-

Posts

408 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jpalmer1970

-

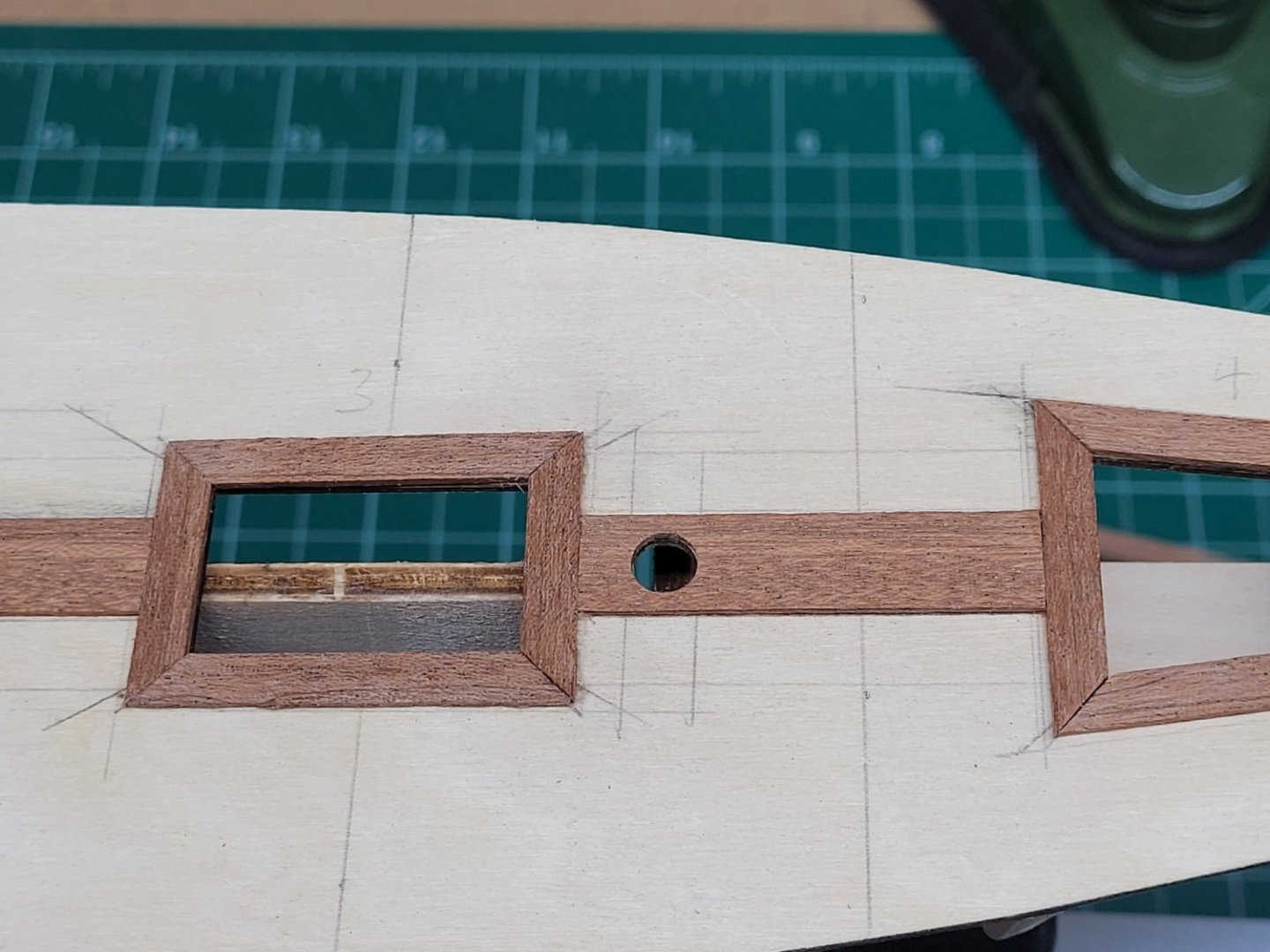

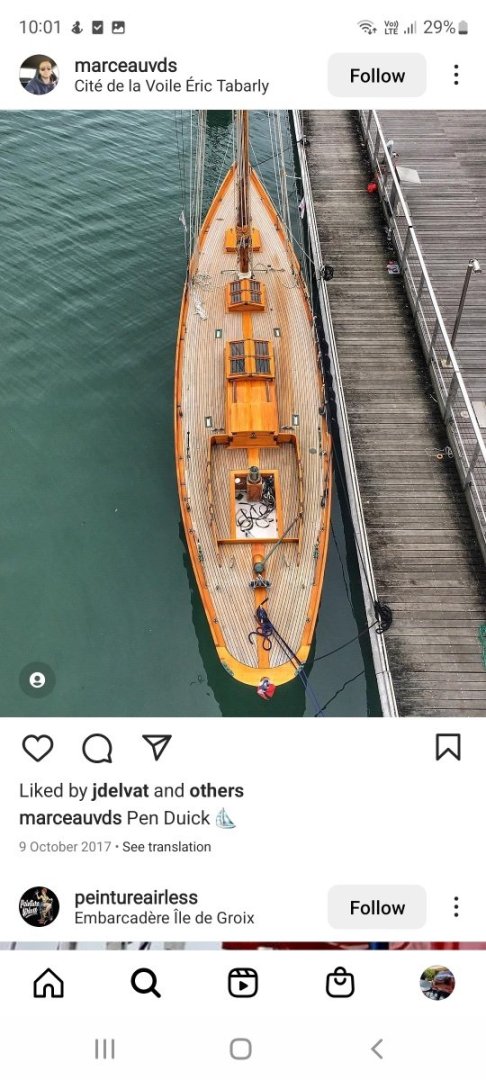

After a little more sanding of the frames and keel I think I have got as far as I can with the fairing until I start on the planking of the hull. The kit instructions actually indicate the next step in the build is to move on and start the deck planking rather than undertaking the hull planking now and so I have decided to follow this process. The deck planking is a pretty simple affair according to the instructions, just 3mm planks butting up to the three forward hatch frames and the king plank and then the frame of the cockpit hatch is set atop the deck planks. The real Pen Duick deck planking is of course a slightly more intricate affair - all four hatch frames are level with the deck planking and the much thinner deck planks are all joggled into the king plank and the hatch frames. It is my intention to copy the real deck planking as much as possible. I began by installing the 10mm wide mahogany king plank and making the frames for the four deck hatches. The hatch frames are 5mm wide mahogany. What seems like a fairly simple task actually took quite a while to execute well. Getting all the frames and the king plank to sit square, equal and parallel where required, and symmetrical along the centre line took a fair amount of fettling, and in one or two cases removing and re-doing! The deck isn't particularly wide, even at its widest point, so being even a fraction of a millimetre off in the placement any of the frames makes things look off - and with only 2mm wide deck planks to be used being a millimetre out to one side will mean that the planking would certainly not look even. One of the sections of the the king planks needs a 6mm diameter hole cutting for the mast - I used my mini drill press to cut this hole starting with a 1mm drill bit and working up in sizes until I was able to fit a semi-circular file into the hole. I didn't want to use large and large drill bits up to 6mm as I feared the mahogany might be too brittle. With the file i was then able to enlarge the hole to the 6mm size required - I think it came out nicely in the end. There is also a slanted 3mm hole for the rudder arm which needs to be drilled through the deck, false keel and keel stiffeners. I am really not sure how to accomplish this as getting the angle right is going to be very tricky and I'm not sure I have long enough drill bits in small enough sizes and so I am wondering whether to cheat and just have a false piece coming out of the deck to the tiller and not have it connected to the rudder at all. The model will be put in a display case so no-one is going to be using the tiller to see if the rudder actually works 😃 For the time being I have simply drilled a 2mm hole squarely in the section of the king plank where the slanted 3mm hole is situated so that later on in the build I have a marker for the correct location. After installing the king plank and frame hatches and the thicker stern piece I then set about adding a margin plank on each side of the deck from some 3mm mahogany. This needs to be joggled into the king plank near the bow and my mini Veritas chisels were ideal for this job. I think I have been fortunate with the 10mm piece of mahogany included in the kit as the king plank as this seems to be far less brittle than the other pieces of supplied mahogany. Therefore it was fairly easy to cut the required joggles using the chisels and a new #11 blade. Hopefully the rest of the joggles will be equally as easy - there are going to be a lot of them to do! I had to experiment a little on the best way to support the model at this stage. The Amati keel clamp which I had been using prior to the fairing work simply wasn't suitable anymore given the bottom of the keel is now an angled section, and after looking at various options, including building a suitable sized cradle, I eventually hit on the solution of using two adjustable workbench vices with soft rubber jaw covers to hold the model. The model can be held securely with one vice in the centre but working at either of the extreme ends of the model did make things a bit tippy - using both vices got around this problem. Whoever said you always need more vices, clamps, grips and other means of holding things was certainly right!

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Hello and welcome!

