-

Posts

53 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Brooklyn

-

Interests

boat building, sailing, woodworking, working small craft, art

Recent Profile Visitors

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

aechmea reacted to a post in a topic:

Chesapeake Sharpie 20' Class by Jim Cricket - 1:8 - from H.I. Chapelle

-

Lots of nice comments, thank you all! It's a fight for time on the bench these days. Jim

- 44 replies

-

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

-

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

-

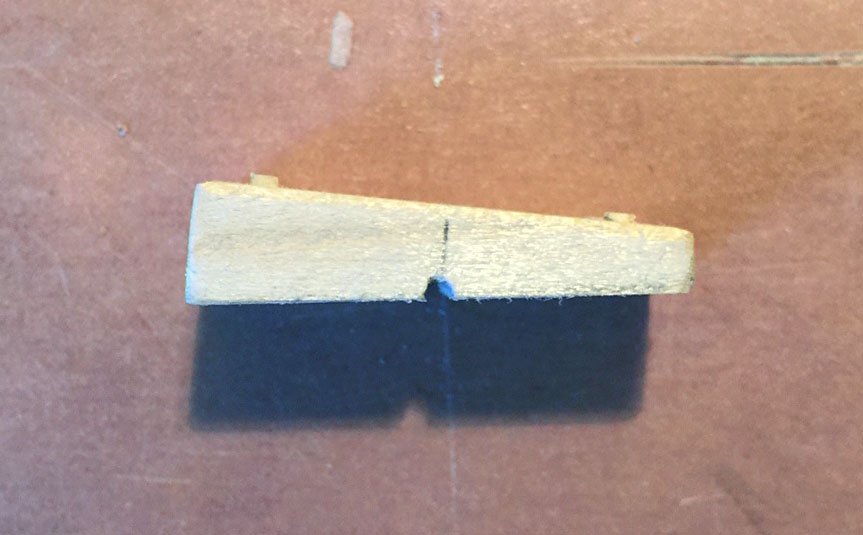

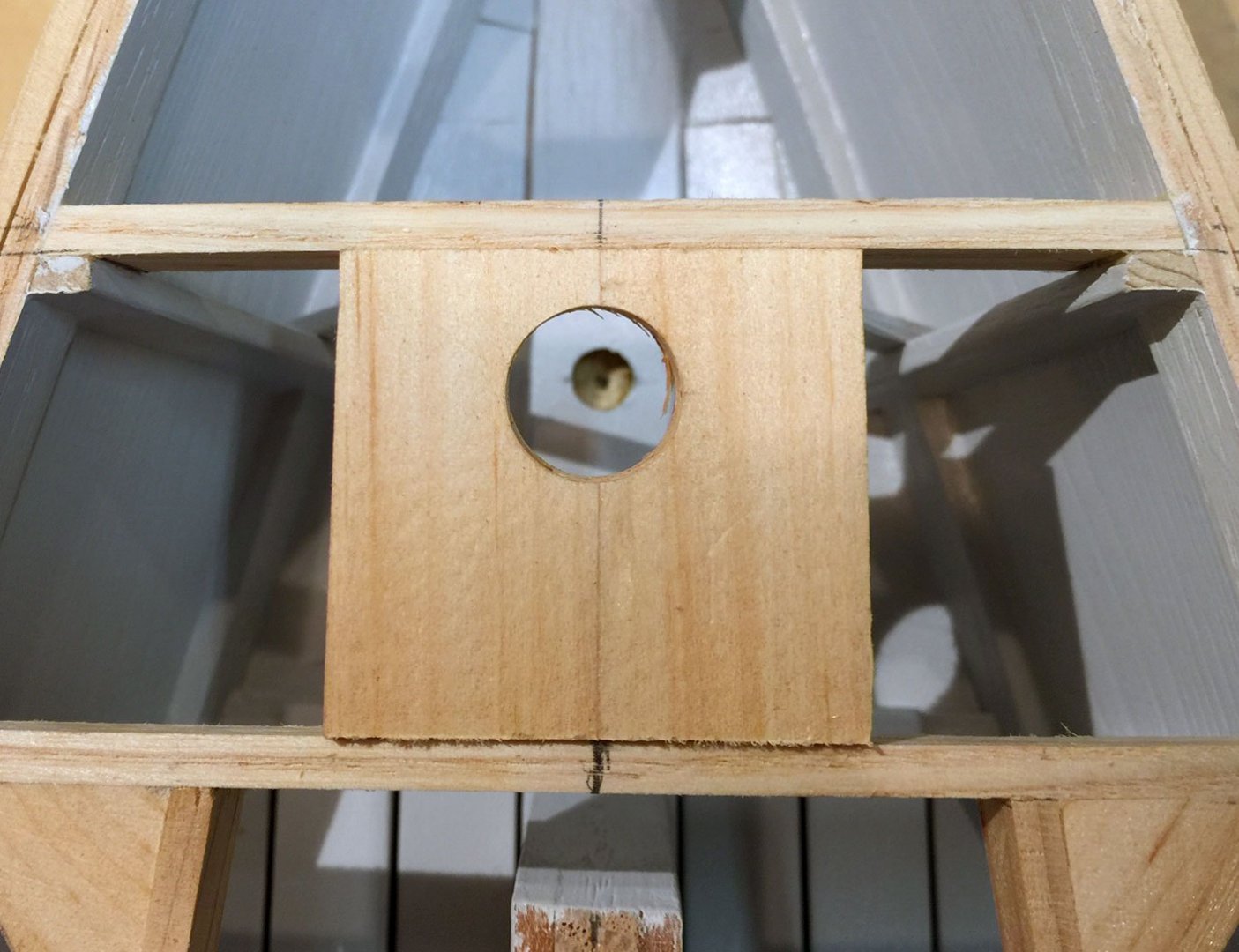

Well, I had to go back to work, so progress on the boat has nearly frozen. I did manage to finish the deck framing today. I made a mast step from poplar. It is wedge shaped, with the mast perpendicular to the raking top face of the step. To drill the step correctly, I made a similar wedge to jack up the step to the correct angle, and bored for the mast tenon on the drill press. The table tilts, but it’s easier on a small scale to just cut the wedge. I simulated the bolts that fasten the step to keelson, with some tooth picks, glued into little holes in the top of the step. You’ll never see it, but I also cut limbers from the center of the tenon mortise out to the edges to drain water from under the mast. In the pic below, the step is as yet unsanded. It looks better in the boat! The partner was bored out on a similar wedge. I made it a little oversize, and I’ll either drill an exact hole down through the finished deck, or I’ll drill that oversize as well and leather it, or wedge it. Not sure yet which. Various corner blocks of pine were also made a fitted, and all of the diagonal bracing in the cockpit was fitted. There are braces at the mast, under the washboards, and under the thwart to brace the centerboard trunk. These and the step were all primed and painted, so I believe we are ready for decking! That's it for now. Thanks for looking!

