-

Posts

234 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James G

-

Thank you for your kind words @FrankWouts! I’ve been enjoying walking through your build log of the Winnie. You are doing a truly masterful job. I’m especially impressed with how meticulous you are on your planking. Will certainly be referring to your log as I progress. Appreciate you checking in along the way! Best, Jim

-

@scrubbyj427, @jfhealey and @glbarlow thank you all for your feedback. Very helpful! Agree, a lot certainly does boil down to personal preference. I didn’t realize that the copper on model ships would patina over time. I like that! We restored a Victorian Queen Ann historical home we owned outside Cincinnati that was built in 1887. We renovated the gutter system and installed new copper downspouts. It was interesting to see how over just a few years they went from shiny copper to a greenish hue over a relatively short period of time. I’ll have to give the copper treenails a second look. Thanks again. Best, Jim

-

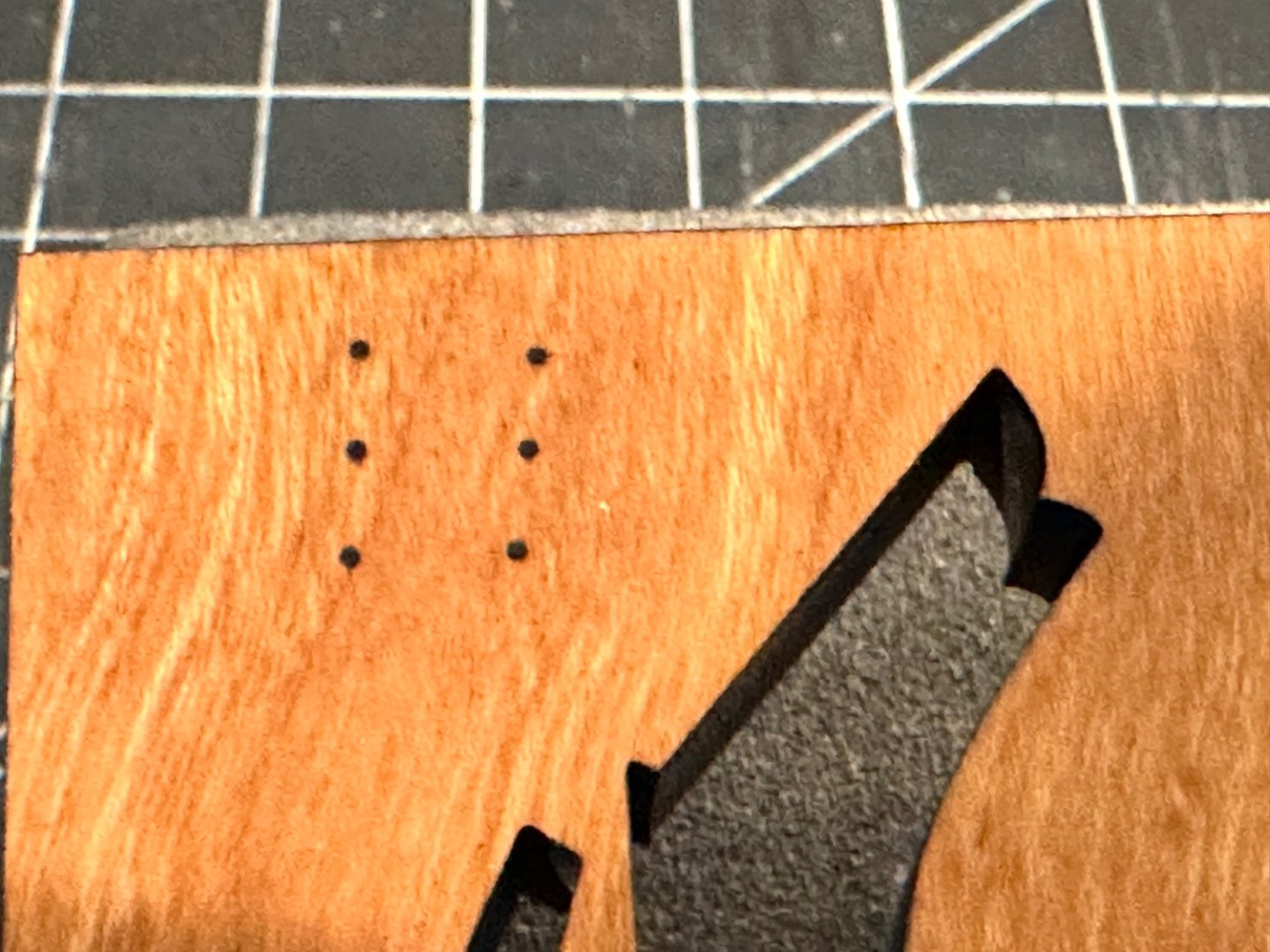

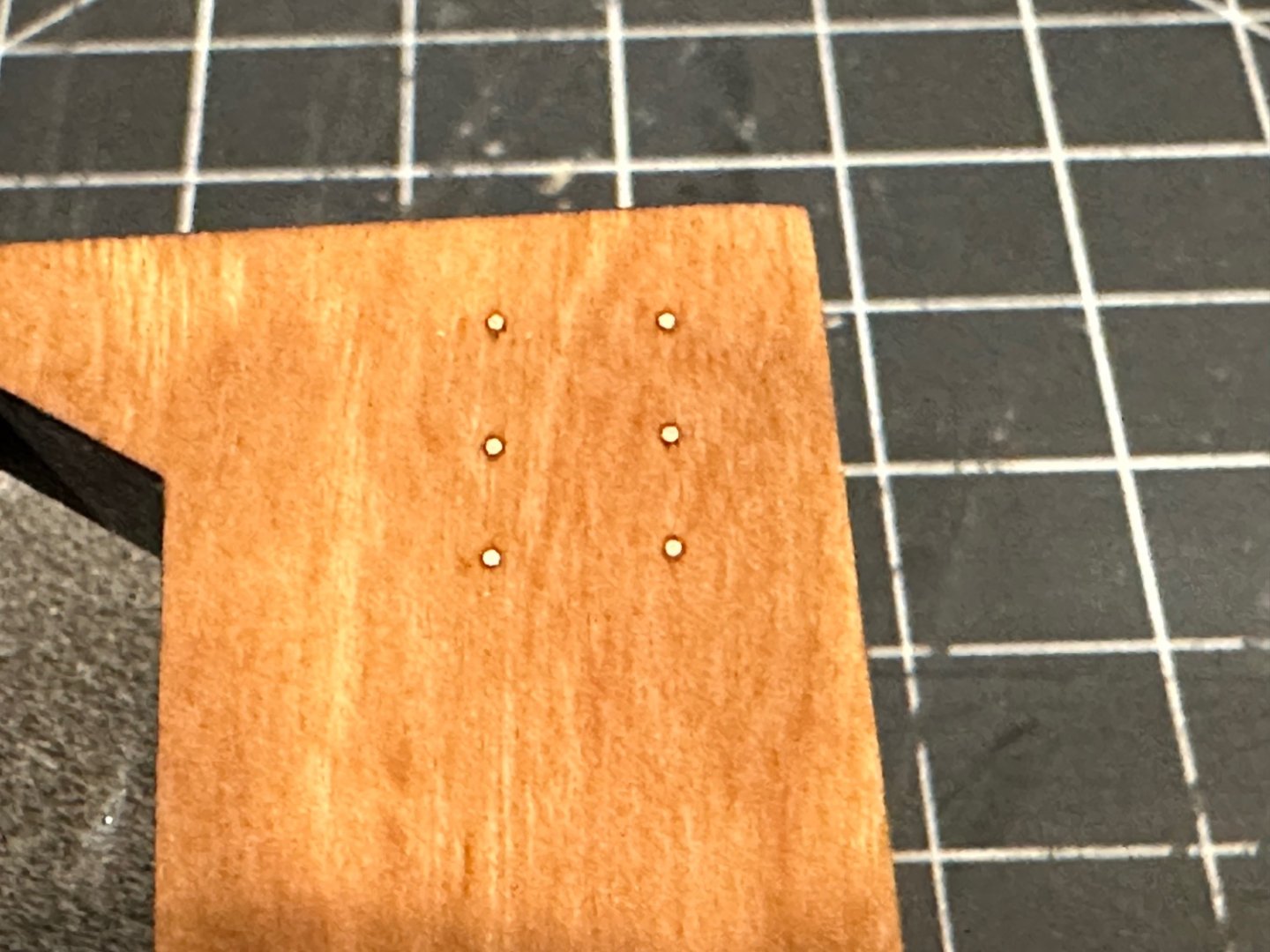

I’ve been experimenting with finishes and bolt types today. I’m building the Winnie with cherry and below are test finishes with linseed oil sanding sealer and wipe on poly. The jury is still out but right now I’m leaning towards the linseed oil. I really like the rich color it offers! As far as bolt types below are samples of black monofilament line and copper. Given the limited number on the model I’m leaning towards the black monofilament. If more were required I probably would prefer the copper which seems more subtle. What do you all think? I would welcome your opinions. Thank you for looking! Best, Jim

