-

Posts

1,062 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by grsjax

-

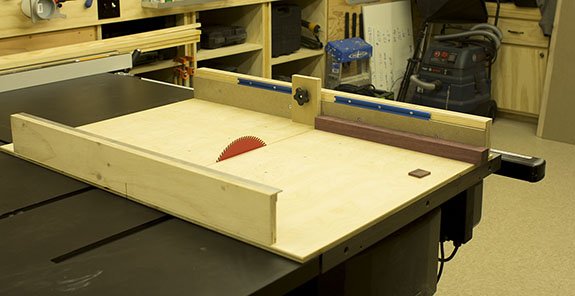

I find a slide on top of the saw table works well for strips. Clamp the wood to be cut to the slide and you can cut thin strips without a fence and without endangering your fingers. Added a picture of a nicely made table saw slide.

-

The Pride of Baltimore or the Latham would be pick. As Ron says the Santa Maria might be difficult. I wouldn't start with the whale boat. Although the whaleboat shape is generally considered easy to plank this kit is very detailed and takes some time to do right.

-

The acid etching results in a surface with a greater area than un-etched surface. The same is true for cleaning with pumice or other abrasives. This is a factor in the blacking process because it gives the blacking solution more area to interact with. I get much the same results using a similar process to that described by Landlocked123 but I use white vinegar instead of sparex. The white vinegar is acidic enough to etch brass and white metal, it is cheap and doesn't require any mixing. An important factor is cleaning the metal very well and rinsing all residue from the cleaning solution from the metal. BTW if you want to make your own blacking solution you can use a super-saturated solution of copper carbonate (CuCO3Cu(OH)2) and regular, over-the-counter ammonia.

-

Did all topsail schooners have ratlines on both masts?

grsjax replied to Cathead's topic in Masting, rigging and sails

On small craft it was not unusual to have only one or even no shrouds on a mast. The mast was a single timber and usually very heavy. As for getting to the top sails sailors would use the mast hoops as a ladder and climb to the top that way.- 18 replies

-

Model Shipway's Paints

grsjax replied to Worldway's topic in Painting, finishing and weathering products and techniques

Mix the paint really well and use a good filler on the wood. -

Pinky Pilot Schooner "Dove" - right pilot's flag of 1875?

grsjax replied to Small Stuff's topic in Nautical/Naval History

Wonderful ship. Lines, construction and rigging plans are available from the Smithsonian Institute and also from ModelShipBuilder. When I was a kid back in the dark ages of the last century there was a pinky yacht named Styx in the Ali Wai yacht harbor in Honolulu. Lovely, long black schooner. Your post set me to wondering if it was a copy of the original Dove. -

Midwest models are no longer being manufactured but are still plentiful on eBay. Any of the level 1 kits are a good place to start. The skiff and dingy are both excellent introductions to working with wood and are not to difficult.

-

Another excellent book is "Junks and Sampans of the Yangzte" by G.R.G. Worcester. Based on decades of experience it is the best book I have seen on the subject. There is also the "Junk Blue Book 1962" put out by the US Government during the Vietnam war that has a lot of info about water craft of the region. Downloadable version is available here http://indigenousboats.blogspot.com/p/junk-blue-book.html

-

Dumas makes one but it is very simple. Both the Amati and AL kits are pretty good. There are some Chinese made kits but I think they are from makers that are on the banned list. Can't think of any others.

-

Ran across this on eBay. It is from Russia. Don't believe I have seen this seller/manufacture before.

-

As said by others eBay is the way to go to get a good pair without breaking the bank. I bought an excellent set for less than $40 including shipping. Well worth the cost. However be wary of the ones being sold from India. They are very cheap copies.

