-

Posts

1,062 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by grsjax

-

A very good model for a second build is the Model Shipways kit of the Skipjack "Willie Bennett". Enough detail to make it interesting but not so complicated as to be beyond a second time builder.

-

Recommendations For A Good Milling Machine

grsjax replied to Thistle17's topic in Modeling tools and Workshop Equipment

The seig X1 mill is a good one for model making. It is sold under a number of brand names in both the US and Europe. Good basic machine that will do anything you need to do for model building. Will require some adjustment to get the best from it. First pic. Another good one and better than the X1 is the Micro Lux 84656 micro mill. Micro Mark no longer sells it but it is available from other distributors or direct from China. A very good mill with ball bearings on the X-Y and Z axis. Second pic. I have worked with both and both are completely adequate for the type of work you want to do. Just my opinion better to spend half as much on the mill and the rest to by accessories when the lower price tool will do the job needed. -

Tools You Can't Live Without

grsjax replied to Justin P.'s topic in Modeling tools and Workshop Equipment

I have one like that. Works really well and has glass lens. I think I paid about US$12 for them on eBay. -

I would think that anything the size of a ship of the lines keel would require bolting as well as wedging. Keels were made up of as many as 7 pieces and must have been under tremendous stress and strain all the time. If I remember correctly there were a couple of different methods of making the scarp in the keel one of which did use a wedge in a similar manner.

-

There are several low temp silver solder pastes available. I purchased some from Amazon and have been pretty happy with it. You have to be careful if you are soldering several pieces together because the earlier joints will soften and/or melt if the piece gets to hot.

-

Did some searching for Polybak online and found this vendor that sells single 49"x97" sheets. Don't know what they charge as you need to setup a business account to see the prices. https://www.wurthlac.com/storefront/pre-fab-components/backing-sheets/polybak-backing-sheet-paint-grade-011-thick-49-x-97-/prodPCCLPGBTN.html Here is another vendor that will provide laserboard (not sure what kind) custom cut to your specs and also sells sheets (from 12"x12") of the material. http://automatedartists.com/laserboard

-

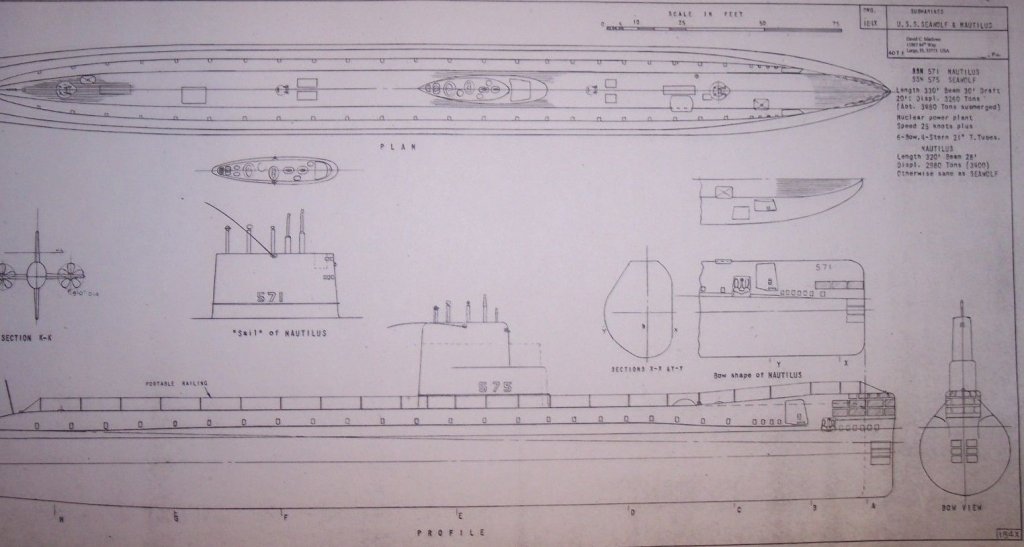

Several 24x10 drawings (one sheet for each sub) of US subs marked "Warship Drawings, Edward H. Wiswesser". Plans are in good shape but have been stored folded and have creases. The paper has darkened some. Price is $8 each including first class shipping in the US. U.S.S. Corsair, SS435 to SS524 U.S.S. Seawolf/Nautilus, SSN571 and 575 U.S.S. Tang, SS563 to SS568 U.S.S. Thresher, SSN593 to SSN615 I had to crib pictures off the net as my camera is acting up. Same drawings but actual may look slightly different.