-

I know this isn't contemporary at all but can you use some of the images from the Vanguard online manuals as a template to form a basis for your own version of the design. There are images in the Alert manual of course but I am also thinking of the ones in the Duchess of Kingston manual as the design there is a bit more intricate?

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

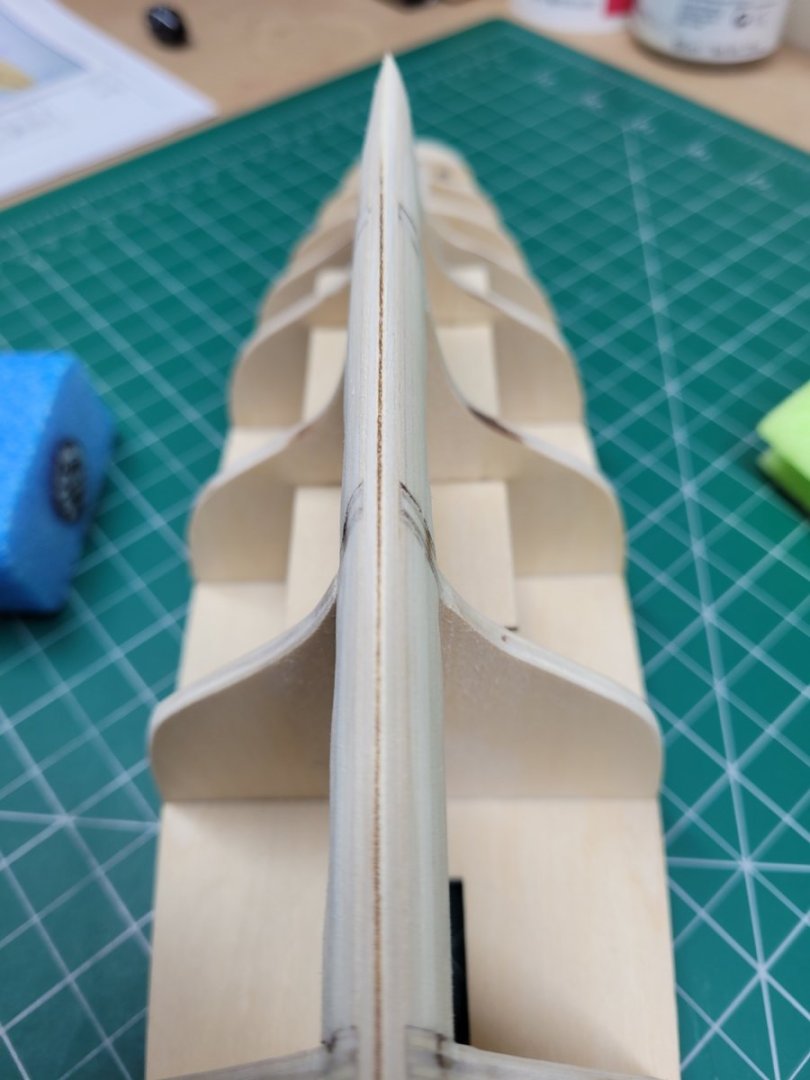

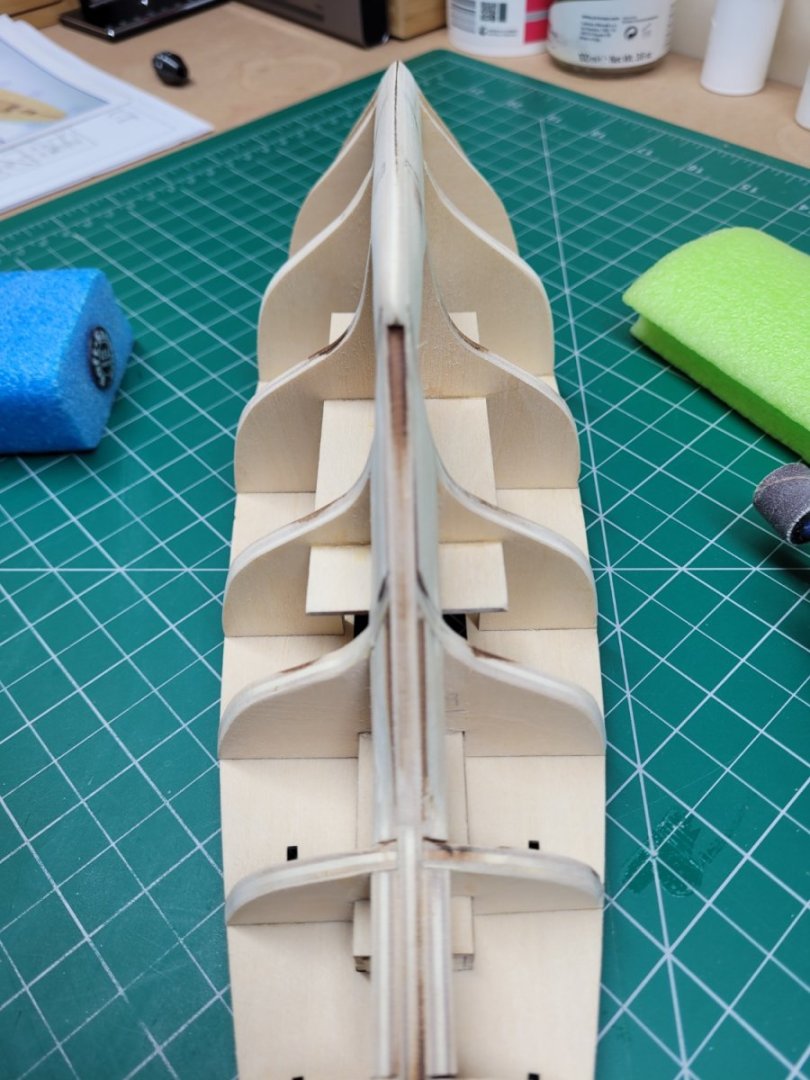

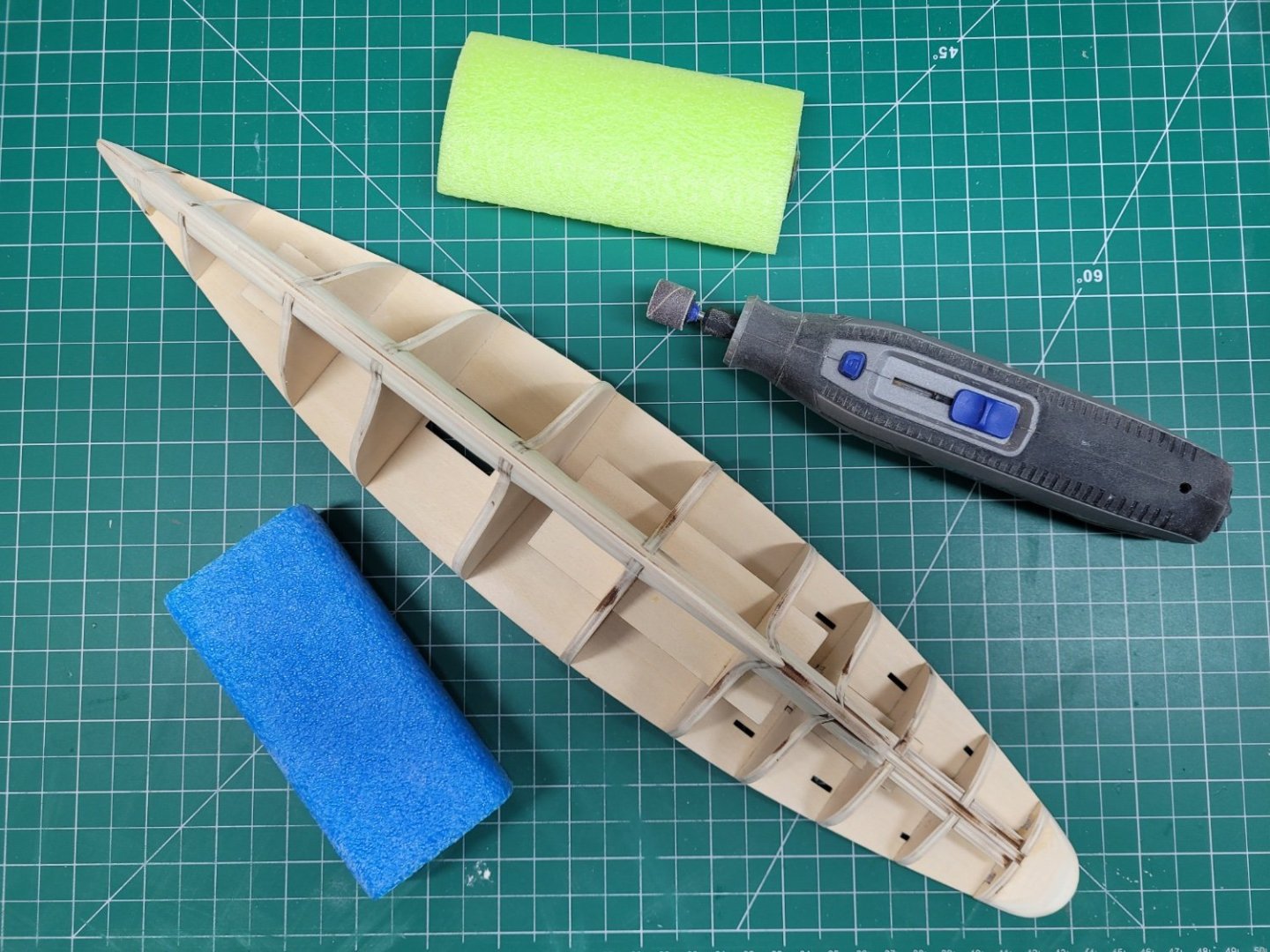

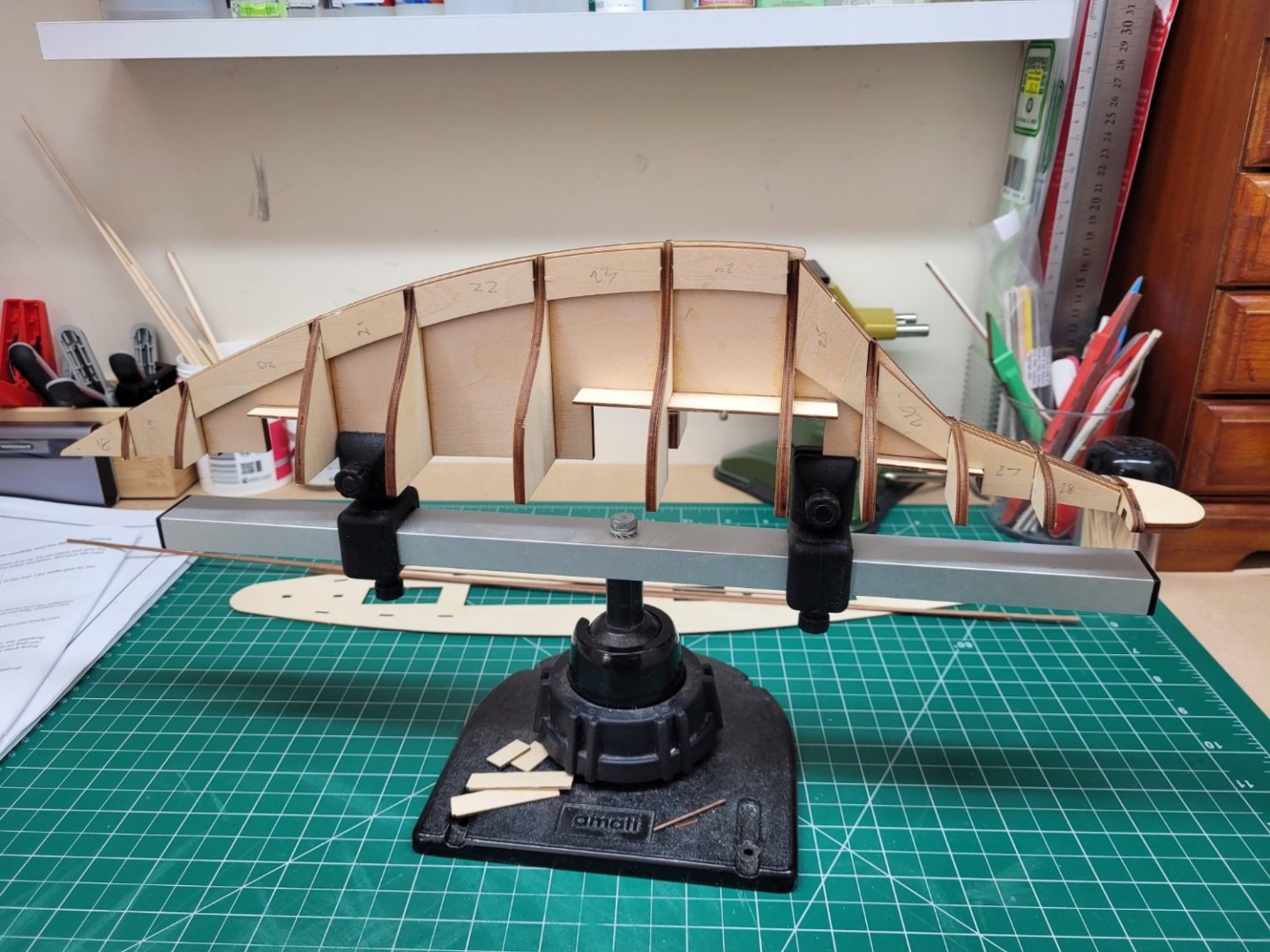

I was able to spend a good few hours working on the fairing of the frames and the keel yesterday. I had already completed a significant part of the failing of the starboard side of the ship last weekend and another hour's work saw that side completed - at least until the port side had been faired to match. These two images hopefully show just how much of the keel stiffeners needs removing in order to get the required shape for the keel. I had done most of the work on the starboard side with just 120 grit sandpaper and the soft sanding blocks but for the port side I decided to use my dremel lite to work away the bulk of the keel stiffeners. This certainly made short work of the plywood stiffeners and only a few minutes use had them to the stage where I could undertake the proper shaping with the sandpaper and sanding blocks. I estimate that 10 minutes work with the dremel was equivalent to well over an hour's work with soft sanding blocks. I was very wary of getting too close with the sanding band on the dremel so stopped well short of where the shape needed to be - but it certainly sped up the whole process. More work with the soft sanders allowed me to shape the port side so that it matched the already shaped starboard side. There was then a little more sanding work to do just to make sure the keel line was straight and equal. I also used a 5mm lime wood plank to check the run of the frames and did my best to have everything equal and smooth. I found that bulkhead 7 seems a little narrow on both sides so I adjusted the angles on bulkheads 6 and 8 slightly to get a better run with the plank. I think I have got to the stage where the fairing is 95% complete now - there are just a few points, like the stern and the very top area of a couple of frames that need some very minor finessing.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

The completed cannon on the carriage looks really good. Thanks also for the latest piece of painting advice - it is a bit of a dark art if you haven't had much experience in that field before.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Hi, Thanks for the comments. Yes I am tending to the idea of sticking with the pencil, though I might try to use a darker one than a standard HB though. The idea about sanding sealer is a good one which should certainly help if a marker is used. I plan to apply wop on the deck so I will use some of that on my next trial run with the 2mm planks to see how much of a difference that makes to the caulking lines.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

