-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Tonphil1960

-

-

-

- Seventynet, KLarsen, No Idea and 8 others

-

11

11

-

-

-

- bruce d, KARAVOKIRIS, No Idea and 5 others

-

8

8

-

13 hours ago, No Idea said:

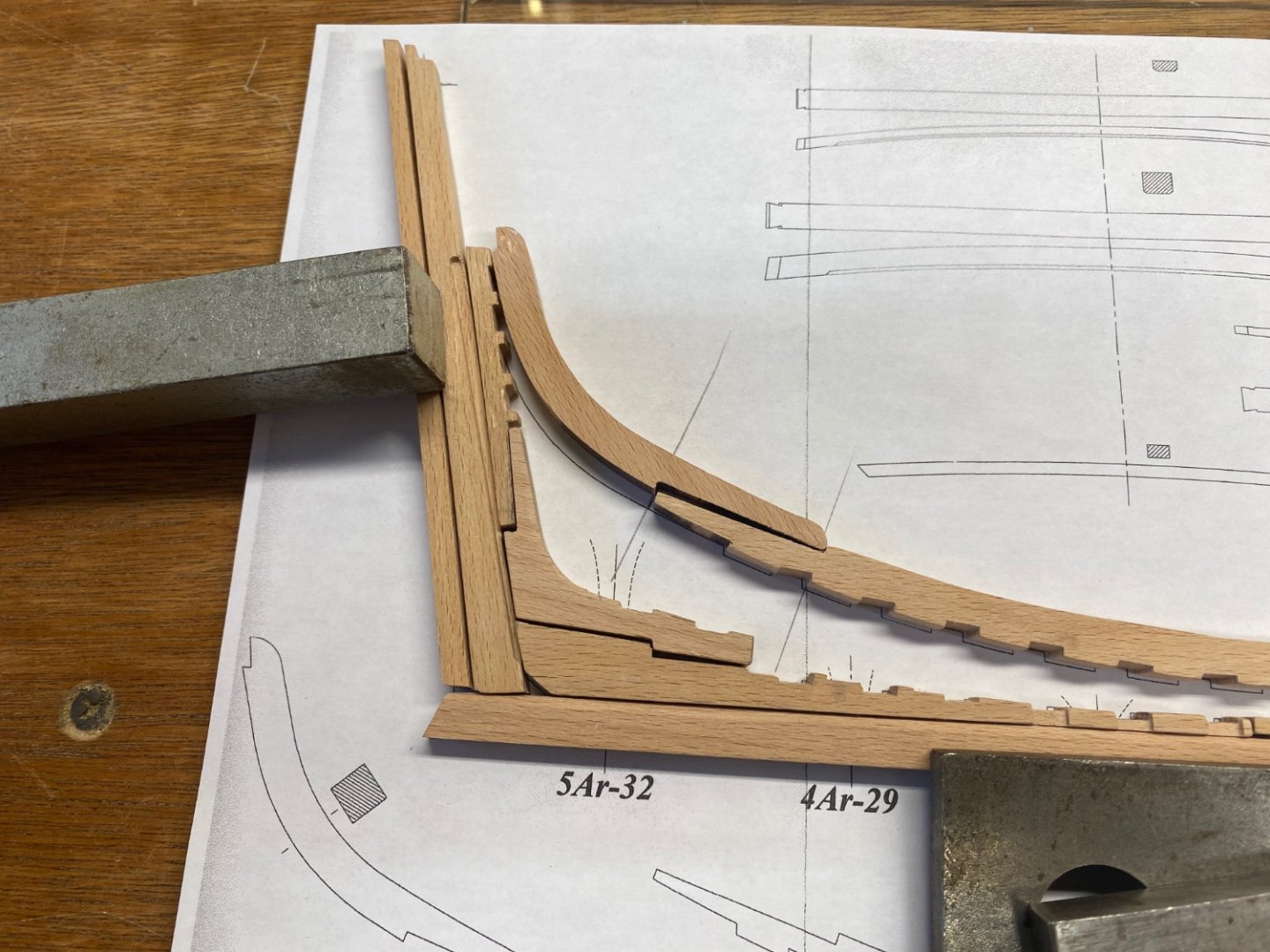

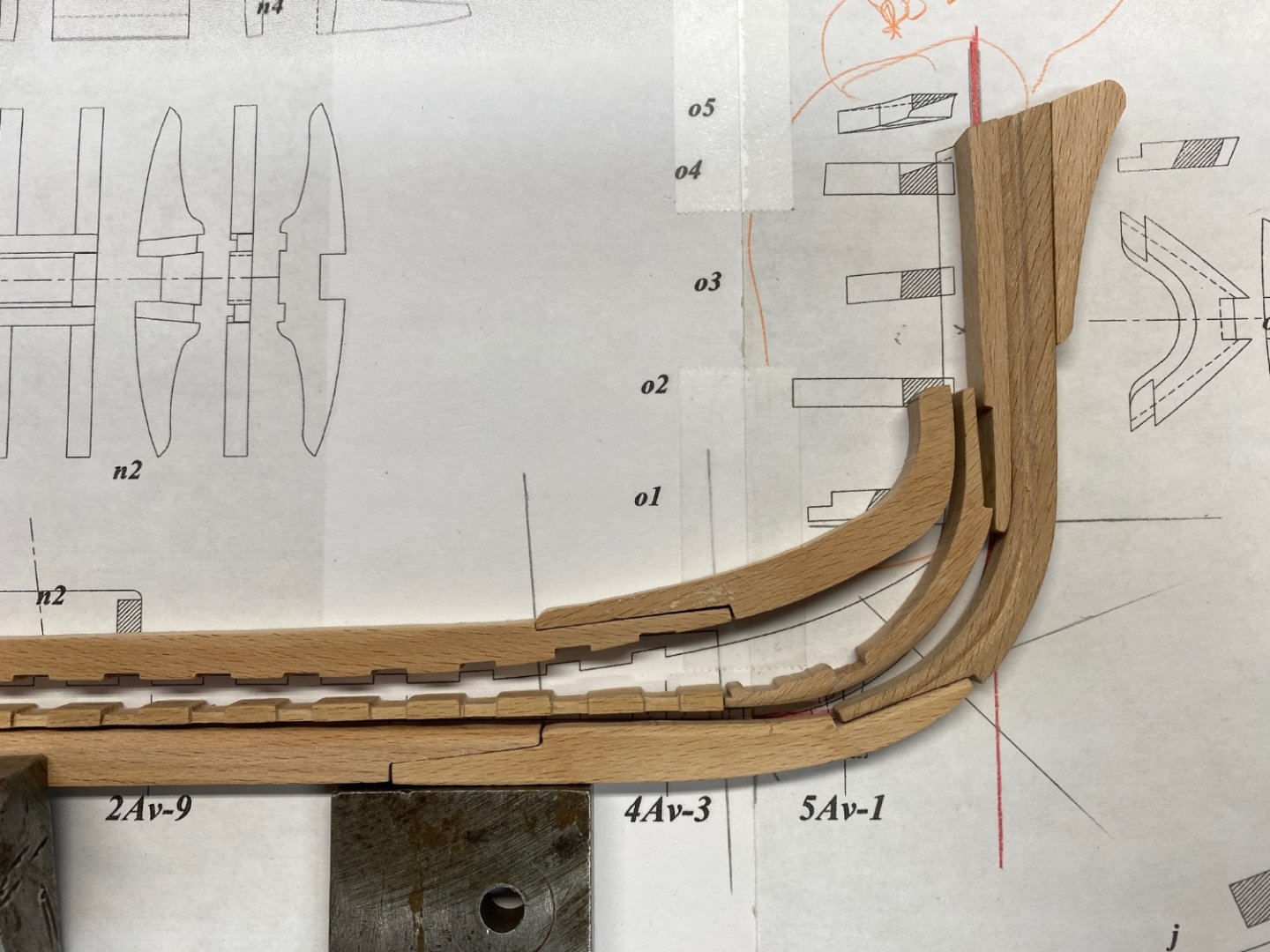

At last a fellow builder 👍

The wing transom is tricky and it looks like you've got it sorted. Keep the ones that didn't make the cut as they will be very handy when you build a jig to build the counter timbers. Keep going mate - it's a small ship but very particular when it comes to accuracy. If I can help just let me know

Oh and by the way if you need answers to any questions drop Gerard a message as he has helped me understand his drawings.

Oh and by the way if you need answers to any questions drop Gerard a message as he has helped me understand his drawings.

I only can build between work so you will probably be finished before me.

Thanks Mark yes indeed. If I can build just moderately close to your accuracy and fitment Ill be a happy camper. Its going to be slow going because like you there will be many parts that will get made several times to get them right. Your photos are so good they explain a lot that the plan and Adrian's book don't. Your build is priceless for reference.

