-

Posts

170 -

Joined

-

Last visited

About Matt H

- Birthday 04/10/1981

Profile Information

-

Gender

Male

-

Location

Tooele, UT

-

Interests

Building model ships, building and painting miniature fantasy figures, reading, woodworking, lathe turning, watching TV, and playing video games. I also like to watch reality shows or documentaries about Alaska, I'm hoping to move there one day after my son graduates.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

clearway reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

clearway reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Knocklouder reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Knocklouder reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

BobG reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

BobG reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Landlubber Mike reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Landlubber Mike reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Matt H reacted to a post in a topic:

SOLD - Merit 1:200 USS Hornet CV-8 kit plus extras

Matt H reacted to a post in a topic:

SOLD - Merit 1:200 USS Hornet CV-8 kit plus extras

-

mtaylor reacted to a post in a topic:

SOLD - Merit 1:200 USS Hornet CV-8 kit plus extras

mtaylor reacted to a post in a topic:

SOLD - Merit 1:200 USS Hornet CV-8 kit plus extras

-

AlleyCat reacted to a post in a topic:

Being a newbie

AlleyCat reacted to a post in a topic:

Being a newbie

-

Keith Black reacted to a post in a topic:

Hello from California

Keith Black reacted to a post in a topic:

Hello from California

-

tomebe reacted to a post in a topic:

Hello from California

tomebe reacted to a post in a topic:

Hello from California

-

catopower reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

catopower reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Blackreed reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Blackreed reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Thank you, it's on a shelf in my living room. I would like to move it into my classroom, I just haven't gotten around to transporting it. I also share the room, I teach from two different classrooms, hoping to stop teaching in one of them and move into my computer lab full time next year, if that happens I'll definitely move it into my room.

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Thanks Ric, it was a great kit and I too watched and just finished the Vikings series! Someone else had that question and I was tagged in their build log. Here is the link to my first response and a couple of posts down I provided a clearer image and an image of that part of the instruction book. I did NOT use the water/glue mixture before placing the planks, I just did a small bit of regular yellow wood glue on the part of the plank that overlapped. You can actually see a bit of glue that didn't get sanded before I applied the stain in the image in this link. If you have any more questions let me know.

-

At the top of the forum is a navigation bar and a tab/button/link for Articles Database. In that Articles Database is sub categories, one of which is for framing and planking. In that framing and planking is the following article written by Chuck and it is a pdf which includes a fan. Hope that helps. This was my first kit I assembled, I enjoyed the challenge of the small size and the well written instructions. https://thenrg.org/resources/Documents/articles/LiningOffYourHullPlankingTutorialAndFan.pdf

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Matt H reacted to a post in a topic:

Swan class plans - now digital!

Matt H reacted to a post in a topic:

Swan class plans - now digital!