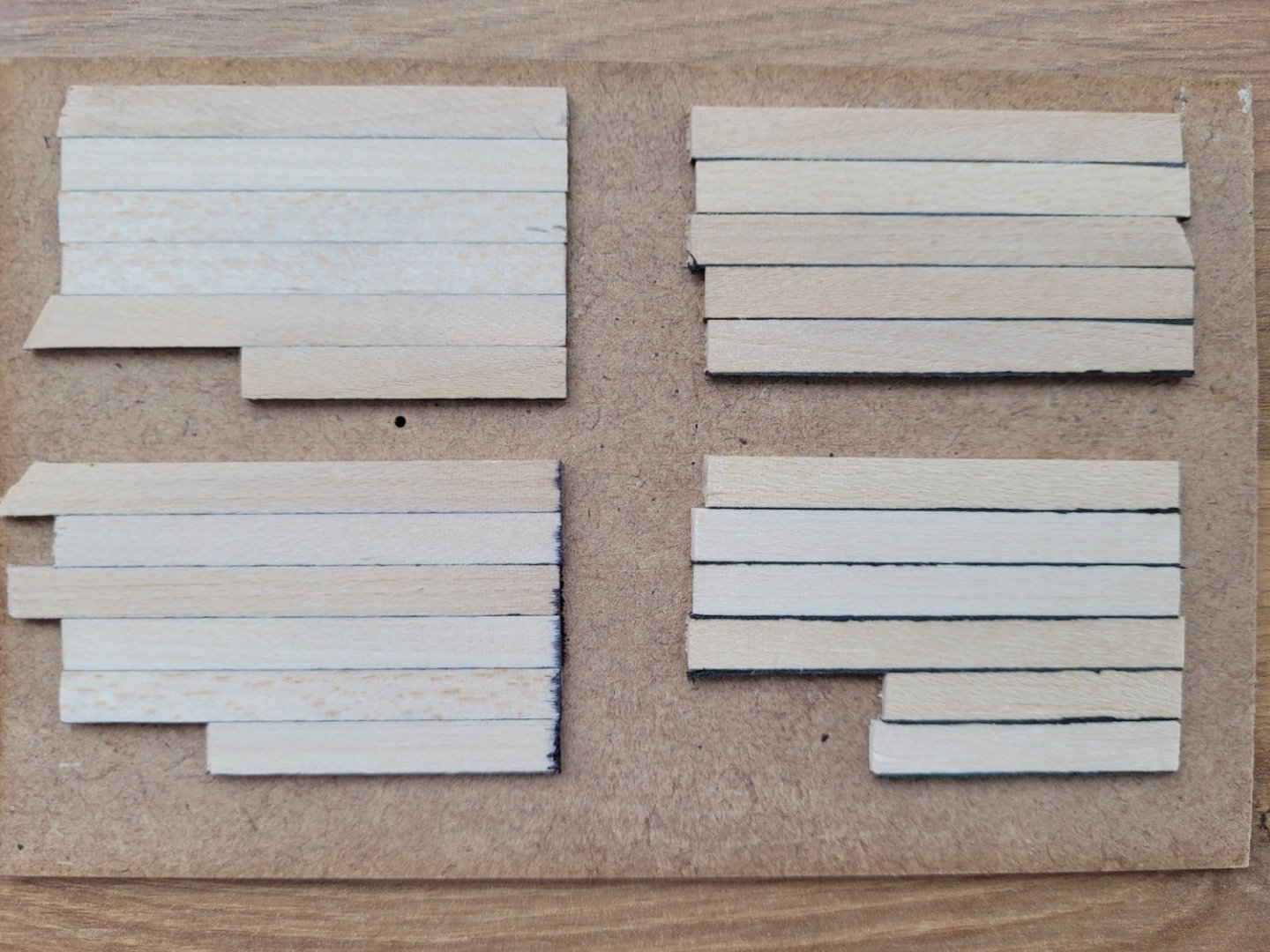

Whilst waiting to get an opportunity to work outside to continue with the fairing of the frames I spent some time considering the planking of the deck. On my previous build of HM Cutter Alert I simulated the caulking between the deck planks using a pencil along the side and end of the plank. I wanted to see how different methods of doing this compared so I put together a little trial of four different caulking alternatives. The caulking in the planking in the top left was done using a pencil as per Alert, the bottom left option used the same method but with a black marker rather than a pencil. For the top right trial piece I cut thin strips of black paper the same height as the planks (1mm) and glued these to the sides of the planks prior to putting the planks together. Finally with the bottom right section I again used black paper but cut this oversize and then trimmed it down to the plank height after the planking had been completed. It was obvious from the outset that there was going to be a problem with the black marker at the ends of the planks where the grain was open – there was some very obvious bleeding of the ink that took place there which doesn’t look good. Of the two black paper trials it was also apparent that cutting the strips to the exact size of the plank height prior to gluing made for a neater appearance compared to trimming the paper down to size afterwards. The black paper certainly gives a more definite appearance of caulking than the pencil mark, at least at this scale – the planks I used for the trial were pieces of 5mm wide limewood. However, I am planning on using much narrower planks on the deck of the model and it is possible that the black paper would become a little too overwhelming at that scale so I have yet to decide on whether to use pencil or paper when I get to that stage. I will repeat this trial with the deck planks of the actual size I will be using later on I think. The deck planking provided with the kit comprises 3mm wide ramin. As I mentioned in a previous post even at 3mm wide the deck planks are very oversized compared to the planking of the real Pen Duick deck and I want to scale these down to give a more realistic appearance to the model. At the widest point of the deck the kit plans show thirteen 3mm wide planks are needed on one side of the centre line. Photos of the actual Pen Duick show that there are about forty planks in that same space so planks of 1mm wide would be much more representational for the model. I think working with such narrow planks would make the job of joggling them into the king plank a lot trickier so I decided to compromise on 2mm wide planks. I decided the easiest way to cut down the deck planking from 3mm to 2mm was with a #11 blade and with the plank clamped to my cutting mat and a metal straight edge as a guide for the cut. I experimented with three or four planks and found that it was very difficult to for me to get a consistently straight cut along the whole plank length. I also tried the same setup with some limewood planks and found that they cut much more easily and consistently so I think there must be some difference in the wood density or grain which makes the ramin more difficult to cut in this manner. Unfortunately, I don’t think I have enough of the kit supplied ramin to cover the whole deck with 2mm planks given the percentage of wastage I am going to encounter in the resizing process. If I could guarantee that all the planks could be cut down to size correctly then I should be ok but I don’t think that is going to happen. Given that the deck planking is suck a key feature of the model I decided not to risk bodging it with the resized ramin and so I have ordered some 2mm wide limewood to use instead.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

I managed to find a little time this weekend to make a start on the fairing of the frames. There is an awful lot of material that needs removing from the keel stiffeners and an hour’s work with 120 grit paper and the soft sanding blocks only took off the worst of the excess on the starboard side of the hull – it is going to be quite a lengthy process to get the whole hull faired properly. Many of the frames really only need a minimal shaping but getting a v shaped edge to the keel is going to be a longer process due to the thickness of the various stiffeners. I am considering breaking out the Dremel to take off the bulk of the material but I am always wary of power tools when sanding frames etc as it is too easy to take off too much. On the plus side my new respirator mask is a comfy fit – I think I’m going to get a fair bit of use out of it in the coming weekends!

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

I think there will still be enough of the kit supplied deck planking if I cut them down to 2mm wide but I will do the maths and work that out for sure before I start anything. I can buy some 1x2mm limewood strips which is an option if I am unable to consistently reduce the kit planks. I do have a Proxxon table saw that I want to get better at using so this is an opportunity for me to learn some of the techniques of making planks with that.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Thanks HOF. Yes, i have put some tape on the edge of the deck in an effort to protect it from any wayward swipes during sanding. There is a lot of wood to remove from the keel pieces but the plan is to take it slow and steady and not muck it up! I also plan to joggle the deck planks into the king plank. I am toying with the idea of reducing the deck planks from 3mm to 2mm wide so that it will look a little more like the deck of the real ship but we'll have to see whether I can do that consistently to all of the planks, as it will be very obvious if some of the planks are wider than others.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Hi Bob, I need you to rig yours so that I'll know how to rig mine! 😄

