-

Posts

431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by rshousha

-

-

-

-

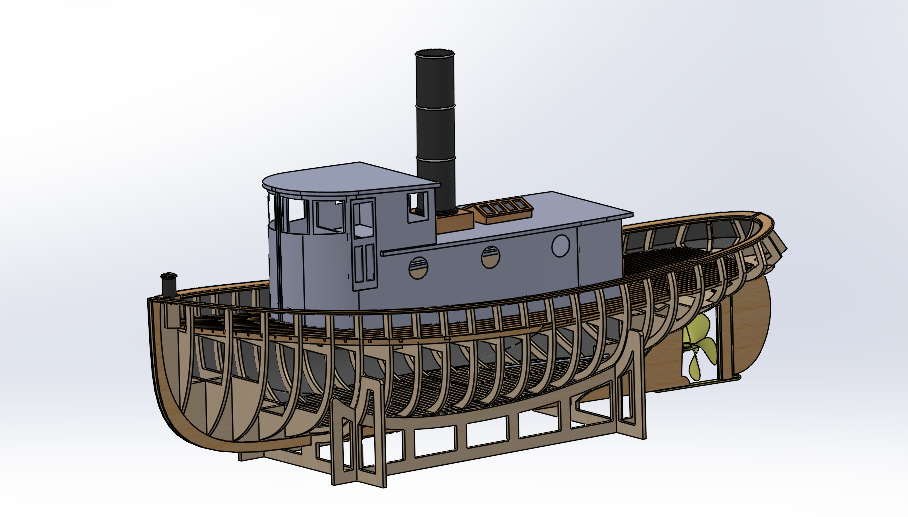

Here is the latest project I am working on. This is a 48" tug. Plywood is 1/4" birch. The hull was done in Rhino. The rest is SW.

- mtaylor, cajunrandy214 and Archi

-

3

3

-

19 hours ago, Richard Dunn said:

I us a tool in Rhino to develop non developable plates and shapes that are not able to be "unrolled" you may know them as ruled surfaces, but Rhino has tools called squish and smash which do it and allow for stretch and compression.

its good enough to use in ship plates productions so....Wow, that's amazing. I just bought a Rhino license, but I have asked a fellow in Ontario to make the organic shapes for me. He's very good and I am sure he can use the features you are mentioning. I will have to talk to him about it. I use Solidworks and I am a bit tired of the $2000 USD annual maintenance fee. The software is really good but I don't use it enough to warrant the cost. I may buy the license for 2025, but that will be my last one.

For now, I use a combination of Rhino, to create the organic shapes, and SW, to create all the internal parts, and make the 2D drawings. I suspect, from looking at your work, that Rhino can deal with the work just as well as Solidworks, for a quarter of the cost.

-

I am looking forward to seeing the fit of the deck. I use pretty good software and can't make my deck conform to curves front-to-back as well as side-to-side. I use sheet metal fabrication to make the curved surfaces and those can only be "flattened" the way they would be with real steel. I do not have "stamping" software that is found in the high-end CAD solutions like Catia.

It looks like you have some real experience with CAD.

-

Nice-looking parts! Going back to the laser-vs-CNC question, these parts look so much more "finished" than anything that could come off a laser. It just takes a tiny bit of cleaning and the parts are pristine. The inside corners of the windows might not be square, like what you come out of a laser, but that is easily rectified with a quick pass of a file.

And any work that you do with a file is directly related to cleaning or adjusting the part. It is not related to simply getting the char off in order to get glue to work well.

-

21 hours ago, Richard Dunn said:

Have you used laser? I am asking because so many people have advised me I should and I have considered it, what have you found with it? if you have used it.

I personalMy company builds frame sets for large-scale R/C boats. We have been making frame sets since 2015 and have always used a laser. When I visited my supplier, Jotika, a couple of years ago, I spent a few hours with John Wright, the owner, and he really opened my eyes about the difference between a laser and a CNC cutter. There is no doubt, for many reasons, that the CNC does a much better job.

First, the precision is much higher with the CNC machine. As long as you measure your drill bit and your material, you can get more precision that with the laser. Even you account for the kerf on the laser, and you measure your material, you still have a char on the laser-cut parts. That char needs to be removed or the glue doesn't penetrate the material.