- No Idea, mtaylor and Seventynet

-

3

3

-

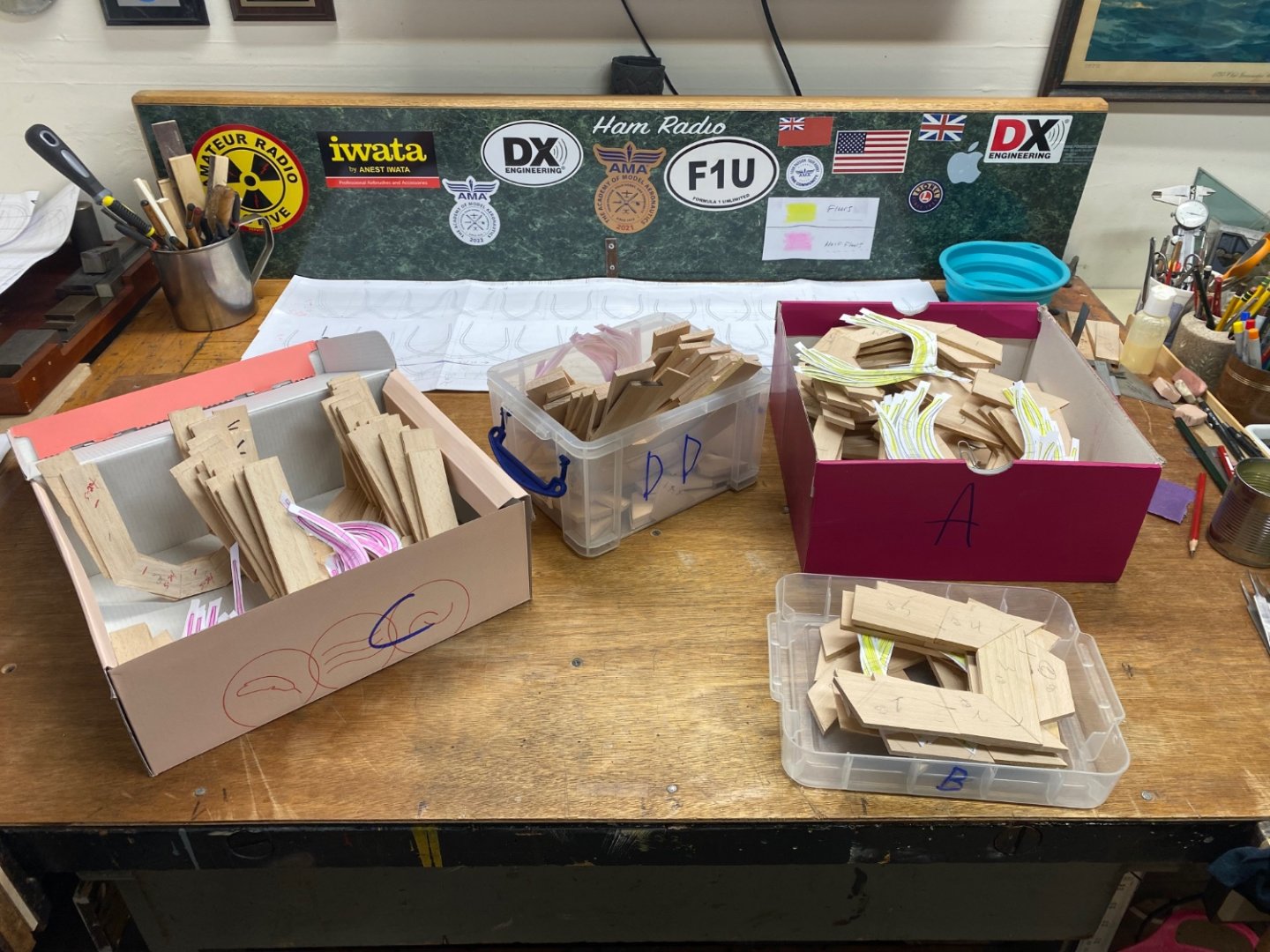

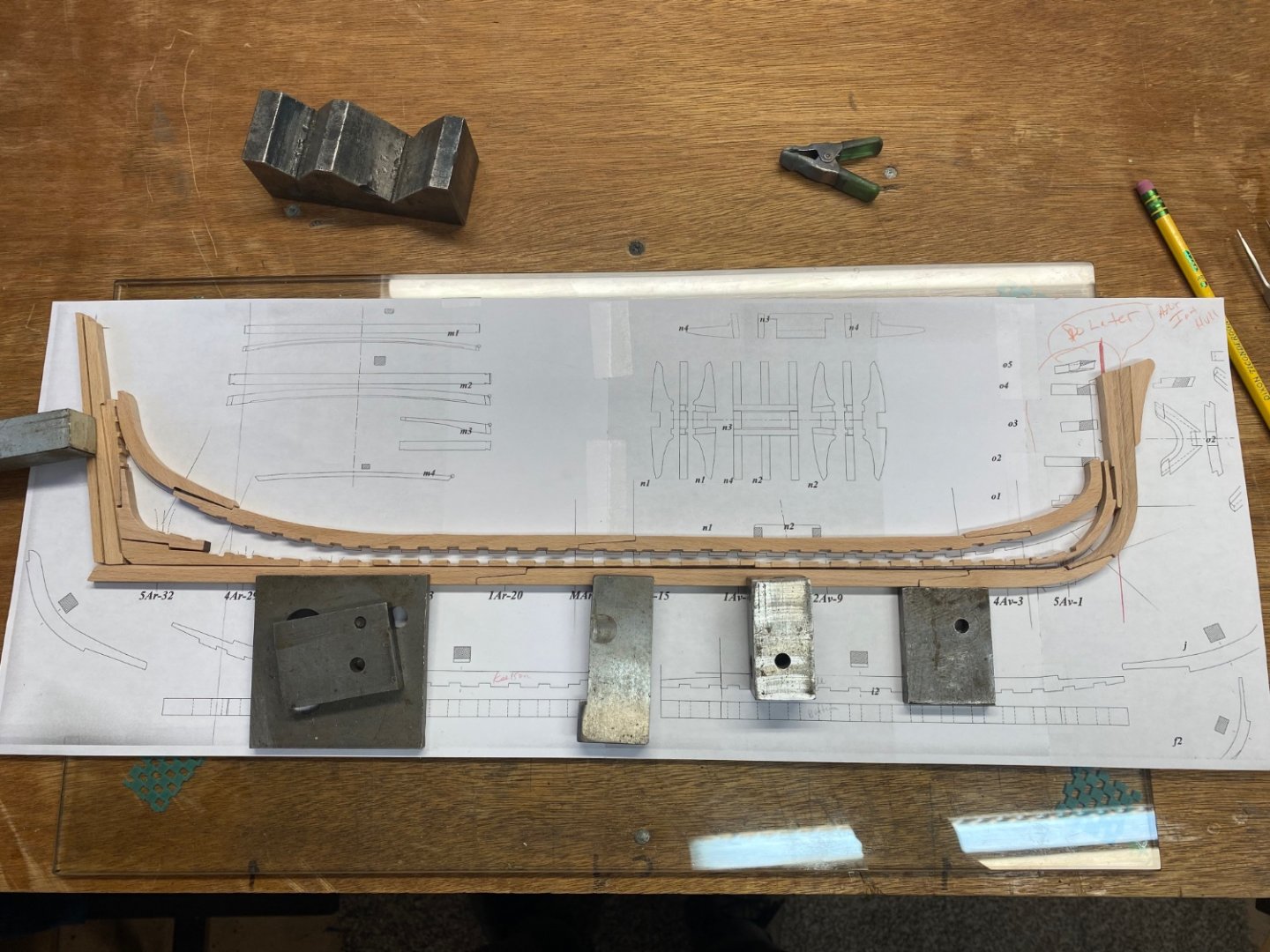

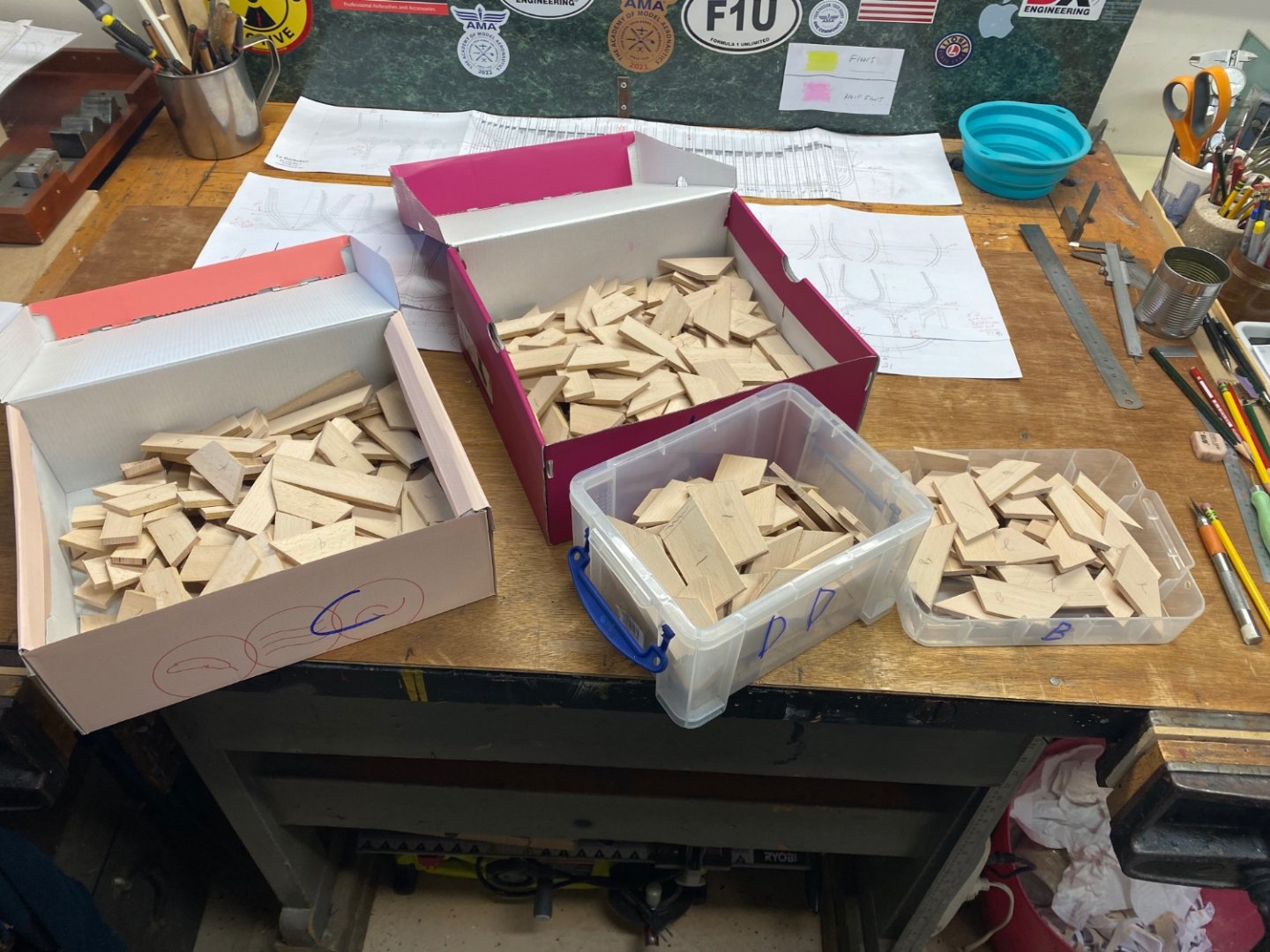

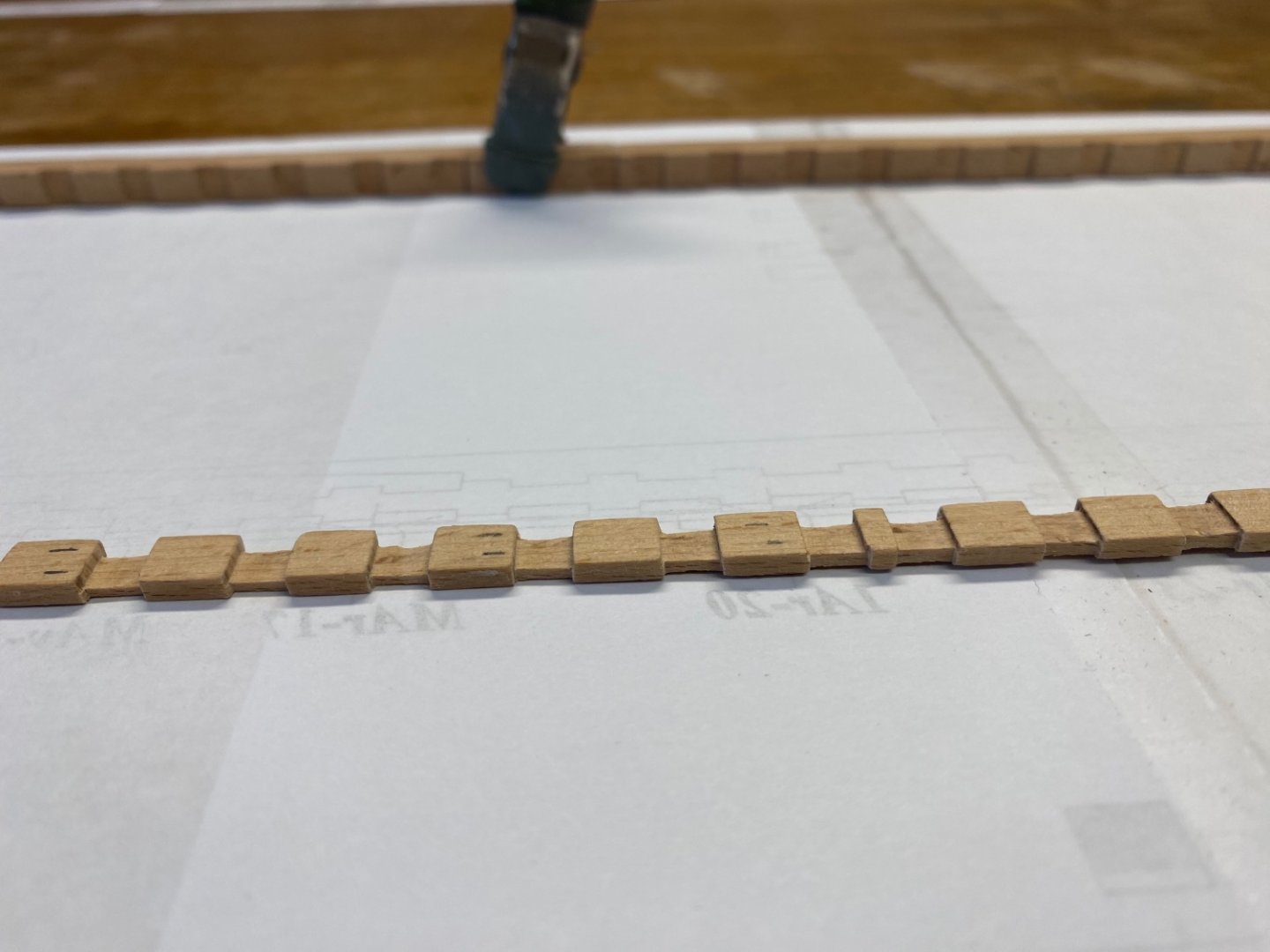