-

Thank you Matt and Fred for your kind words and thoughts on fabricating vs using laser cut parts. I agree with you both. I do enjoy the challenge and personal satisfaction of fabricating my own parts and have done a fair amount of kit bashing on my previous builds. With the Winnie where I get a bit frustrated is I still lack the tools to achieve the precision that Chuck offers with his mini kits. I haven’t invested yet in equipment like a laser cutter or cnc machine and don’t know if I ever will. Being still relatively new to the ship modeling world I’m still trying to figure out how much I want to scratch vs kit build. I guess time will tell. In the meantime it’s a fun question to wrestle with on an amazing model like the Winne! Best, Jim

-

Good morning! I wanted to pass along a quick update on my progress over the last three weeks. I’ve finally finished cutting and shaping all of the bulkheads and bulkhead former. Wow! This certainly does take some time so be prepared if you plan to go this route. I did it because I wanted to purchase a scroll saw. If that’s not important I would recommend buying the bulkheads and former from Chuck. My bulkheads are pretty accurate but starting with laser cut versions would have been much easier. If I were to do it again that is the path I would take. Lessons learned, right? However, I certainly am having fun! Thanks for looking and to all the Winnie builders thanks for sharing your wonderful logs! Jim

-

At some point I’d like to own both as well. I’m trying to decide which one to purchase first. Yes, wouldn’t it be great if there was a tool “take it for a spin” store? Sadly, I don’t see it coming soon. Can you imagine the liability costs? 😆 Thanks Greg!

-

Greg, Thank you much for your response…very helpful! At some point I’d like to get a spindle sander but would prefer not to spend a ton of money. Currently, my trusty Dremel in its stand is doing the job. Although it can flex a bit if I’m not careful. I’m still debating which would be preferable for ship modeling, a spindle or bench disc sander. The jury’s still out but your experience is certainly helpful. I had no idea you could get a decent spindle sander at this price point. I have a Wen scroll saw that works quite well that had a similar price. Again, thanks. Finally, I continue to enjoy following your beautiful build! Jim

-

Looks like a nice spindle sander you have there, Greg! What manufacturer and model is it? If you don’t mind my asking.

-

Looks really nice, Jim! I’ll be referring to your log as I’m building mine.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Joe, I don’t personally see it as an error! You took an educated direction that didn’t work out and that happens when building anything. Be it a bird house, chicken coop or a highly-detailed, well-crafted model ship. What Glenn says is so true. Practice does make perfect and in this hobby there is a certain amount of repetition in our builds. I’m learning that being patient and not afraid to start over does improve the final result. I simply have to be ok with saying it’s not good enough and willing to try again. I don’t always do it but am getting better at it as I gain more model ship building experience. I continue to enjoy following your build and appreciate you sharing both your successes AND challenges. Keep on rolling! Best, Jim

-

Looks so nice, Glenn. Hope you have a wonderful trip!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