-

Shipping is $3 ea. within the US. The Neophyte Shipmodelers Jackstay by George F. Campbell, M.R.I.N.A. Very good condition 1988 reprint. Softcover, tight binding, clean pages. $6 Ship Models: How to Build Them by Charles G. Davis Very good condition Dover reprint. Softcover, tight binding, clean pages. $5 The Ship Model Builders Assistant by Charles G. Davis Very good condition Dover reprint. Softcover, tight binding, clean pages. $5

-

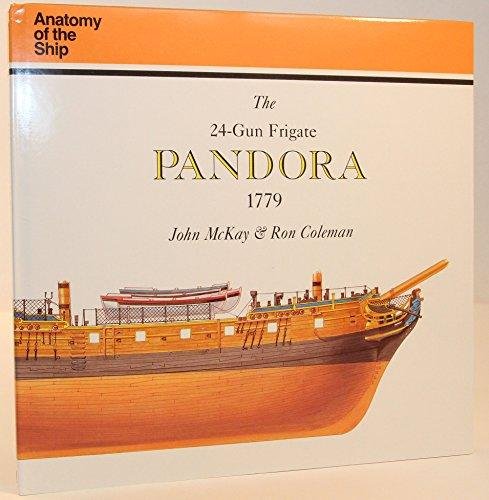

All books are in very good or better condition with dust jackets. Tight bindings and clean pages. Shipping is $4 ea. within the US. International shipment will require figuring shipping for destination. The 20-Gun Ship Blandford by Peter Goodwin $25 The 100-Gun Ship Victory by John McKay (some very minor marks on the dust cover) $25 The 24-Gun Frigate Pandora by John McKay and Ron Coleman $40 All 3 books for $80 shipping included in the US.

-

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

That looks like twisted wire rope to me. -

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

Could you post a closeup picture of the wire? I would like to see what kind of wire you are using. Thanks -

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

When I attempted it to do it that way the twist was either to loose, or the twisted wire would kink. Never could get wire rope that actually looked like the real thing. BTW wire rope is usually made with more than 3 wires. Common classifications are 7x7, 7x19, 6x26, 6x36 and 19x7 strands. There are other configurations but these are most common. -

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

You might be right. Just going with what I have observed. When I heat a piece of steel and let it cool it bends easier. Of course that might be highly dependent on type of steel and how hot I got it. Didn't do any scientific experiments, just what I observed in practice. -

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

Making twisted wire rope isn't easy, even at small scales. Takes a lot of tension to keep the twist tight. A regular rope walk probably wouldn't be enough. -

Working with braided steel lines

grsjax replied to skipper1947's topic in Masting, rigging and sails

Depending on what type of steel is used it may be possible to anneal the ends to make them less springy. Use a propane torch and hold the wire with a set of pliers. The pliers should be metal and fairly large to act as a heat sink to keep the annealing confined to the part you want to bend. If you can't get the wire into a condition you want you might want to check out jewelry suppliers for braided wire that is less springy. It comes in a large range of sizes in a couple of different braids (5 strand, 7 strand, 9 strand, etc). -

Is "To Build a Whaleboat: Historical Notes and a Modelmaker's Guide" by Erik Ronnberg the book you are going to get at Mystic Seaport? If not you should take a look at Mr. Ronnberg's book. It is the best I have found on building a whaleboat model.

-

Software recommendations

grsjax replied to Sailor1234567890's topic in CAD and 3D Modelling/Drafting Plans with Software

DesignCad 3D is a good program and doesn't cost a lot. I picked up one that was an earlier version for less than $20 on eBay. I don't know if it will work with a Mac but you can get a Windows emulator for the Mac that can run this software.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.