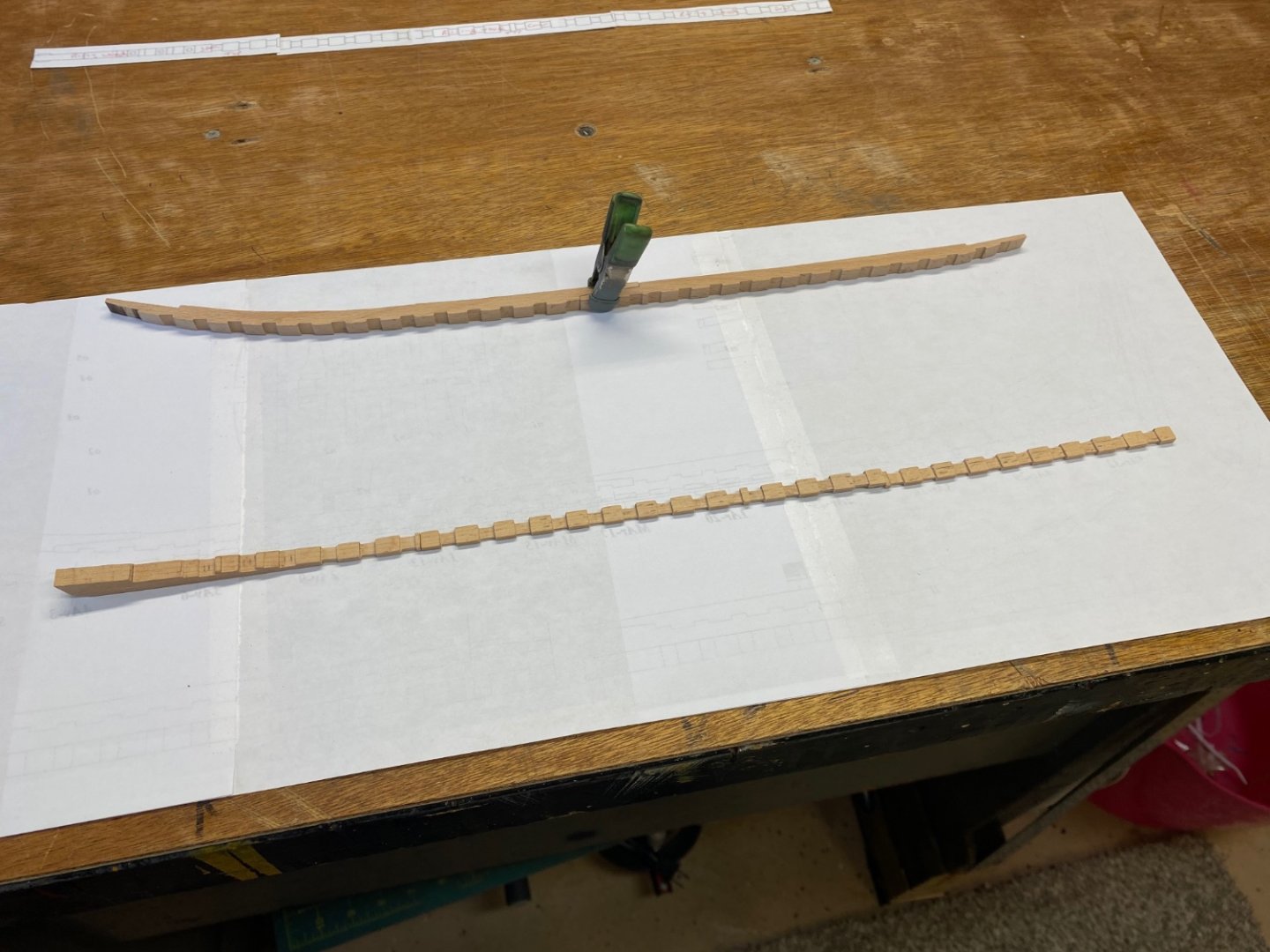

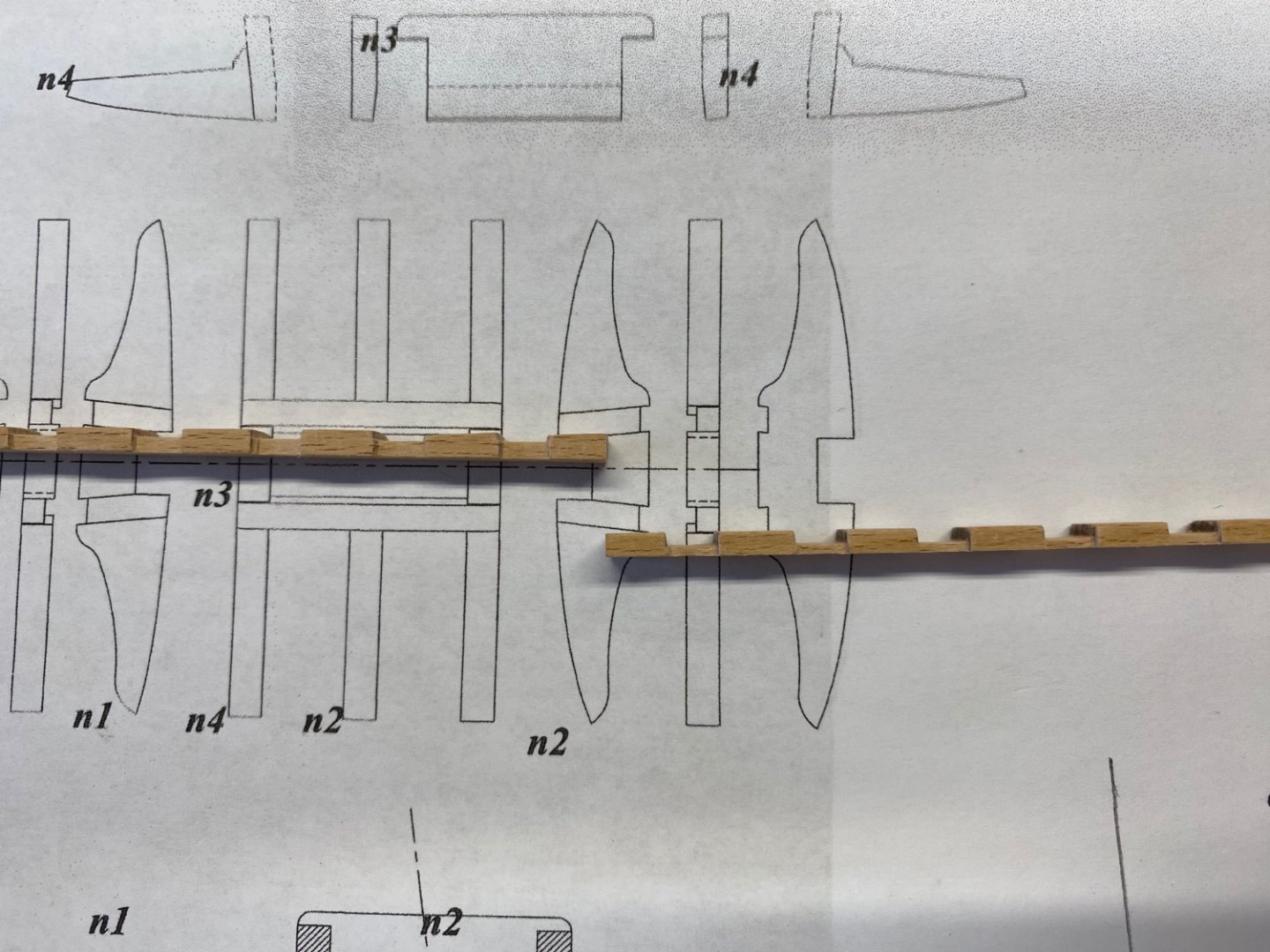

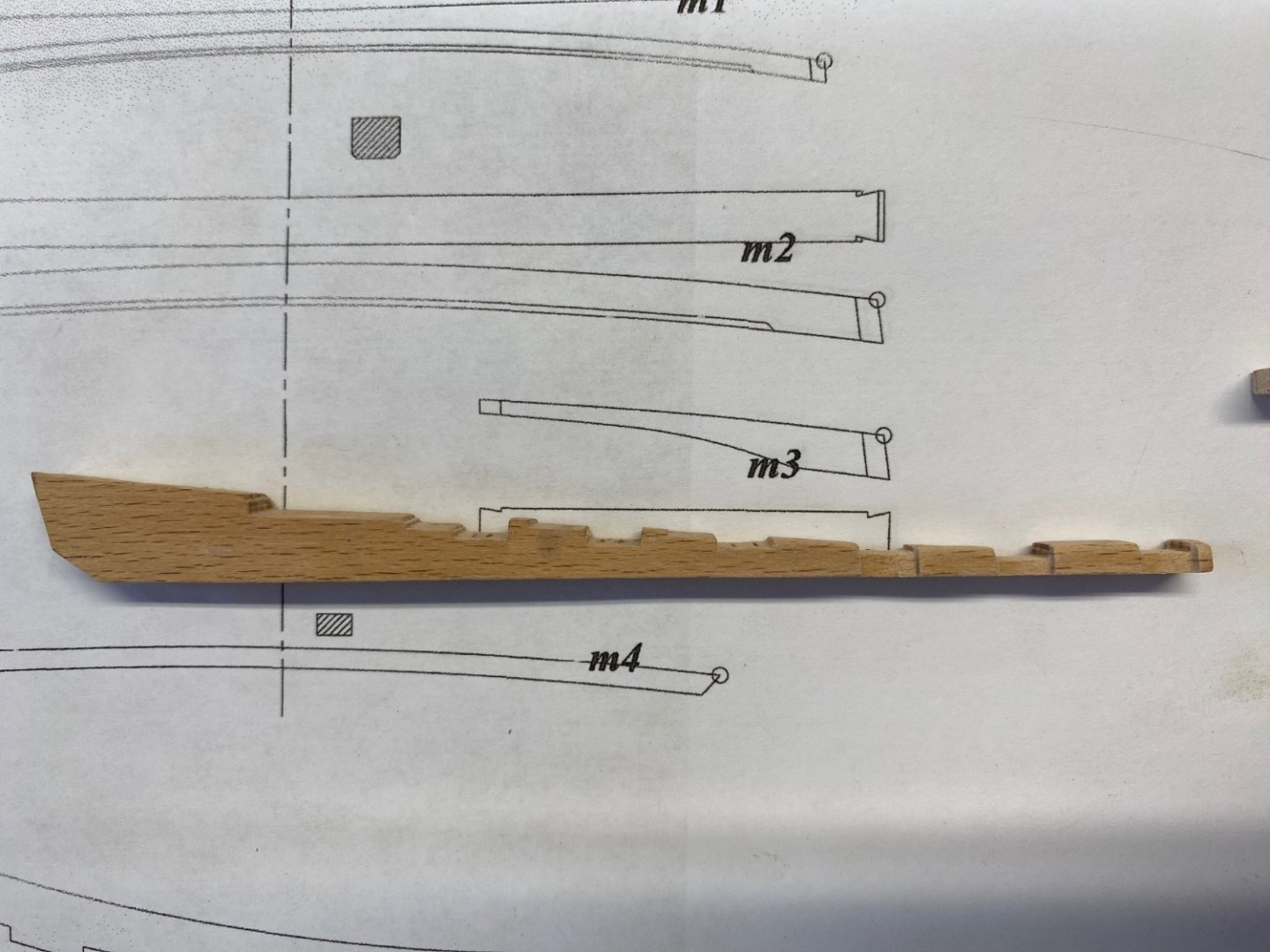

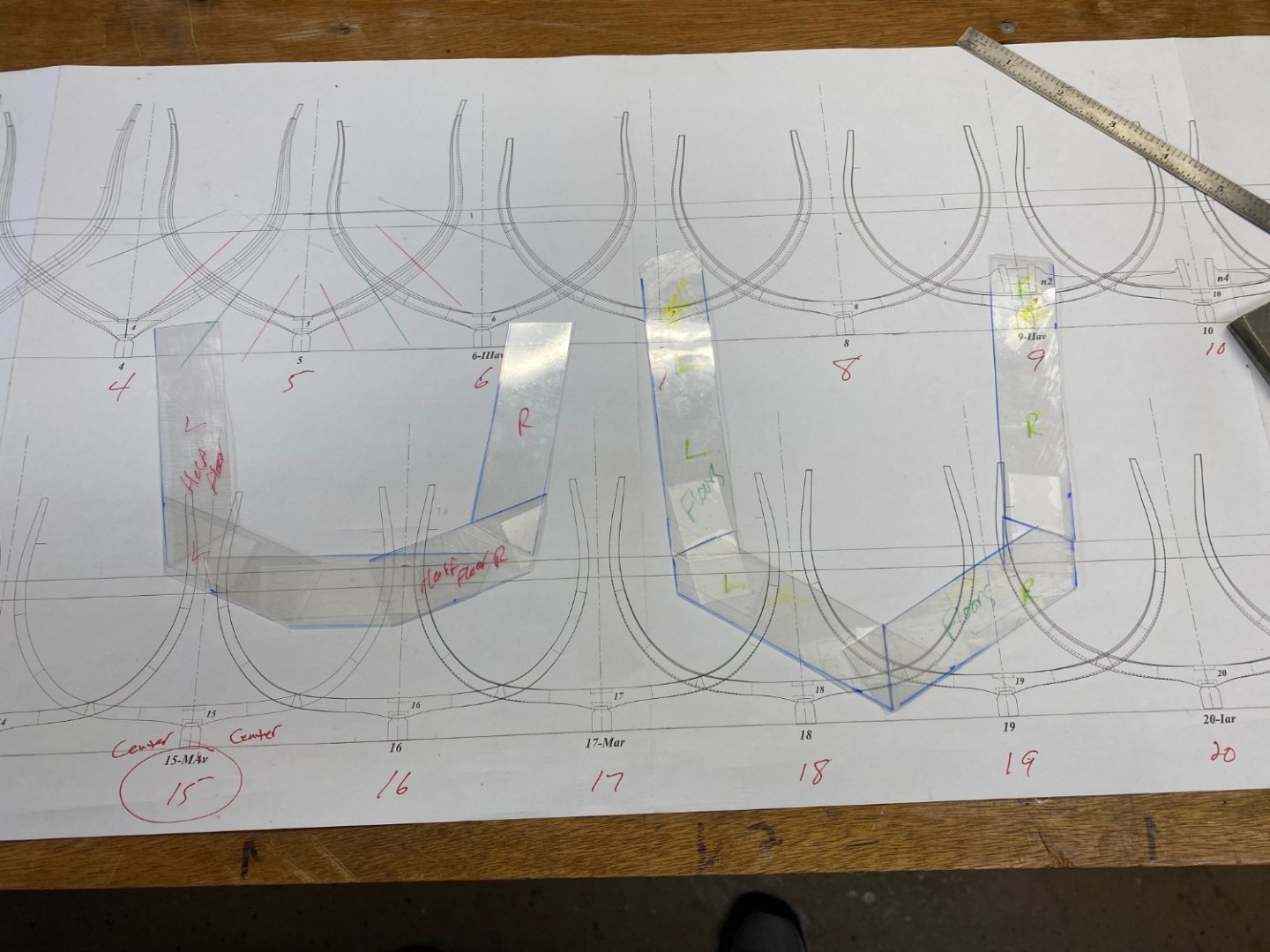

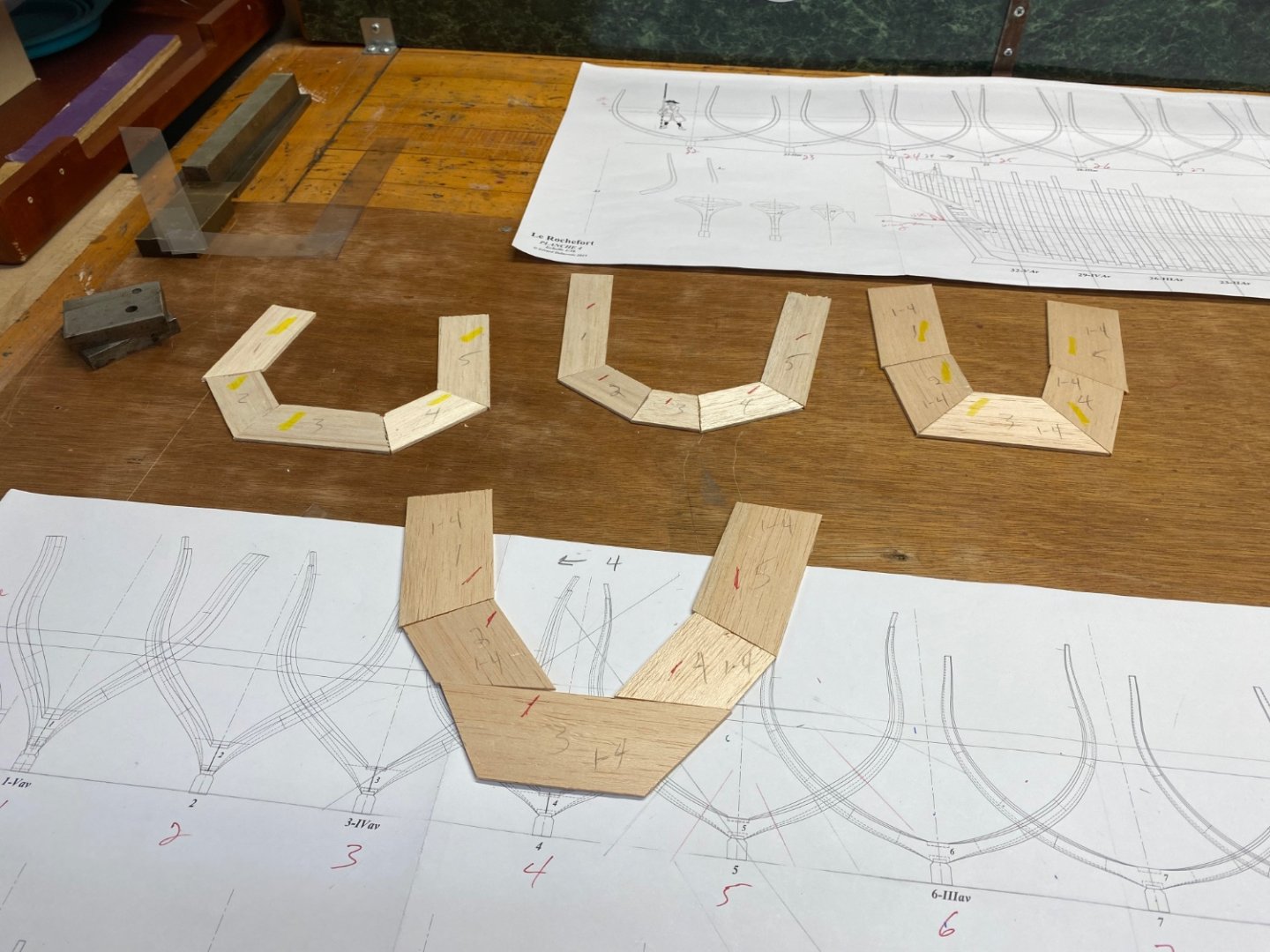