-

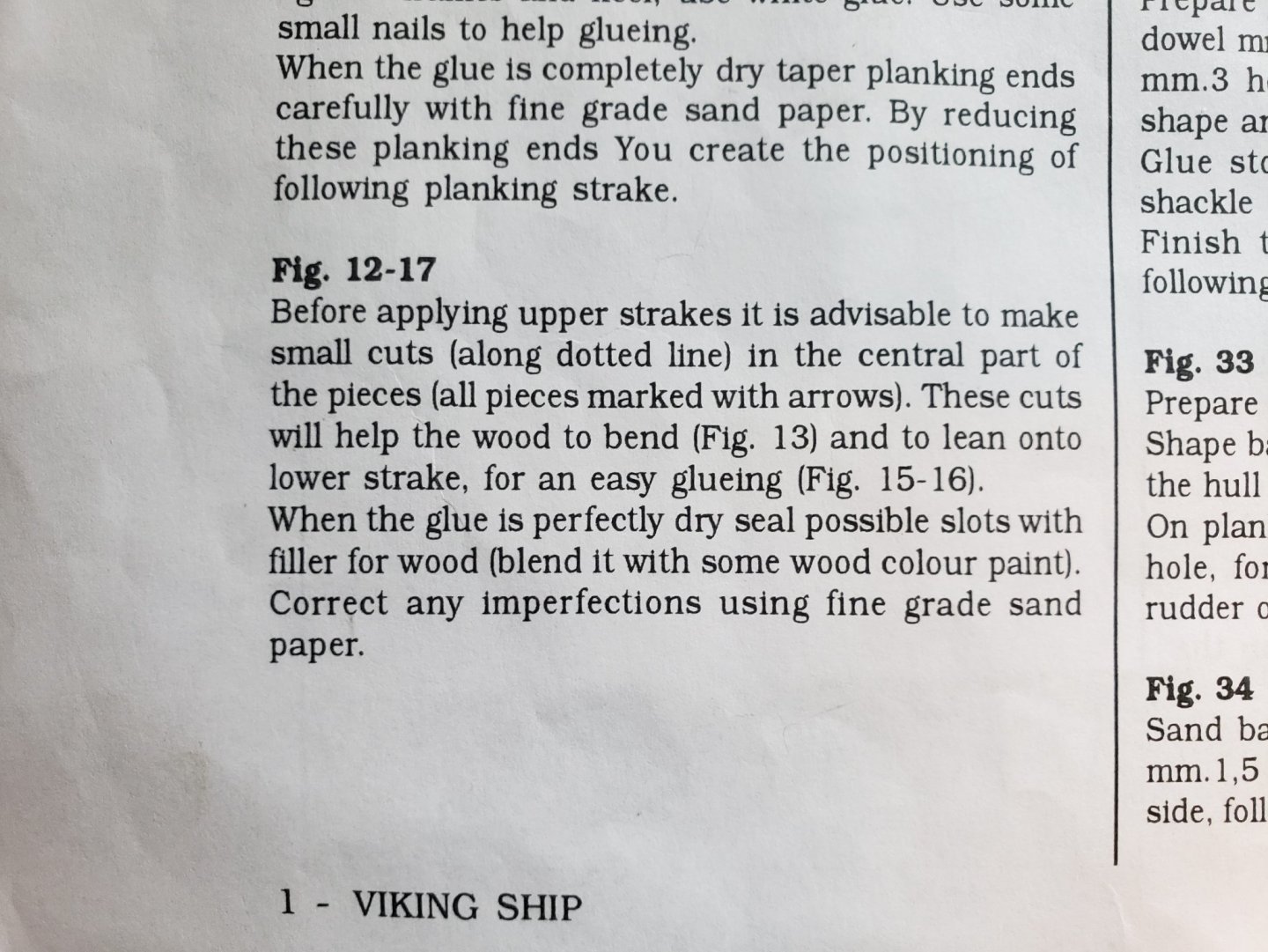

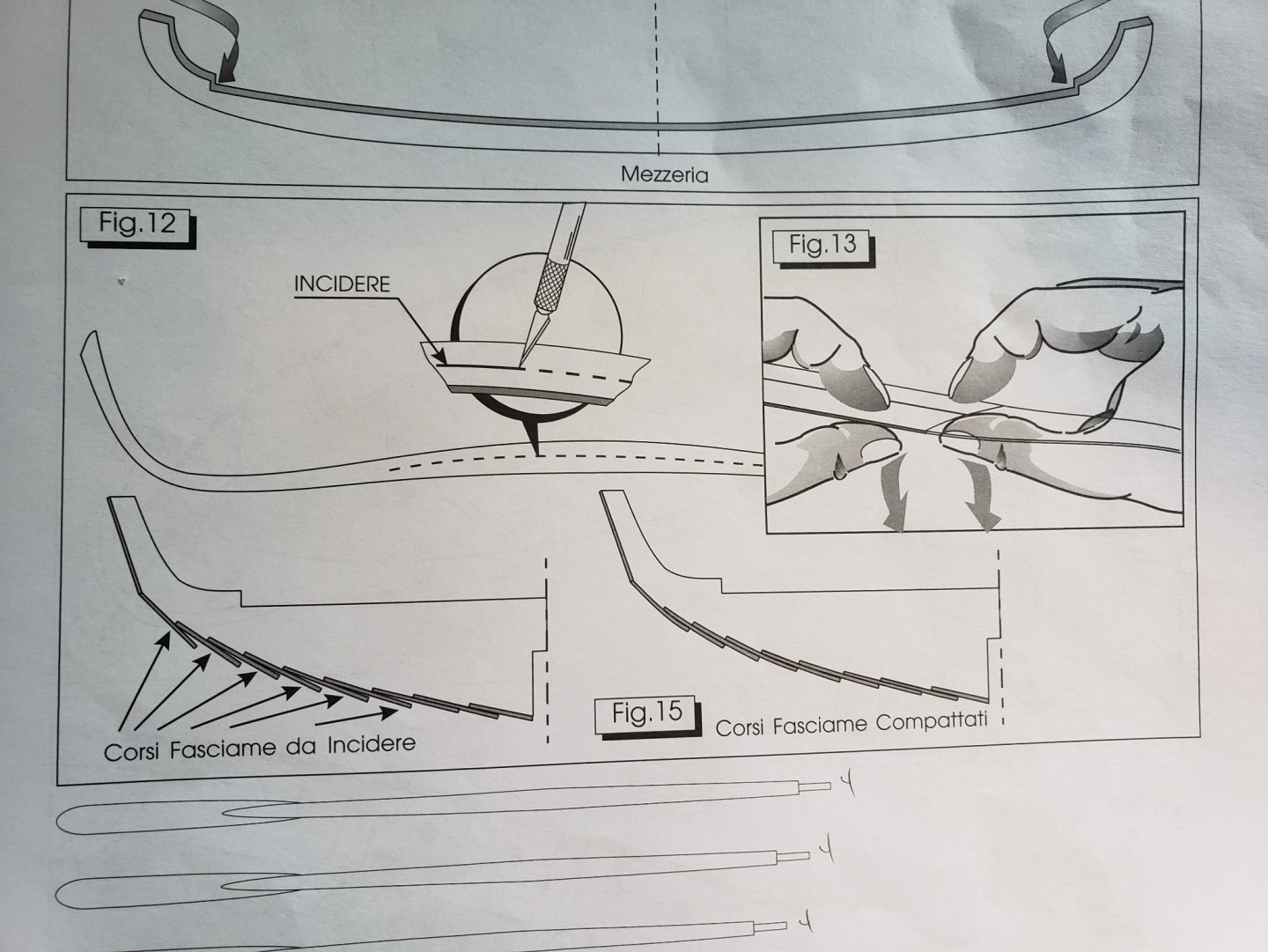

You're right the photos weren't very good so I snapped this one and the instructions. Here the number 1 is pointing to the seam where I cut partway through the plank so it could be folded along the cut. The number 2 indicates where the bottom edge of the plank is. Hope these help, the pictures portion of the instructions are in Italian, and a separate instruction sheet is printed in English. **Edit - Nope, no relation to James J as far as I am aware!

-

Thanks Louie! If I recall, I did have that problem, but I believe the instructions said that as you got higher in the planking, you should cut partway through the plank horizontally along the length of the plank. Not along the entire plank but rather the middle section up to about 3 bulkheads from the bow and stern. Cutting partway through from the outside of the plank allows the plank to fold and the bottom half lies on the plank below it, and the top half is able to be folded up against the bulkhead. I just checked the instructions and this is demonstrated in figure 12 on page 3. If you look closely you may see that slice and fold/bend in my photos.

-

Matt H reacted to a post in a topic:

Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Matt H reacted to a post in a topic:

Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Thank you very much, yes I did complete it in the time presented here in the build. Probably a bit shorter because it took a couple 2 or 3 weeks to get the final post and images uploaded. I am a teacher and so I had a lot of time at home after we closed down in March for Covid-19. In normal circumstances I would not have been able to get as much done so quickly. The Amati instructions are for what you see in my image in post #6 using the rope. The only modification I made was on the top of the rudder where the rope is wrapped around the rudder. The instructions were not clear on how to attach the rope on the top of that wrapping. So I drilled a hole through the rudder twice, once below the wrap where you can see the rope wrap go through the rudder and through the ship plank and another at the top of the wrap where it is just knotted behind the rudder where you can't see it. So I started the rope wrap at the top, knotted one