-

Red Paint or Red Ochre

grsjax replied to davyboy's topic in Painting, finishing and weathering products and techniques

Not sure if this has already been brought up but I believe the most common mixture was red ochre mixed with turpentine and linseed oil. This would have been the most commonly available material in a dockyard. The actual color would have varied a great deal depending on ingredients, how fine the pigment was ground and how good a job of mixing was done. A recipe I found is 1 part linseed oil, 3 parts turpentine, Drying agent, Pigment. Not sure what was used as a drying agent or if a drying agent was even used. -

Depends on what you define as a trawler. Billings Boats makes a couple of nice kits and Laughing Whale (now owned by Bluejacket) used to make a couple but not sure if they still do. Soclaine makes some sailing trawler kits. Not sure about other makers.

-

I have a lot of scrap wood left over from projects. I find that if the piece is big enough to handle easily I keep it. Really small stuff gets tossed. Also if I find that I am accumulating a lot of one type of material, like the left overs from kit laser cut sheets, I tend to throw out the less useful bits. No rules, just do what works for you.

-

Got the wood de-barked. Used a 1" chisel as the trunk of the tree is fluted and a draw knife will only hit the high areas. Painted the ends and cut a few pieces to see what it looks like. Found some insect damage and staining under the bark. Wood is nearly white (sort of a very light cream color) but still pretty wet so probably going to change color a bit as it seasons. I will cut out the stained areas for pen blanks. A friend of mine is a pen turner and I send him pieces of interesting wood. Very hard wood. Might make a good substitute for holly.

-

No problem to find lead free solder these days. Most are tin based.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

My neighbor cut down an old meyer lemon tree and gave me the wood. Just got it so it will be drying for at least several months and I don't know much about it. All I could find on the net was that the wood was hard and fine grained with little or no figure. Anyone have any experience with lemon or citrus wood in model making?

-

Being naturally a cheap guy I look for interesting kits, materials and tools used or on sale. I have picked up some amazing bargains from eBay and garage sales. All depends on what you want. If you have your heart set on a particular kit you are probably going to have to bite the bullet and pay the going price for a new one or wait a long time to find it for sale on eBay cheap. Same goes for tools. Over 40 years of looking for deals I have accumulated a pretty good workshop but I didn't spend a great deal of money on it. Same for my stash of models. I have some very expensive model kits that I picked up cheap. Cheapest way to go is to get plans and build scratch using found materials (salvaged wood, etc.) and building your own specialized tools. For me that is part of the fun and interest of the hobby but I don't expect it is for everyone.

-

It is, IMHO, worthless. Not enough power to be useful for much of anything. Look for a sale on the Dremel knock off of your choice or go on eBay and look for a good deal on a used one.

-

SIEG SXO micro Milling Machine

grsjax replied to grsjax's topic in Modeling tools and Workshop Equipment

That is a nice one. I really like the 5.5" throat. Makes it a lot more usable. -

SIEG SXO micro Milling Machine

grsjax replied to grsjax's topic in Modeling tools and Workshop Equipment

Specs on this one say it has 8mm table slots (same as Sherline) and a top speed of 2800rpm. Maybe the Micro Mark model is an earlier model. I would guess that any accessory that works with a Sherline mill would work with the Sieg. The Sieg is a bit larger than the Sherline and might be able to use some of the mini mill accessories as well. -

Ran across a reference to this mill and was wondering if anyone had any experience with one? It looks like a good compromise between the larger Sieg X2 mill and the smaller Sherline and Taig offerings. One thing that looked very good compared to the smaller mills was the all cast iron construction. Heavier the aluminum mills but much more rigid. It also has a larger motor (150w vs 90w for the Sherline) and uses ER16 collets rather than the 8mm collets for the Sherline.

-

Spoke shaves are good for working on spars and other long thin sections. Use them for doing the initial shaping before finishing with scraper and sandpaper.

-

They are all good choices. The banks dory may be a bit simple but it is a good place to start. The swampscott dory is a little more of a challenge. I would rank these from least complicated to most; Banks dory Swampscott dory Philadelphia 18th Century longboat All good places to start.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.