Bill97

-

Posts

2,332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Bill97

-

-

- wvdhee, Ian_Grant and jpalmer1970

-

2

2

-

1

1

-

Coming along great Jake. I do remember that extensive masking so well!

-

Thanks S.Coleman. I appreciate your comment. What will really be interesting is adding the timbers that I have stained blue. They will finish up to the top of the wales.

How is the bow shaped on your model?

Thanks again for following.

Bill

-

-

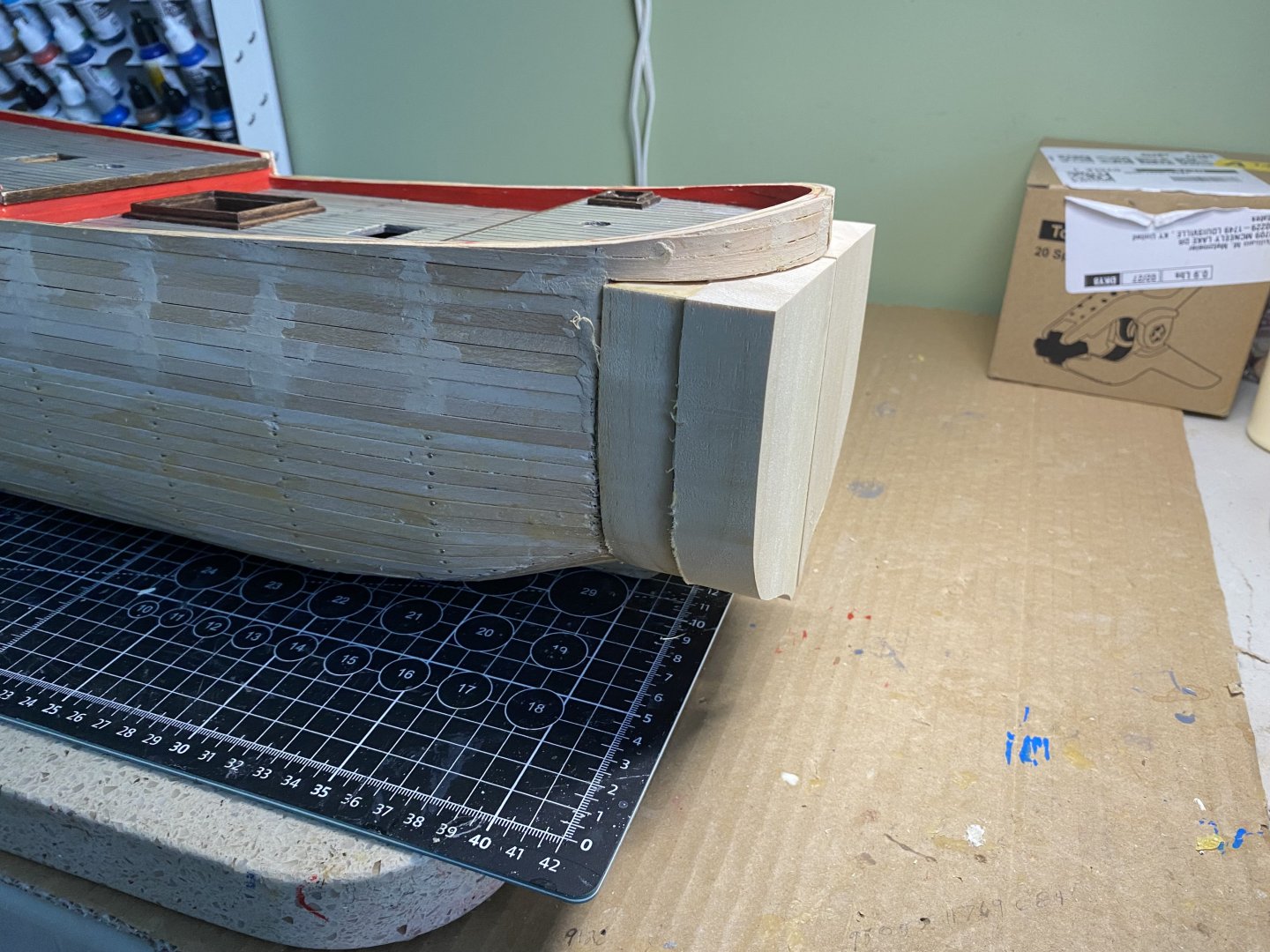

It has been a little over a week since my last update. I am continuing the second planking which is just a slow price of putting a jig-saw puzzle together and making the pieces at the same time. I decided to add the sections of the keel that goes down the front of the bow and behind the rudder early so that I could but the planking right up to those pieces. Instead of cutting and trimming the planking pieces later when I installed the keel sections as OcCre suggests.

-

Where I struggled when soldering my links was trying to trying to solder the the wire loop end to end. Eventually I had to overlap the wires just a bit then solder.

-

Marc I think they are looking fine. When I built my Victory I ordered Daniel’s (Dafi’s) chains. For my SR I decided to attempt to make my own as you are. I experienced the exact issues with finding the best spot to solder and when to attempt the crimp. It is frustrating. I think a fault I have in modeling that you don’t have, and I compliment you, is after a number of tries at perfection I give up and use my best attempt. Especially if it is an item I expect will not be that visible to others. Like chains under the channels. You however my friend, and again I compliment you, are an absolute perfectionist. You work truly shows it.