- 44 replies

-

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

-

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

-

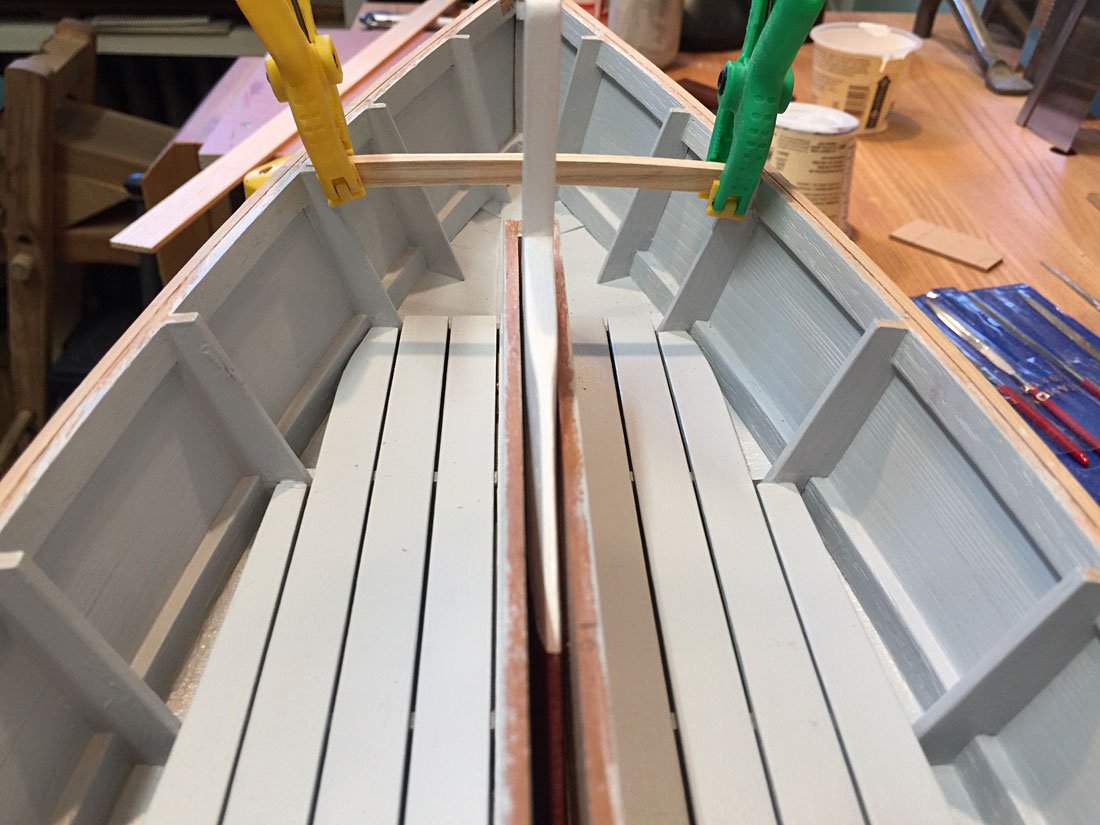

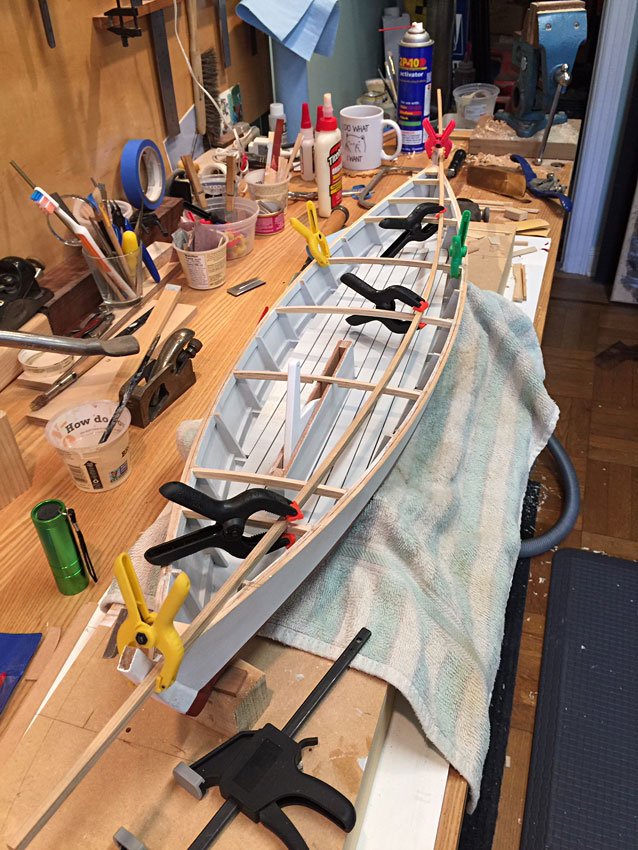

Deck Framing- I thought I would post my progress on the deck framing. I’m not done with it yet, but it’s moving along well. One thing that has to be done which I forgot about until now, is to fabricate and install the mast step! Before the forward deck framing is complete, I’ll have to stop and do that fussy little thing. But for now, I need to see some cosmetic progress, at least. I approach the deck framing similarly to the side and floor framing, with an oversize piece fitted to the sheer first, and then the top and bottom camber marked out and cut. I used the deck curve template/sander again to mark the camber, just pinching it to the raw frame by hand and marking it out, which worked well. The completed beam was the glued to the frame heads. My approach for fitting the short, partial washboard framing (side decks in sharpie parlance) is a little unorthodox, and would be wasteful of timber in a full size boat. I made and glued in an entire athwartship beam at 3 locations (where the angled deck bracing occurs), then sprung in a batten to lay out the cockpit opening curve, marked for the cuts, and fitted the angle braces. This assured that my inboard heights remained true, and that the beams would remain square to the hull. Also, I had to sand a little paint off of the side frames for good bonding before gluing in the braces. After the braces were glued in, I cut the beams at the marked location and correct angle. Chapelle shows a plumb cut on the frame ends, but I like a little outward sloping angle to the finished coaming. That angle requires a wider piece of timber for the coaming to be cut out of, but it’s usually worth it, in my experience with actual boats. Once the beam ends were cut, I fitted and glued in the carlins. I departed from Chapelle’s drawings