Second, you can make pockets with a CNC. For example, you can make parts fit without passing all the way through. Also, with pockets, you can do things like "engrave" windows in the stern panels of models. In your case, you might find that quite interesting for your model. That cannot be done with a laser-cutter.

I spent about a year using a full-size CNC machine at a furniture-maker, designing furniture, and then actually using the machine and making the prototypes myself. It was great fun and taught me a lot about woodworking.

So, as soon as I can find someone around here that has a decent CNC machine, I will start designing for that. I suspect the price of my frame sets will go up slightly but, when people are paying many thousands of dollars to build a big R/C model, I think they will appreciate the improvement in quality.

(By the way, I am planning on building the Cutty Sark myself, in 1/48 but, hey, your model might be even more fun to do!)

In brackets because I do not want to market a kit in 1/40 scale. It just isn't part of the large scales that I use.

Best Regards,

Rick -

-

I painted the hull, as well, and ended up using that thin mahogany for a zillion other models. For example, it worked beautifully as the outside surface of a large model of a stagecoach.

-

Where were all these extra spars stored? That's another forest they had to carry.

- markjay, mtaylor and Keith Black

-

3

3

-

-

Hi Snug Harbor Johnny,

You make an interesting point about the lack of carvings, etc. I see what you mean. Still, I doubt the company expected to sell many of those kits so the price may have been a little higher than you mention because of that but I am sure your price estimate is pretty close.

I had no idea you were so interested in this period. This model will surely be a prized display among your friends!

I am looking forward to seeing the construction develop.

Cheers,

Rick

-

-

Hello All!

So Johnny Snug Harbour has decided to buy the Henri Grace-a-Dieu kit I had in stock. Actually, it's a good thing he bought it because it really is the most amazing kit I have ever seen, with almost 200 cannons and zillions and zillions of small parts. I had decided to keep for myself. I just love those period ships and there are very few kits out there.

So, Bounty is still for sale.

-

Email sent, thanks!

And, yes, you are first.