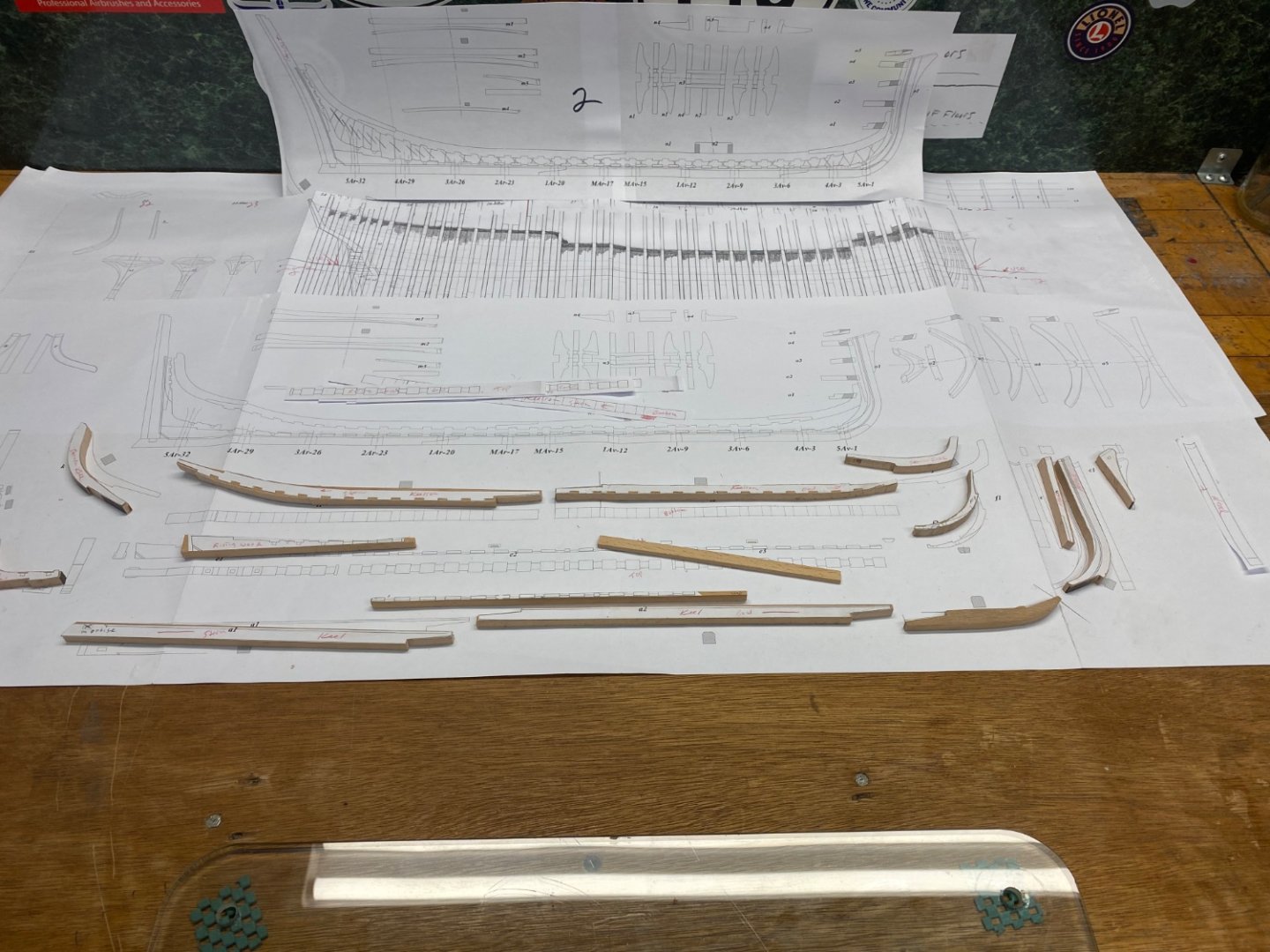

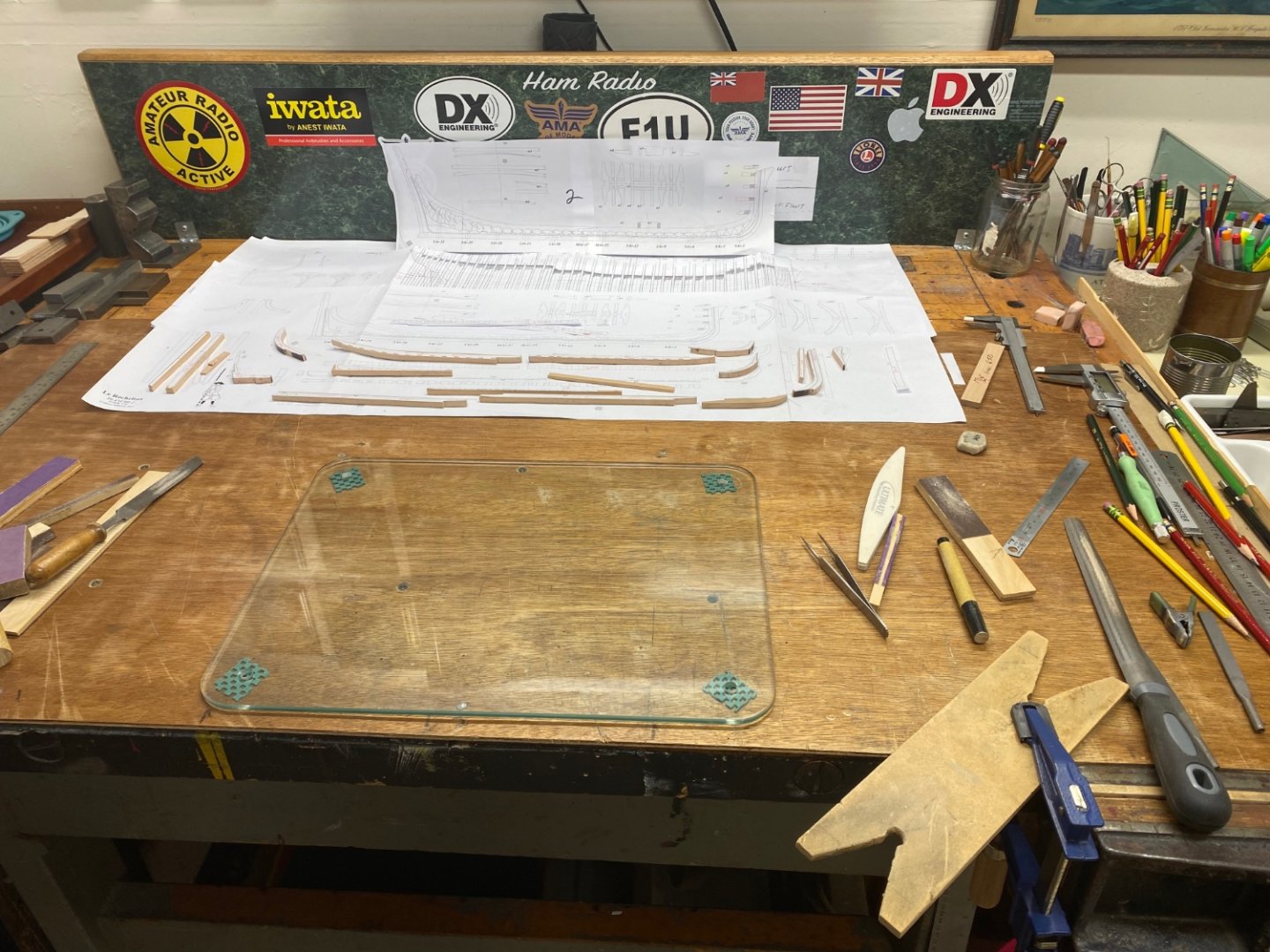

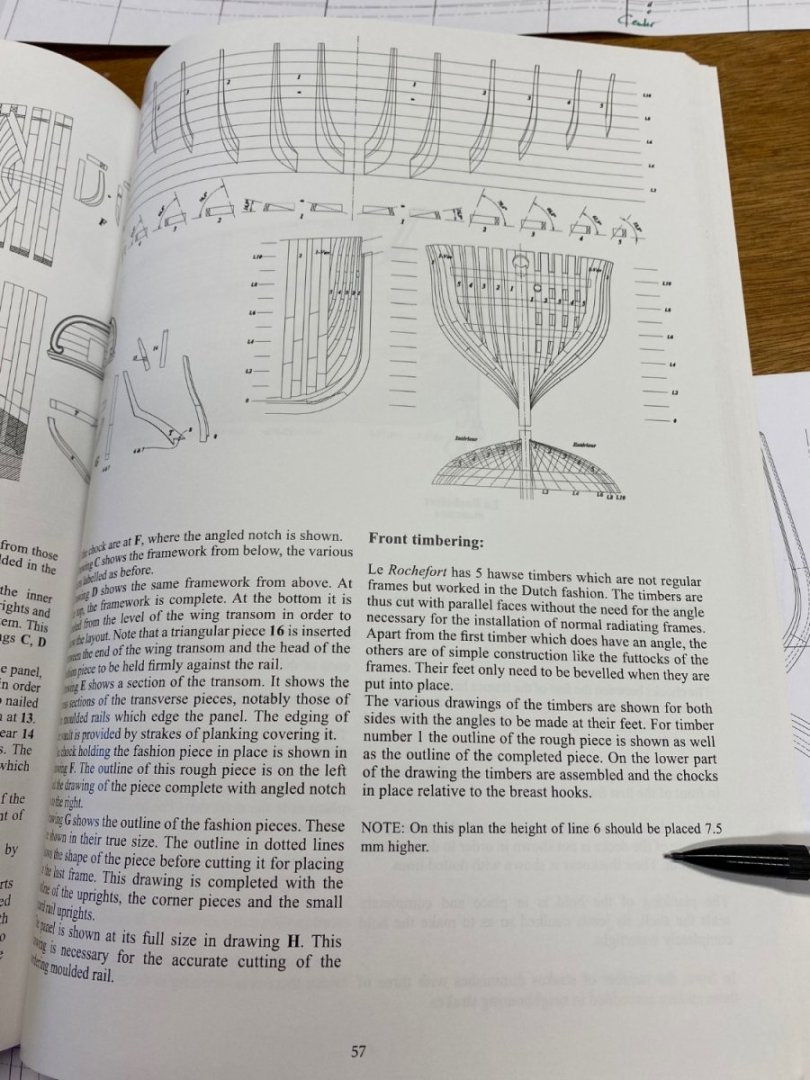

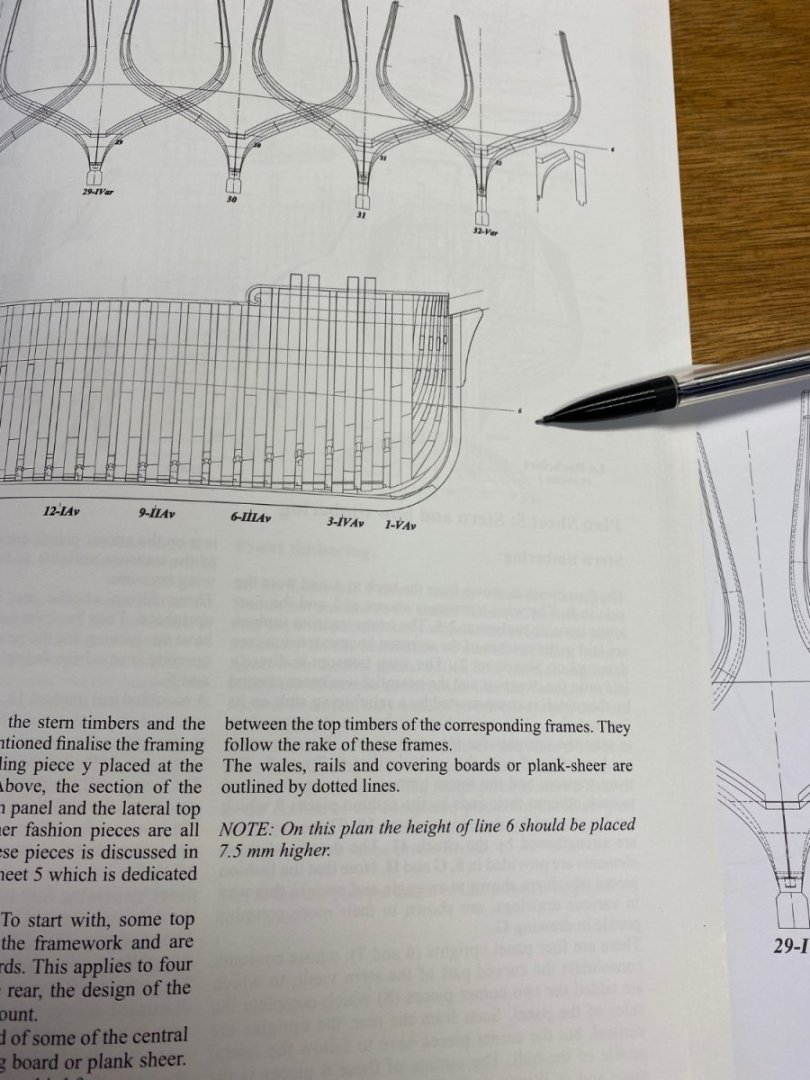

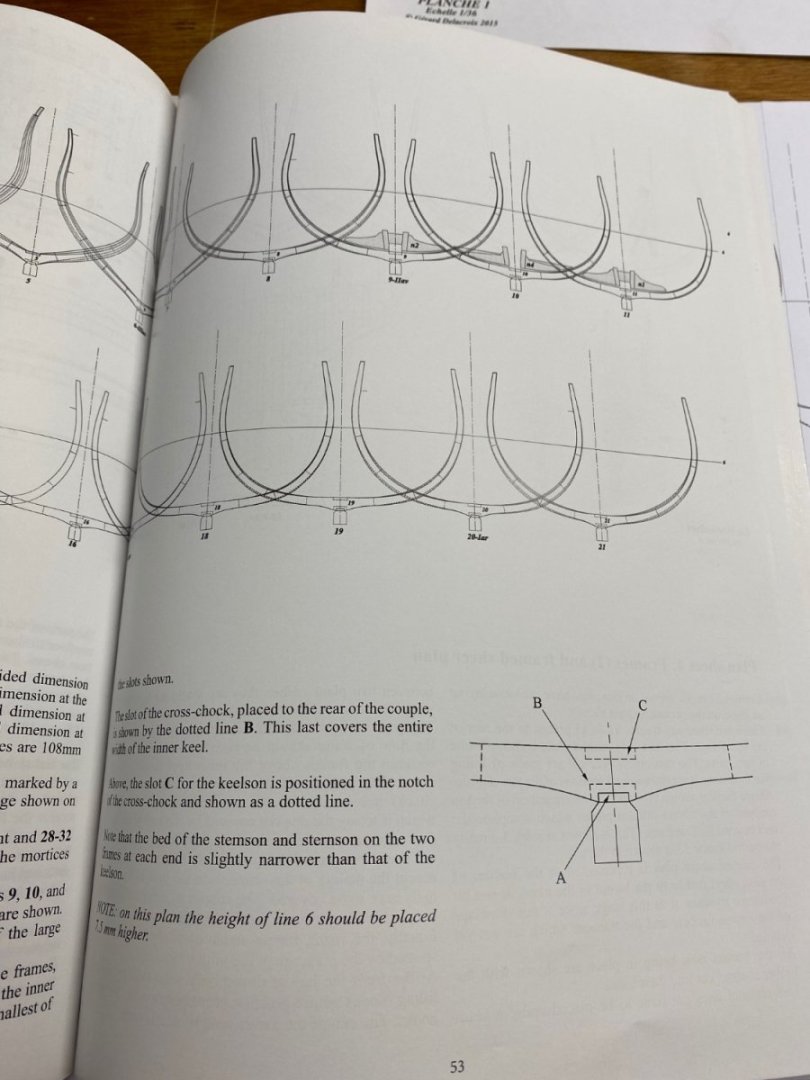

