marsalv

NRG Member-

Posts

620 -

Joined

-

Last visited

About marsalv

Profile Information

-

Gender

Male

Recent Profile Visitors

-

Willi reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Willi reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Siggi52 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Siggi52 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

TJM reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

TJM reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Keith Black reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

Keith Black reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

Some Idea reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

Some Idea reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

marsalv reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

marsalv reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

marsalv reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

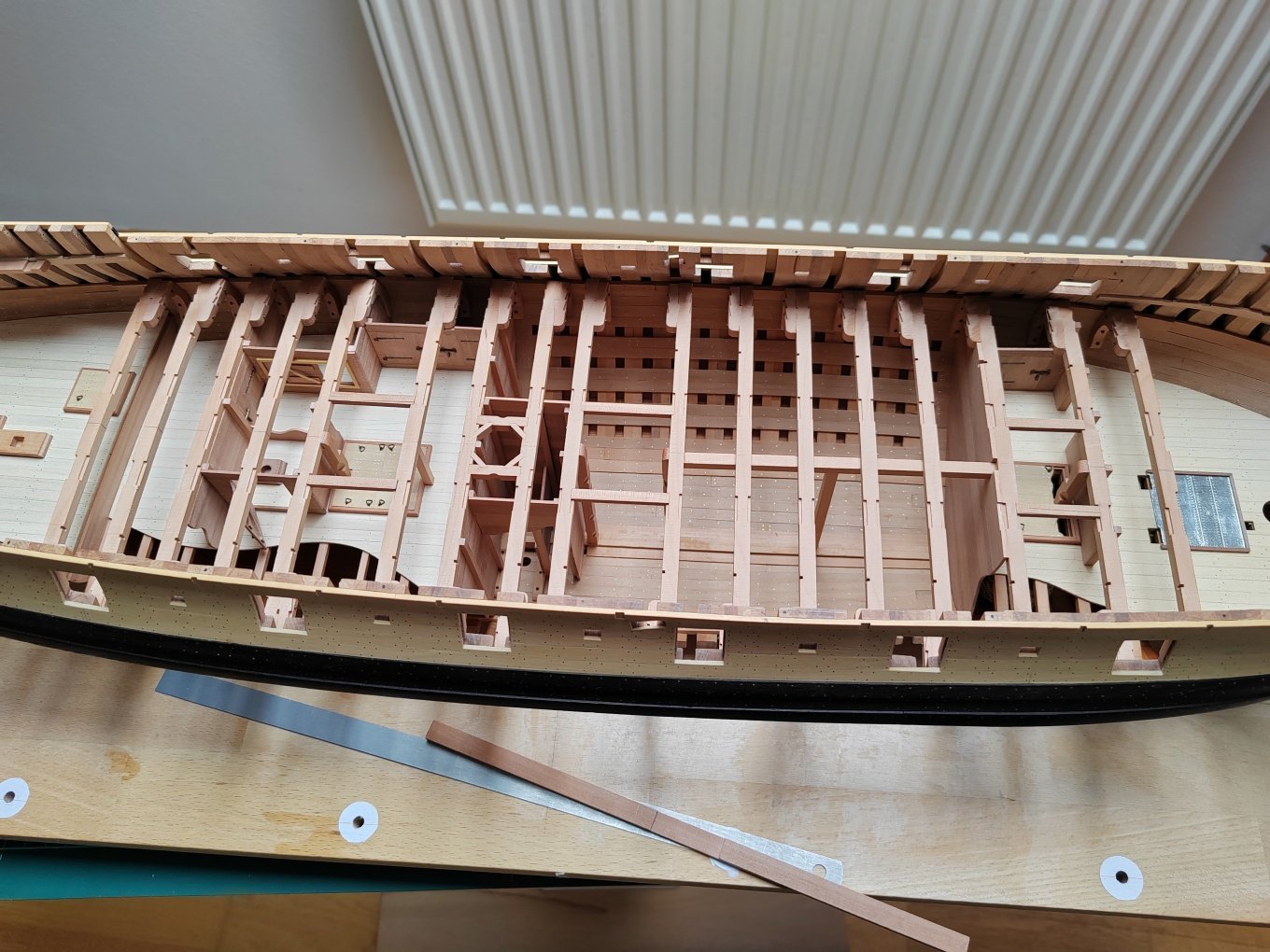

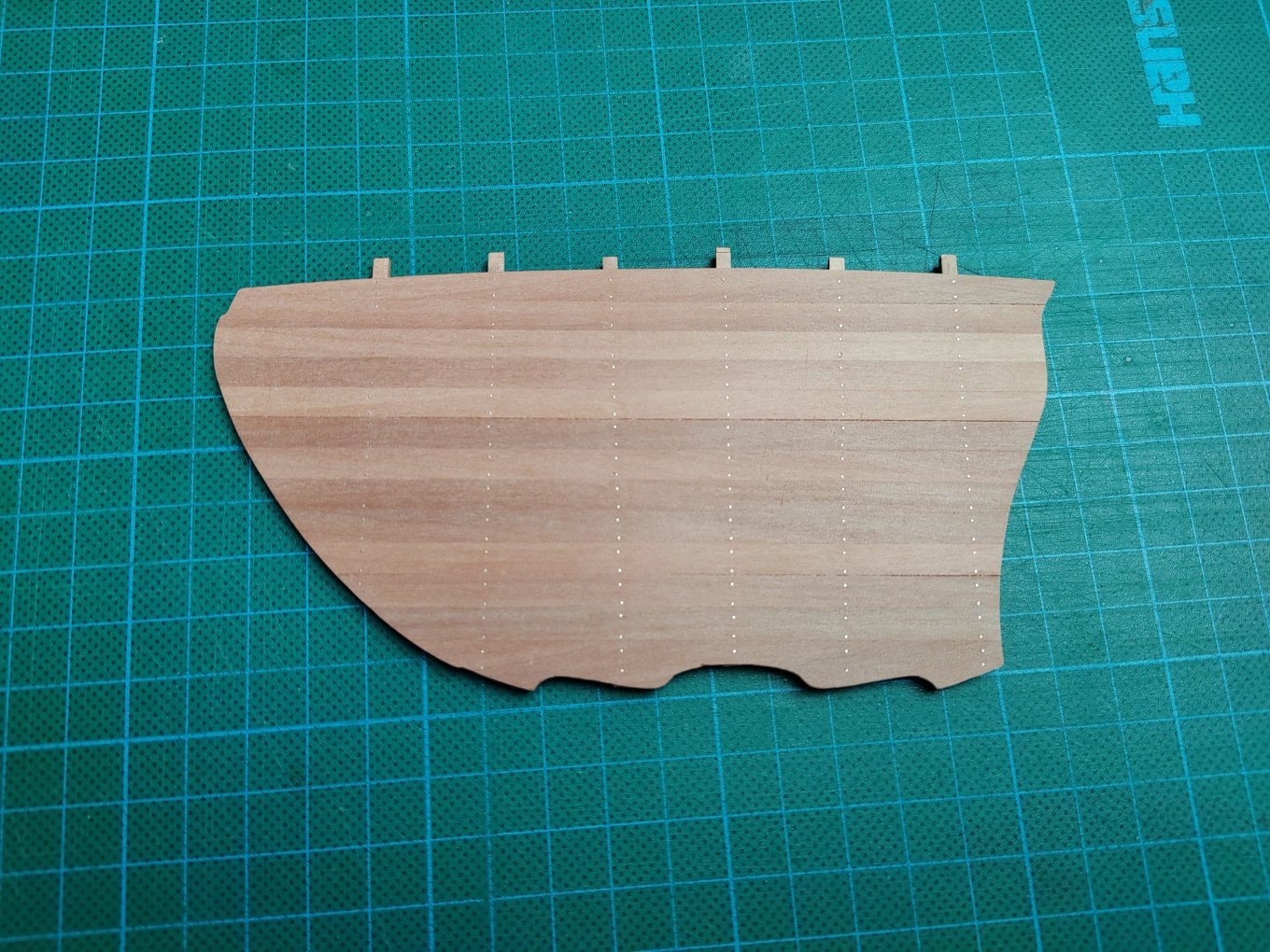

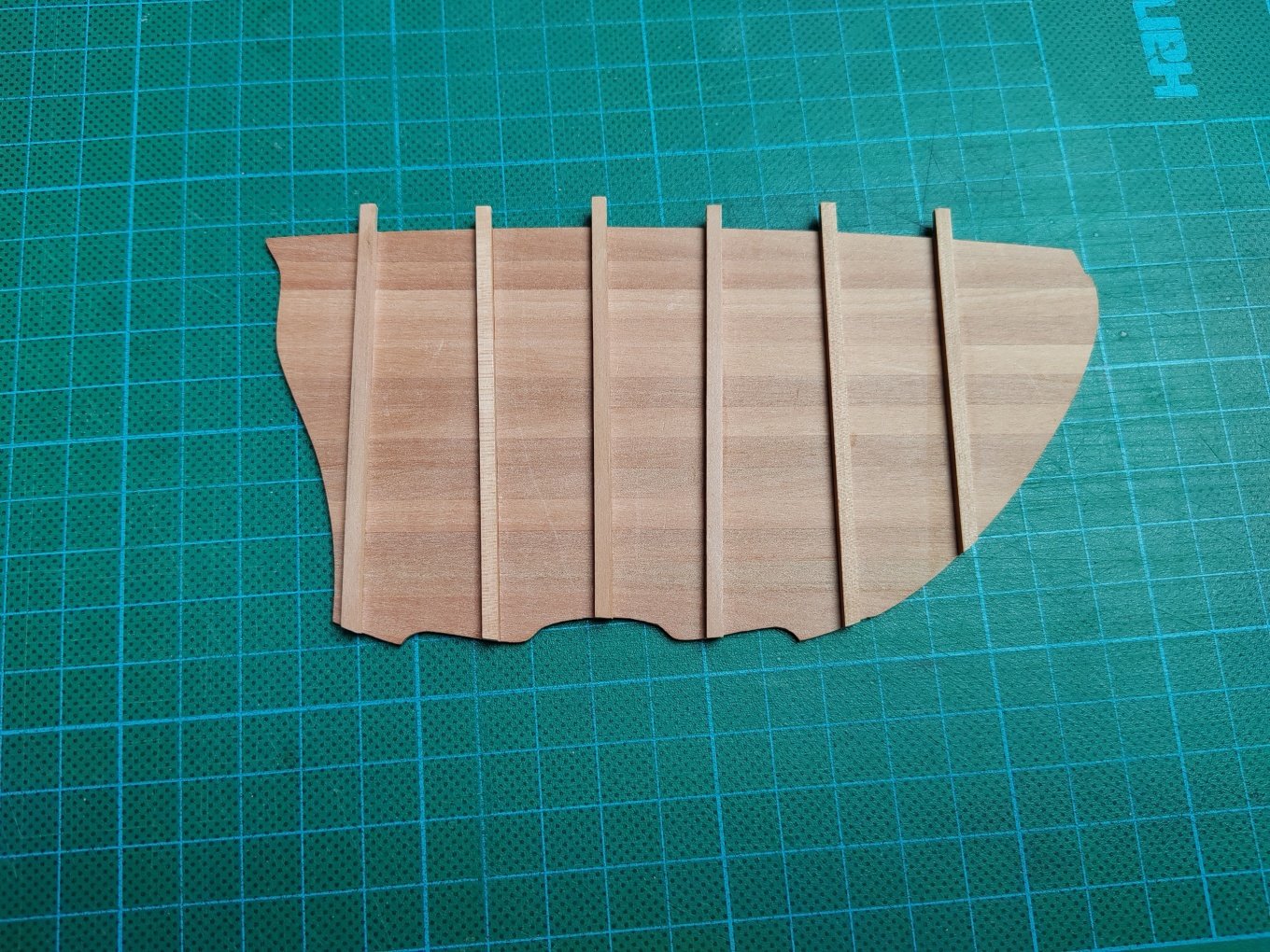

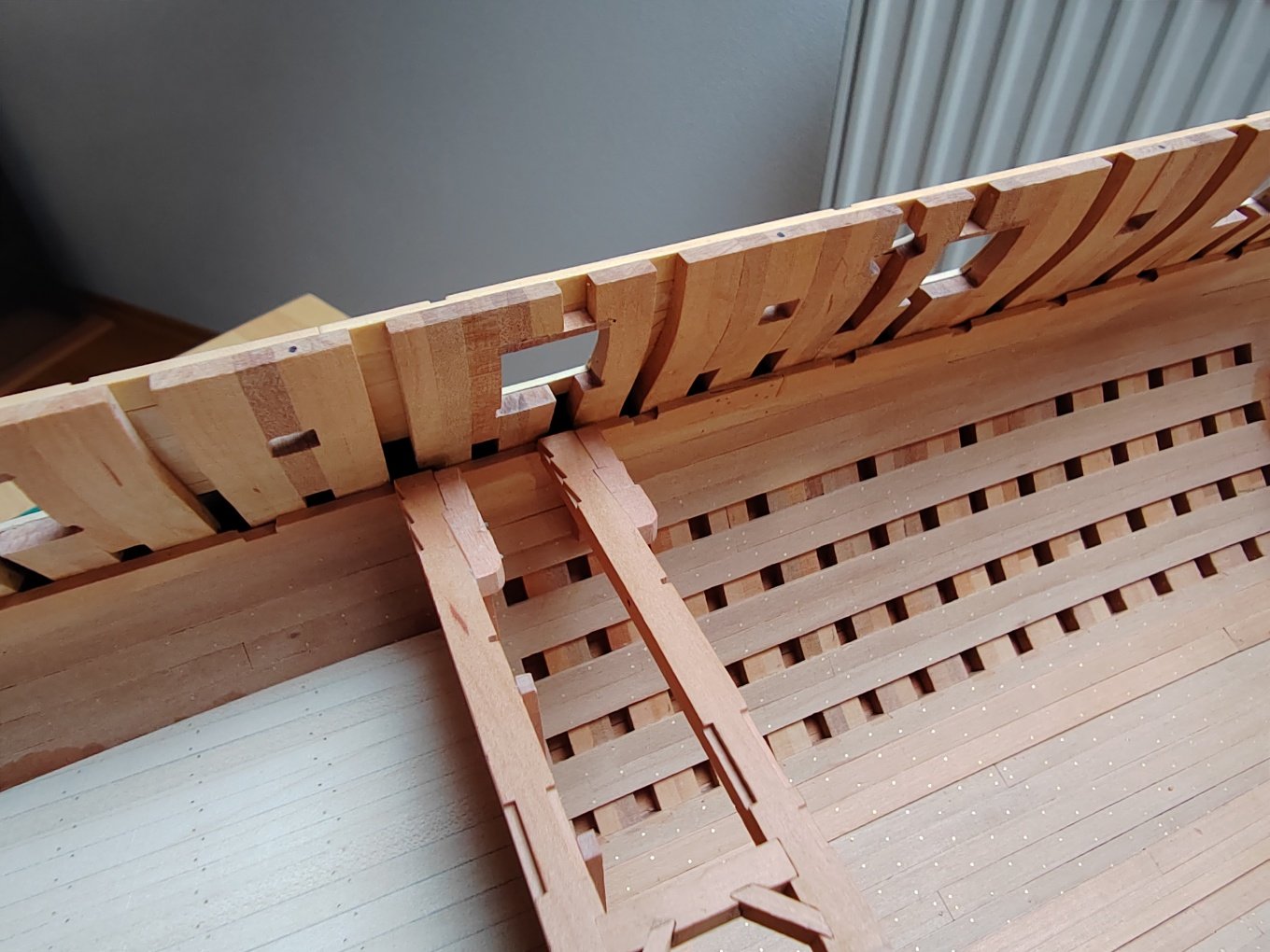

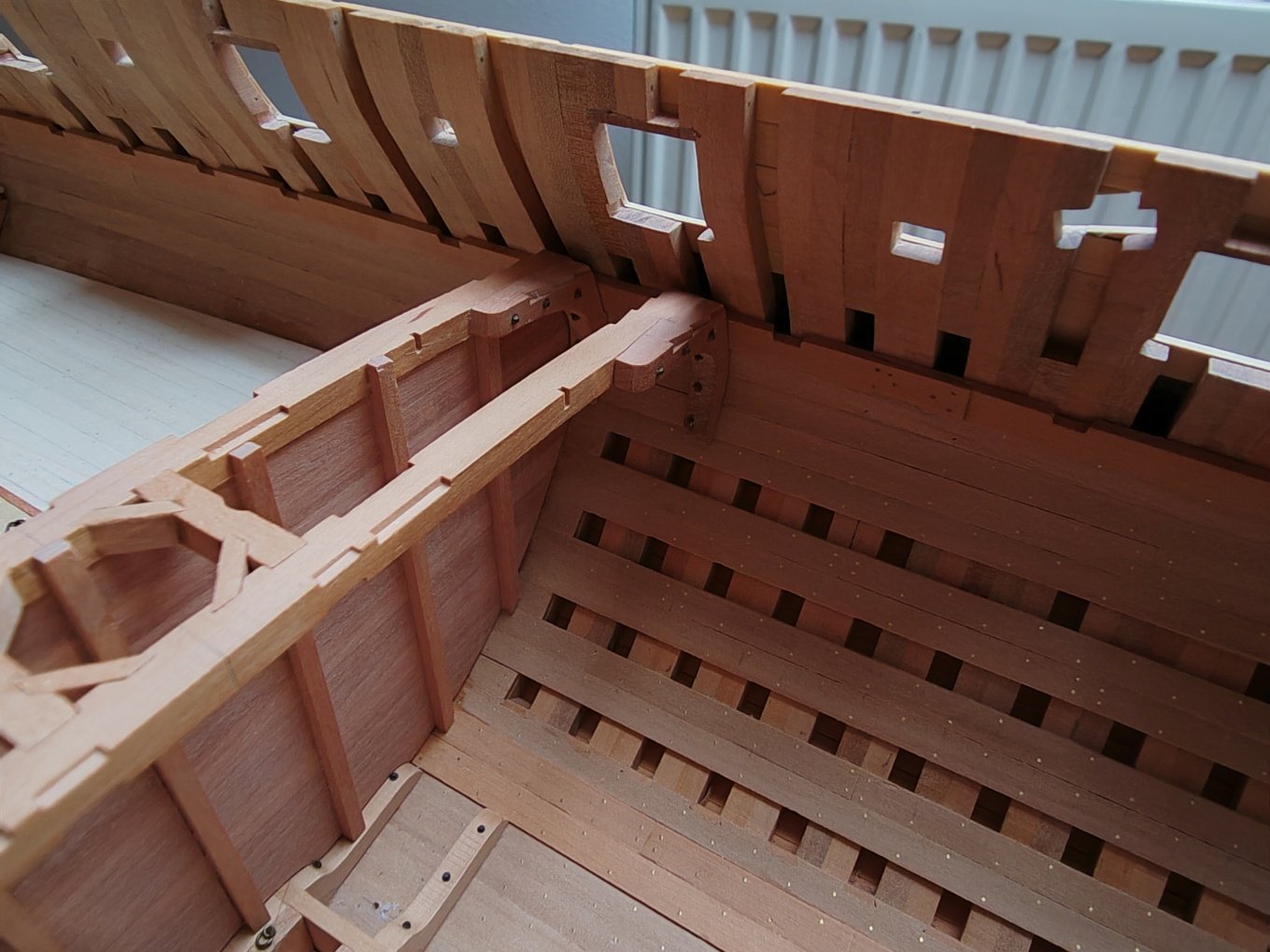

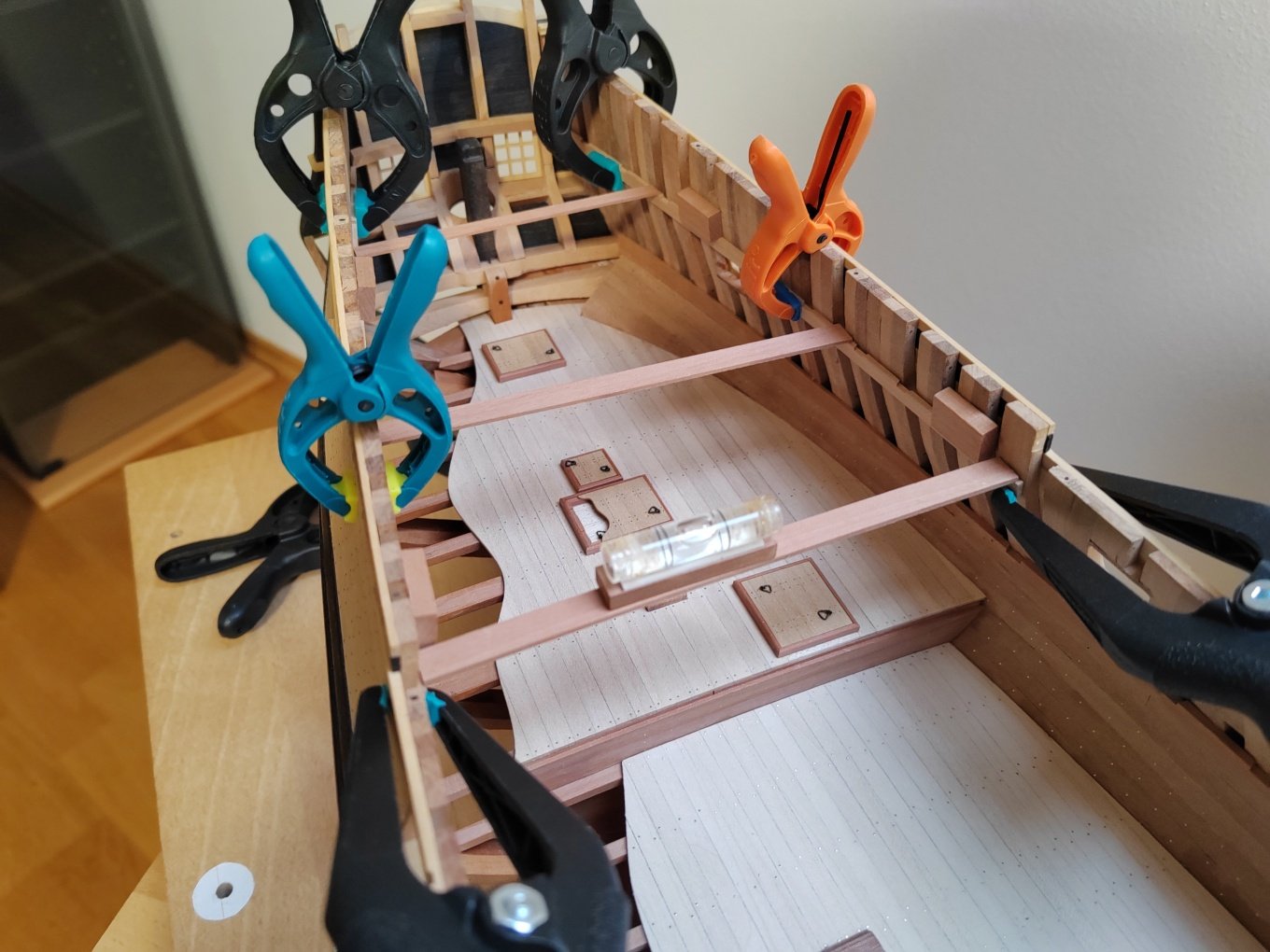

