Rick310

NRG Member-

Posts

833 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick310

-

This is an excellent build!! Well done!! Rick

- 155 replies

-

- Mikasa

- Merit International

-

(and 1 more)

Tagged with:

-

That sounds like a good technique, less chance of something breaking as has happened to me when I soldered the deadeyes strap to the chain plate. Rick

- 200 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Next time you go to MDI, let me know and stop in! We are in. We are across the river ( East Belfast), 1/2 miles off of Rt 1 on the river. Rick

-

Really think you should add the lower channels as this is historically correct, even if it means remaking the chain plates. If you don’t, I think you will always regret not adding them when you had the chance. Beautiful model!! Rick

- 200 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Looking great!! Happy New Year also!!

- 60 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks George! Really appreciate your input! There is a lot of trial and error that goes into the metal work. I still refer back to your FF as a lot of questions and decisions come up. Now if I could only limit the self inflicted wounds!! Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Rick!! loved your build also! As an Endodontist, there were plenty of molar root canals I wished I’d never had started!! Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

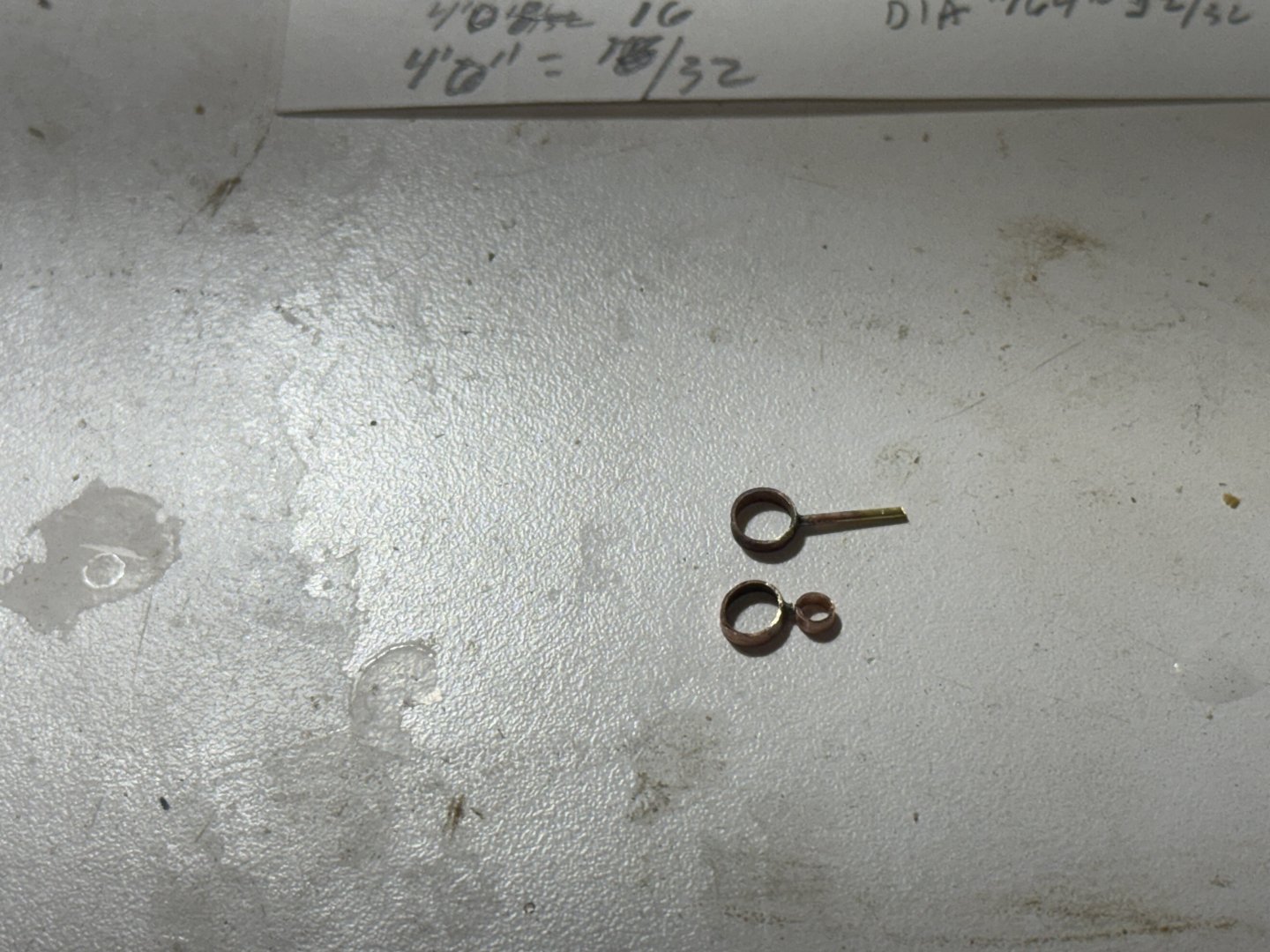

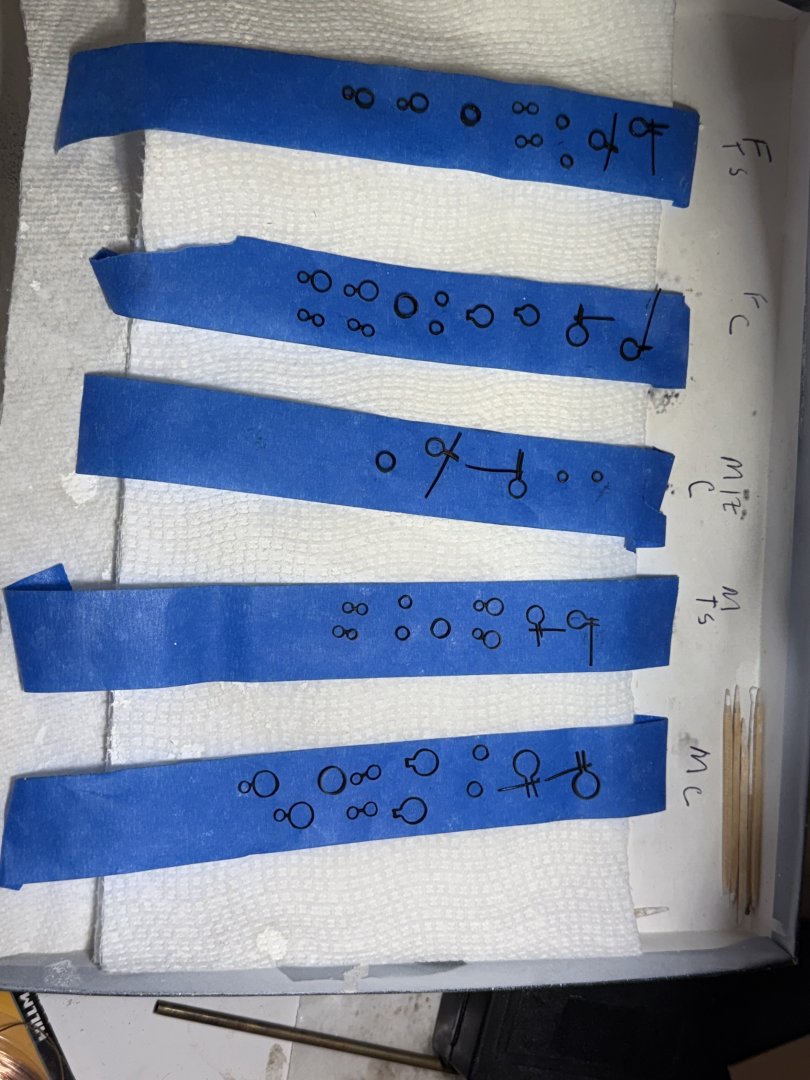

