SandyBay

Members-

Posts

37 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SandyBay

-

I shall sit in and watch this build if I may. It’s a model I’ve tried to buy here in the U.K. but can’t seem to find any for sale.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I bet you’re really pleased with it, I love the detail in the rigging and your sails look very realistic

- 55 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

You’re making a superb model there. It’s a pleasure to watch your progress.

- 231 replies

-

- model shipways

- armed virginia sloop

-

(and 1 more)

Tagged with:

-

I’m not sure which planks to start with now I’ve had another look. On reflection I believe I’ll follow Chucks instructions and do the top four planks first. This means I’ll need to fit the transom but I will take your advice and fix some bracing to it before I fair it. I’ve just had a look at your build of the longboat Steve and if my planking turns out as nice as yours I’ll be over the moon.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

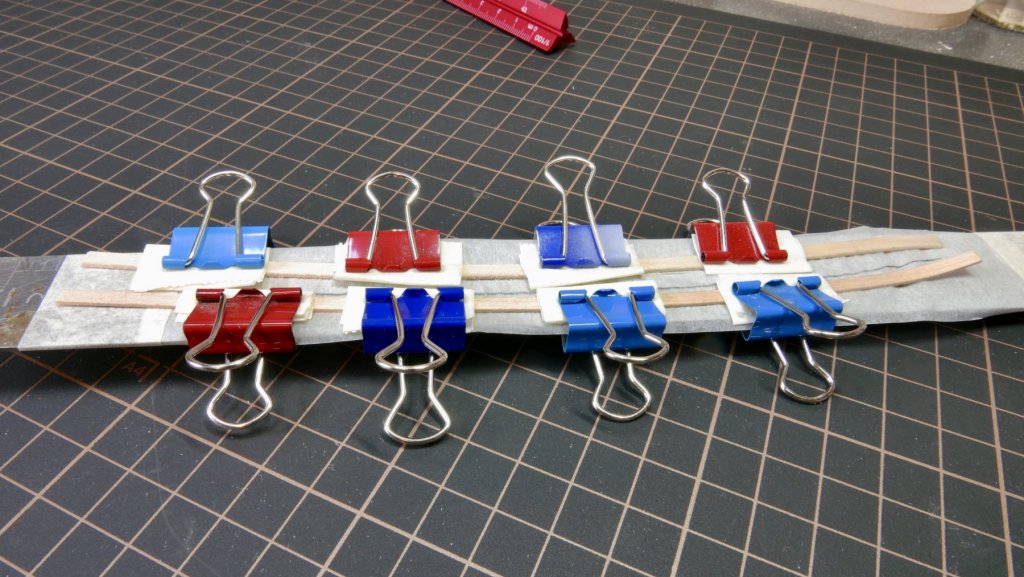

Had a play with the planks today, first job was to transfer the line of the top plank from the plans onto the model. I was a bit wary of bending the planks at first but with a bit of warm water and gentle manipulation they bent and curved easily. I did the bow bend around my glasses case and was as pleased as a dog with two tails when the plank sat perfectly around the bulkheads touching each one all the way to the stern. Then I realised that I had to do some side bending so made a tracing from the plans and clamped up the two top planks. It’s good fun this boat building lark isn’t it?