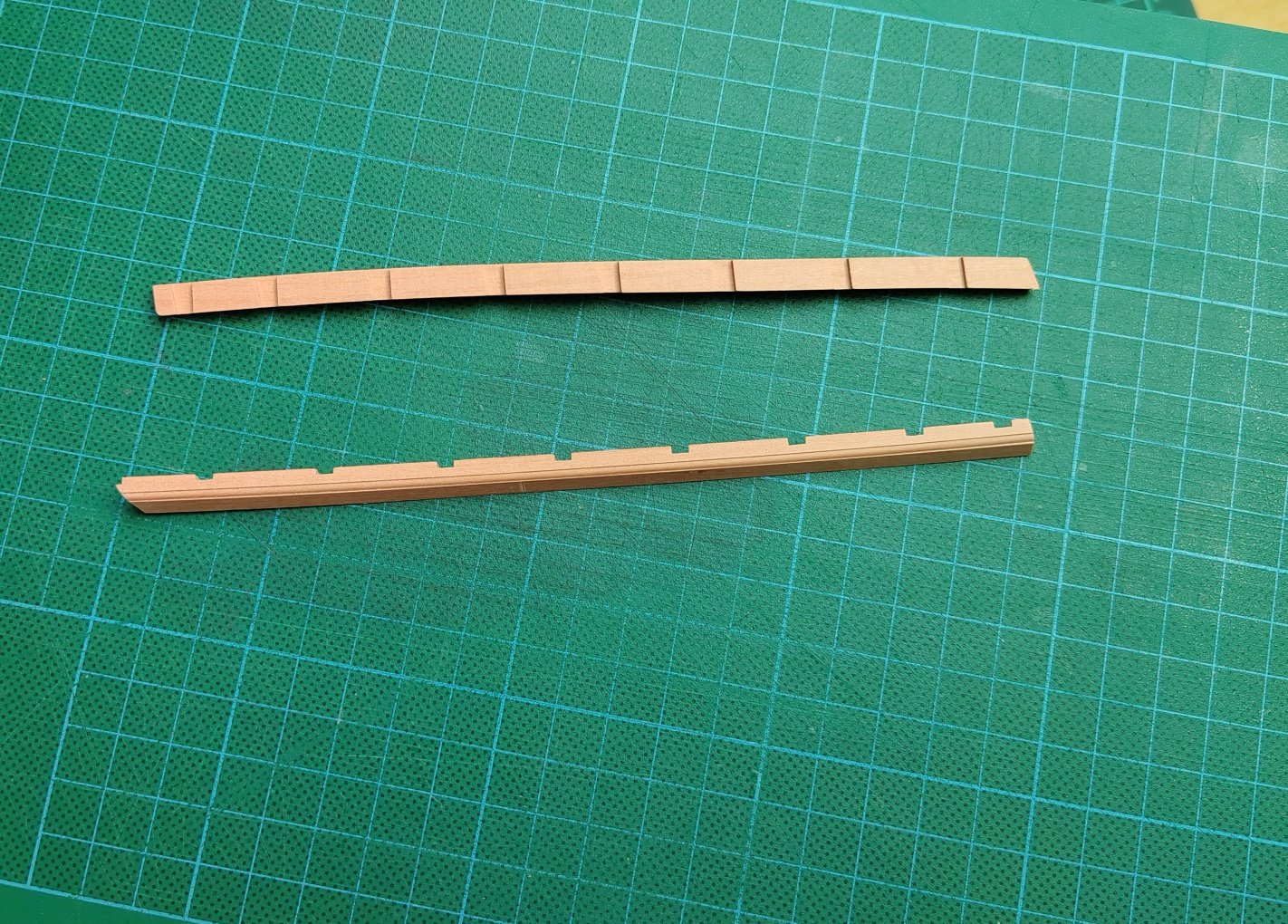

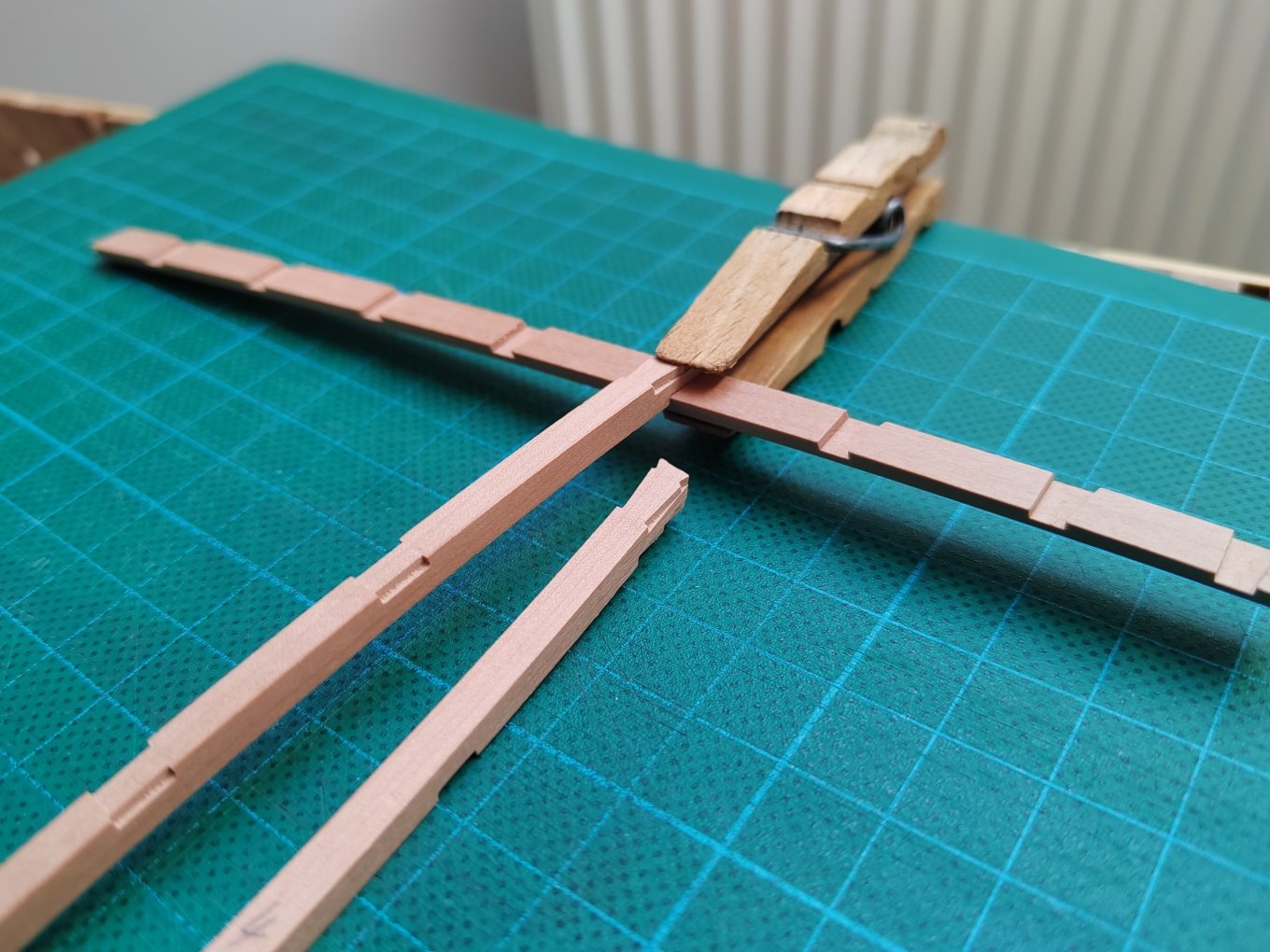

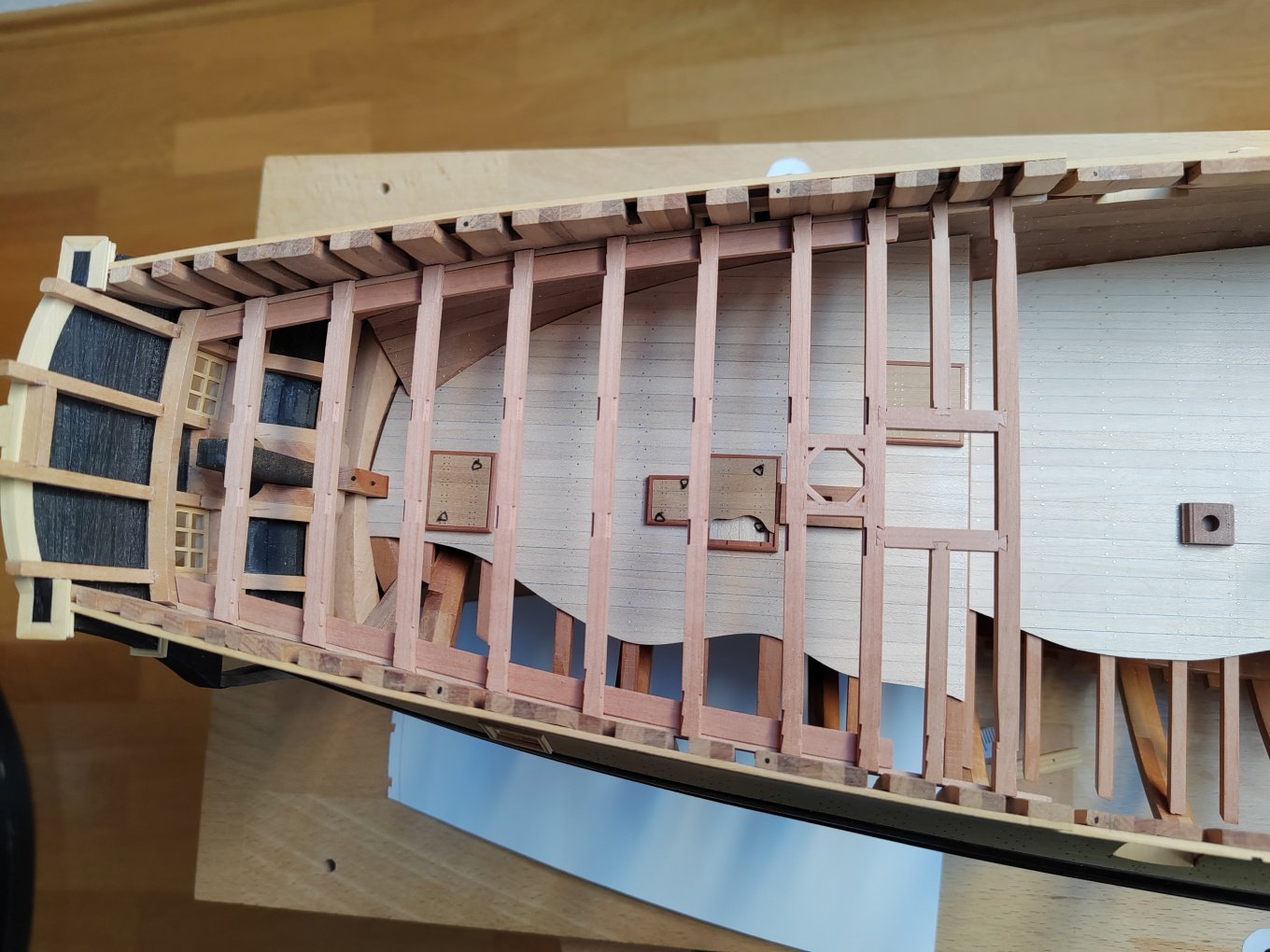

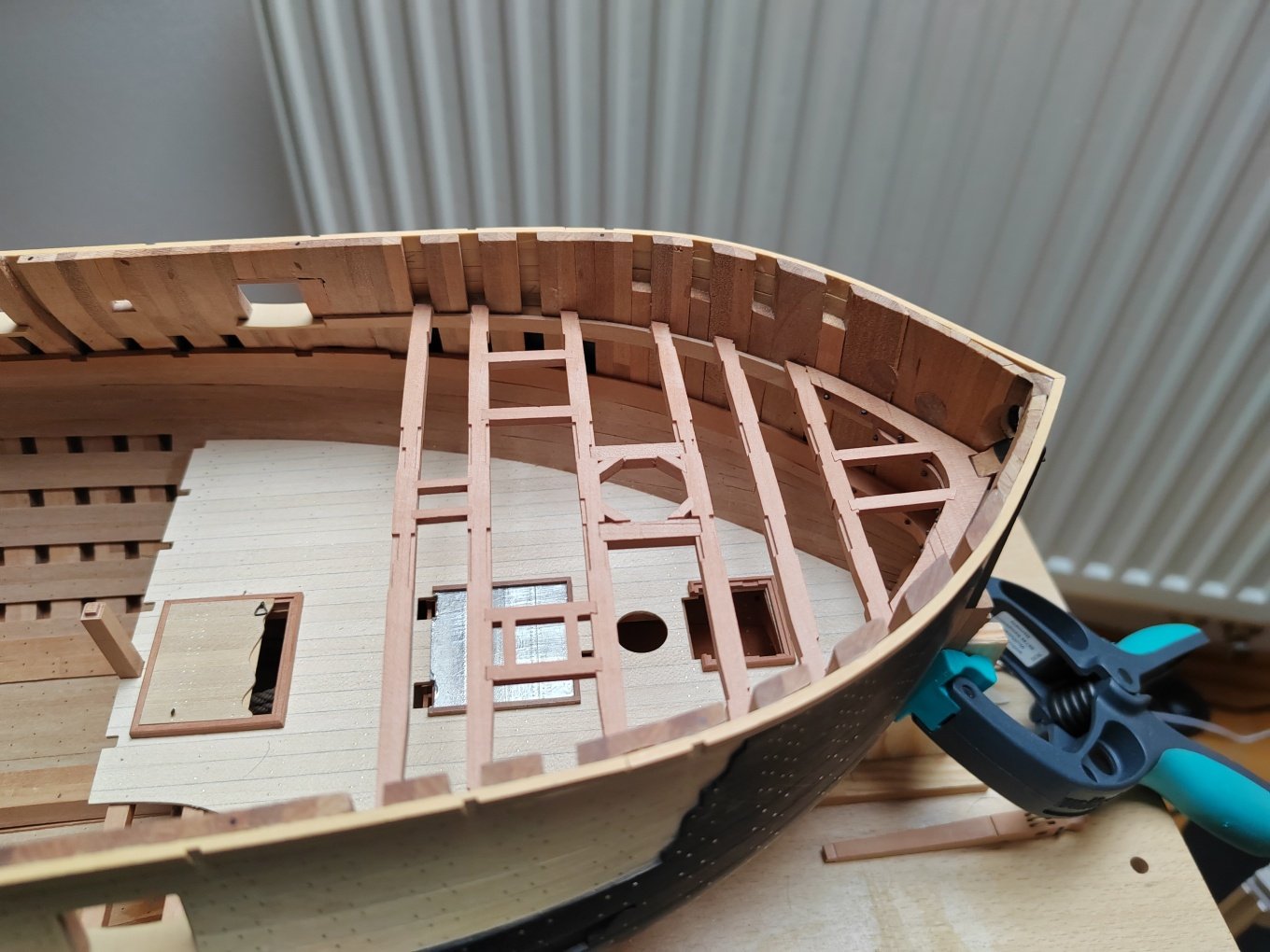

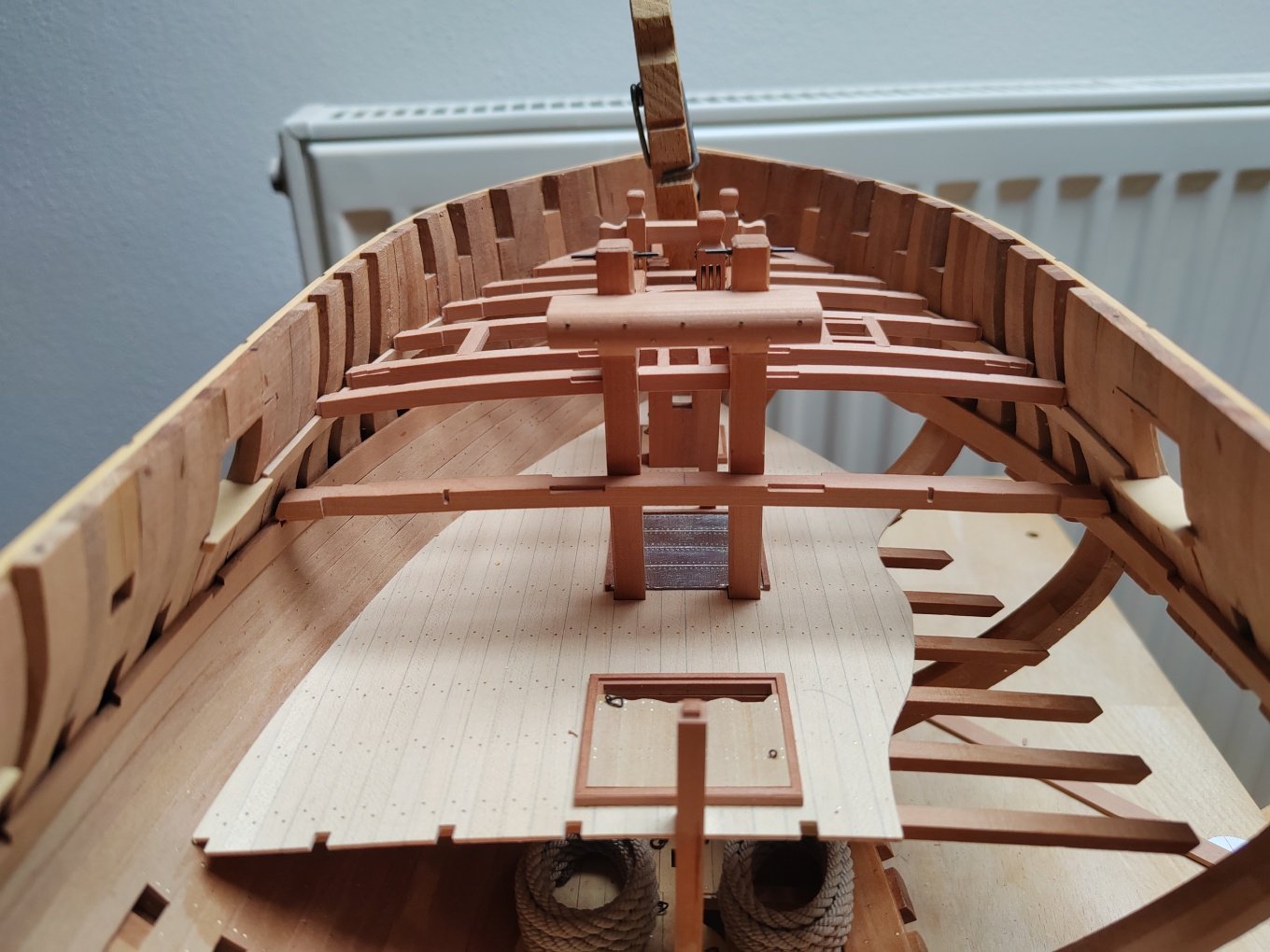