Well, it’s been 3 months since my last post. In that time I made the 5 lower yards, main and fore topsail yards, fore, main and mizzen course yards. Actually made 6 as I broke the yard arm on the fore topsail yard trying to push one of the bands on and had to remake it. Good news is it’s better than the first one. I also made the stunsl booms prior to making the stunsl irons. There were a lot of iron work on each yard. These were made from copper tube and sheet. Each had to be individually fitted to the yard. All the iron work was blackened. Yards were painted flat black, bands pushed on,sheaves rivited in and the yards rivited to the parrels. Blocks are strapped with 26 ga copper wire as were the stirrups. Foot ropes are .012 black ( dark brown) rope from Syren as are the blocks. Currently in the process of attaching the blocks with their rigging to the yards.

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Merry Christmas Johann! This is a fascinating build, especially the question of the bowlines. I am currently trying to figure out how they were done on an American clipper ship when the sails were sent down. Also where did the bowlines on the main and mizzen run to? The fore mast is pretty obvious, Rick

-

Rick what a great job!! Everything about this build is first rate!! Well done!! Rick

- 167 replies

-

- Picket Boat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Micheal, just sent you my email address. I think it would be worthwhile to post the thread for others interested in building this model. Rick

- 38 replies

-

- Pillsbury

- Clemson-class

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.