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

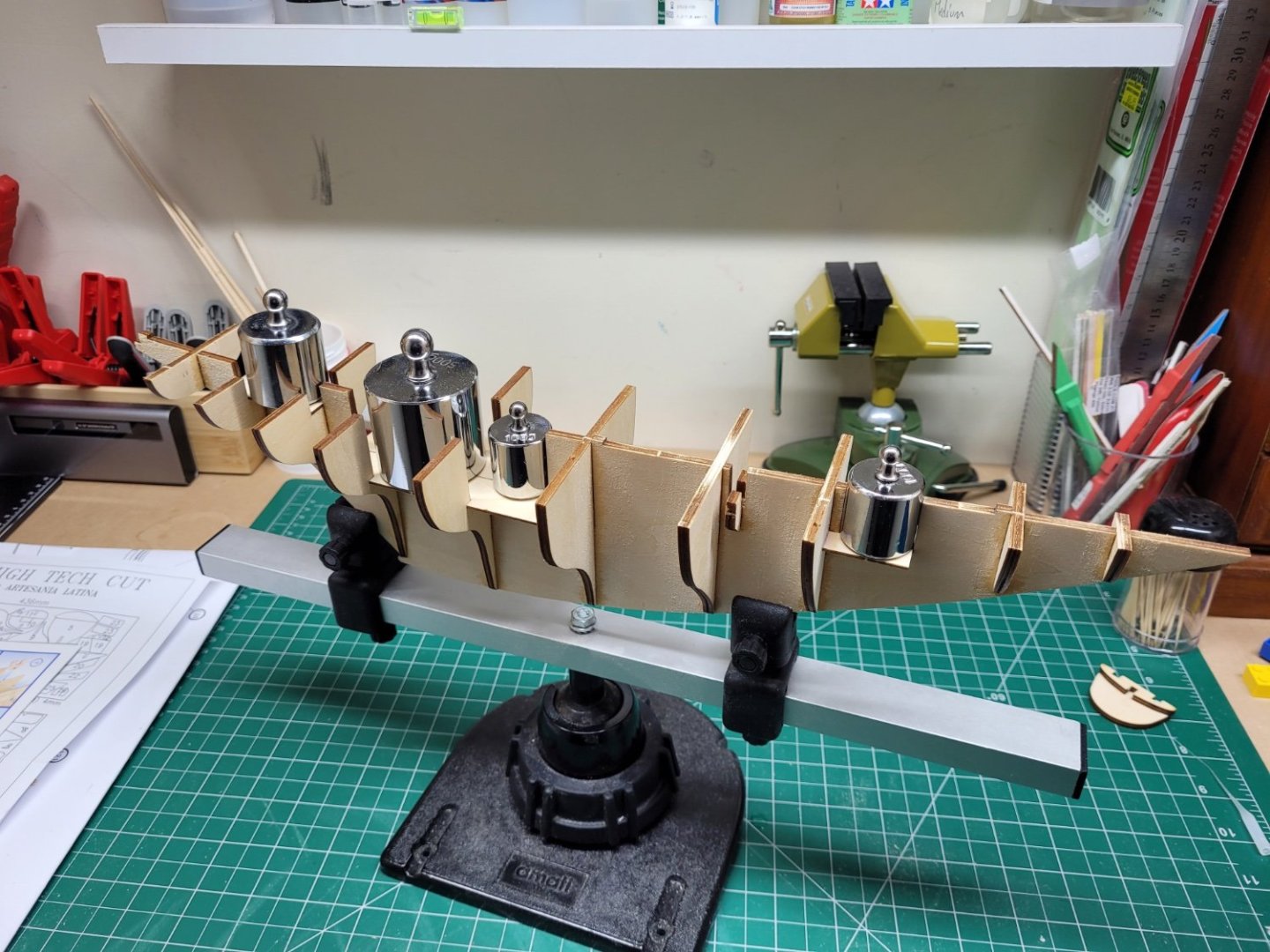

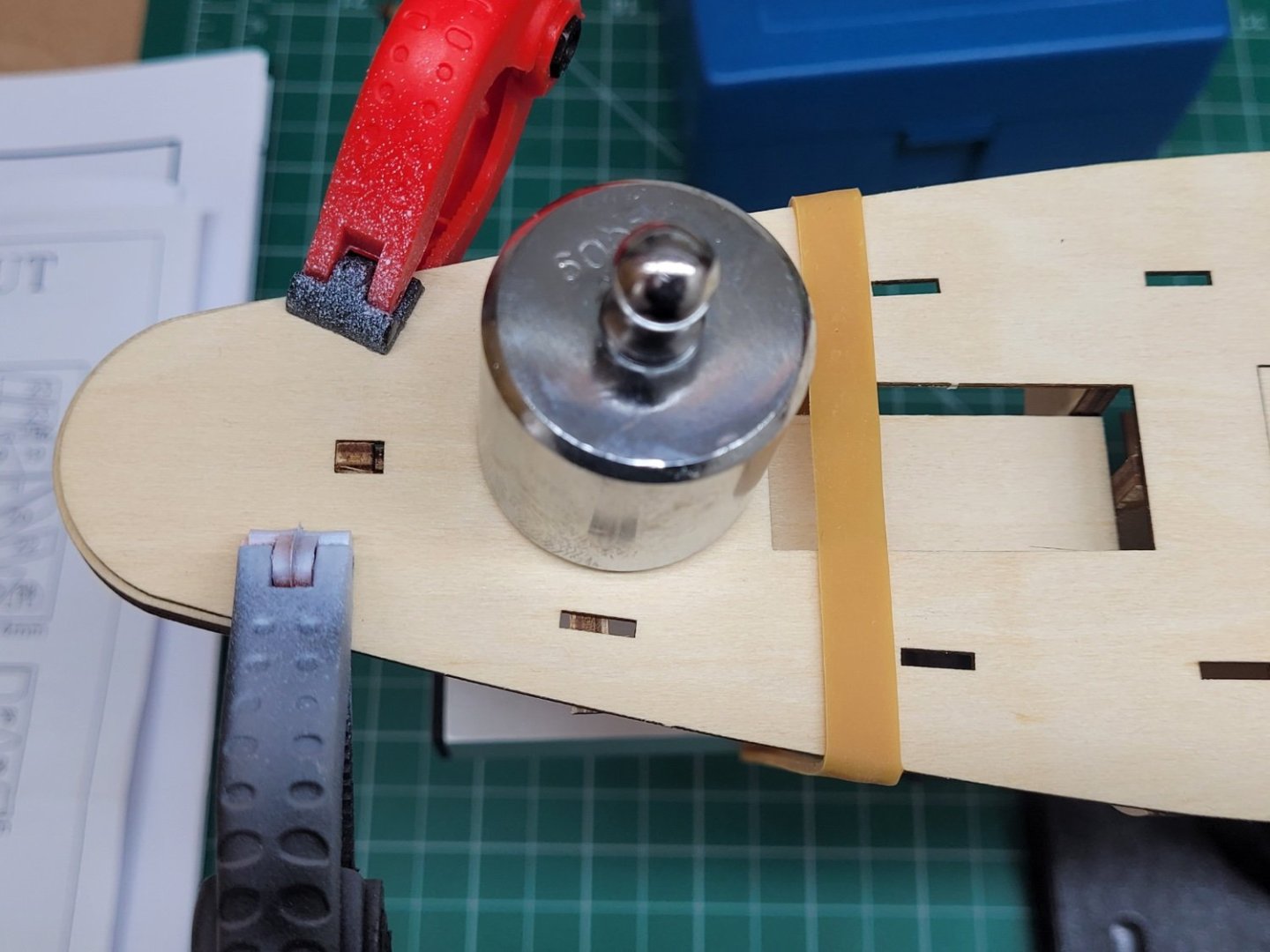

Today’s task was to fit the keel stiffeners, parts 18-28, on either side of the false keel. The written instructions merely indicate that these need to be glued either side of the keel but as @BobG pointed out in his log there is more to this than the instructions suggest. A careful look at the plans indicates that whilst the forward two pairs of stiffener pieces (18-19) and the rear four pairs of stiffener pieces (25-28) are sited flush with the bottom of the keel, the five middle pairs of stiffeners are actually located 1mm up from the base of the keel. I found a scrap of plank 1mm thick and used this as a shim to correctly gauge the positioning of these parts when gluing them into place. The next step in the instructions is to glue on the plywood deck and then frame the steerman’s hatch or cockpit. The cockpit floor and sides are planked with mahogany later in the build but it seemed to me that it would be easier to plank the floor of the cockpit now before the plywood deck was glued onto the frames. There are a variety of mahogany strips included with the kit and the instructions suggest using the 1x5mm sized strip for this. However, I was not very keen on using these as the strips in my kit are very mottled and the grain pattern is quite prominent. This strip is also later to be used for the framing of the deck hatches and I would prefer to have something different. I had previously purchased some 1x6mm mahogany strip and this is much less mottled and altogether a nicer piece of wood. However, being 6mm wide it is wider than the kit suggestion and so I decided to trim my strip down to two 3mm wide pieces. I then used this to plank the floor of the cockpit – I think the 3mm wide planks give a much better scale effect that the 5mm wide kit suggestion. After planking the cockpit floor I then gave the top of the false keel a quick run over with a sanding block just to make sure the plywood deck would sit nicely across all of the frames. I used PVA glue on the frames and false keel and set the deck in place, securing it with elastic bands and small weights to ensure a good solid fit across all of the frames. Finally, the walls of the cockpit were glued into place. All is now ready for fairing of the frames. It may be a short while before I get the fairing completed as I can really only do this outside, which means I am limited to whatever spare time I can find at the weekends to work on it, but hopefully it will be done in the next couple of weeks. In the meantime I may be able to start on some other sub assemblies or having a trial go at the best way to approach the decking.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

The pumps look great - that is a neat little enhancement !

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Well done Chris and James - another great kit!

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Artesania Latina do not number the frames and parts in the laser cut wooden sheets but instead they provide a small piece of paper with a diagram of the parts, so the first task is to number the actual parts in pencil so that things don't get mixed up when the frames are removed from the fret. The false keel and frames all seem to be nice and flat. Already the lack of detail in the written instructions is apparent as the first step guides the builder to remove frames 2 - 8 from the fret and then glue frames 2 - 13 to the false keel. Luckily the pictorial guide shows that you also have to remove frames 9 - 13 from the fret as well 😃. The frame joints were all too tight to fit to the false keel correctly right away and so some minor sanding of both the frame slots and the keel was required. The slots for frames 2, 3 and 4 also needed deepening slightly so that the tops of the frames sat flush with the top of the false keel. I then did a trial fit of the sub deck floor pieces 15, 16 and 17 and these were a good fit right away. The frames all sat nice and squarely against the false keel without any issues but I did hold them in place temporarily with some lego blocks whilst I glued them - this was done with some thin CA piped into the frame / false keel joints. At this point frame 12 and the stern under deck piece 13 have not been attached. The mast support, part 14, was then glued in place along with the sub deck floor parts 15, 16 and 17. I then tried a test fit of the plywood false deck. There are three tabs on top of the false keel that fit into slots in the deck to key it into position. However only the front and middle slots easily aligned with the tabs and I had to trim a tiny amount off the back of the rear tab for it to sit properly in the rear deck slot. With the deck sitting on the frames, held down by elastic bands, I was then able to determine the position of the rear most frame, frame 12, and the stern under deck piece 13. There is a noticeable upwards curve of the deck at the stern so setting the angle of the rear frame and deck support in this manner ensure the sweep is nice and consistent. This was clamped in place whilst the glue set.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Thank you all for for the encouragement. Your build area is a lot cleaner and tidier than mine Thukydides!

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Your build is looking great. It is a good idea to keep all the fiddly little parts like the swivels and anchors etc off until you have finished the rigging. Watch out for those pump handles too Dan!

