-

Posts

976 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

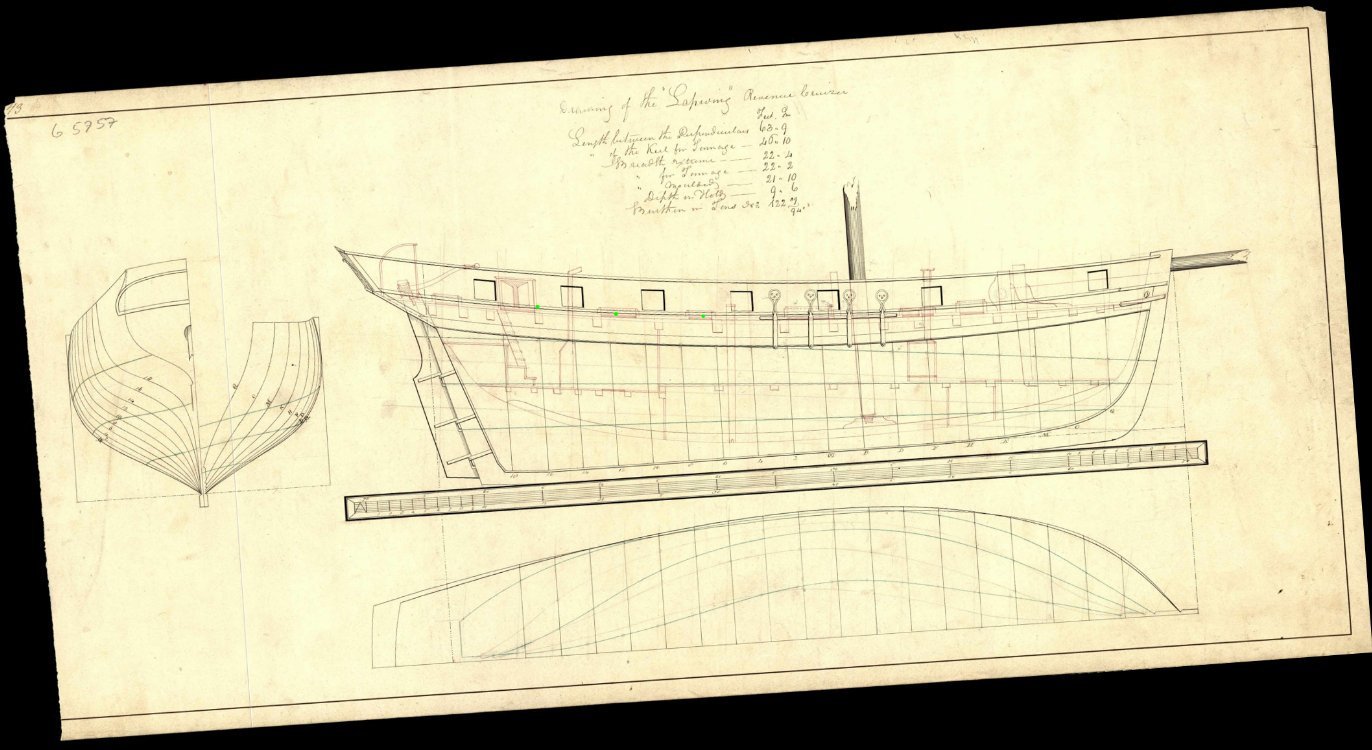

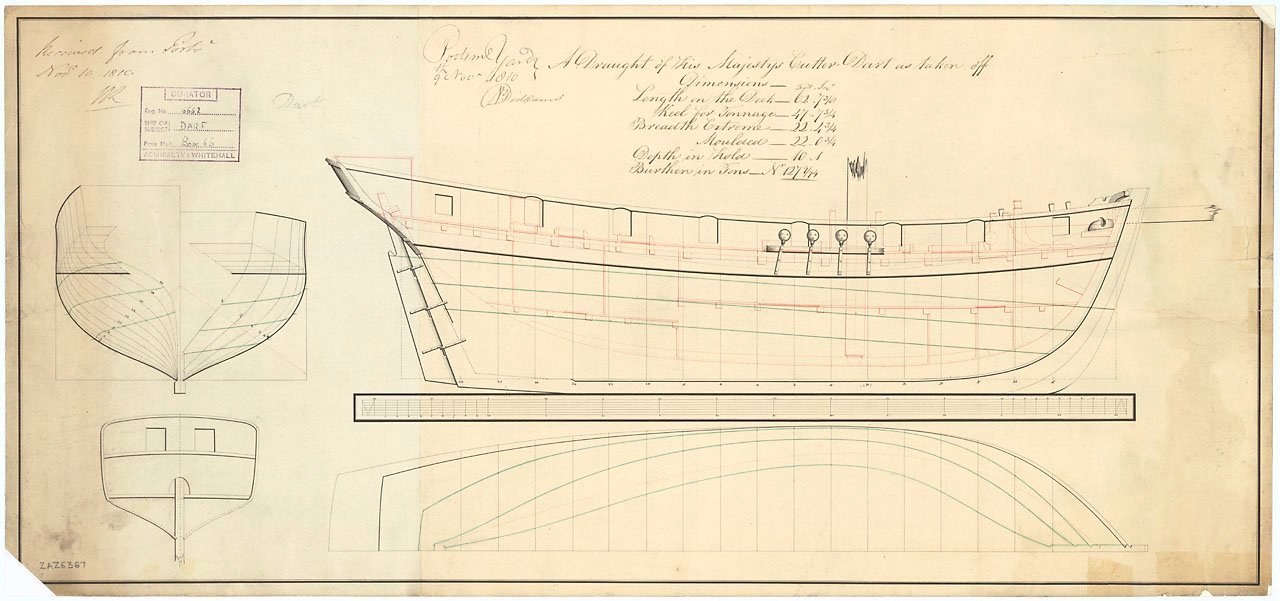

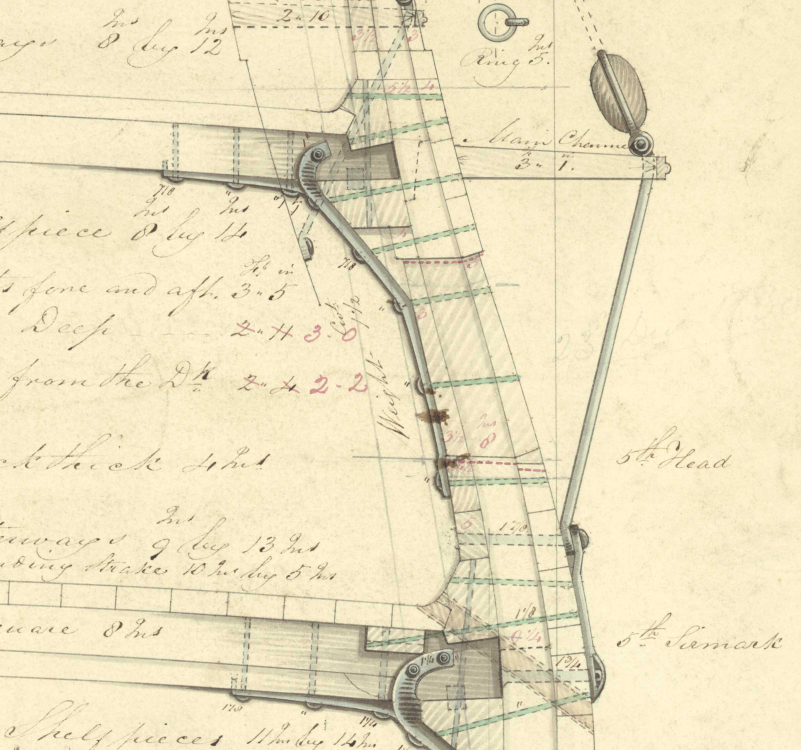

I can find only one picture showing what are probably scuppers, none of the drawings show them. However there must have been some kind of deck drainage. It is possible that the bulwark planking had a gap at deck level but Lapwing/Speedy drawings show waterways so that's ruled out, which leaves scuppers. Given the waterline, I would guess aft of the pumps possibly between the gun ports as below (tiny green dots).

-

Well, hopefully third times the charm. Yep stuffed up again, the second one's too tall. So I've deleted all my transom drawings and have started agian. Measurements taken from the plans. These are in full scale inches and model scale millimetres and the two heights above keel have been transferred to the model. The other two measurements are the height of the transom, vertically as drawn and the actual height. So the drawing must be stretched vertically by the ratio 47 1/8 divided by 44 1/8 (or 24.9/23.3). The green dashed lines below represent the as drawn, the orange as stretched. Then I have to work out the trim pieces and the rabbets. As the orange line now represents the transom inside the hull planking I need a new line 2" outside the orange line. So with the aid of the small pink circles, we get the pink line (this ignores the fact that the hull widens as it goes forwards). This also gives the hull planking rabbet on the forward side of the trim pieces (between the pink and orange lines). To get the width of the trim (6 inches) I use the big circles giving the dark green line. And the small blue circles give the aft rabbet (light blue line) for the transom planking. Oh what fun.