again, and sprung in a continuous carlin, rather than sawing out multiple short pieces fit between the beams. I think that better assures fairness, in the long run. Doesn’t matter, once the decking is on, at any rate. Either way, there is a lot of end grain to long grain gluing, so the entire deck structure will be well braced with blocking, as Chapelle shows as well. At the extreme ends of the carlins, I fit a temporary brace to land the carlin on, and a prop underneath the beam to keep the carlin in plane. These I wrapped with scotch tape to keep the glue from sticking. I still have a bit of fitting and gluing to do, but I can’t get back to it for a day or two. Stay tuned!

- 44 replies

-

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

Jim Cricket reacted to a post in a topic:

East Coast Oyster Sharpie 1880-1900 by davec - FINISHED - 1/16 scale

-

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

-

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

Jim Cricket reacted to a post in a topic:

Generic Sharpie by Jim T - SMALL - Scale 1:16

-

- 44 replies

-

Thanks gents. Dave, I like the hue, but the value is a tad dark. With the Golden acrylic colors, I used a Pyrole Red base, then added Raw Umber, Carbon Black, Permanent Green Light, and Titanium White. Some people I've heard use Rustoleum Red Metal Primer, in a spray can. I'm trying to avoid the spray cans, if I can, though that would be easy if planned for.

- 44 replies

-

Gary, I have only scratched the surface of your build log. But what an awesome adventure! Your weathering details are extraordinary. I have become interested in working with styrene after seeing some of your constructions, and I'll be checking back in for a much closer look. Thanks for the detailed log. Cricket

-

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

-

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

-

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

Jim Cricket reacted to a post in a topic:

