-

Posts

7,422 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Welcome to the build Jason, glad to have you on board, and many thanks for looking in and catching up. Little Caspar is doing so well, one can see the improvement and also the growth from week to week (yesterday 10 weeks, since birth). He is still "leaking" a bit, but also that will be soon overcome... Nils

-

Getting further on with the ribs... shaping, saw-cutting, a bit fairing to fit, glueing, I get about 4 per day placed. The lead weight I still had, it was orignaly intended as an internal weight block for a schooner some years ago. Nils

-

Excellent build Christian, you`ve done a fantastic job, shes a beauty !! Nils

- 550 replies

-

- confederacy

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you very much Geert, the overstanding rib ends will be trimmed to the sheer-edge line later on, when the deckbeams and cabin interior are fitted.... Nils

-

Hi freinds, many thanks for the "likes".... further on with the ribs of the front section, on the stb. side I will need to add half a plank to get the hight acc. to the port side planking Nils

-

Antony, great work, I`m enjoying your build, the idea for building a half-model is realy special to look at... Nils

-

Thank you Martin, I`ve been working on the front bulkhead its seperating the cabin area from the compartment ( as a locker for anchor chain, ropes and other things that need to be stowed out of the way ) Nils

-

Hi Gary, many thanks your words are much appreciated. The use of the contour gauge was the recomendation by a fellow member and I would`nt want to mis it anymore Nils

-

Thats a beautiful steam launch Ian... and a very nice Billngs kit Nils

- 27 replies

-

- renown

- billing boats

-

(and 1 more)

Tagged with:

-

An improvement for taking off inner lapstrake contours of the hullplanking...... Yesterday had a vist by a freind and fellow MSW member, we meet now and then to exchange thoughts on our builds and general building techniqes... Many thanks to Siggi52 and appreciations, for introducing his contour gauge that he lent to me, to try it out, and that will make the production of the interior hull ribs with improved contour quality, vs. my humble methode shown here earlier I tried it out today and am very pleased with the results. It also saves time. Nils

-

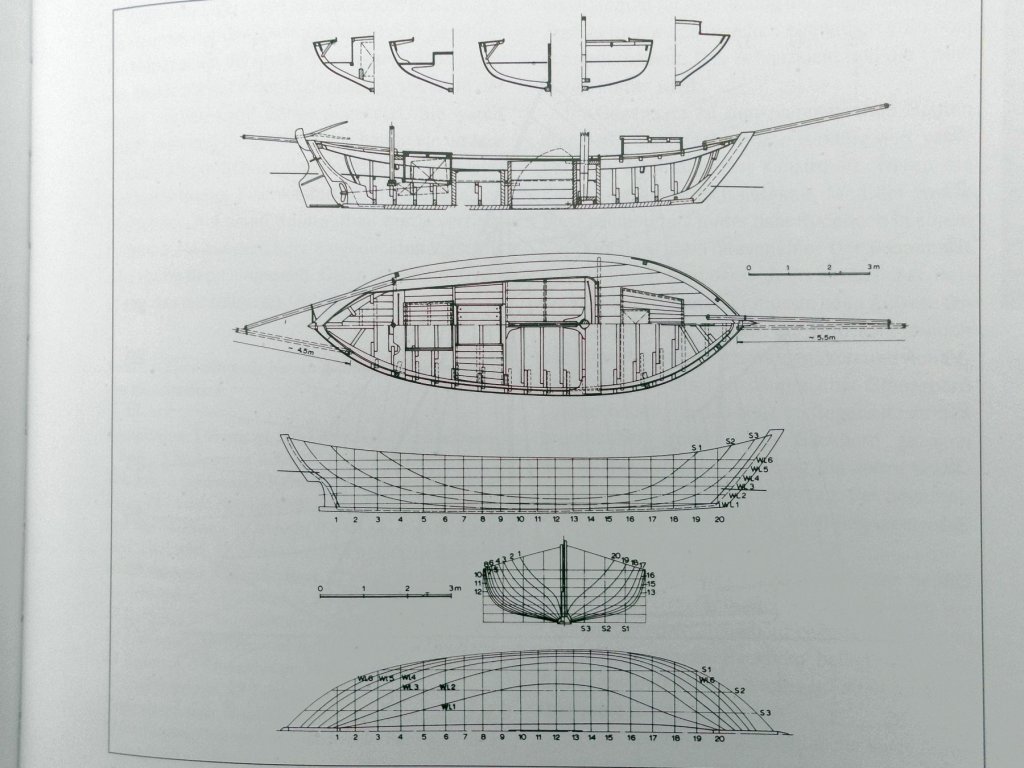

Hi Bruce, I intend to install the things that were necessary for this type of working boat in general, such as : Cockpit planked floors, well-box for live fish, motor well, both access form above. Diesel tuck-tuck motor (Dummy) 1-2 cylinders, gear clutch, reverse gear, with large flywheel, machine exhaust Cabin with 2 berths, locker, ladder, cast iron oven with exhaust over cabin roof, fresh air vent, perhaps a small foldable table. As it is a workboat, it will mainly be held in varnished wood The motor pics I borowed from the web. I intend to to work some outcuts into the main cockpit floor to enable view to the stone Ballast beneath, and perhaps into deck /cabin to view underneath /resp inside cabin Unfortunately I have no other finish details or plans (pics) available at this time, other than the enclosed.... Nils

-

Many thanks Geert and Bruce, Geert, it realy seems to work... , there will be a sectional bulkhead in combination with the two first half-frames I`m working on this monent. Behind it the main mast will be situated, and in front of that bulkhead the cabin fits in, with entry from above Bruce, I`m pleased that you are enjoying the build. The little one is so sweet, he`s laying at my feet at the desk in my hobby room, although he still "leaks", sometimes also on the carpet, if we`re not fast enough to recognise what he has in mind. Nils

-

Next sequence is doing the framing ribs.... need to make some well fitting templates fist, that adopt to the inner lapstrake contour Nils flexible ruler is of great help fot this job A flexible ruler to take off the rough shape for transfering it to card card for taking off the clinker stagered strake outcuts doing it in a bit of 4mm thick scrap wood provides the template for the final ribs I must admit, its a bit tricky job.....

-

hello Tim, I liked your introduction, wish you a pleasant stay with MSW, and look forward to your first buildlog here... Nils

-

Thanks for your welcoming words B.E. we`re just back in from a walk in the park not far from the house... Caspar and Nils

-

Thank you Geert, yes, he`s a real clever little chap, but it takes much attension at this stage of age to help in learning and during discovering new impressions daily... Nils

-

Hi Peta, excellent work ! its a real beauty, and the progress is lovely to follow, what a nice pricise planking !... Nils

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

New family member, after our Ronny (Foxterrier) passed away 7 months ago, due to a stroke from which he unfortunately could`nt recover, we did`nt want to have a new dog again. To make it short, the decision did not last long, we missed the house being without any four legged pal...... Here now is our new two months old darling "Caspar", (rough haired Dachshund), puppy pet, since last Saturday, and picked up in southern Germay. There is much life and joy in the house again Nils

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.508ad85b69dc12b89325bdc8457c936f.jpg)