-

Posts

7,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Bob, perhaps you may like these wonderful detailed ship`s boats. As you are building in 1:96 scale there are for instance lapstrake double ender boats and more..... At least a nice sample fore a selfmade one... http://www.model-dockyard.com/acatalog/1_96_Scale.html Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Mirabell61 replied to rafine's topic in - Build logs for subjects built 1801 - 1850

very nice looking rigging Bob, Nils- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

very nice "White Ensign" Peter, I remember, you already had some practice with your nice "Pegasus`s" selfmade ensign Nils

- 293 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

Many thanks for your compliment Rob, and also for dropping in again......, as there is no proven build plan available, many of these metal parts are created so, as to fit and suit the idea I have in mind and the scale, and very often there was a last change / improvement shortly before the part is made. The foremost part of the promenade deck for example shall get an extrance integrated into the railing which leads over an access- gangway to the forecastle railing. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks very much Greg, much appreciated, your tip with Paracetamol is good, its already in use in our household Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Frigate Boston by overdale - FINISHED

Mirabell61 replied to overdale's topic in - Build logs for subjects built 1751 - 1800

wonderful built model Dan, a delight to see this beautiful build... Nils -

thanks David and Bob, also for the good wishes..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks for looking at,... and liking the recent pics Grant, Nigel, Carl, Sal, Ed, Gerhard, Peter and Martin, also for your good good wishes (health), greatly appreciated... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks so much to my fellow builders for your much appreciated and kind compliments .........Jason, Pete, Bob (Rafine), Kees, Piet, Greg, Grant, and all the "likes" for looking in... I may have to "step a little slower" in the next days and weeks, because my doc diagnostified suspect on cervical disc herniation, currently causing me much pain in neck shoulder and arm, right down to the hand. I have an appointment for MRT examination and will the know more then, meantime wil be having therapeutical massages, and swallowing much "Aspirines" Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Ed, thanks for looking in and for your nice compliment. I was stuck a bit in the winch fabrication, lifeboats and vents, and sorting out the related design, so there is not much progress on the basic model, but following your wish, I`m happy to show the present state (pics taken this afternoon ) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thanks for your input Denis, I have looked up all my books of the great liners, especially trying in vain to find somewhere a photo of the boats deck showing that sort of winch, and possibly showing also how the davit`s lines (if used for lowering boats) were rigged to the winch Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

wonderful work Druxey, for the cabin I`m with Michael, curious already... Nils

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

wish you ongoing pleasure and fun with this project Bob, one sure can see that you`re enjoying this fine build.... Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

I find the topsail size looks just right Peter, the whole outfit of sails together with the rigging looks great.... Nils

- 293 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

a super fleet Patrick, so much to study from all angles and distances... Nils

- 1,083 replies

-

good looking rigging of the rudder-tiller Steve, to lead the steering chain over blocks in order to halften the chain pull forces is a good idea Nils

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

very nice looking pilot house Bob, even the drainpipes are put on,.... lovely Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Thanks very much Zeh, for your input on this, and for looking in, a good analysis of yours, yes it makes sense, that the machine is a kind of "multi purpose winch", in combination with appropriate rollers, blocks, etc, for leading the lines into the required directions. Unfortunately impossible to get a detailed plan of the eyebolts Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thank you for your thoughts, suggestions, etc... Gerhard, Mark, Piet and Greg Gerhard, mark is right, those half rounds are vents in bird`s view Mark, to date I also have no theory what those narrow winches are for. The wind drums are orientated to pull in longside deck direction Piet, at the end of the port / Stb lifeboat rows there is on each side a stack of three collapsable lifeboats (stapled). Thought that perhaps these boats would have been pulled / slid over the boatsdeck by means of a winch, into a position where there was just an empty place under the davits, that had already lowered their actual boat. But there are too many deck components and vents in the way, so that would`nt work either Greg, not a bad idea Greg, but around 1900 I do`nt think that the shipowners had the wellfare of "disabled" in their mind yet. Also as Mark mentioned there are no booms, no pulleys, etc. installed Perhaps some day by coinsidence someone may come across the solution to that question... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

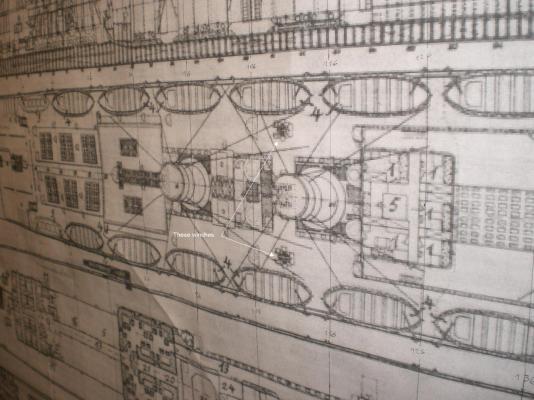

Many thanks Gerhard and Steve,... Gerhard, unfortunately I have no other pics of these other winches on the boats deck, I`m adding an outcut of the appropriate boatsdeck`s length, but also there is no hint for the possible ussage.... Steve, I also thought of that explaination Steve, but in an emergency case there would have to be several boats swung out and and lowered simultaneously and each single boat having fore and aft line, and what in case of lack of steam (explosion in Boiler rooms or so) Nils click on to enlarge !

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update the winches are coming together quite well. Have meantime made out another two slightly different (narrower) looking winches on the boats deck, of which I unfortunately do`nt know the function....and there are only two of them on the entire boatsdeck The status of the 6 cargo winches.... Nils this pic is borrowed from the St. Petersberger "Qvartett KWdG" Perhaps they have some relation in order to hoist the lifeboat lines or so..... Does anybody know ?

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Mirabell61 replied to rafine's topic in - Build logs for subjects built 1801 - 1850

good looking standing rigging Bob , Nils- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks very much Denis, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.