New England Stonington Dragger by FriedClams - FINISHED - 1:48 POB

-

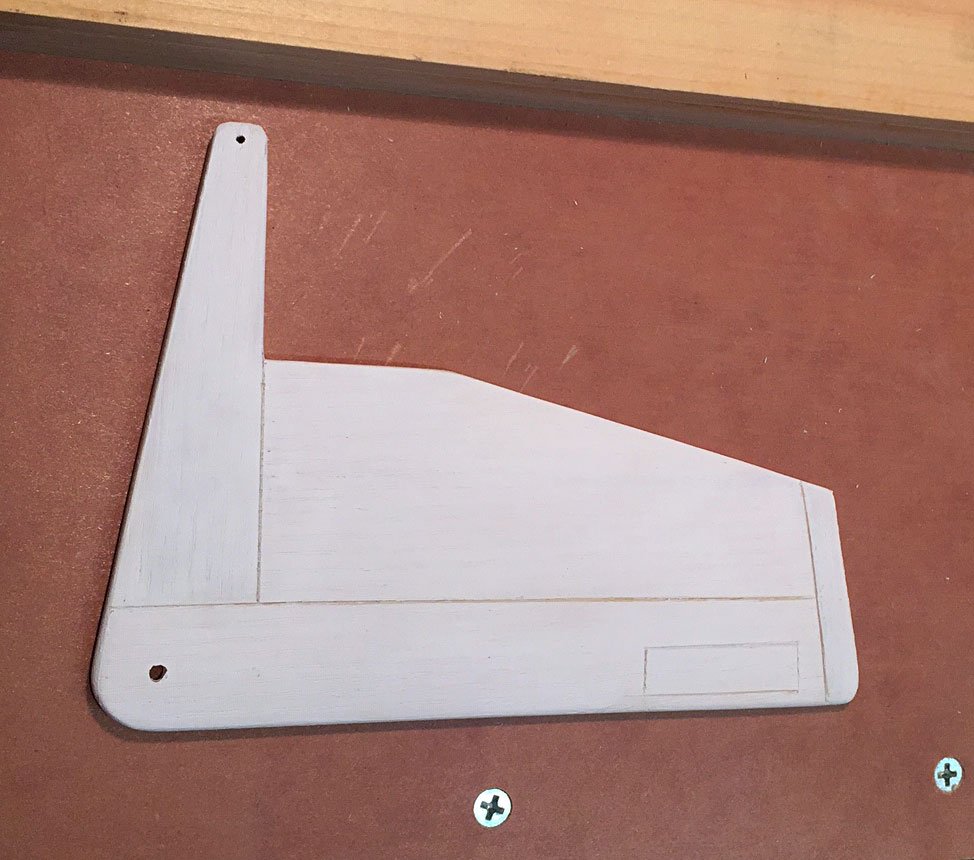

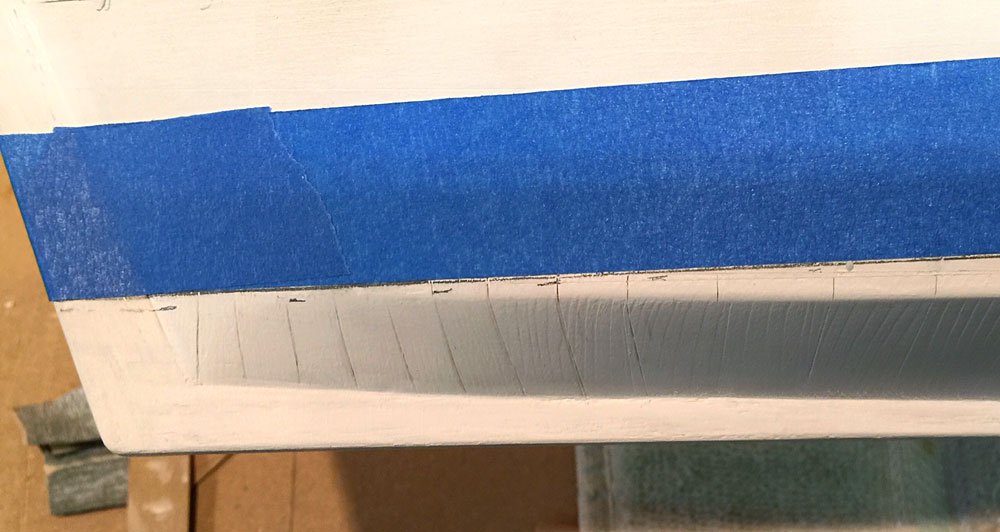

Thanks Gary! The centerboard turned out to be relatively easy to shape, and I worked a nice foil on it. Not as sharp a trailing edge as in real life, but not as fragile either, and not bad for a 90 year old boat! I wanted the construction to show up, so to that end I etched lines along the joinery, and faked in a lead insert. My intention was to let some dark paint run into the seams, to show them up. I also had to decide how far down, and how far up to show the board in the model, so I could use bottom paint below the hull, and white above the trunk. I don’t want to see the junction of the two colors in the finished model. On the hull bottom, I etched in some seams as well, hoping for a little depth and color variation in the finish. I taped off the board, and the waterline on the hull, and mixed up a deep red. The hull took four coats to cover well, over the white primer. I ended up mixing some matte medium and retarder into the acrylic, and sanded with 1000 abranet between coats. worked reasonably well. On the next model, I may experiment with milk paint, which is dead flat. I’ve used it on furniture, to good effect. I used matte varnish on the centerboard, and that knocks the sheen down well. For the seam lines, I took an ink pen, and drew the lines in black, then wiped some of it away, and painted in some dark dilute acrylic, and fiddled around with it. The effect is okay, but I think my color is darker than it should be, particularly since the bottom is in shadow. I may go back later, and lighten the red selectively with a dry brush. I’ll varnish the hull and deck at the end, after all painting is done. I’m ready to glue the floorboards in now, and then move onto the deck framing. Progress. Thanks for tuning in.