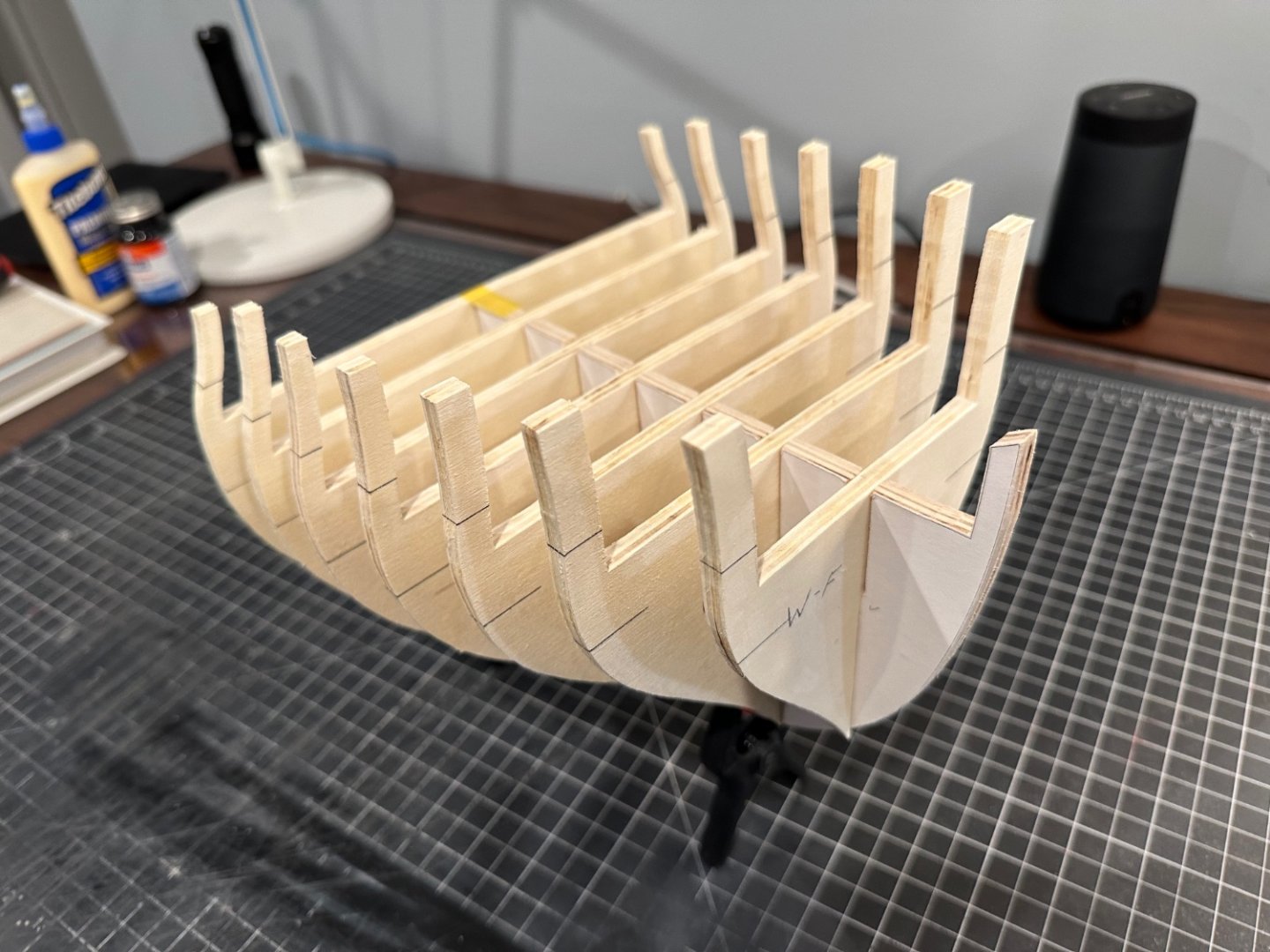

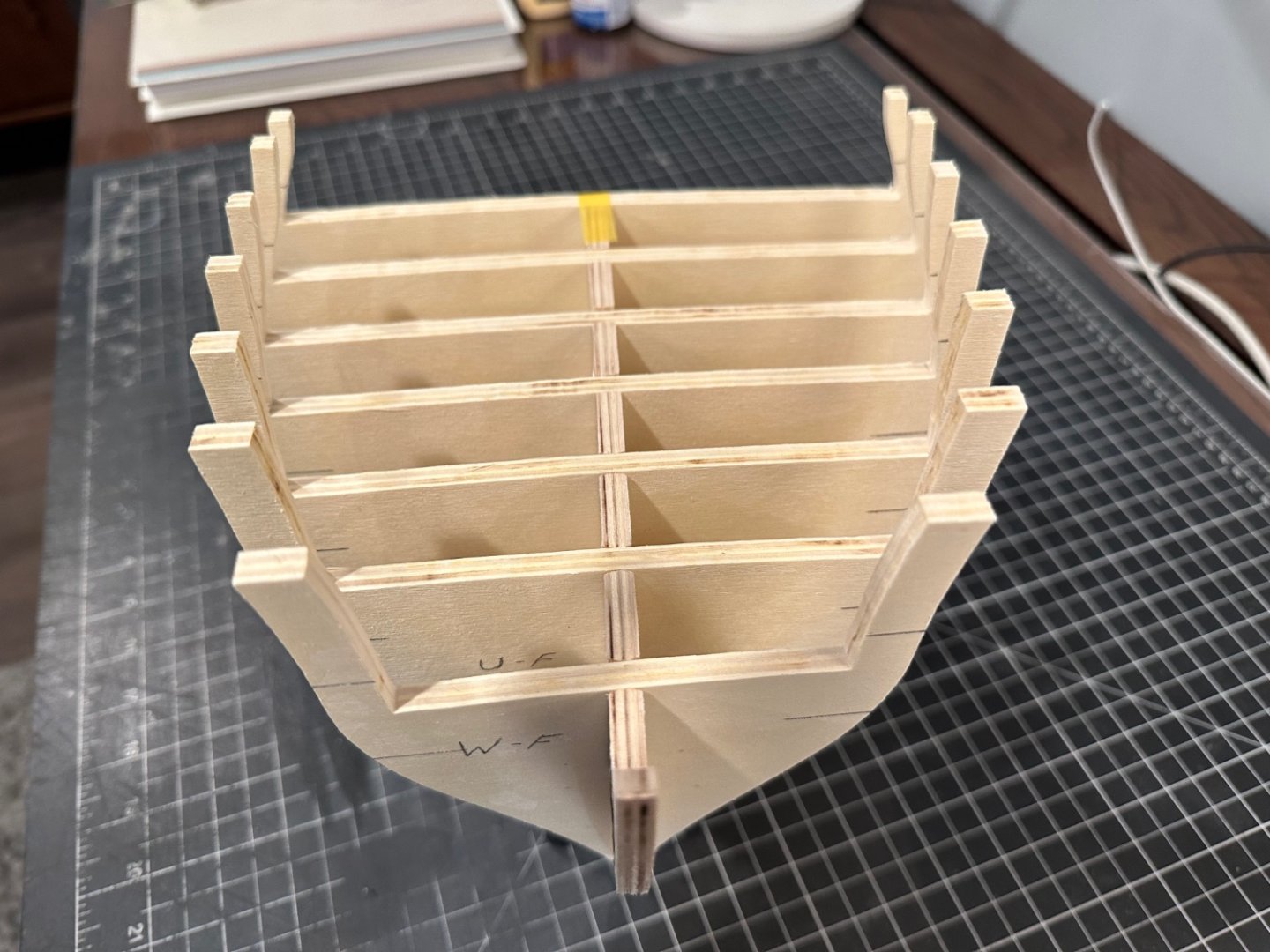

A quick update on my progress over the last several days. I’ve been busy cutting and shaping the bulkheads and also the bulkhead former. Following Chuck’s and others advice I did use lite ply for the bulkheads and birch ply for the bulkhead former. So glad I followed the advice! The lite ply sands easy while the birch feels like sanding steel. This will definitely make faring easier. Below is a shot of the first section of the bulkhead former dry fitted with the bulkheads. They’re still rough but it’s a start. Also a shot of the knee. Still requires final sanding and shaping. I do love the cherry! Thanks for looking and especially for sharing your expertise! Best, Jim

-

Used Cameron Drill Press Opinions Requested

James G replied to James G's topic in Modeling tools and Workshop Equipment

Thank you all for the wonderful feedback! Exactly what I was hoping for. Based on your responses it looks like there are several better solutions than a used Cameron. I’ve been using a Dremel in the plastic stand they offer and have been extremely frustrated with the lack of concentricity. The main use will indeed be for ship modeling. At this time I’m building from the many fine kits offered. I enjoy kit bashing and hope to do more scratch work as my skills improve. A Sherman mill is a possibility down the road. However, I have much to learn before I get to that point. I’m trying to take my time and make the right tool selections as my abilities dictate. I do love my Jim Byrnes table saw! However, nothing worse than spending a lot of money on tools that you don’t even understand how to fully maximize. It seems in ship building this is an easy thing to do! Again, many thanks for sharing your knowledge and experiences. Sincerely, Jim -

Hi Wxchsr! I’m new to the group as well and also highly recommend a build log. The group here is so friendly and helpful. Any questions I’ve had to date have been quickly answered by Chuck and or other members that are further along in their builds. Never too late to join the party! Glad you’re here. Best, Jim

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’m in the process of fitting out my shop with quality tools that will both perform at a high level and will last for many years. I’ve been shopping for a micro drill press and have reviewed some of the excellent threads that are available on MSW. They’ve been very helpful. I’m now considering purchasing a used Cameron Drill Press on EBay. Used ones come on the market periodically and range in price from $300 to $800 depending on condition, age and accessories included. I’d prefer not to purchase a new Cameron if possible if a used one will do the job our hobby demands. Here are my key questions. 1) Is a used Cameron a good direction to take vs new? 2) Does age matter? I see on our forum some members are using drill presses that are decades old. 3) Will a used Cameron perform at the level needed? 4) Should I be concerned about getting replacement parts if needed? Thank you in advance for any input you can offer! I’m on the fence on the direction to go and am hoping your feedback will give me a nudge in the right direction. Best, Jim

-

Beautiful Glenn! Your work makes me even more excited that I decided to build my own version of the Winnie. I appreciate your sharing and the inspiration of your example.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.