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

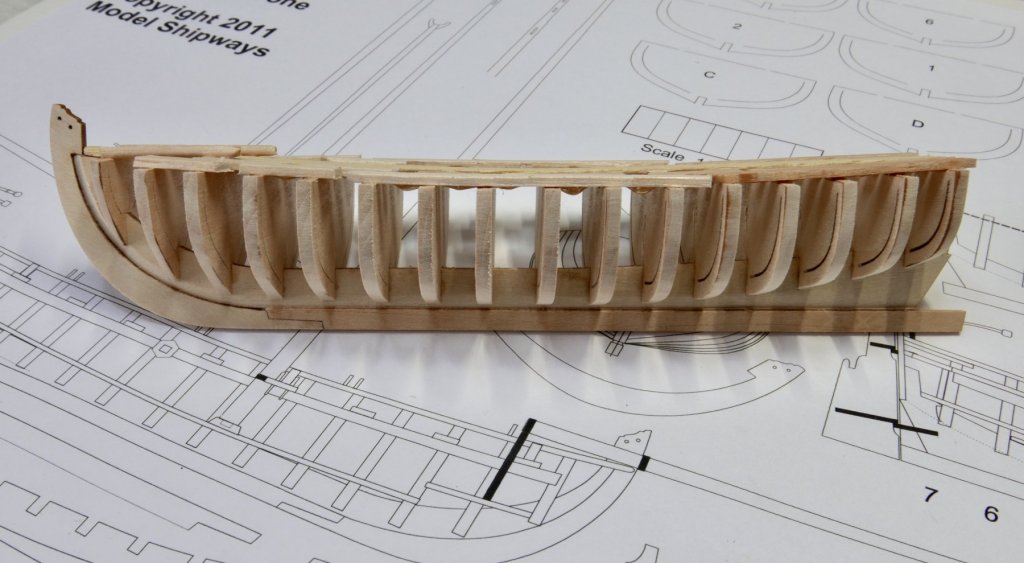

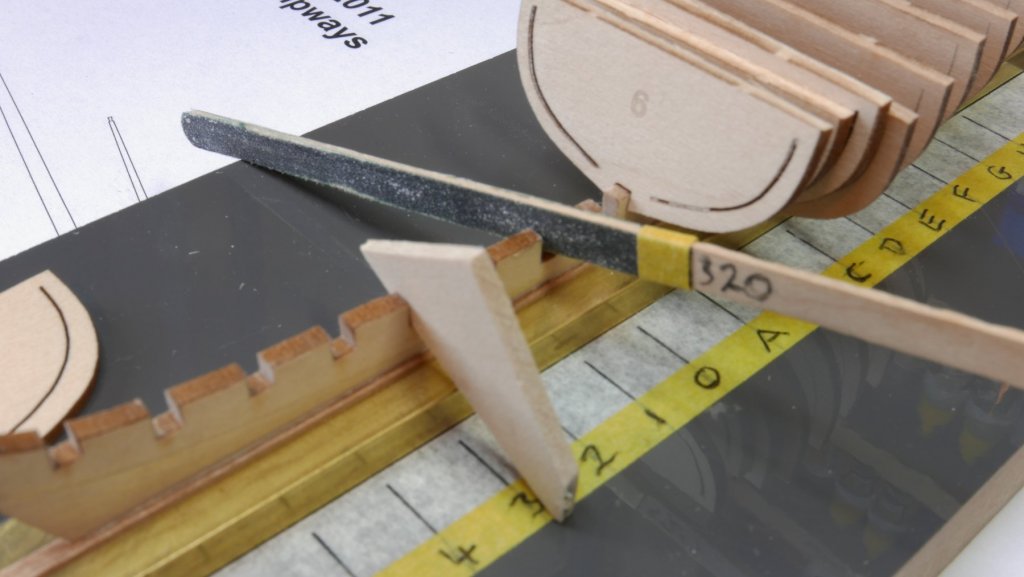

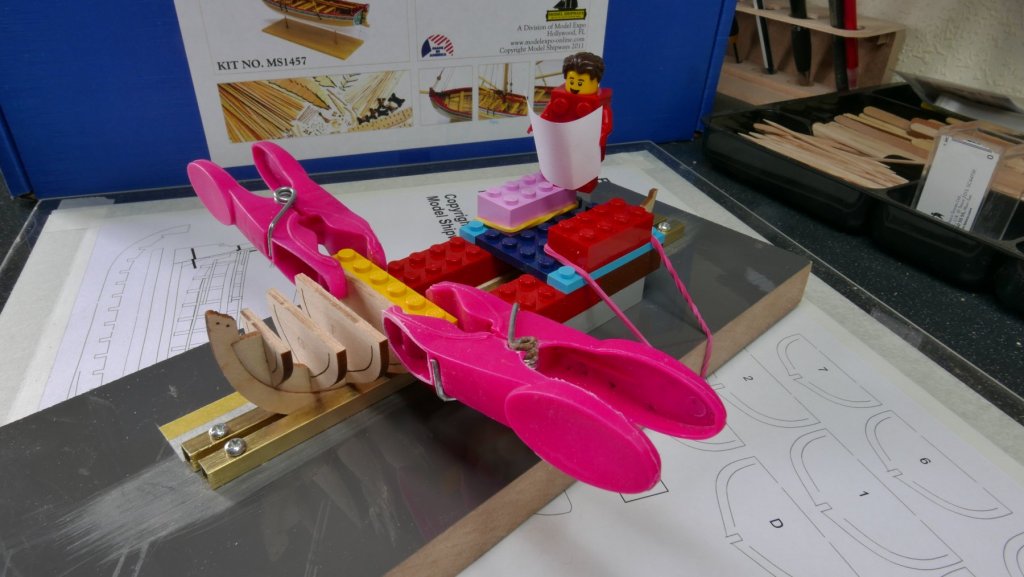

Moving on... I’ve glued all the frames / ribs / bulkheads ? onto the keel using my patented multicoloured lego “Sticking Things On Properly” machine. Then Mr McDonalds kindly donated some coffee stirrers which I used to strengthen the ribs for fairing. I used the Tesco £1 nail files to do the majority of the fairing and found it was much easier to hold and manipulate the file after I’d stuck a little wooden handle on the back. The fine side of the Albion Alloys flexible file finished the job off nicely and leaves a lovely smooth surface for glueing. I ‘think’ I’ve faired the hull properly but would appreciate a heads up if I’ve missed or messed up somewhere. The instructions would have me add the transom now but it’s so delicate that I’m inclined to leave it off, at least until I’ve fitted the garboard strakes so any tips or advice would be appreciated. I’m off to a model show in Milton Keynes tomorrow so it’ll be Monday before I can start my first ever planking job.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Those two decks are like chalk and cheese, your one is fantastic.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