end to keep it from going through with the knot positioned in the back of the rudder towards the plank where it is not visible. Then I wrapped it around and ran it through the bottom hole drilled through the rudder and through the plank and knotted on the back side of the plank. The lower attachment point is also rope that is knotted through the rudder where the blade is attached to the rudder in the front side where it is visible and it goes through that small button cap looking piece and through the plank and into the ship. It is under the deck planking and I did not think of it before I finished the deck so I attached a small wire shaped into an inverted V that when pressed through the hole would open up and prevent the rope from being pulled out since I could not knot it behind the plank due to the decking. The final small rope I believe is more for positioning and keeping the rudder in line with the ship and not drifting outwards to the waterway or inwards up against the ship. It too is just rope with knots on both ends. Hopefully that helps clear things up. I did not do any research into Viking ships, I relied on the Amati instructions. I did a bit of research into the paint colors of the shields and ultimately decided to go with colors I liked rather than the typical red, yellow, or black. I did try to keep the colors more natural looking as if they were able to make/find pigments in similar colors. I also did have to use a website to translate Italian to English because the prints were only in Italian for Amati. I also had a picture encyclopedia book for ships and used that to reference parts of the viking ship I was not familiar with. Otherwise all my info came from the provided instructions.

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

Matt H reacted to a post in a topic:

Viking Drakkar by Matt H - FINISHED - Amati - Scale 1:50

-

Thank you very much. I am quite proud of her and I think she was an excellent 2nd model and I think I'm finally ready to move on to something bigger and with more masts and rigging. My next one is already on the table, plans hung up, and ready to go. HM Bomb Vessel Granado is in the shipyard.

-

Thank you very much, I appreciate the compliment. If you have any questions on yours along the way don't hesitate to ask, and enjoy the build.