Regards,

Rick

-

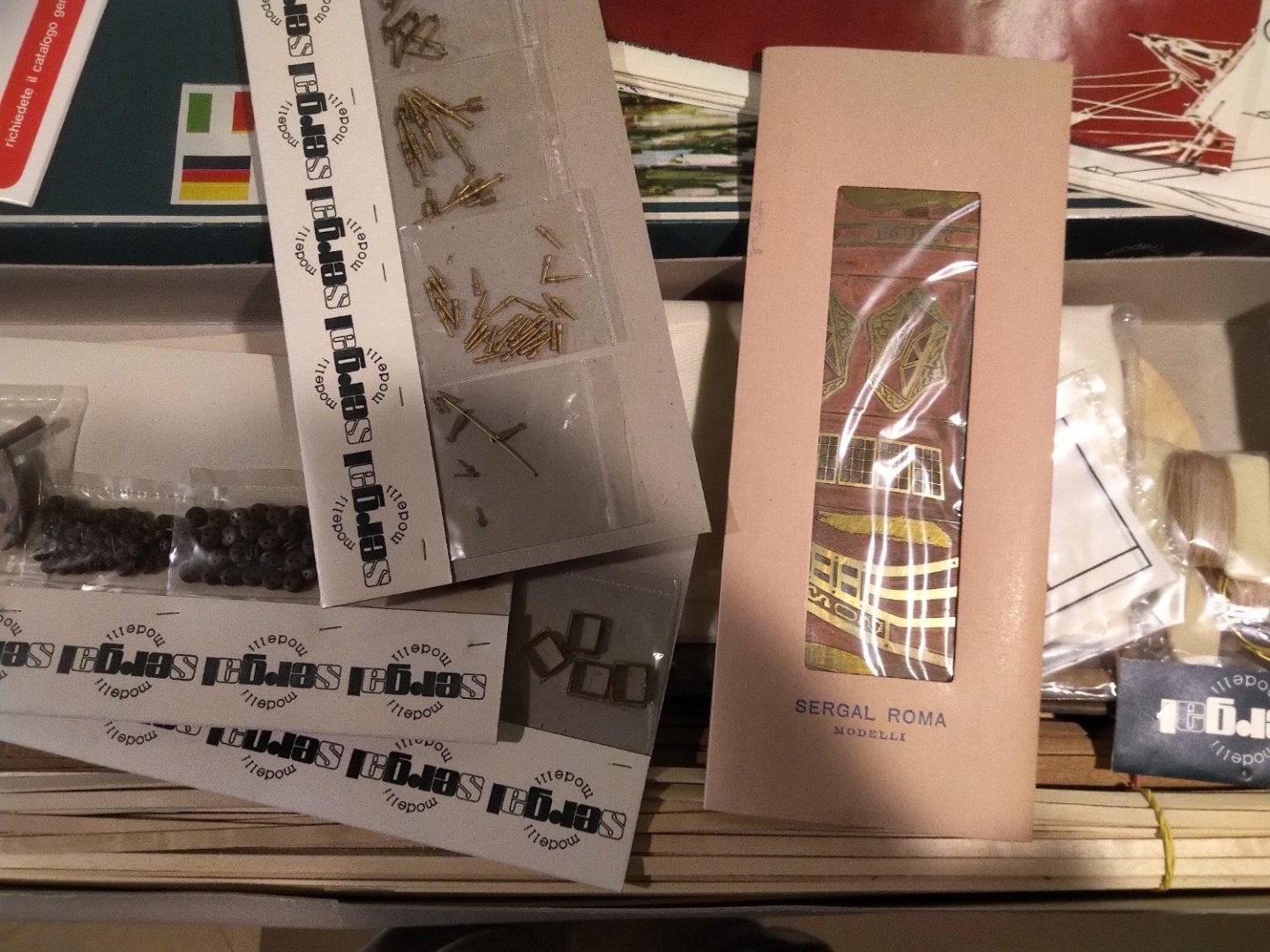

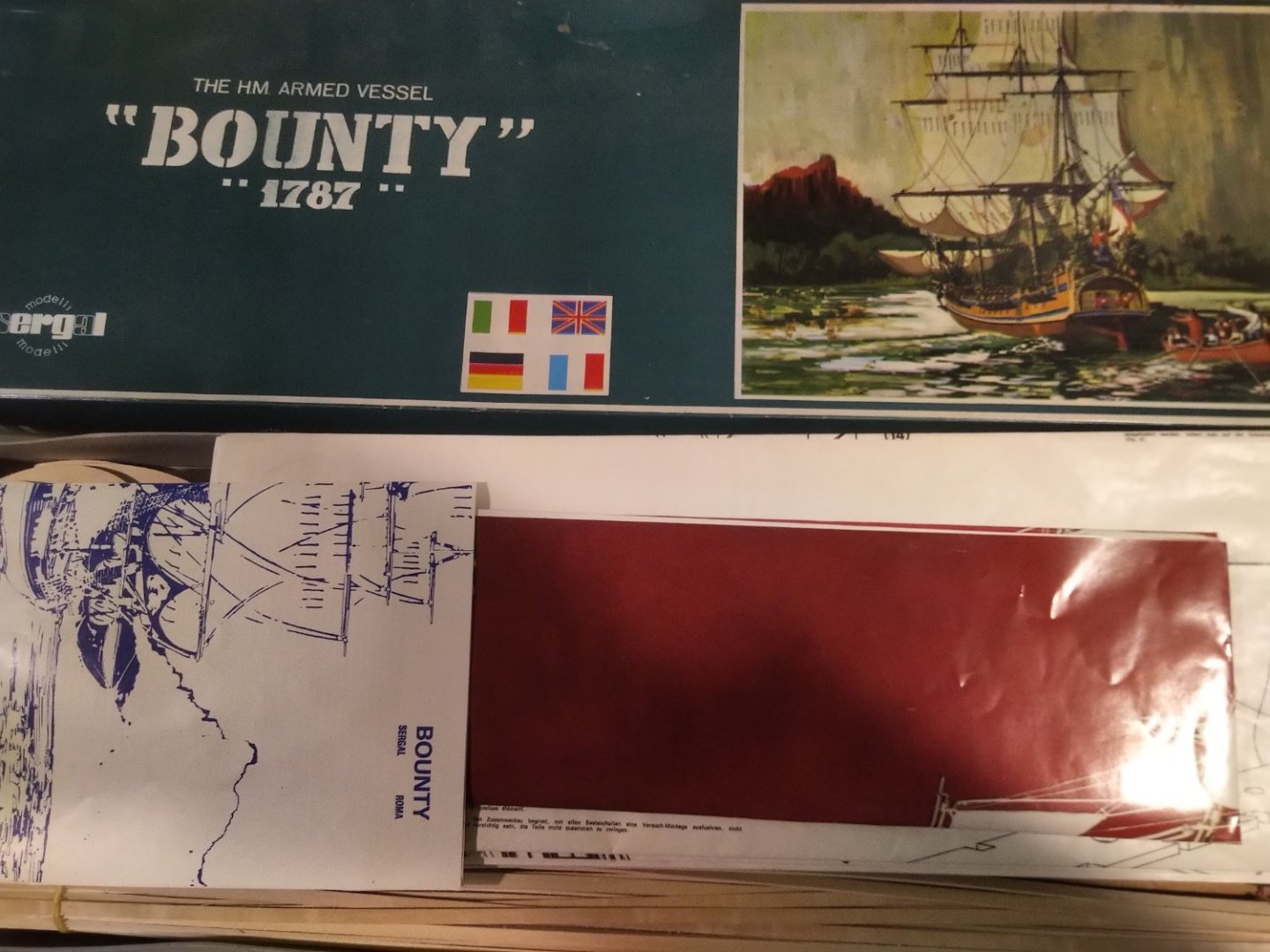

I sure wish I had a lot more time. Every now and then I get these wonderful collections of kits and here I have a few for sale, including this lovely edition of the Sergal Bounty. I'm pretty sure this kit has been kept in one place for exactly fifty years. Everything is there, still nicely packaged, and even the box is in good condition. Of course, the frames are hand-made, long before laser-cutters came into the picture.

I am looking for $100 USD for this kit, plus shipping; $50 USD across Canada or the US. For Europe, shipping will be $125 USD for surface, and $225 USD for air mail.

It's a really nice kit and should go to someone who would like to build a vintage kit.

- mtaylor, mtdoramike and Diver

-

3

3

-

Wow, this is such an interesting project; it is like reaching back in time and meeting up with your younger self. We should all be so lucky at some point in our lives.