- mtaylor, Hubac's Historian and FriedClams

-

2

2

-

1

1

-

It is really looking good Jake. Your client will be very pleased. That is an interesting subject I have thought about. My ship room is becoming overcrowded. Many times people who have viewed my ships have said “you should sell these”. I would have no idea what I would charge. Two of mine, the Heller HMS Victory and Le Soleil Royal, each took well over a year to build. How in the world do you put a price to that. And I would think it would be after it is completed that a client would offer to purchase it. Can’t imagine a client asking me to build a ship for them that may take a year or more to get. I have offered my Mayflower to my grandson’s school library. They study the subject in their history classes and he told me it would be cool to look at it in the library and brag to his classmates that his grandfather made it😊.

-

-

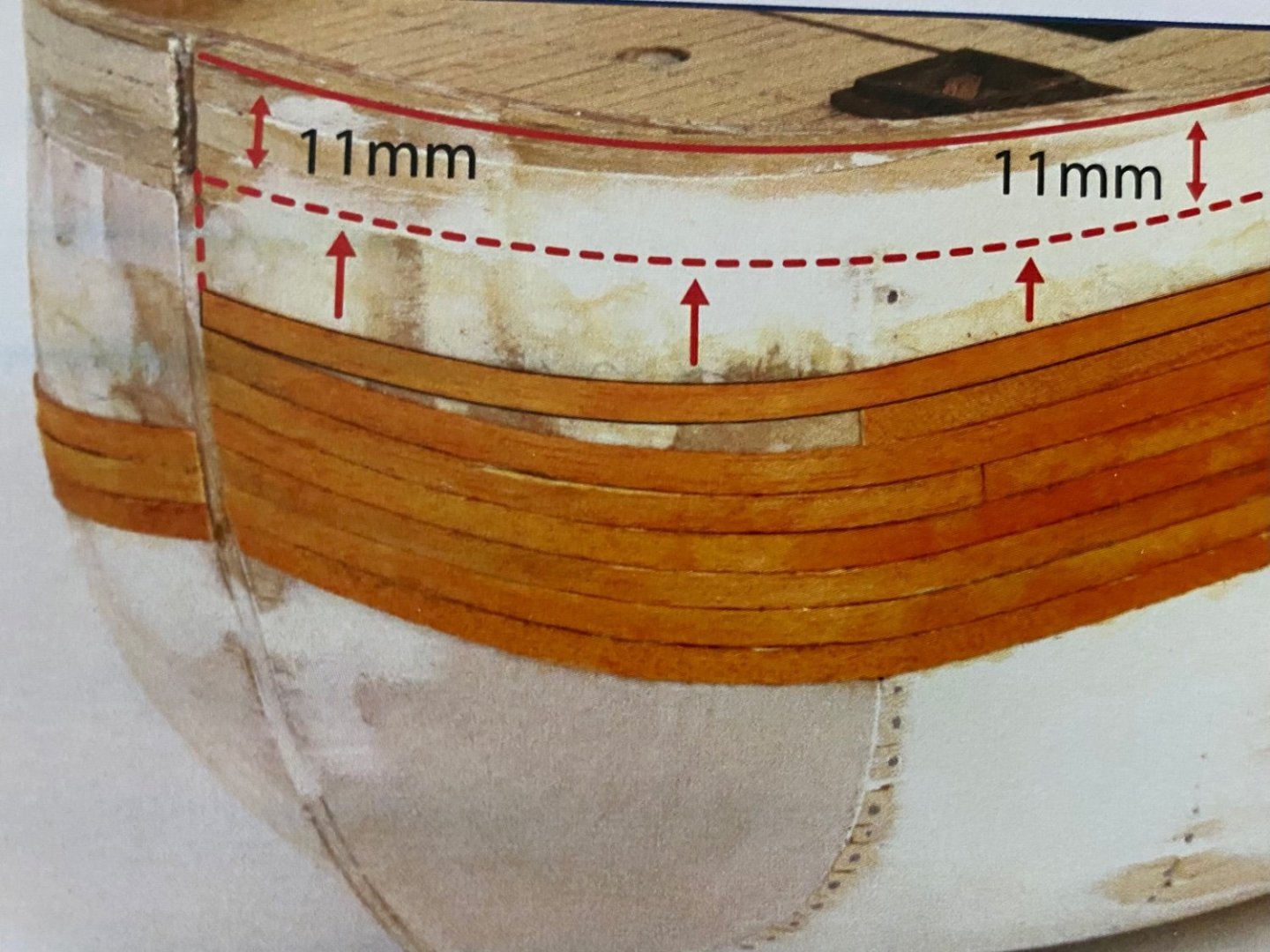

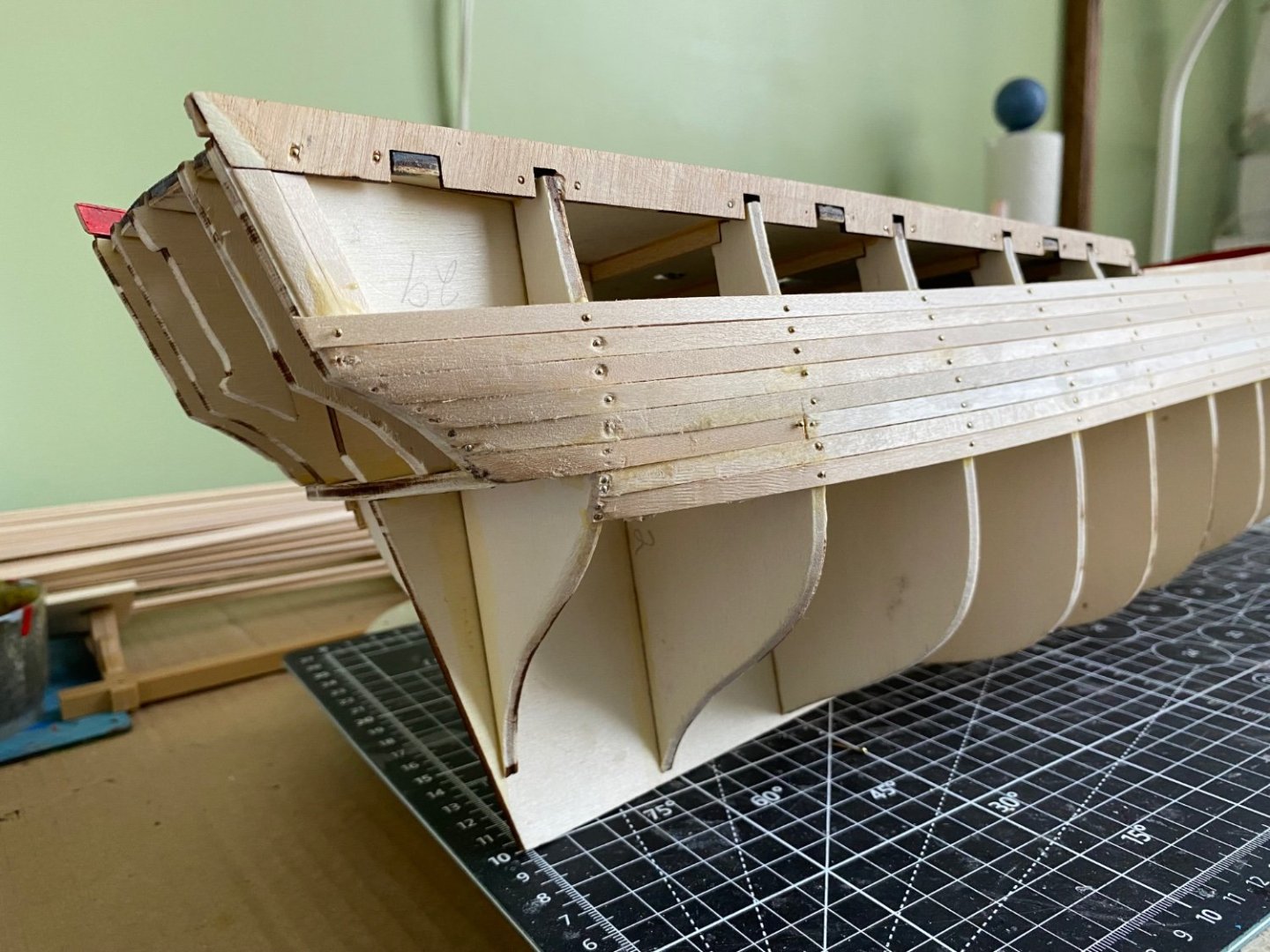

Second planking underway. Stained the planking strips. Following the OcCre instructions I established the starting position for these strips and began working upward toward the bulwarks. As with the 1st planking, various planks along the way will need to be custom cut to fill where a full plank is not used. I discovered after a few failed attempts and some non-church words I found push-pins to be the way to go.

