps, the gun ports (including “eyebrows”), the hammock railing & cap rail, and the channels & deadeyes.

For whatever reason, I chose the steps first. Ten step assemblies on each side means cutting various lengths of 1/32” thick strips (incorrectly said to be 1/64” in the instructions) with widths of 3/32”, 1/16” and 1/32”, for a total of 60 tiny pieces. Each piece needs to be sanded round at the outside corners, and then a piece of each dimension needs to be glued together to create a single step assembly. The instructions suggest building a jig for cutting the pieces, but years ago I bought something called “The Chopper”, and it has proved to be one of the most valuable of my collection of tools. Only complaint I have is that it does not have a built- in ruler, but that’s really not much of an issue.

Once cut, assembled and painted, I glued 10 on each side, 1/16” back from the forward rib. The instructions say the four steps glued to the wales need to be flush with that rib, to make room for the forward scupper. I found enough room while maintaining a consistent 1/16” back, and I thought consistency looked better if it was possible, as it was. The instructions also say to space the steps apart with a piece of 3/32” strip, but fortunately I measured the space to be filled and did the arithmetic, and 3/32” was not wide enough. I laid the steps out with 1/8“, and that was a little too big. We all know that wood strips are not milled as precisely as we’d like, so I found a “narrow” 1/8“ piece and used that. The space between the top built step and the deck level step (yet to be glued in) is a little too large, but not enough so to be noticeable.

It then occurred to me that I ought to assemble, stain and attach the stand while I could still turn the hull upside down. The smallest wood screws I could find were bigger than the ⅛” thick frame pieces, so I installed a cross beam along the keel to put a couple of screws in. For stain I used Verathane’s “Traditional Pecan”. It’s a bit bright for my taste, but not as much as the photos would lead you to believe. I think I’m OK with the color, but I’m having some doubts about the stand as a whole, since it obscures so much of the hull. A decision for another day, but I’m thinking about a couple to conventional pedestals mounted on a wood base.

Finally I glued the “eyebrows” above the gun deck ports.

Next step is the port lids, which is likely to be delayed a bit as the shipyard is becoming a guest room for the holidays. Merry Christmas everyone.

- etubino, usedtosail and schooner

-

3

3

.thumb.jpg.1844fe71c0b17022d9d900eab49f2f8e.jpg)

.thumb.jpg.5494b01c85a7f1799e8ad42839931d4b.jpg)

Hobie Cat by phebe - Dumas

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Great work Phebe! A lifetime ago I lived in Hawaii and raced Hobie 16s, like the model, then Hobie 18s. Definitely an exciting pastime. Your beautiful model brings back some wonderful memories. Thanks