-

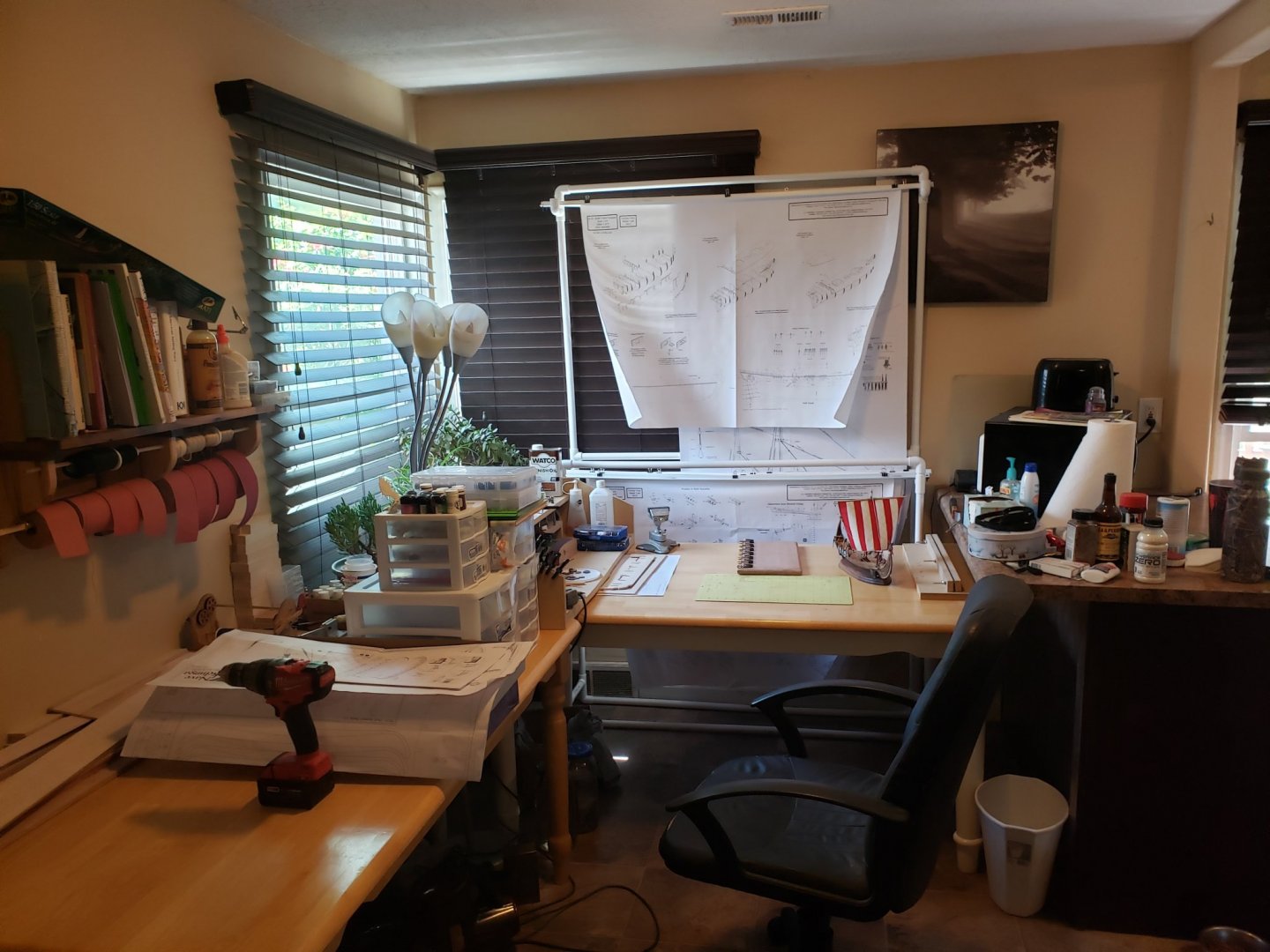

In the background you will see my next ship I am beginning. I built a frame to hold up the various prints. I got the idea for this from this post from Kevin53. I modified mine a bit to make it slightly wider and taller to accommodate the larger prints. Mine is in the photo below.

-

Sorry for the delay in getting an update. I have been busy with other things. She is finished, with the exception of the oars and the two swinging booms. I will get around to making up the oars eventually, but with the sail down they would have been stored any way. So here she is. Starting with some deck and other details and finally with the whole thing.

-

I did end up placing an order to get some admiralty paints and a couple other items. The paints are out of stock at Ages of Sail. I haven't heard from anyone regarding my order that was placed on the 11th, or regarding the missing items from the kit. The status shows payment as pending and order status as not shipped. Payment hasn't been deducted from my account, although I did get a small .22 cent charge from Visa I think and it looks like it's some kind of international fee, not sure. I haven't ordered anything else from overseas so I assume it has something to do with this. I guess all I can do is wait. Will update further if/when something happens.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.63af0ca81bbc689f4f2bee1cdb4b7b78.jpg)