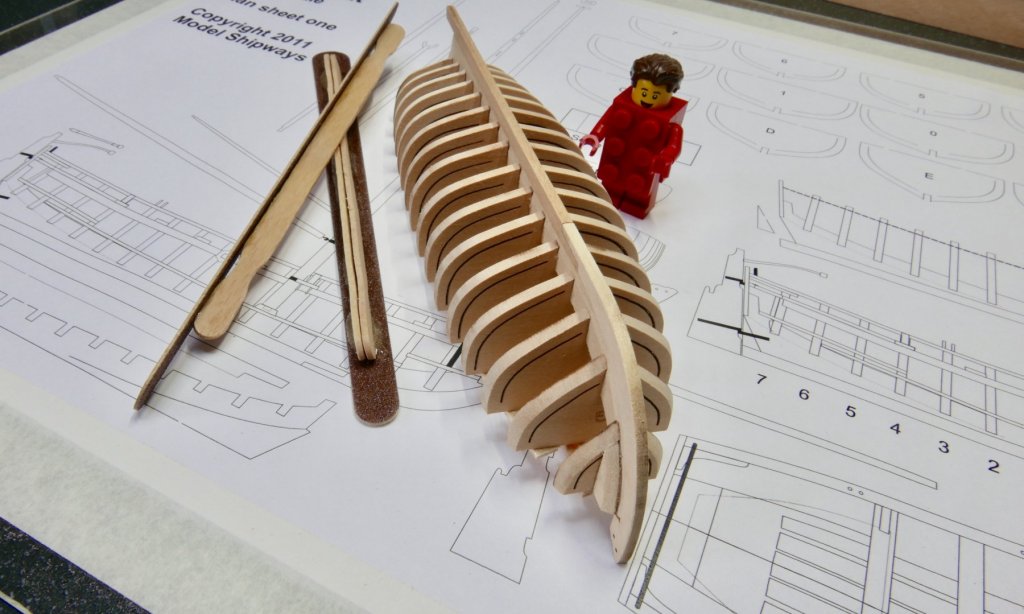

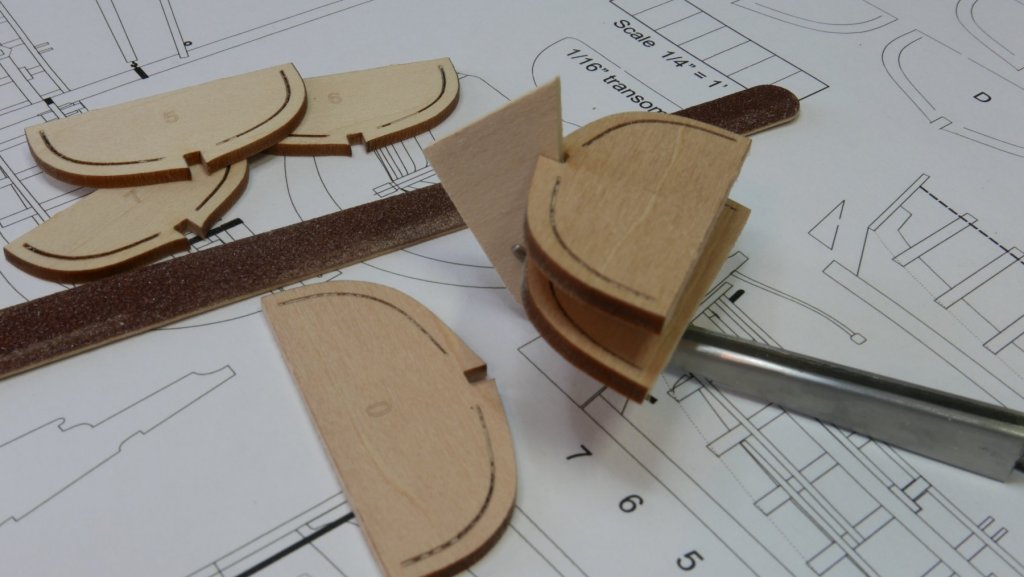

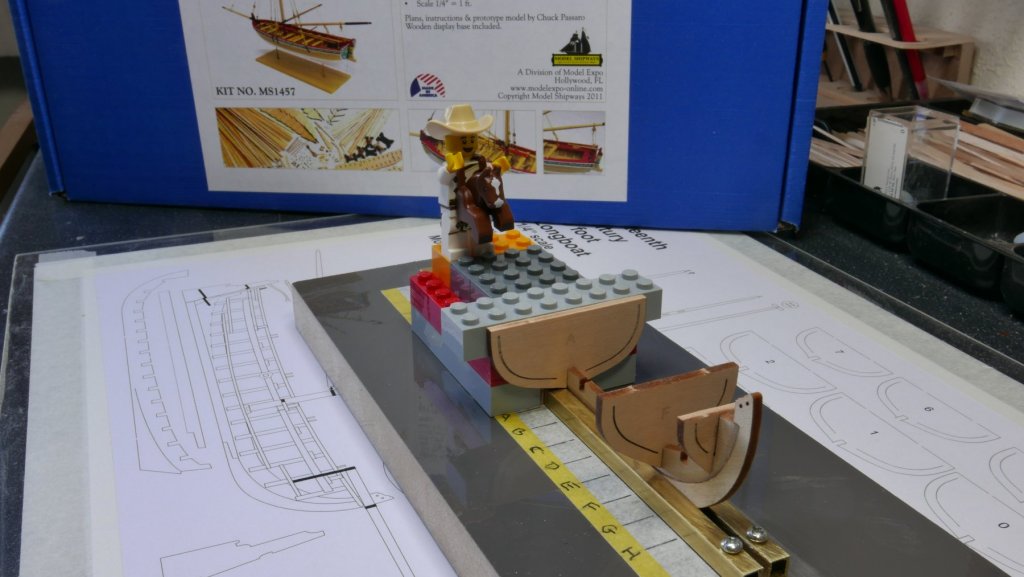

A little bit more progress today, I found that the joints between the frames and the false keel were very tight. Too tight to fit without sanding and as it’s so delicate I decided to work on each section in isolation. First sanding the frames and using a scrap piece of the same size wood as a go/no go gauge. Then working on each slot on the false keel using the same piece of scrap wood to check for the fit. once each piece was sanded it was time to start some gluing. This is a critical part of the build so I asked Lego Man himself if he’d oversee the operation and ensure that it was proceeding according to the plans.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I’ve also got a Lego helper, but he looks like a bit of a cowboy to me, which means we’ll get on well, one of my mottos is “No job is too small to bodge”.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

There are plenty of build logs on MSW for this boat so I’ll omit the traditional photographs of the kit box and it’s contents and leap straight into my plans for glueing the frames on square and true. I don’t possess any of the lovely engineers squares or 123 blocks, what I do have is lots of Lego. Each Lego block is manufactured to incredible tolerances of 0.001mm which I’m guessing will be accurate enough for my purposes. I’ve made a build board and keel clamp from square brass tube and a sliding Lego block which, hopefully, will make the gluing of the frames easy and accurate. Time will tell.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

This will be my first wooden model and also my first model ship, as an ex-RAF engineer I’ve been making plastic models of the aircraft I served on. I do have a long history of working with wood though so hopefully the engineering/woodworking/plastic modelling skills will come together to result in a wooden boat I can show off with pride.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.