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks for the kind words. I wasn't sure I would have the time or ability to put together an interesting log so I'm afraid I never made the decision to start one. However, given how much inspiration and information I have received from reading other logs on MSW I have just started a log today for my latest build.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

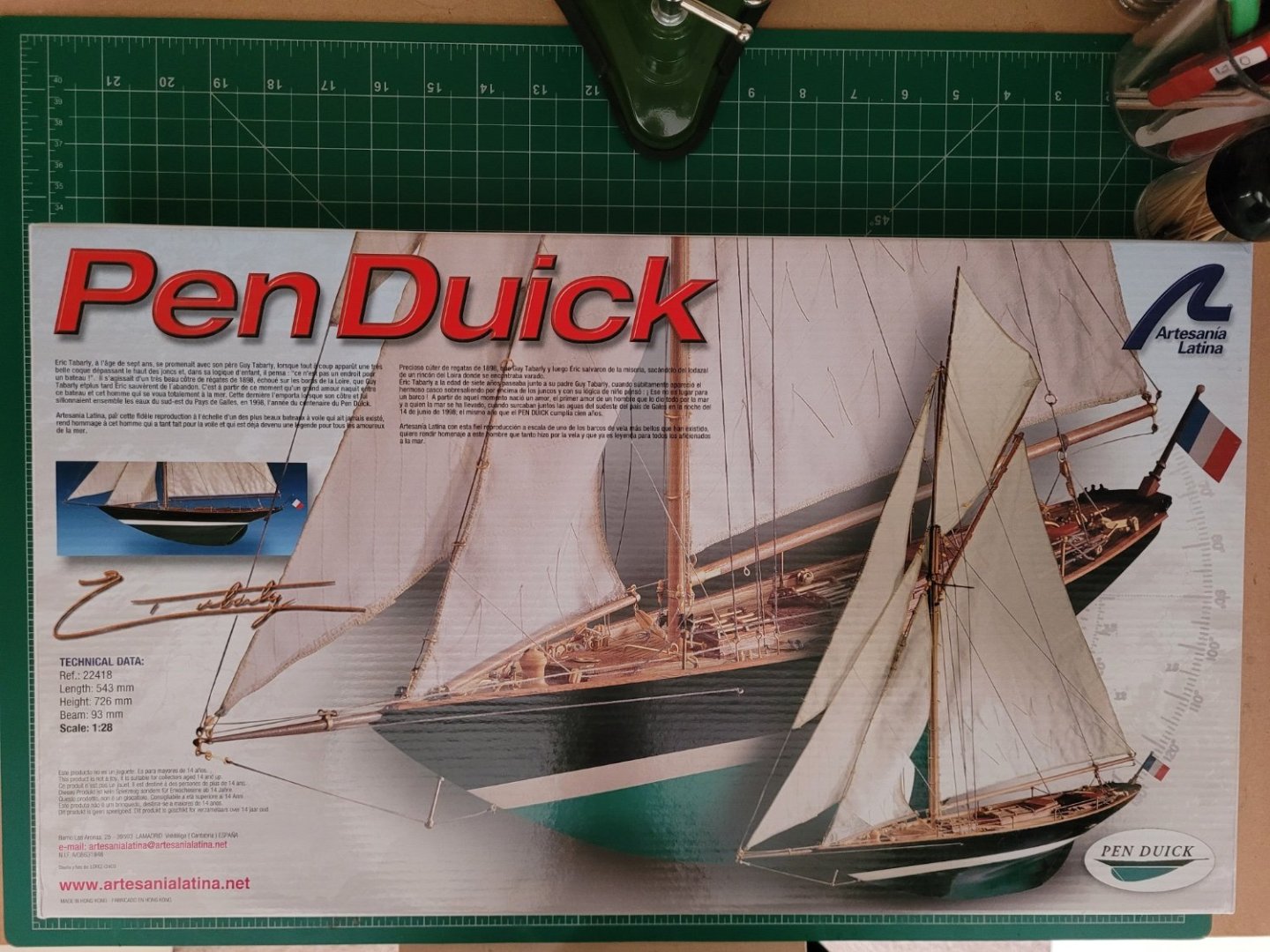

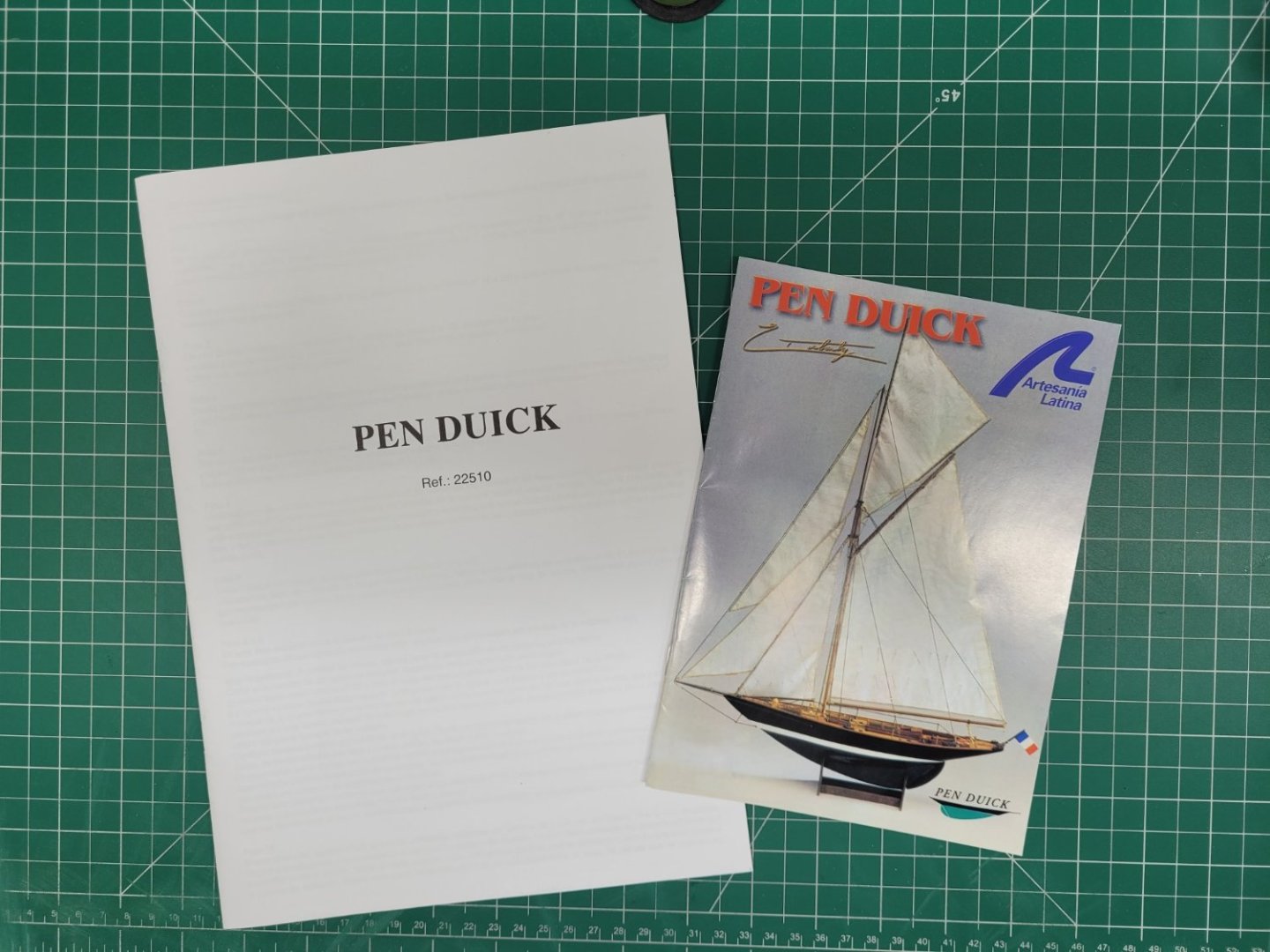

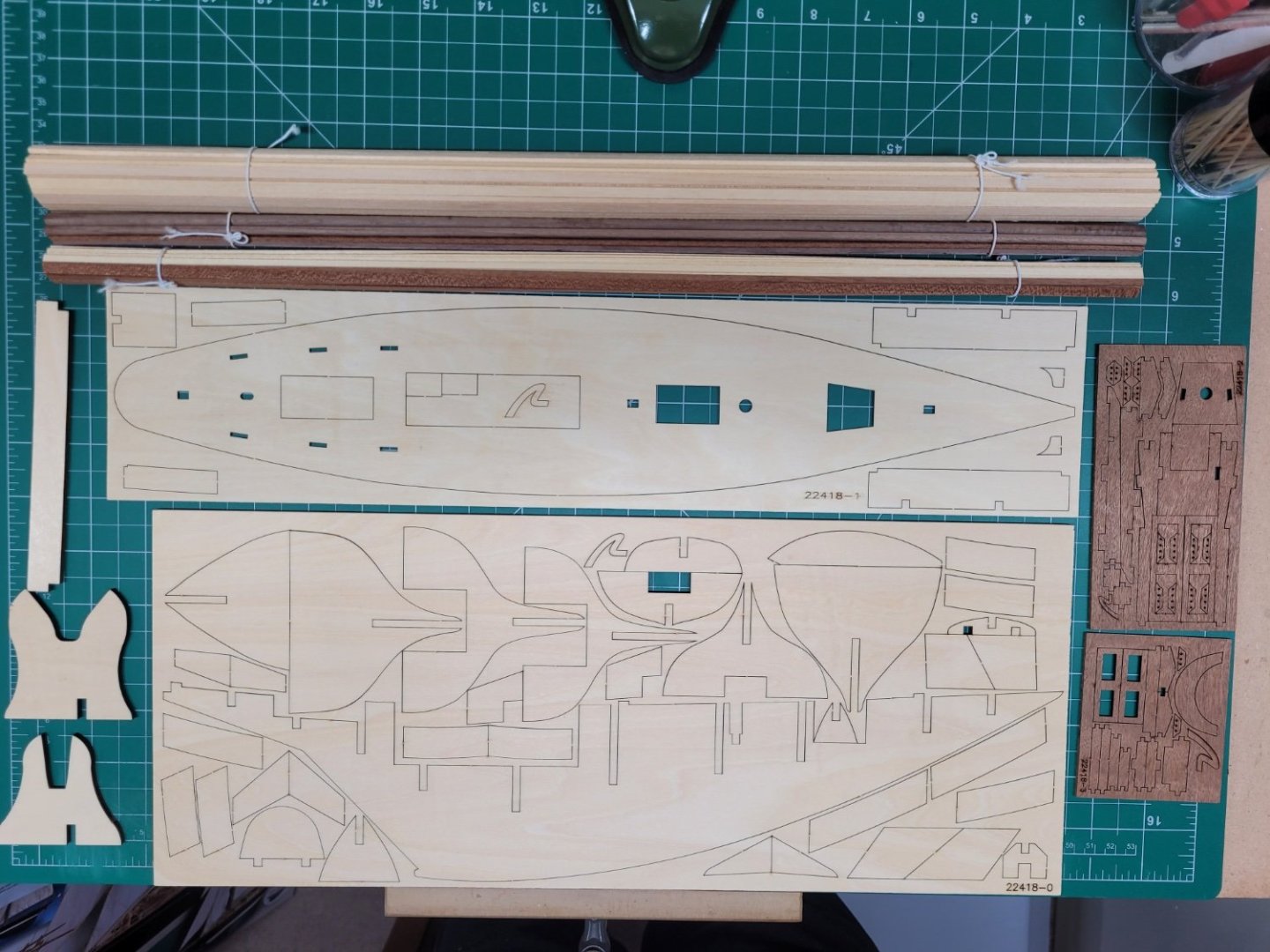

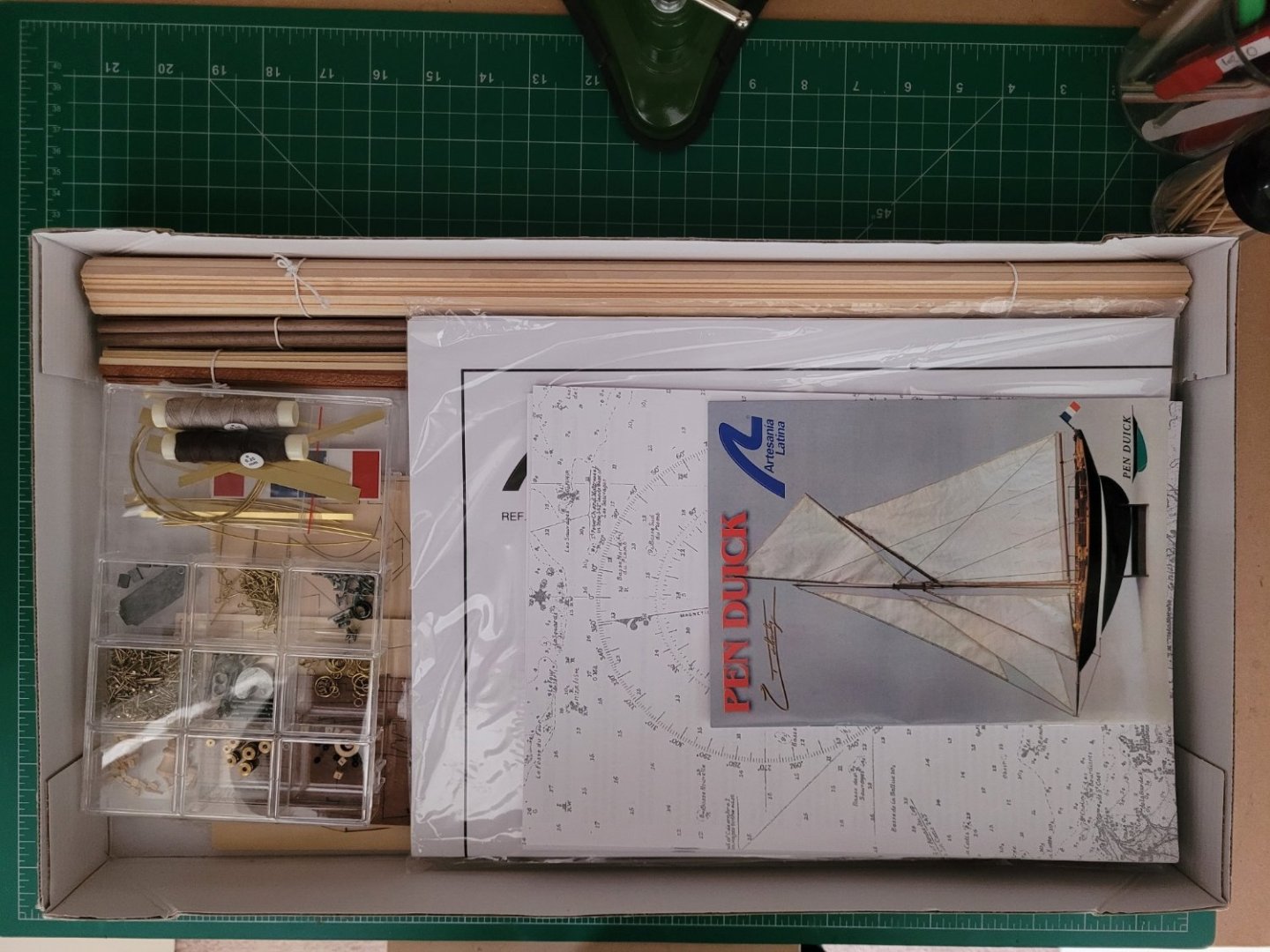

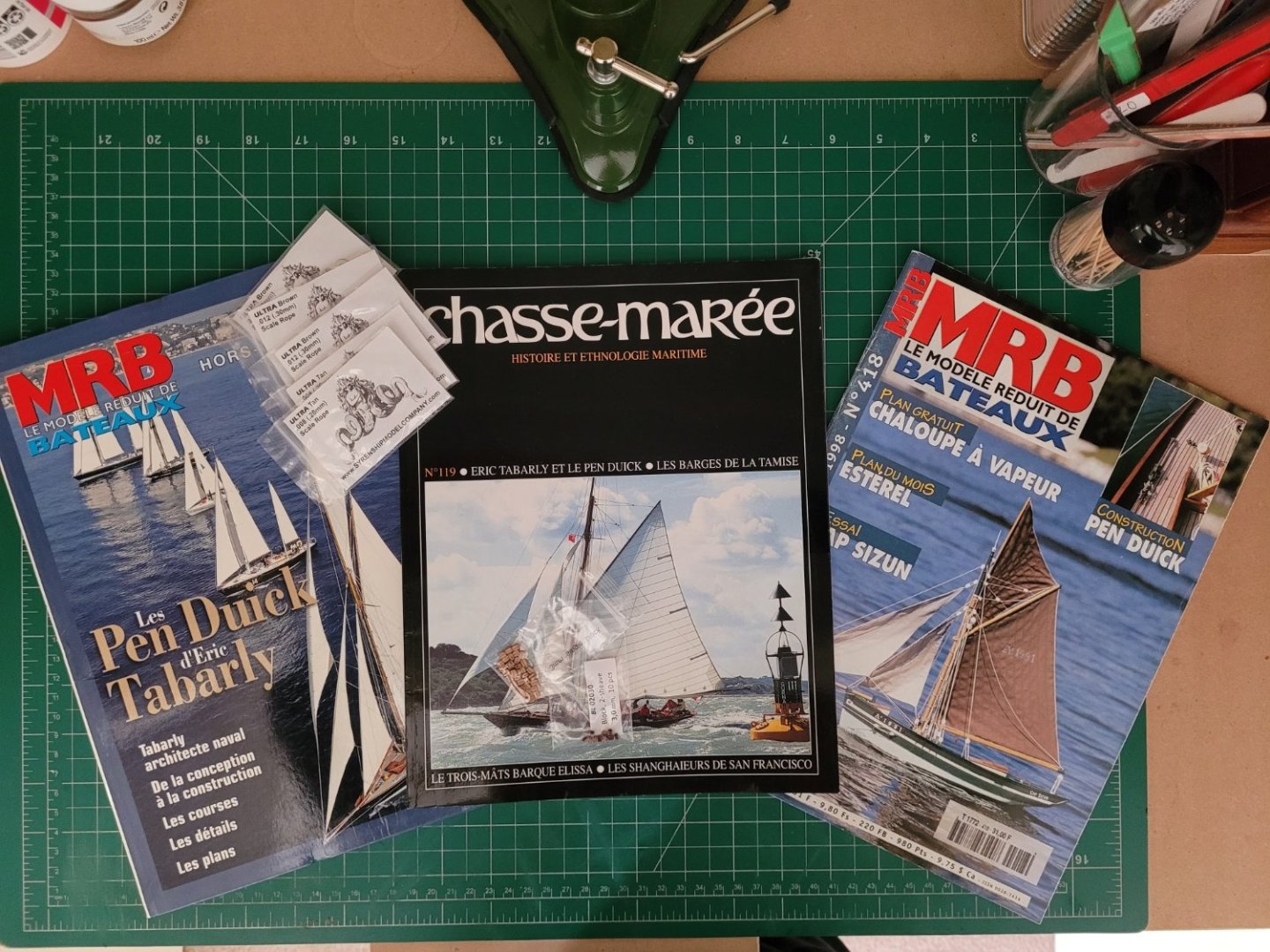

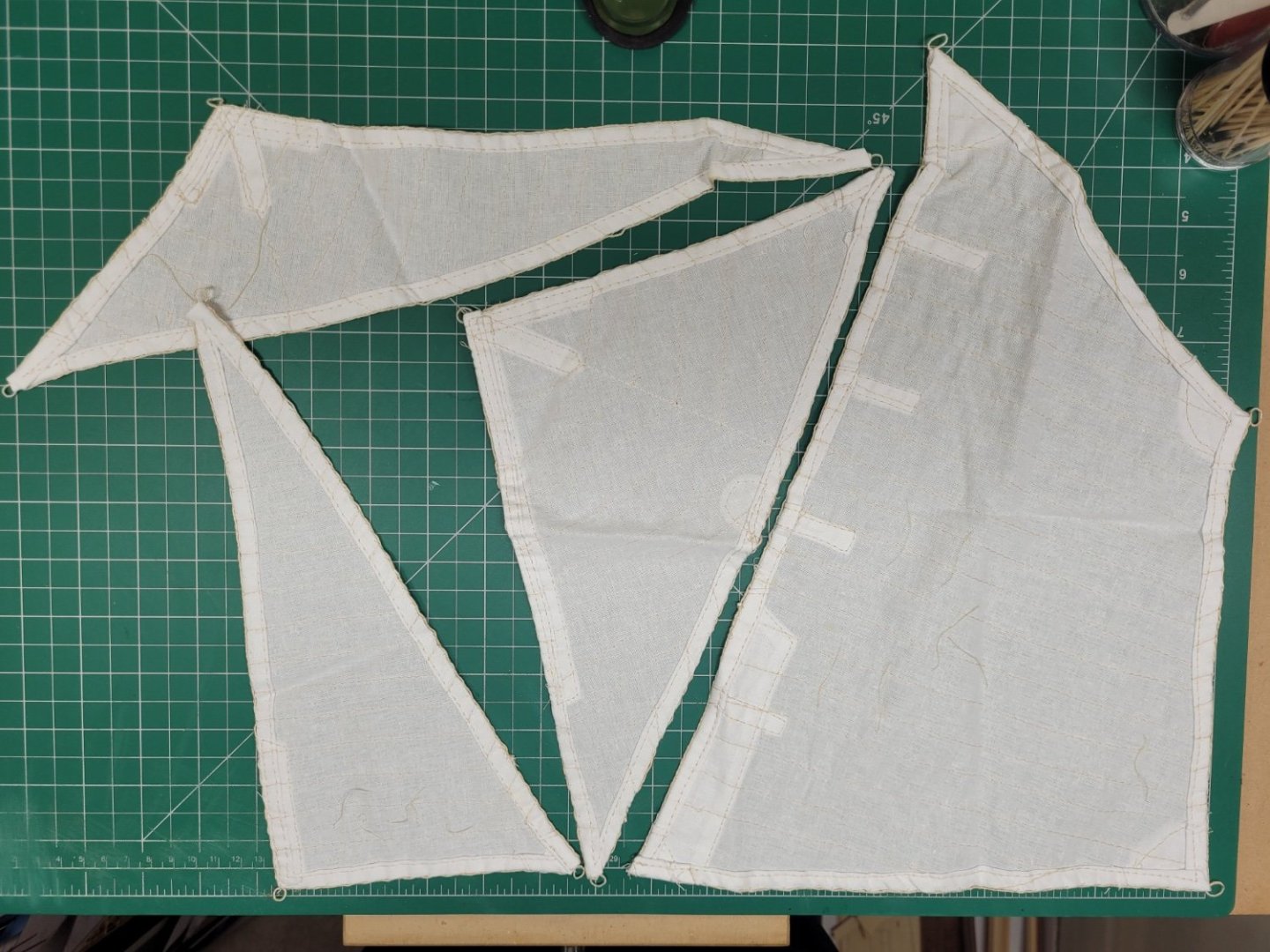

This will be my first build log on MSW so I hope I can provide something that may be interesting. As the title indicates this will be a build log of the Artesania Latina's Pen Duick. According to the article on Wikipedia, 'The YRA 36ft linear rater Pen Duick (formerly Yum) was designed by William Fife III and built in 1898 by Gridiron &B Marine Motor Works at Carrigaloe in Cork Harbour, Ireland for Cork yachtsman W.J.C. Cummins. The gaff-rigged cutter was quickly noted as a successful racer in Irish, British and French waters'. I like the fine lines and design of this historic yacht and decided to try a build of this type of vessel, and so hopefully I can do justice to this and end up with an attractive model. I have already received a lot of inspiration from the other build logs on this site and I will no doubt rely heavily on the work of @BobG, @hof00 and @Reci when progressing with this project. Here is a look at the kit. The kit comprises a plywood false keel and frames, and according to the pictorial guide a selection of basswood planking strips and some sapelli and walnut lasercut pieces and dowels. However, the parts list gives the woods as ramin, walnut and mahogany, so I'm not quite sure which to believe! (Or