-

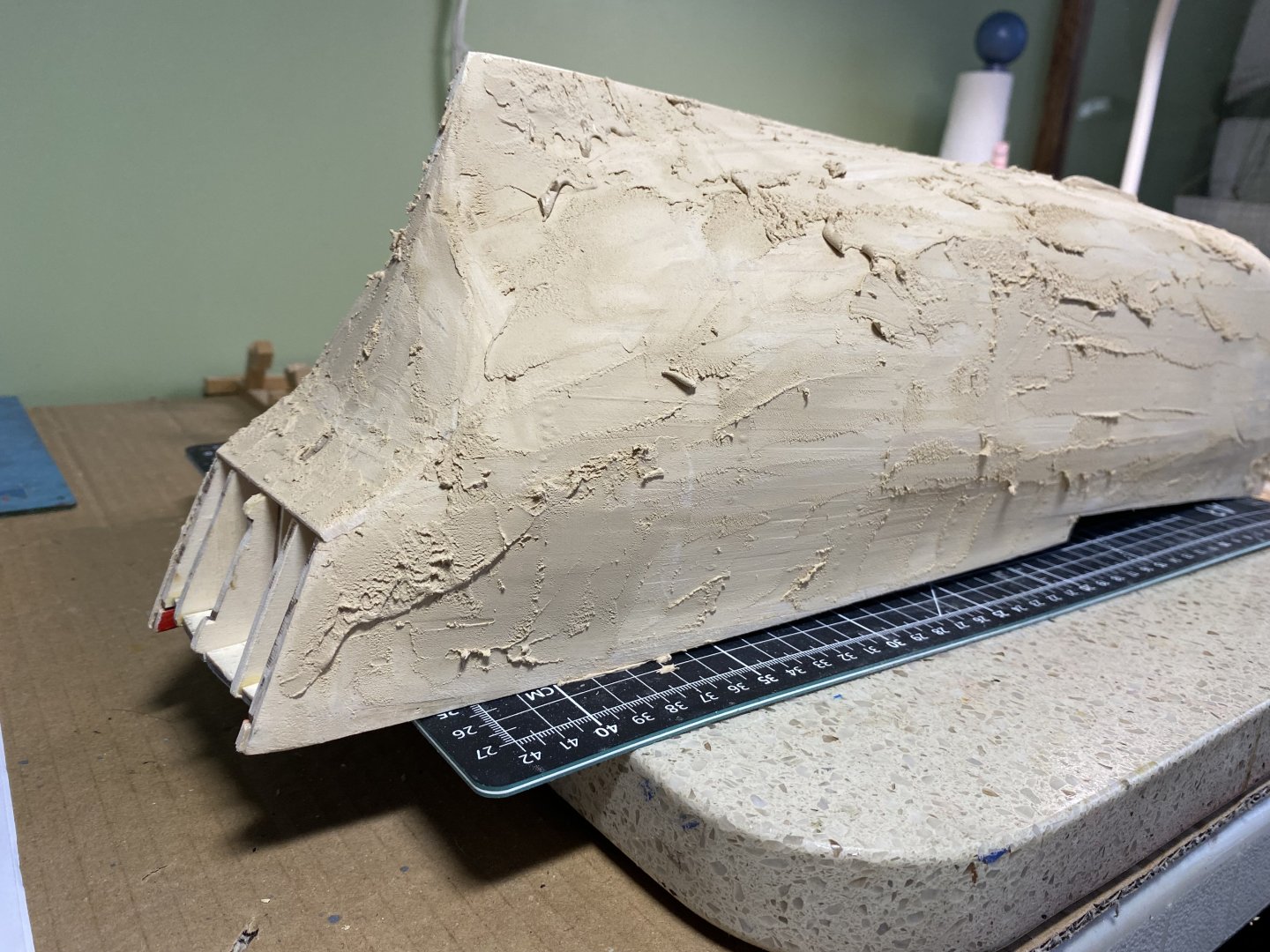

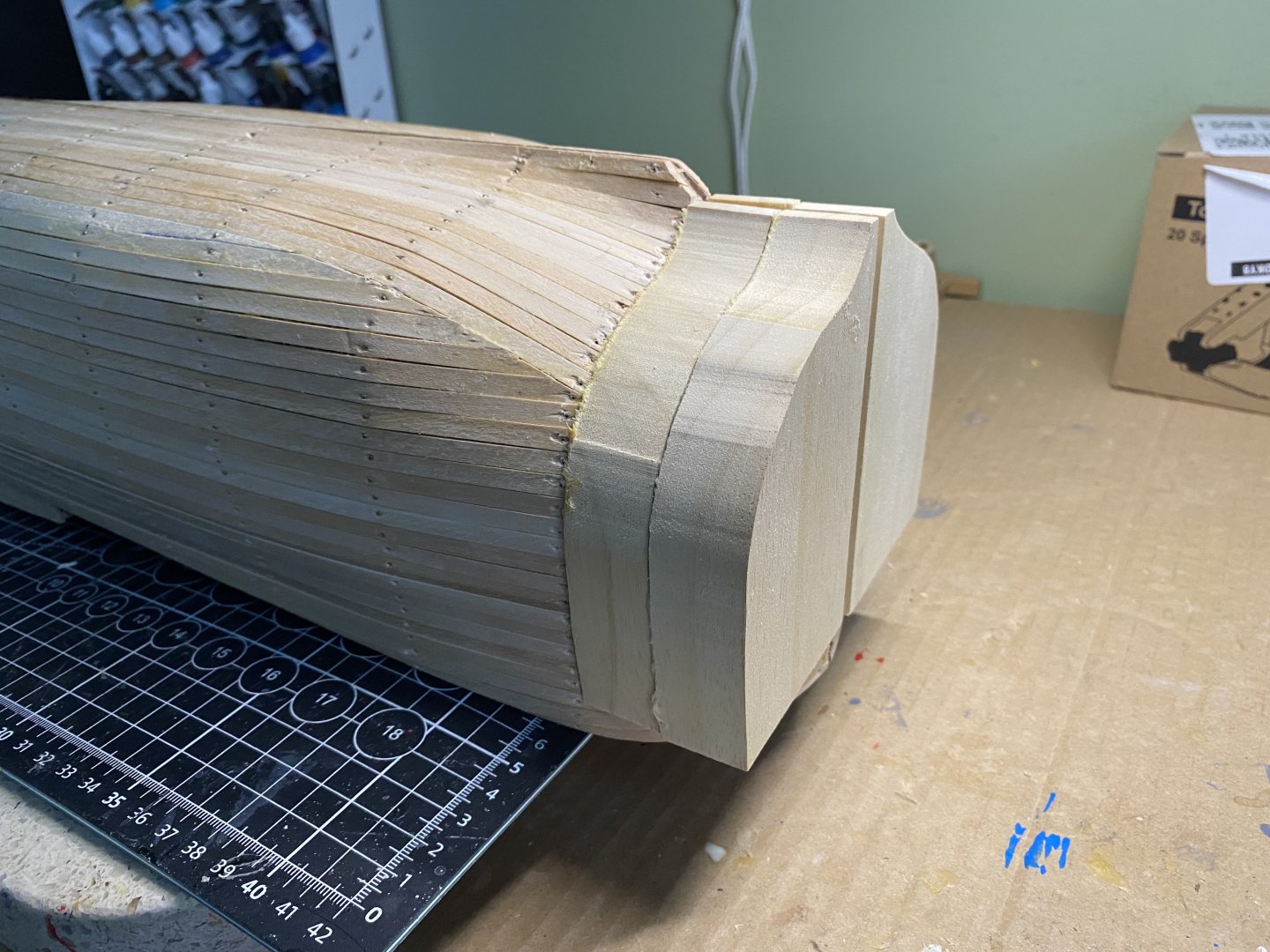

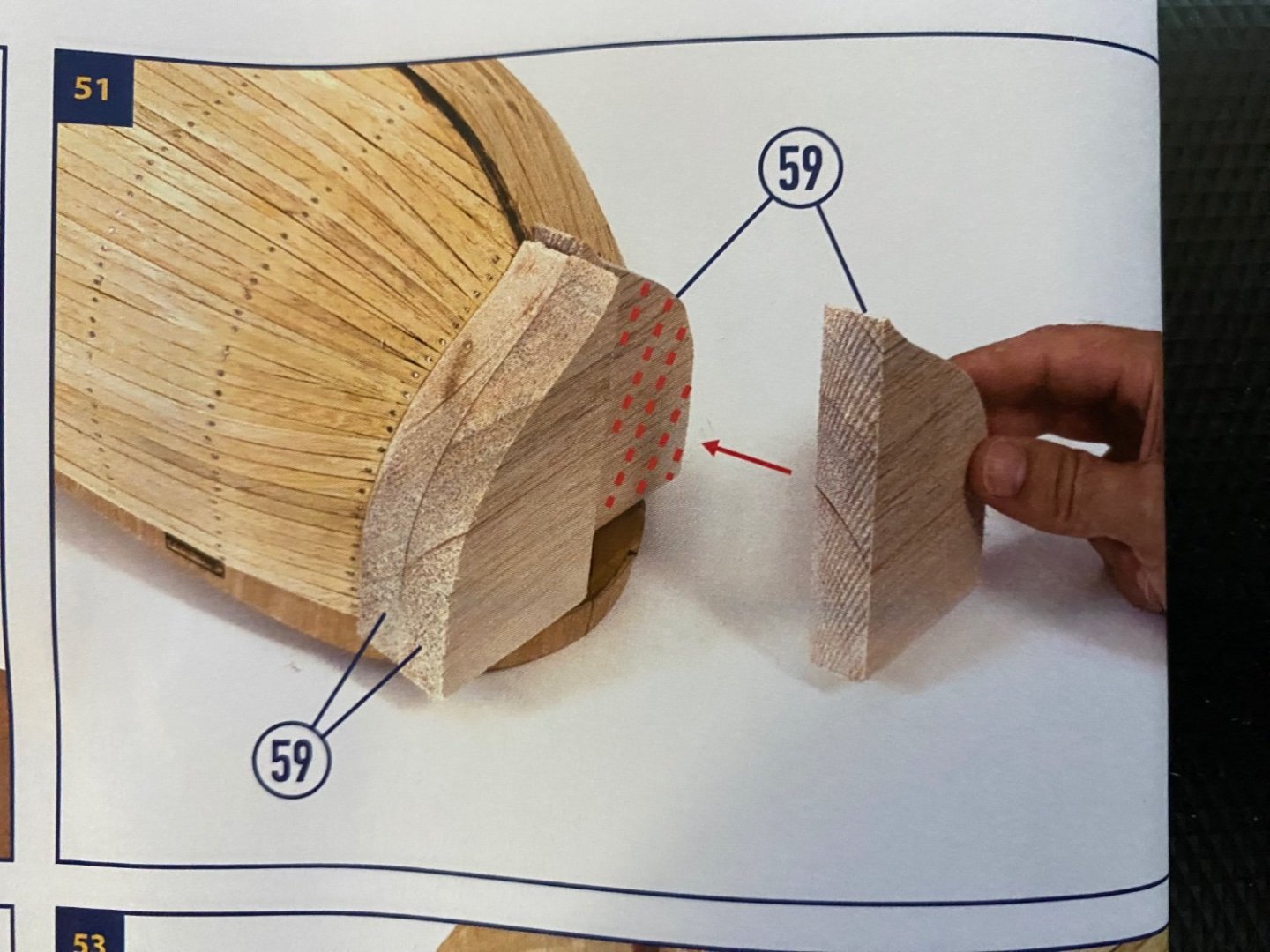

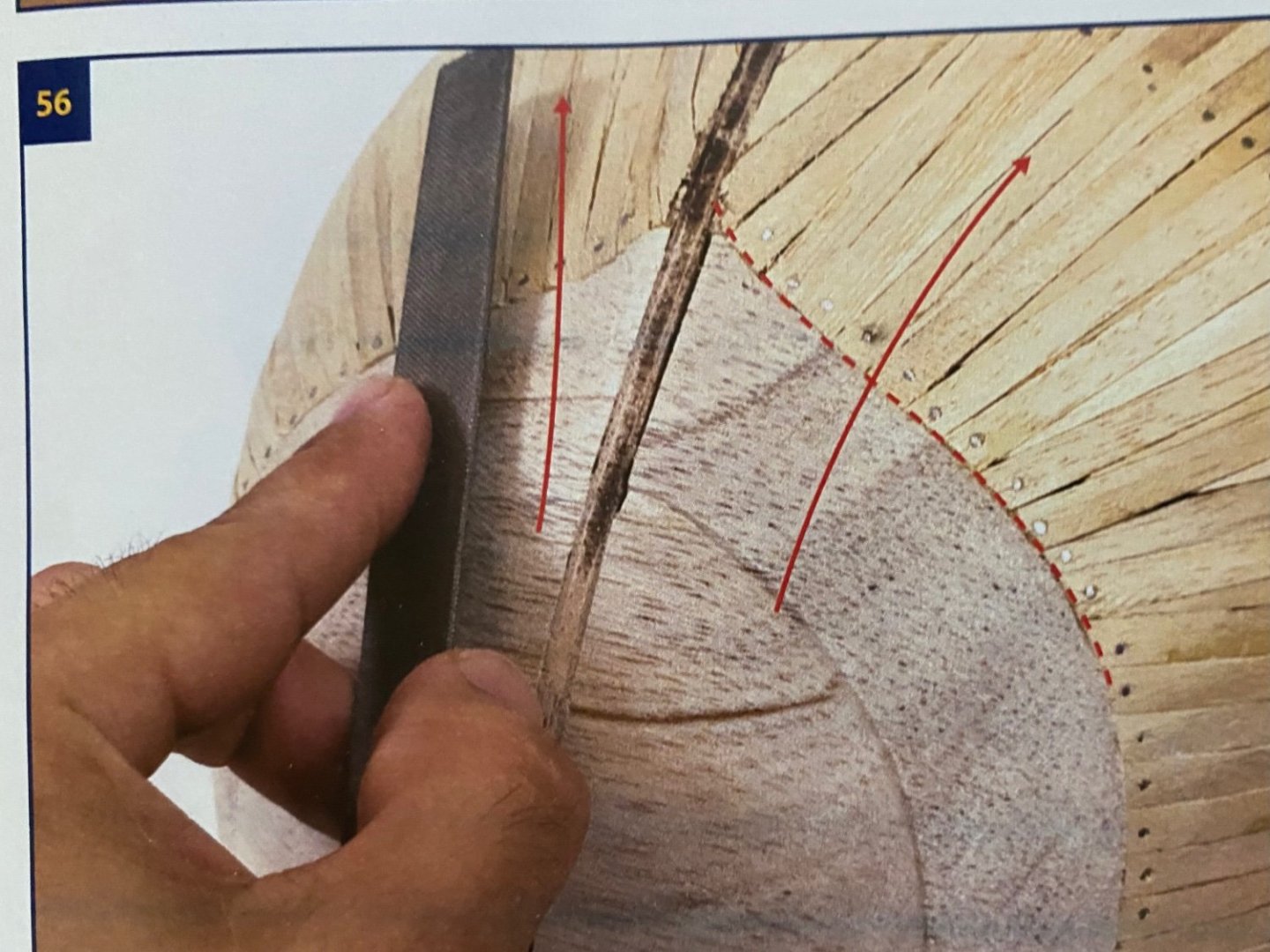

Bow and stern reinforcements sanded and shaped to make a smooth transition from the sides of the ship. Also sanded the planking to achieve a smooth surface keel to bulwarks. Let me advise anyone getting ready to do this to work outside or in a room you don’t care to get dusty. Wow sanding the two ends left a lot of sanding dust all over my workshop! Spent a little time with my ShopVac after I was finished. I then took a piece of the veneer strip and slid it over the two different reinforcements checking for any high or low spots that need some extra sanding. Once I was satisfied with the shape I coated the entire hull with wood filler putty to fill the nail holes and spaces between planks. Tomorrow after the wood filler drys and hardens I will sand the hull again with a fine grit sandpaper to remove the unnecessary dried putty.

