-

Posts

696 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Moab

-

Our "craft" doesn't get any better than this. Beautiful! Great photos and text. Thank you...Moab

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Michael; thank you....this really helps. I'll keep you all posted...Moab

-

Michael; what’s the best way to do this? “Something” (very technical description) in a Dremel? By the way, how old is that Dremel in you photo. Thank you so much...Moab

-

Michael et all; what type of file did you use....brand, cut, etc? I have a set of Vallorbe #2 cut. I “think” these are good files. Are they good enough to get this done...Moab

-

Thanx guys. I do have better files . I’ll give them a try both ways...Moab

-

Thanx guys. I do have better files . I’ll give them a try both ways...Moab

-

-

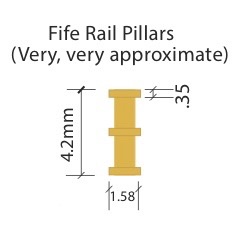

99% of the modeling I do is with wood. I want to try some other materials one of which is copper. I'm attempting to build a top sail schooner named Julia. The dimensions of the part I need to make are (roughly) shown below. The bar stock is 1/16"D. I don't own a lathe/mill/large drill press. I usually use a Dremel file and sandpaper to get a desired shape. So, I chucked the 1/16 copper rod in my Dremel and figured I could use a file to get the desired shape......that always worked with wood...! But the file basically did little. I certainly can use some suggestions regarding what I can do with the limited equipment/knowledge I possess. If I need to purchase some form of cutting tool I can do that. As always thank you for any feedback. I must admit I'm more than jealous when I see some of the equipment many of you are using and even more jealous of the incredible knowledge and skill...Moab p.s. I'll post the drawing in a few moments.

-

Electric sanding belt file

Moab replied to Don Case's topic in Modeling tools and Workshop Equipment

Great reminder Roger. I have a 35 year old Inca 10" bandsaw that I want them to bury with me....who knows!...Moiab -

Electric sanding belt file

Moab replied to Don Case's topic in Modeling tools and Workshop Equipment

Wow guys. I feel the pain. I must admit I was fooled by Wen. Are there any brands that we might deal with that still produce great tools?...Moab -

Great feedback all. Per Gregory’s suggestion I’ve contacted them to determine if I can get wood milled to 1/32”. I’ll let everyone know when I hear from them. I would suggest anyone’s interested check out their website. They may be a good resource for some of our needs. Again thanx to Gregory for getting the ball rolling...Moab

-

I regularly fabricate small wood parts. The parts are approximately 3mm x 5mm +- with two +- holes drilled. I've mostly used bass in the past but not happy with the results. I don't have the equipment to mill my own wood and don't want to use another material like plastic. So what can I use that is commercially available in 1/32 sheets and very tight grained? Parts will eventually be stained or painted. As always thanks for any suggestions...Moab

-

That photo of the boat in the display stand is a “knockout.” Congratulations for crafting a beautiful, beautiful boat...Moab

-

That sounds like one totally awesome week!!!! The Spray looks great.. congrats....Moab

- 82 replies

-

- spray

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

That $50 case looks terrific. A perfect home for a beautiful boat...Moab

- 104 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

Looking outstanding...Moab

- 104 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

A wonderful looking boat. The description of making the sails was VERY helpful. Not sure if I’m being redundant but I came across an excellent documentary on youtube about the fifie The series is “The boats that made Britain” or something close to that title. My apologies if this has been mentioned previously...Moab

-

A beautiful boat beautifully crafted. Congrats...Moab

- 90 replies

-

- finished

- Midwest Products

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.