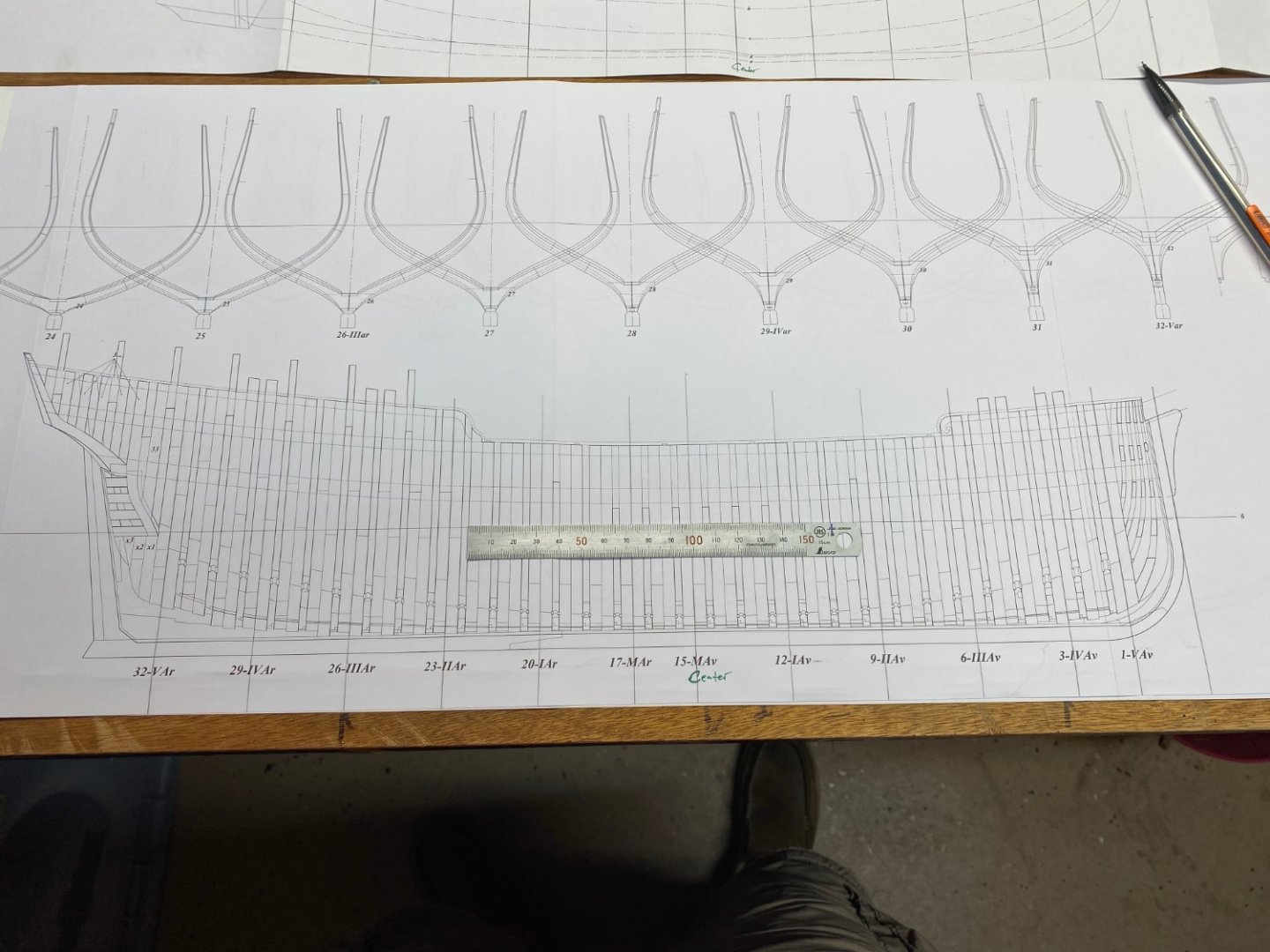

The past two days work. Made two wing transoms one from one piece of cherry one from 2 pcs of beech. During the forming process I ended up just going too thin for it liking. Made another today thicker and also made the other transom pieces. The plan is to mill the keelson and rising wood and get the axial structure all cut and fit. Then move into the frames since I gave my lumber now.