-

- wvdhee, jpalmer1970, Ian_Grant and 1 other

-

4

4

-

- wvdhee and jpalmer1970

-

2

2

-

-

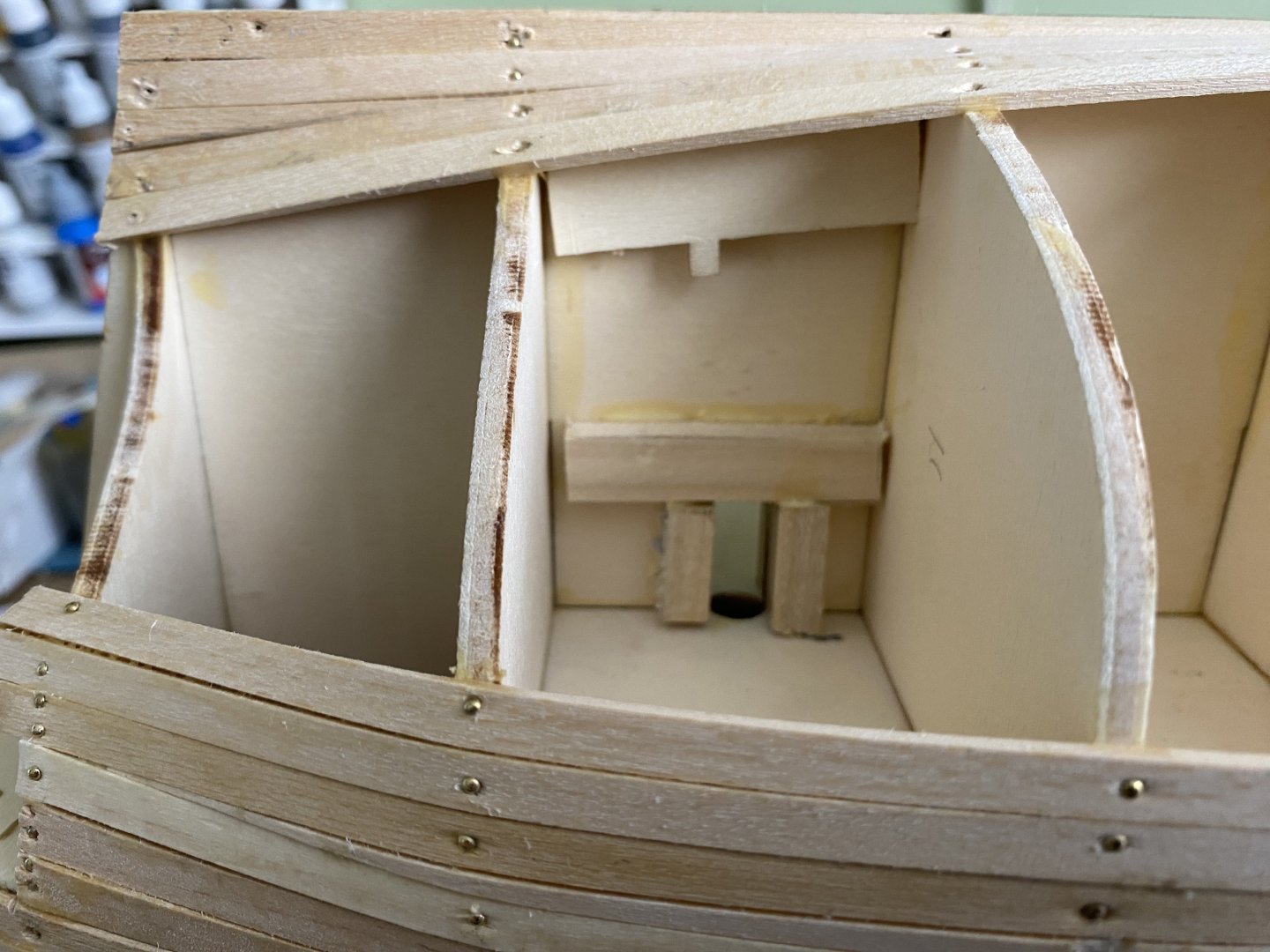

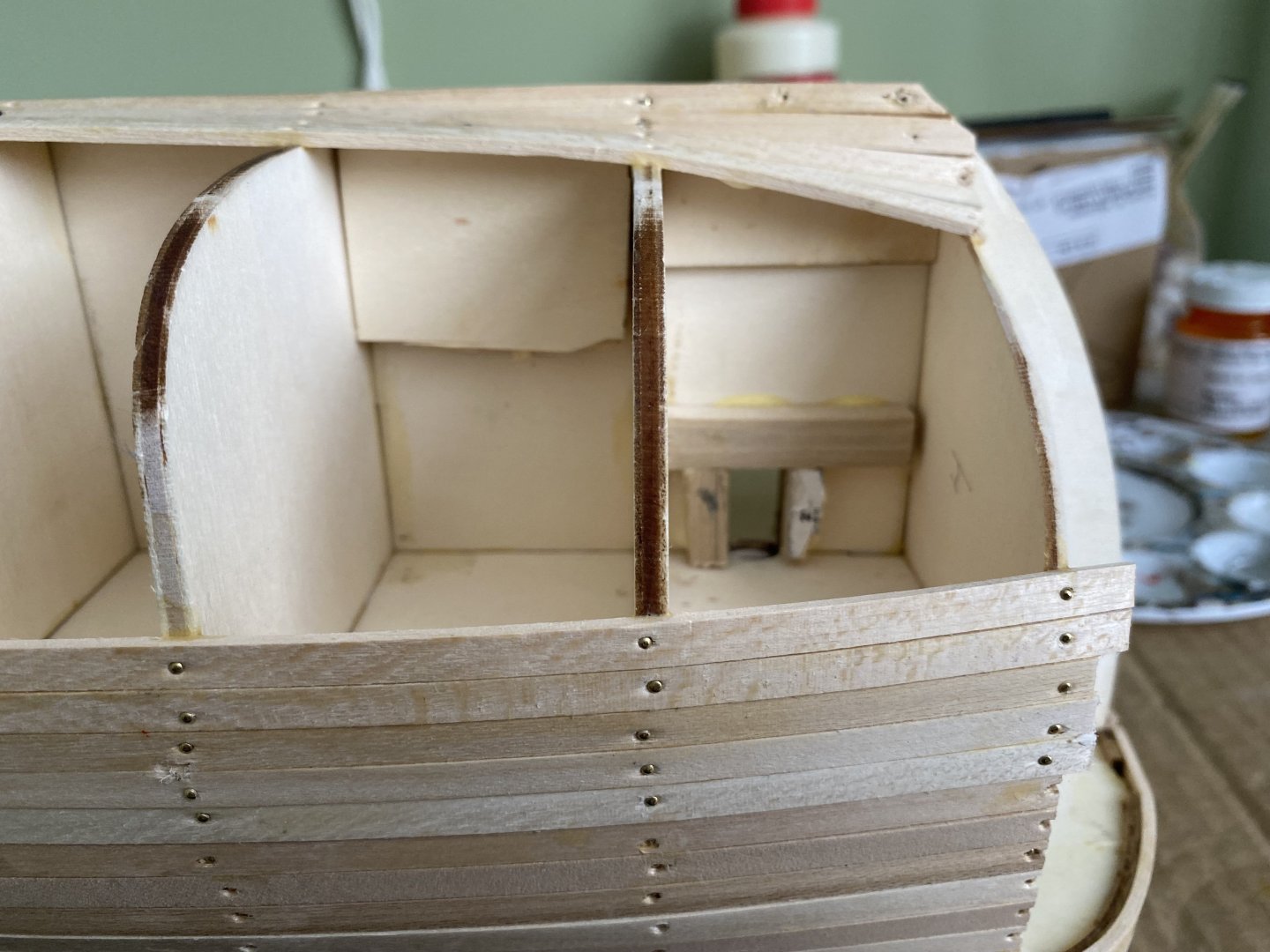

Progress continues on the planking. Pace is slower now that I am at the area where I need to put it together like a puzzle. Before I completely close up the hull I decided to use some scrap wood to reinforce the seat for the three masts also added some scrap material to widen the false keel where my the screws from my display stand will penetrate the keel up into the inner hull.