maybe they are just alternate names for the same thing?) There is also the usual collection of brass and other metal accessories in the familiar perspex box. The kit also comes with pre-sewn sails although a comparison of these with the plans show that they seem a little undersized. In my case they are also under represented, there are five sails needed for the rig but my kit only contains four! I am considering displaying the kit with sails which will be the first time I have tried this but that will be a long way down the track so I will see how things are going before deciding later on whether I have the skills to make my own sails. The kit comes with a leaflet of instructions in a variety of languages, a pictorial build guide and two large double sided plans. The plans detail the sail templates and a rigging plan on one sheet and a full sized profile and deck plan and mast and spar plan on the second sheet. As with many of the older Artesnaia Latina kits, the instructions are pretty basic, only one and a half pages of text for the whole build. Having come from building some of Chris Watton's fabulous Vanguard Model ships with their impressive manuals this will be something of a challenge again. I have built a previous kit from Artesania Latina though so if I was able to do that then I am sure I should be able to manage once more. I have bought a few items as upgrades to the kit offered accessories as the Artesania Latina components are not the best in the world. I have some blocks from Vanguard Models and rigging line from Syren. I also have some alternate strips available for planking as the kit provided ones are 2mm thick which may perhaps prove tricky to bend appropriately - I have some 1mm limewood planks which I may use. Thanks to the information in @BobG's log I have also been fortunate to collect a few resources to help with the build. These include a few