- No Idea, Tobias, Vladimir_Wairoa and 8 others

-

11

11

-

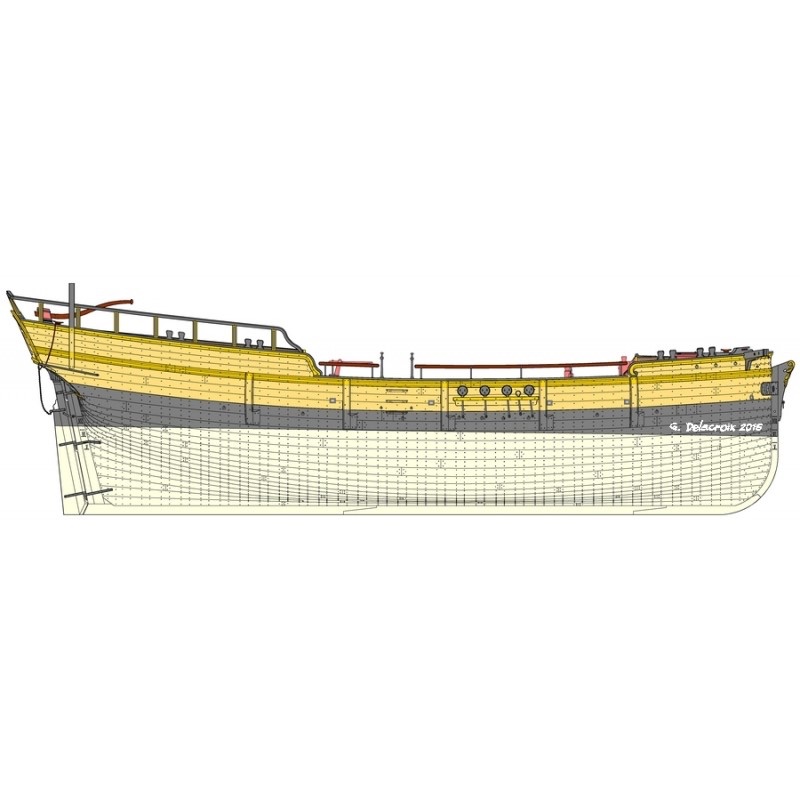

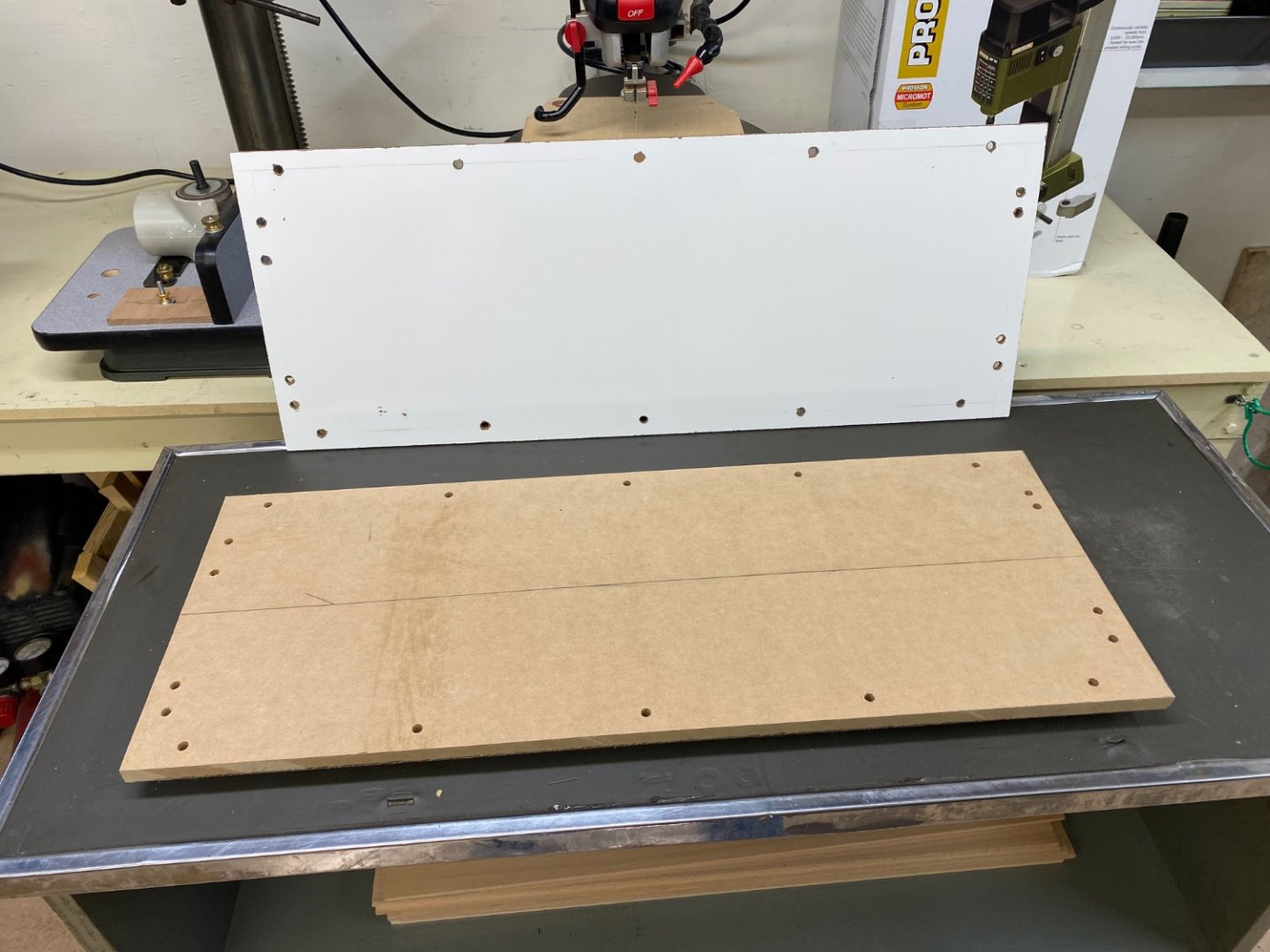

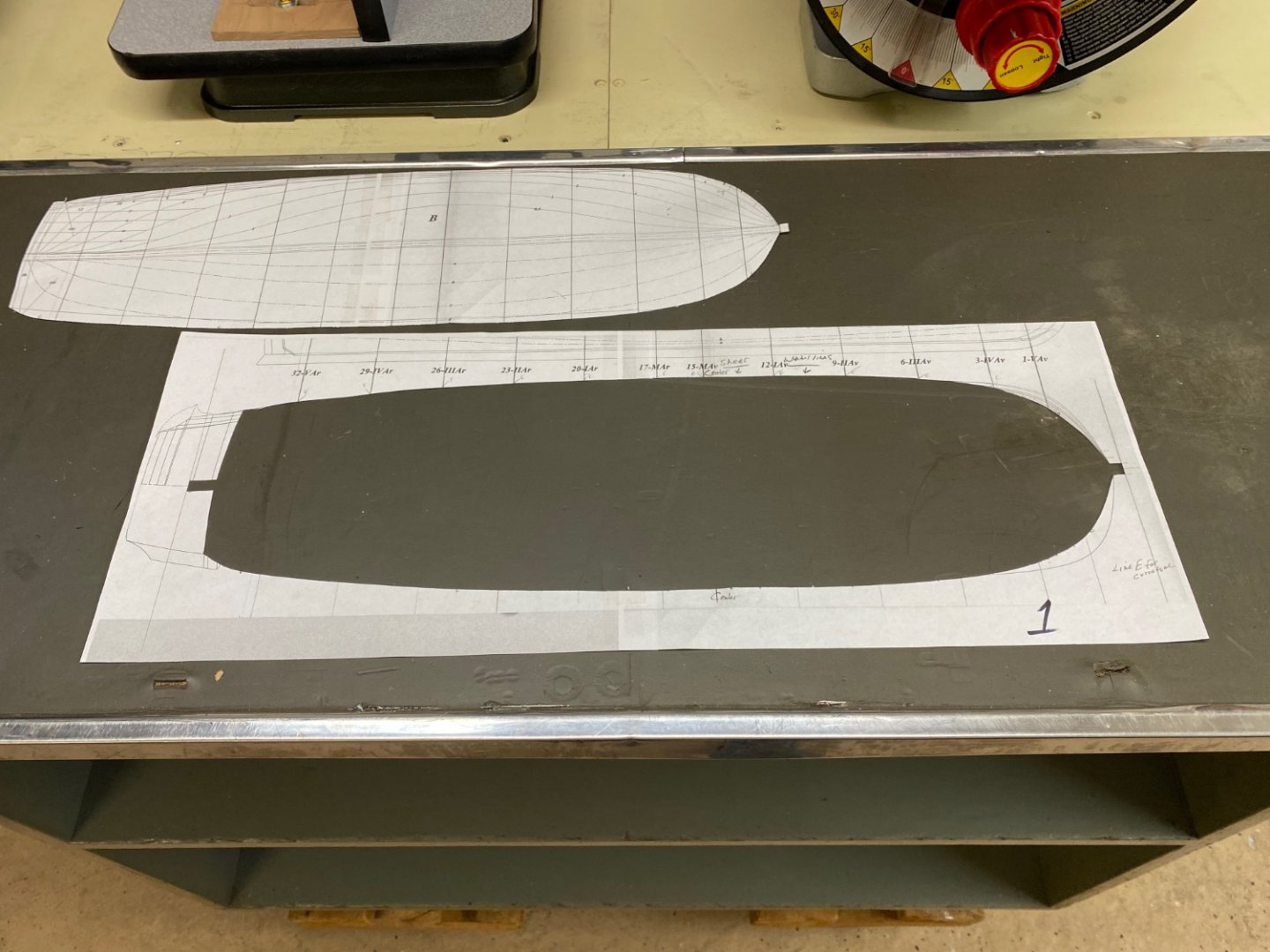

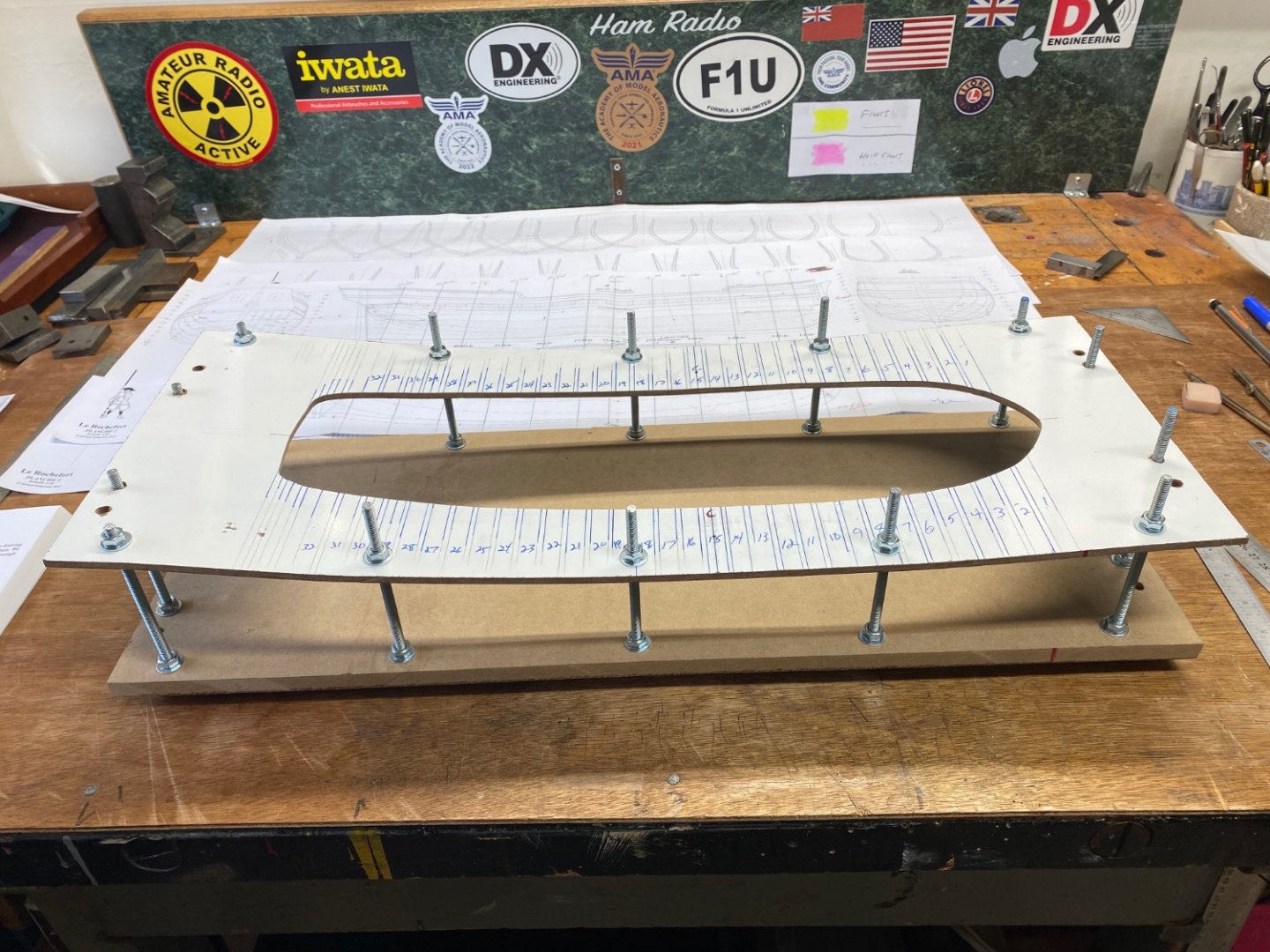

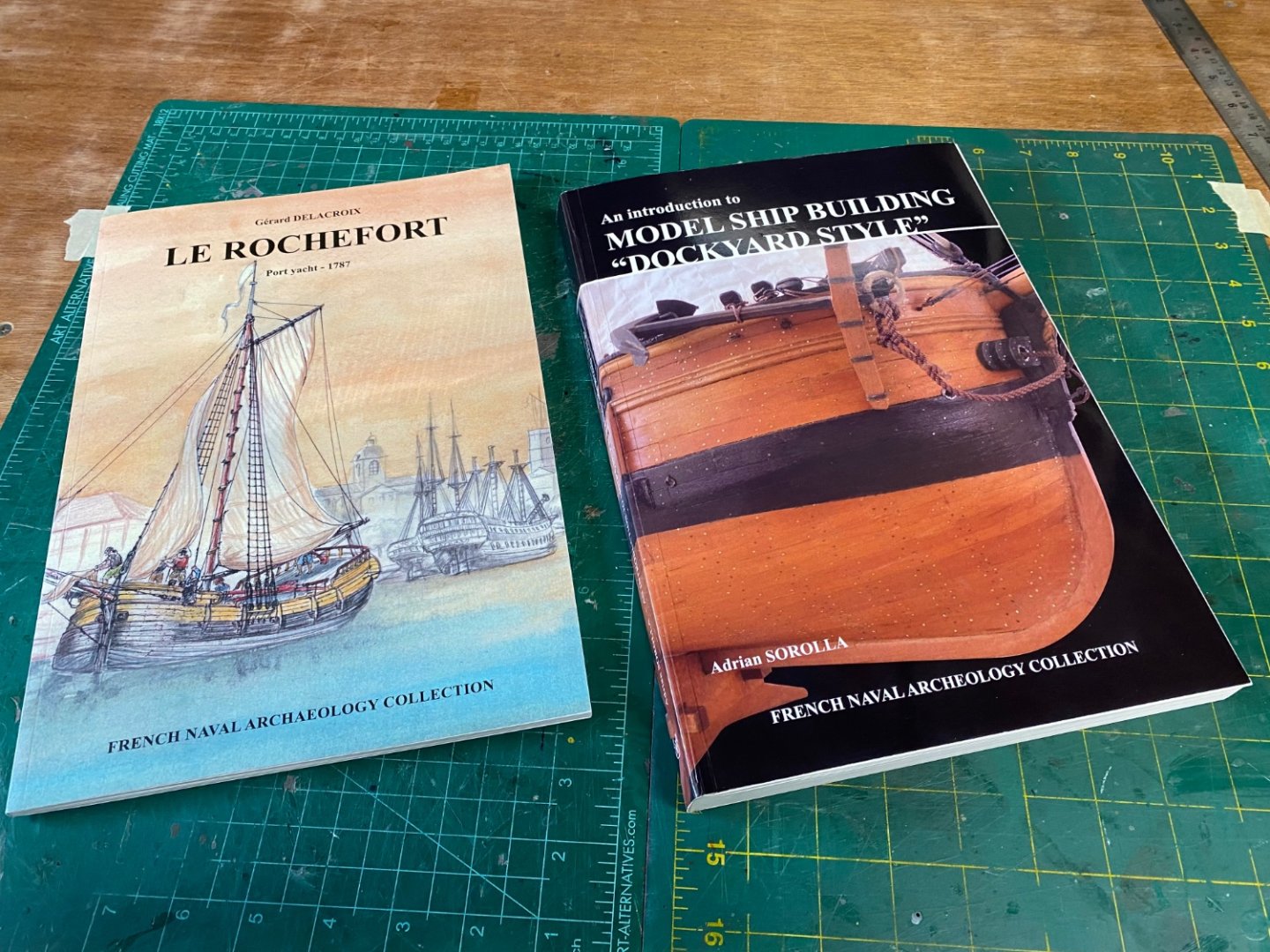

This is my second POF project. I also did a Blandford section last year. This is quite a project I see already. I’m still at the beginning stages. I’m going to use the Hahn method (attempt it anyway) but just for the frames. I’ll build the hull in the normal shipyard style. Progress so far. Keel bow and stern axial timbers and made and fitted. I’m waiting for my frame wood before I mill out the rising wood and continue. I’m working in the stern timbers now. I’ve been following Mark’s “No Idea’s” build since he started. I don’t expect to get near that quality but in the end I’ll still have a model I can be proud of.

- ccoyle, KLarsen, Vladimir_Wairoa and 7 others

-

10

10

-

- ccoyle, Prowler901 and mtaylor

-

3

3

-

Beautiful clean work. Congrats

- Seventynet, billocrates and mtaylor

-

3

3

-

-

Beautiful clean work indeed.

- billocrates, Tobias, Keith Black and 1 other

-

4

4

-

-

-

-

So great to see an update ! I'm still up in the air if I should start mine soon or not. Still have to buy the lumber. You were wise to go to 1/24 I think. more material but easier of handling of the parts I'd say. I hope this log stays forever cuz Ill need it for every step. There isn't very many Rochefort scratch builds out there in cyber land.

- mtaylor, No Idea, Seventynet and 1 other

-

4

4

-

-

On 9/1/2022 at 7:06 AM, No Idea said:

The French used both iron nails and tree nails in their ship construction hence the iron nails are dark and the tree nails just blend in. I believe that English ships only used tree nails in their construction.

At 1/24 scale this ship is roughly 900mm long 👍