- Ian_Grant, wvdhee and jpalmer1970

-

3

3

-

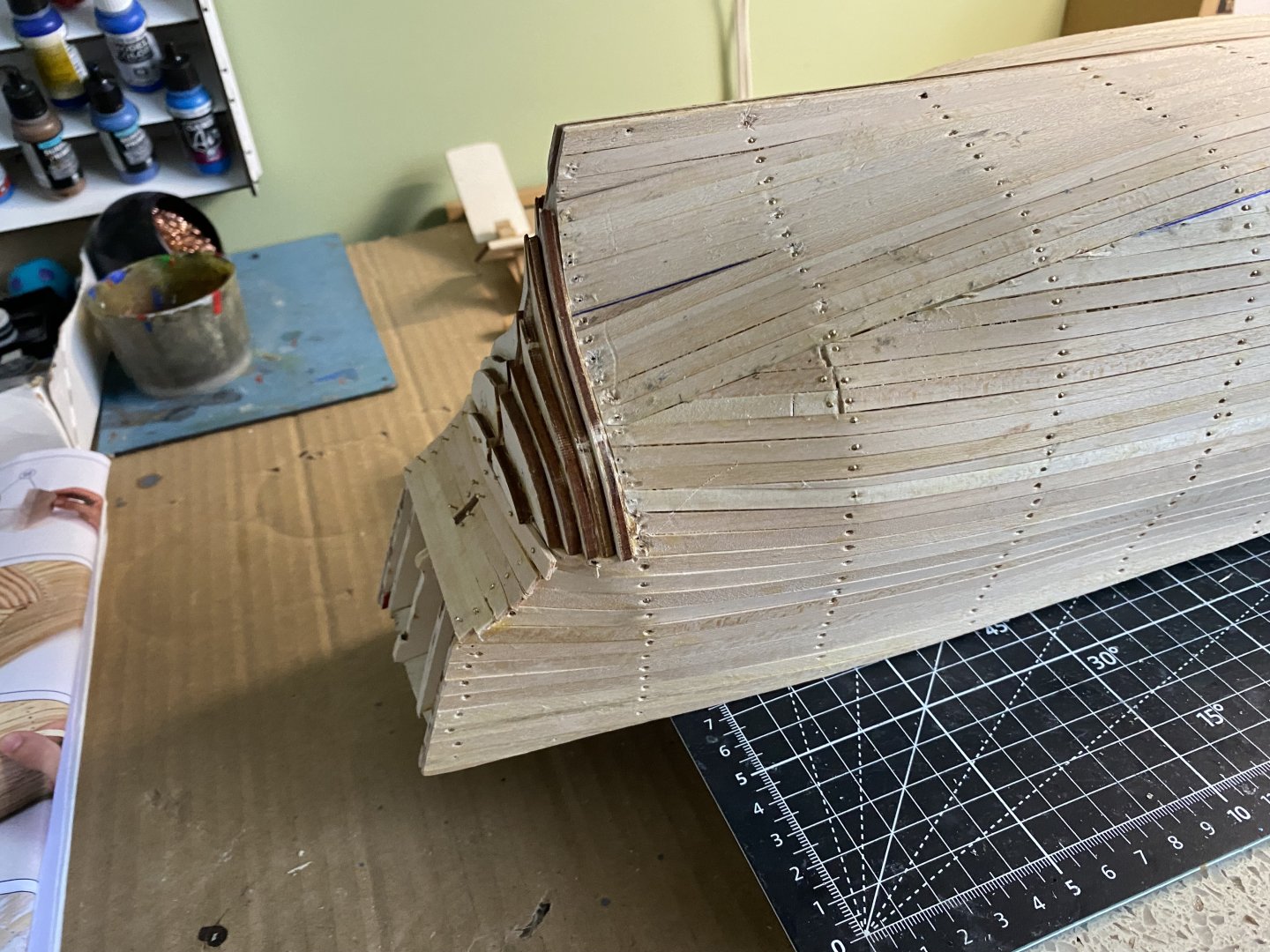

Finished the upper 1st planking on both sides of the ship now and will now start the bottom area. OcCre had me do the section from the lower deck up to the top of the bulwarks first and then start at the false keel and work my way up to meet. This next section will require numerous pie shaped pieces to fill in between planks as you can see in the last example photo. Looking to reuse, with modifications, the base I originally made for my Soleil Royal but now have in a diorama.

- jpalmer1970 and wvdhee

-

2

2

-

Yes Ian I have looked at them. They also hav a great line of street cars/trams.

I bought an airbrush kit on Amazon back when I started building the Victory. With a little practice you would have no trouble. I use Vallejo Model Air paints with it. They are designed especially for use with airbrushing.

- jpalmer1970 and Ian_Grant

-

2

2

-

-

-

-

-

Good morning shipaholic. Just found your build after you commented over on mine. Some beautiful work you have done. Will definitely bookmark your’s for reference.

-

-

Yes Kevin. So far everything has been part of the kit. Got a big box of different size wood, a sort of plastic tackle box filled with all sorts of bits and pieces hardware, and an instruction book telling me the size to cut the wood. Great thing I have a caliper! The instructions might call for a 2x5mm piece of wood for example to complete a task. There are numerous bundles of sizes. Some 2x4, 2x5, 2x6, etc. Caliper makes that part easy. Very different from a plastic kit with pieces attached to sprues. Yes I like the deck better as well. As I told Marc it was different working with wood instead of plastic.

Always great to hear from you Kevin. I continue to check in on your build but don’t always comment. Beautiful work as always my friend.

Endeavour by Bill97 - OcCre - 1/54

in - Kit build logs for subjects built from 1751 - 1800

Posted

Thanks Ian. It has actually been quite enjoyable employing my years of woodworking experience. There have truly been some challenges so far but I hope I have overcome them successfully. Now once I get into making everything that goes on the deck, and above the deck, we will see if I still feel the same!