-

Six hours later While I wait for the glue to dry enough to sand it here's the other transom. I posted above that I had already cut the trim pieces for this version but I still had to mill the rabbets, this was a pain. First I started milling the wrong corner, just a touch before I noticed but it will have to be patched. Second the bit kept grabbing the grain. But I succeeded reasonably. I milled (saw mill not mill mill) some timber for the transoms and fitted them with 'big' rebates. The wing transom gets mounted a little high as it gets a slightly curved top. Rinse and repeat for the other three. A bit rough but they will be hidden and I've taken measurements for the drawings so future builders should do better. You can see the milled rabbets, on the forward side for the hull planking and on the aft side for the transom planking. Planked and awaiting sanding. Disaster delayed

-

Thanks Tim. To finish off this transom a strip the thickness of the planking is glued to the edge of the transom. When both sides are done a second MDF transom the same size as the first will be glued inside the first creating a step (or rabbet) so that the plank ends will but against the trim as in this mock-up.

-

First, a couple of shots that I left out the other day. The rabbet. And tapering the spine, from zero at the bearding line to just under the thickness of the planking at the rabbets (keel and stern post). Yesterday my band saw died (it was only an Aldi cheapie). Luckily I had planned for that and had a spare (same but cheaper, bought on sale) but I still had a lot of setting up to do. The build restarted with the transom/s. I will be building two, as built and easier. Easier first: 1st I cut out 2 3mm MDF transoms. Like the one on the right, the other bits covered by paper are the trims for both methods. Next I made a 'raft' from 6.6mm x 1mm Huon Pine. Glued (rubber cement) on the template and cut it out. Glued the 'raft' and some trim I made earlier to one MDF transom. Cleaned it up a bit (look at that grain, perfect size). Ant took a gratuitous photo of the model. It's not finished yet, more to come. I've also done more work on the drawings, coming soon.

-

Just one of those learning things. With photos of curved surfaces it isn't easy to tell so it was just a caution. basically, the sill is the same distance above and parallel to the deck, the head is the same and the jams (sides) are perpendicular to the keel. This does often give trapezoidal ports. Do some tests and on the model, start lighter. You can darken it with another coat if needed.

-

Well, it's been a long road getting here but I've laid the keel so to speak. My Great Grandfather sailed as crew to Adelaide Australia aboard Lapwing in 1850, hence the interest. I've been attempting to create drawings of her for some time https://modelshipworld.com/topic/23486-lapwing-1816-revenue-cutter/ and have reached the point where cutting wood helps me with the drawings and vice versa. So it's time for this log. I will attach a PDF of the drawings here and replace the attachment with newer versions as I go along. Lapwing Drawings V1.0.pdf Drawings, Version 1.0 incomplete but should make a hull minus the stern and counter. Please let me know of any issues. First issue, moulds 2 and 4 have the labels swapped, 2 should be 4 and 4 should be 2. Second issue, transom needs to be reworked Meanwhile: In the title I said 'PoB (mostly)', eventually there will probably be a PoF version and sometimes I will try that out in this build. I will also try a more simplified when I do something more complicated than needed for PoB. Such as the keel. I certainly overcomplicated the keel for this build, several pieces scarphed together, milled rabbet and a keelson that gets mostly cut away. There are easier ways, delete the keelson and add it to the spine (the drawings now show this) or cut the rabbet out from the keel completely and add it to the spine. Both of these methods require some bevelling on the spine. I will add drawings later. I could have sworn I took more photos of the keel construction but......... Cutting wood: Note: The 'False Keel' is now referred to as the Spine. And test fitting. End of first instalment. Thanks for visiting.

-

Lapwing 1816 Revenue Cutter

iMustBeCrazy replied to iMustBeCrazy's topic in CAD and 3D Modelling/Drafting Plans with Software

-

Lapwing 1816 Revenue Cutter

iMustBeCrazy replied to iMustBeCrazy's topic in CAD and 3D Modelling/Drafting Plans with Software

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.