- 44 replies

-

Hi Jim, Glad to see you back on it! I will come back when I have more time to read your log from the beginning. Nothing like having a few people working on the same, or similar, projects to get your interest piqued again. I'm trying to get a hole in my house closed up today (door repair). So this evening. Thanks for posting, Cricket

-

I went ahead and fitted the floorboards, before working on the centerboard. This will give me a chance to get them painted before installing. This pic shows them just sitting there, so not properly spaced and fastened down yet. In actual practice on a big boat, I would make a portion removable with buttons or whatever, to inspect the bilge easily. The pic below shows our deadrise skiff floor, with cleated center section, removable with turn buttons. Those oiled floorboards have since been painted. I'll paint the sharpie model floorboards as well, because I think the typical boats of the era would have them painted. Moving on...

- 44 replies

-

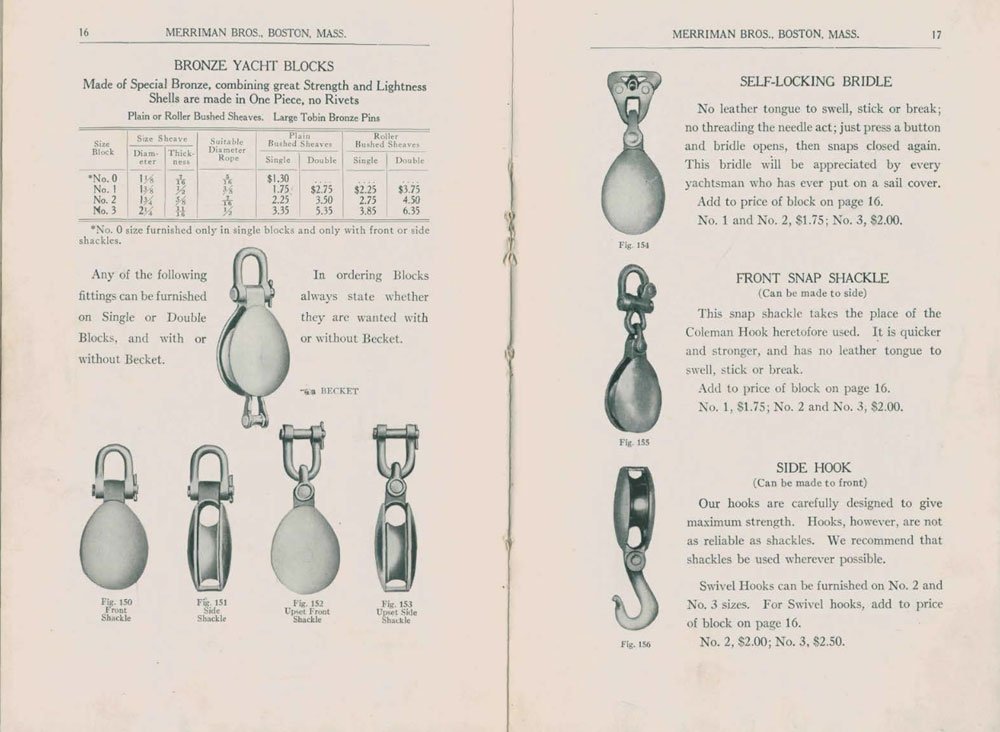

Bridgman, I also read that Merriman were manufacturers of Nat Herreshoff designed blocks.