Ok yes, big, very impressive. You're doing clean beautiful work. Kudos

-

-

On 8/20/2022 at 8:33 AM, No Idea said:

Definitely - I use my Byrnes saw every day I'm working on this model for one thing or another. Best tool that I own and it flies through some of the thicker sections which on this model at 1/24 are sometimes 13mm thick. It just gives you that repetitive accuracy that helps to combat accumulative error.

Thanks , I doubt I can spend that much $$. The Micro Mark is a clone of the larger Proxxon so I think, hope it'll do the job. I have the smaller Proxxon and its pretty poor. I managed to struggle through my section build but the time wasted just trying to cut material is huge !

-

Looking great Mark. Yea I don't know what that line is for but I found that yes it needs to be moved up on certain drawings. As you said though its not critical. I'm seriously thinking of going up to 1/24 also for ease of handling the parts and ease of working inside the hull etc. The down side is more material and more work to cut the heavier lumber. Need to get the Byrnes or Micro mark 4' saw asap

-

- mtaylor and GrandpaPhil

-

2

2

-

Fantastic beautiful work

- Keith Black, mtaylor and Obormotov

-

3

3

-

Le Rochefort by Tonphil1960 - 1/36 - POF

in - Build logs for subjects built 1751 - 1800

Posted

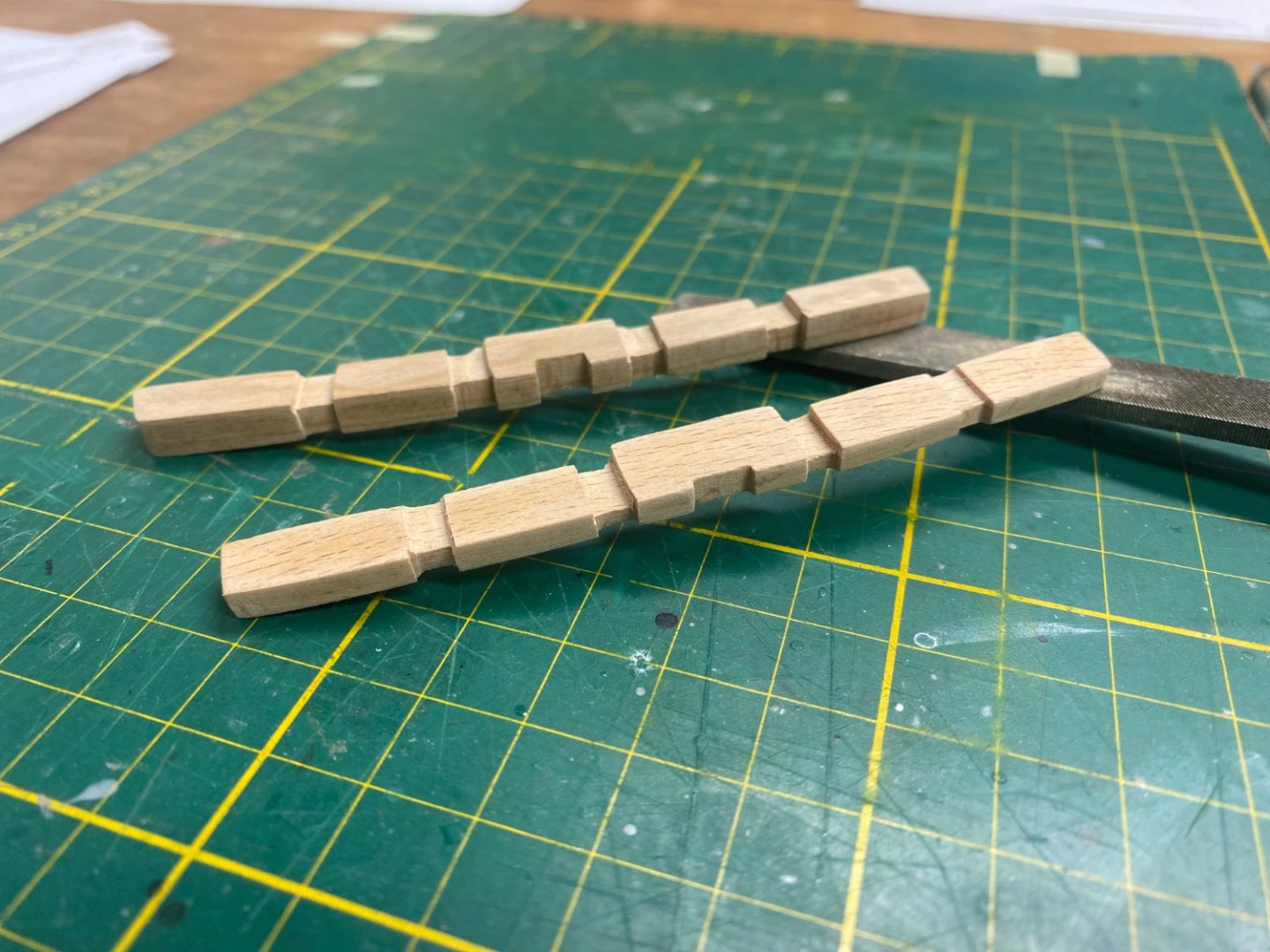

Thanks Mark. I just made four different size frame blanks to fit the different frames one for the floor side and one for the other. Im

not sure even that was necessary. I’ll glue them together and cut them out that way. The joints are close on some to where they should be and not close on others. I understand that with the Hahn method we’re not trying to match the plan’s joints. We’re just trying to make frames out of multiple pieces as in the real ones. I’m new to this like you !

You too, have a great holiday ! Tony