French modelling and sailing magazines with useful articles about the Pen Duick and her history. There are also a lot of images available online which will help with the details of the deck fittings etc. Finally in this first post I thought I would also show my build area. This is in one of the spare bedrooms and is actually one half of the wardrobes - do many other modellers on this site work in a cupboard? Despite its size limitations it is actually quite convenient because when I am done for the day I can simply shut the doors and everything appears nice and tidy. It is therefore convenient sometimes to just to spend 20 minutes or so working on a particular part of the build and not have to worry about getting everything out and setting up a work area elsewhere in the house. On the downside the bedroom carpet has claimed an awful lot of small parts which find their way onto the floor! Oh, I'm also not a particularly quick builder so this may not be a log with regular updates but I will try to do my best to keep things ticking along!

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

The mizzen mast isn't included in the kit but you can make one from scratch and store it on the deck like Blue Ensign did in his build. The Alert book does give a diagram of the mizzen mast and its yard but I decided not to make them for my model just to keep it less complicated. My reasoning was if I make the mizzen and yard should I then also make spare yards for the main? And then what about the cutter and longboat and mounting them on the deck? (I am making the cutter separately to display but not on the deck). If you do want the dimensions for the mizzen and yard I can look them up for you.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks. That's a really interesting guide on how you add detail and depth with your painting.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.