-

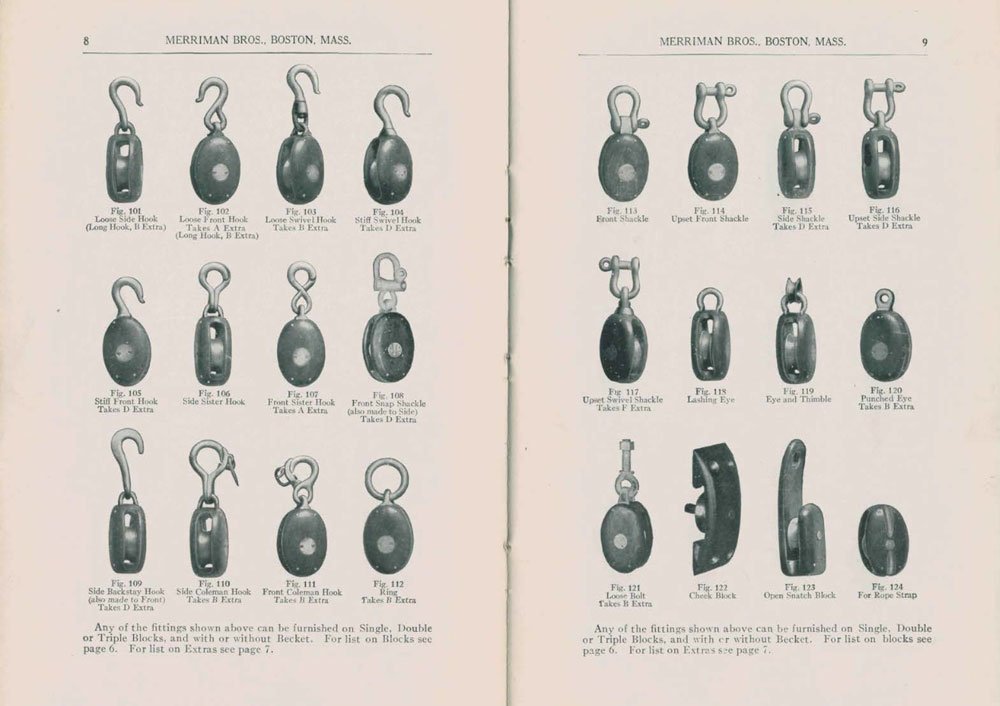

Thanks everyone for your input. Bob, Chapelle's "Boatbuilding" doesn't have an appendix, per se, but he does say that "Blocks having wooden shells are preferable for rope, those having metal shells for wire. Bronze blocks, for rope, are popular, however, because of their small, neat appearance. "American Fishing Schooners" is the one with more extensive rigging sketches and diagrams, but of course, more relevant to schooners. The Merriman suggestion, however, was spot on. I found a pdf of a 1928 Merriman catalog, available from Wooden Boat. https://www.woodenboat.com/sites/default/files/library-content/merriman1928.pdf which I downloaded. There are appropriate wood shell, and bronze shell blocks, along with shackles and turnbuckles, sheet horse fittings, etc. Great resource for my time period. Since my sharpie is not really a working boat, but one that might have built for pleasure or racing, it seems like the small bronze yacht blocks might be appropriate. I'm going to look further to see if I can find a source for galvanised blocks. Those might have been standard hardware store issue. At any rate, I think the Merriman pattern would be suitable for a scale block that could be finished appropriately. Cheers, Cricket

-

Hi Folks, I'm looking for some info on blocks used before the second war. I'm going to be rigging my Chapelle sharpie soon(ish), and thought I might reproduce metal blocks, either bronze or galvanised. But I'm not sure if metal blocks were common. The design from Chapelle is from "Boatbuilding", published in 1941. There is no date on the drawings, but I'm guessing it originates in the 30's some time. the boat is not lines from a hulk or existing boat, but I'm pretty sure new from Chapelle, as he was wont to do at that time. There are many sharpie yacht derivatives penned by Chapelle that were influenced by the work boats of the day. Running rigging is all from 1/4" to 3/8", so a 2" (full scale) block would be about right. I can buy 1/4" iron stropped blocks from Bluejacket, etc. or make my own and paint to resemble metal. Thanks in advance- Cricket

-

Heh heh, I've been known to be "creative" in regards to millwork finish samples in the fussy NYC cabinetry world, too. Sometimes you have to find the spot where the light works to your advantage, before calling the architect and client over.

- 44 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)