- Glen McGuire, Louie da fly, Keith Black and 1 other

-

3

3

-

1

1

-

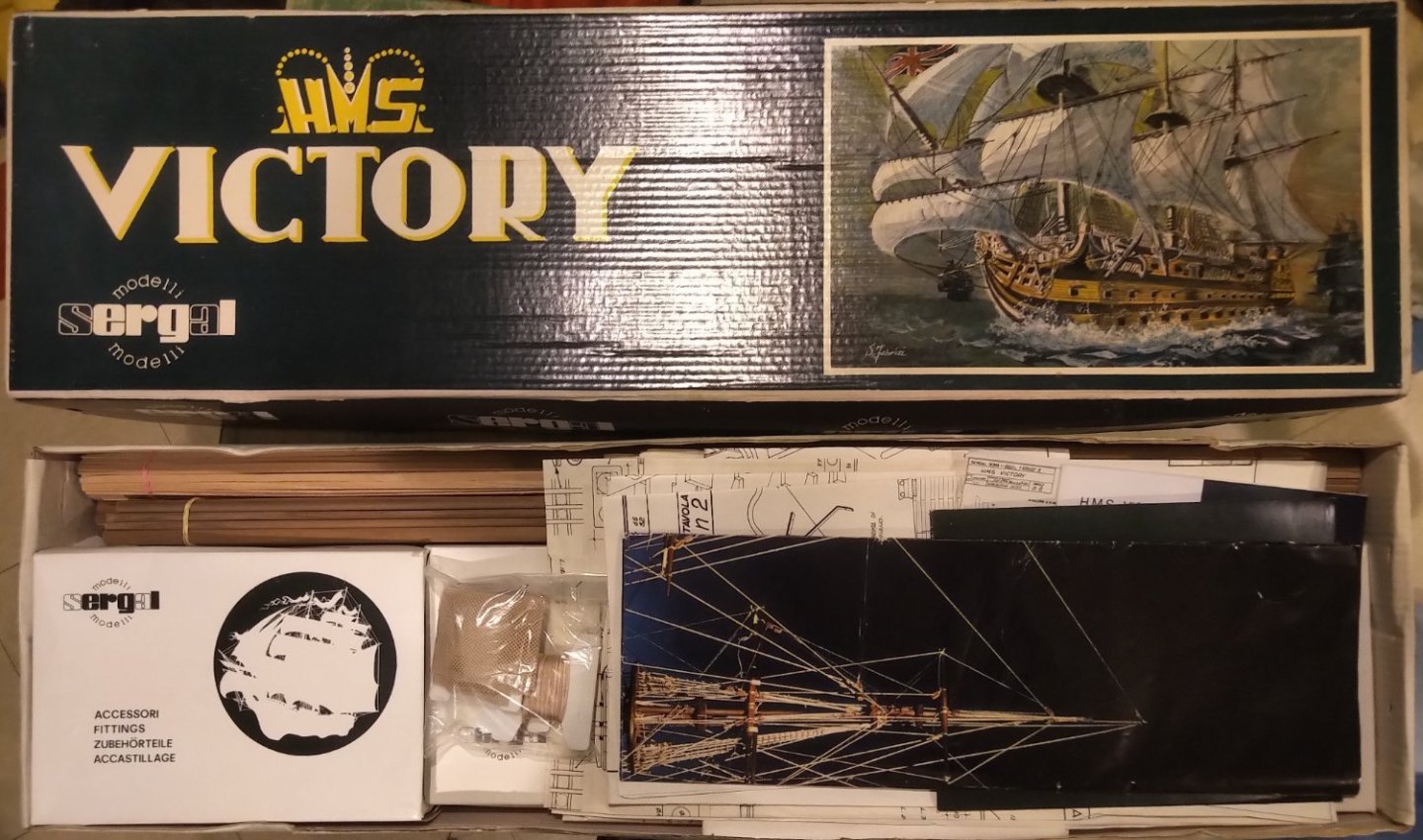

A friend has asked me to help him sell quite a large collection of models and this Sergal HMS Victory was in the collection. Would anyone care to have it? I think a fair price would be $400 USD, plus postage but I will entertain offers. It's quite a large collection so we just need to get a move on.

-

-

-

-

This wonderful model of RMS Servia was started in the 1960s or 70s and was never completed. About 90% of the parts to finish the model are available. I was hoping to get this model finished for my own interest, but time passes, space is limited, and interests change.

She was started by Wolfgang Buce, of Maine, and is available for pick up for $1000 USD.

She should be in a Cunard office somewhere, which was the original intent for the model but, again, time and interests change.

Shipping this across the US or Canada is possible but crating and shipping charges will run easily over $2000 USD.

- grsjax, GrandpaPhil, Knocklouder and 9 others

-

4

4

-

8

8

-

-

Hello Jim,

I think the concept of "instructions" that come with a kit, is overrated. With YouTube, various other fora, and this one, you can find some really nice build logs of just about any model you might want to build. Instead of asking the question, "which manufacturer has the best instructions", I would focus on the subject you want to build and look around and see if there is a build log that suits your skill level.

- thibaultron and mtaylor

-

2

2

.thumb.jpg.1144574e4e6093c2f9d41cd3b78d949c.jpg)

.thumb.jpg.2a2571b908e0c70ce53911ef10782ae0.jpg)

.thumb.jpg.ec98ae61395bc98d8c3aef5d8b5626ce.jpg)

.thumb.jpg.d4bc36592cc2452d4be3016d46d11eaf.jpg)

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

in - Build logs for subjects built 1851 - 1900

Posted

Great job with this model. I sure wish I could participate more but I can no longer do so.

Good luck to you.

Best Regards,

Rick