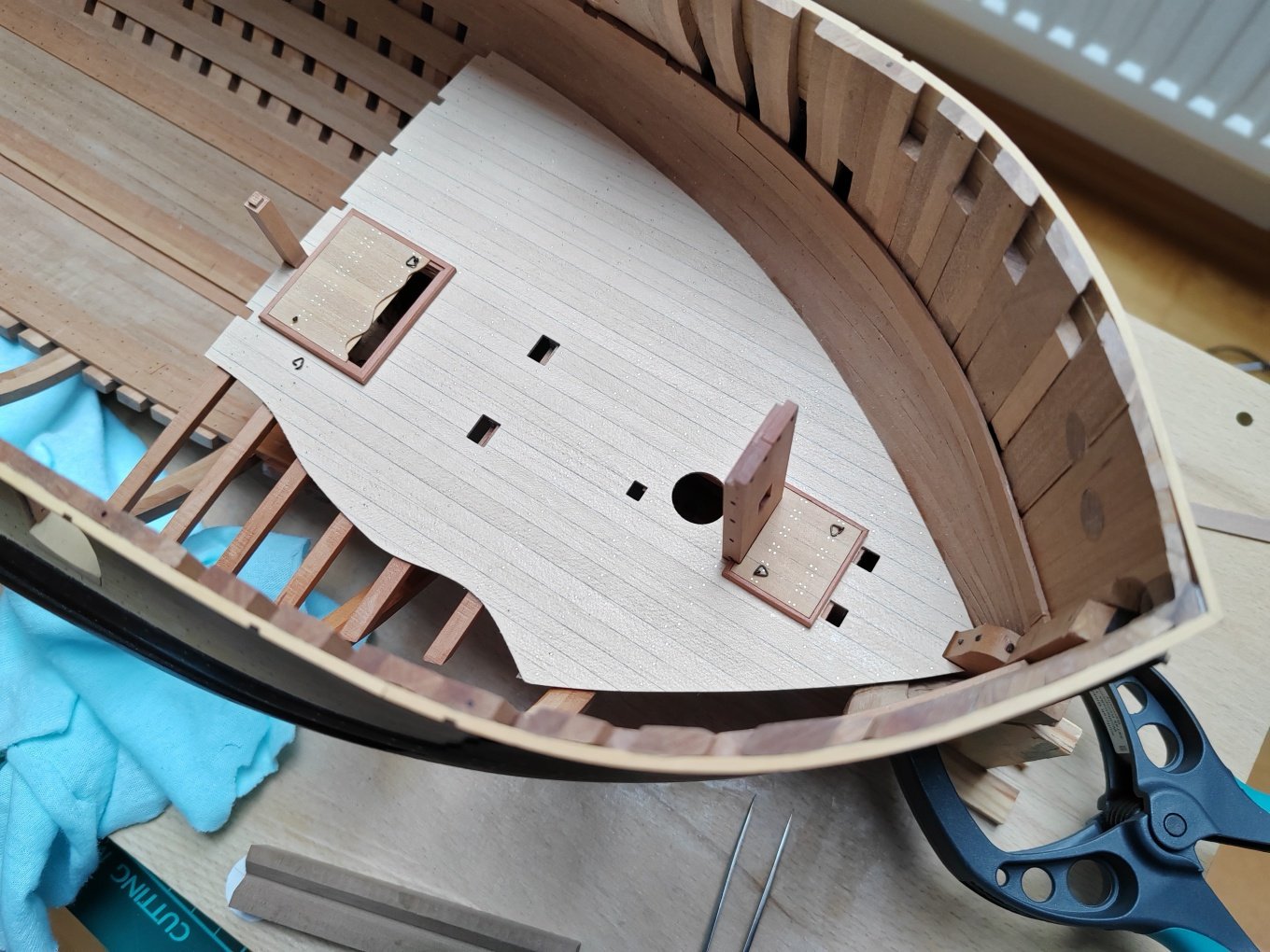

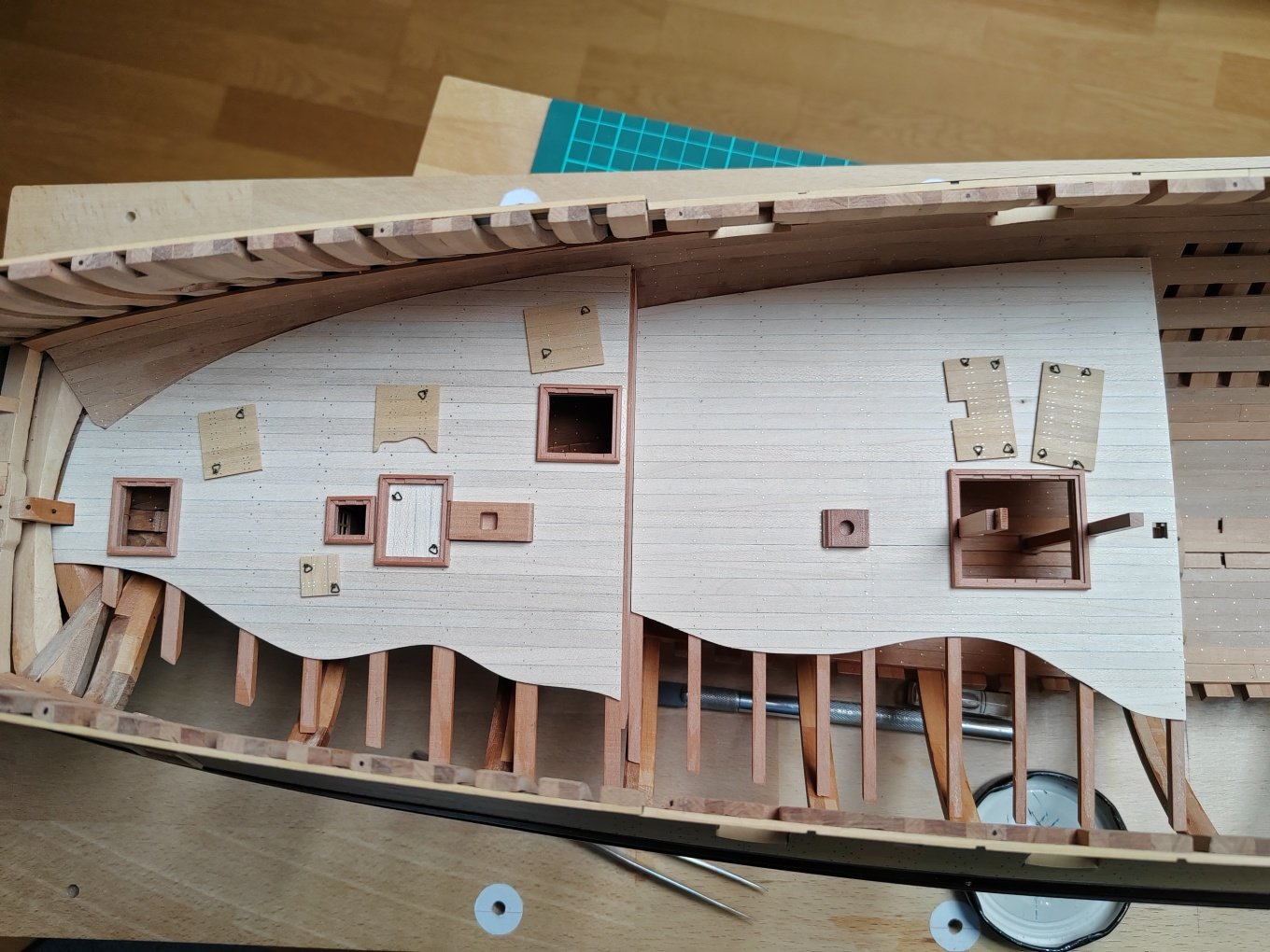

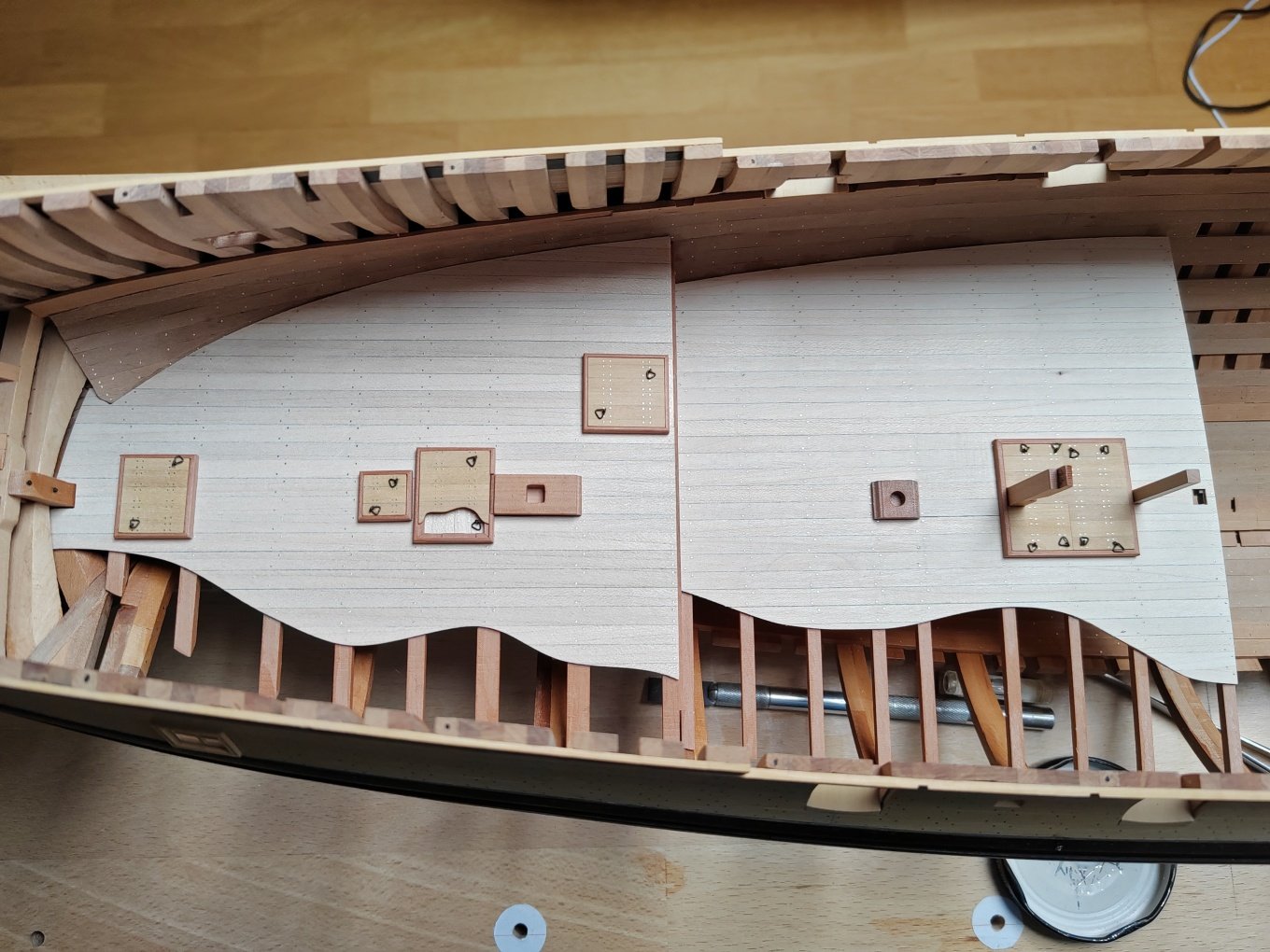

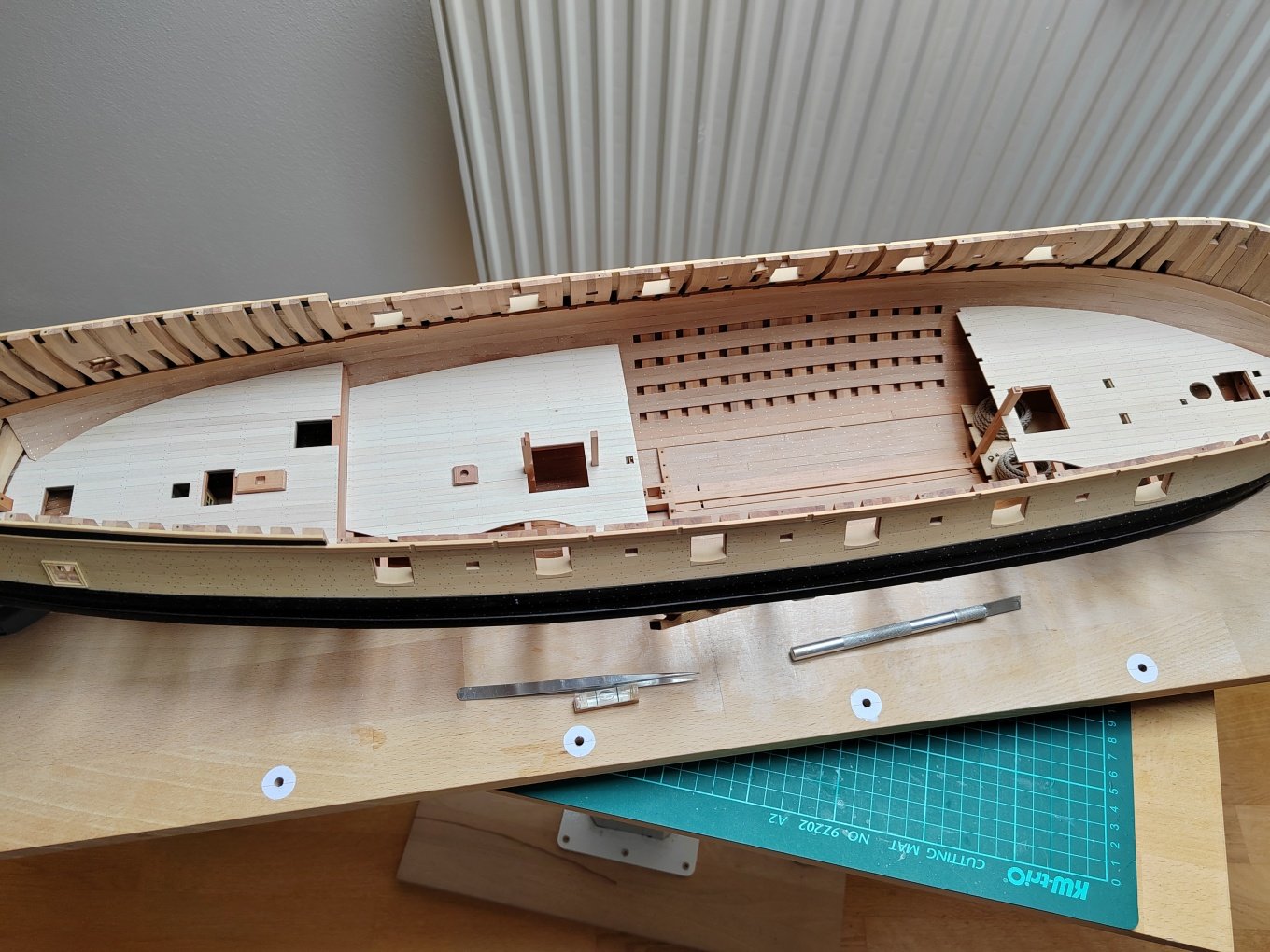

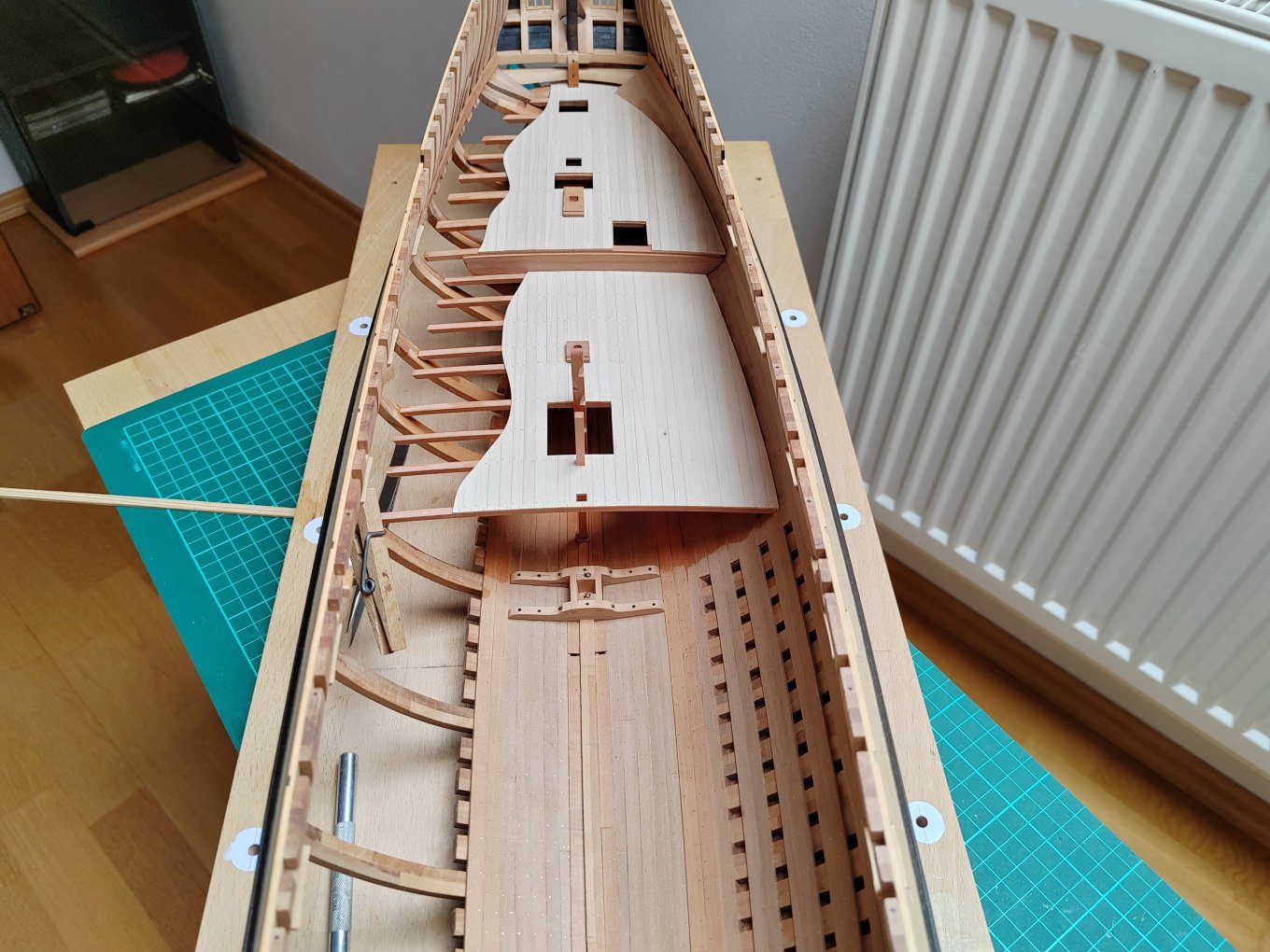

Thank you guys for nice comments . I gradually finished the remaining bulkheads in the center section of the hull and attached all the deck beams. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Thank you John and Happy New Year to all. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

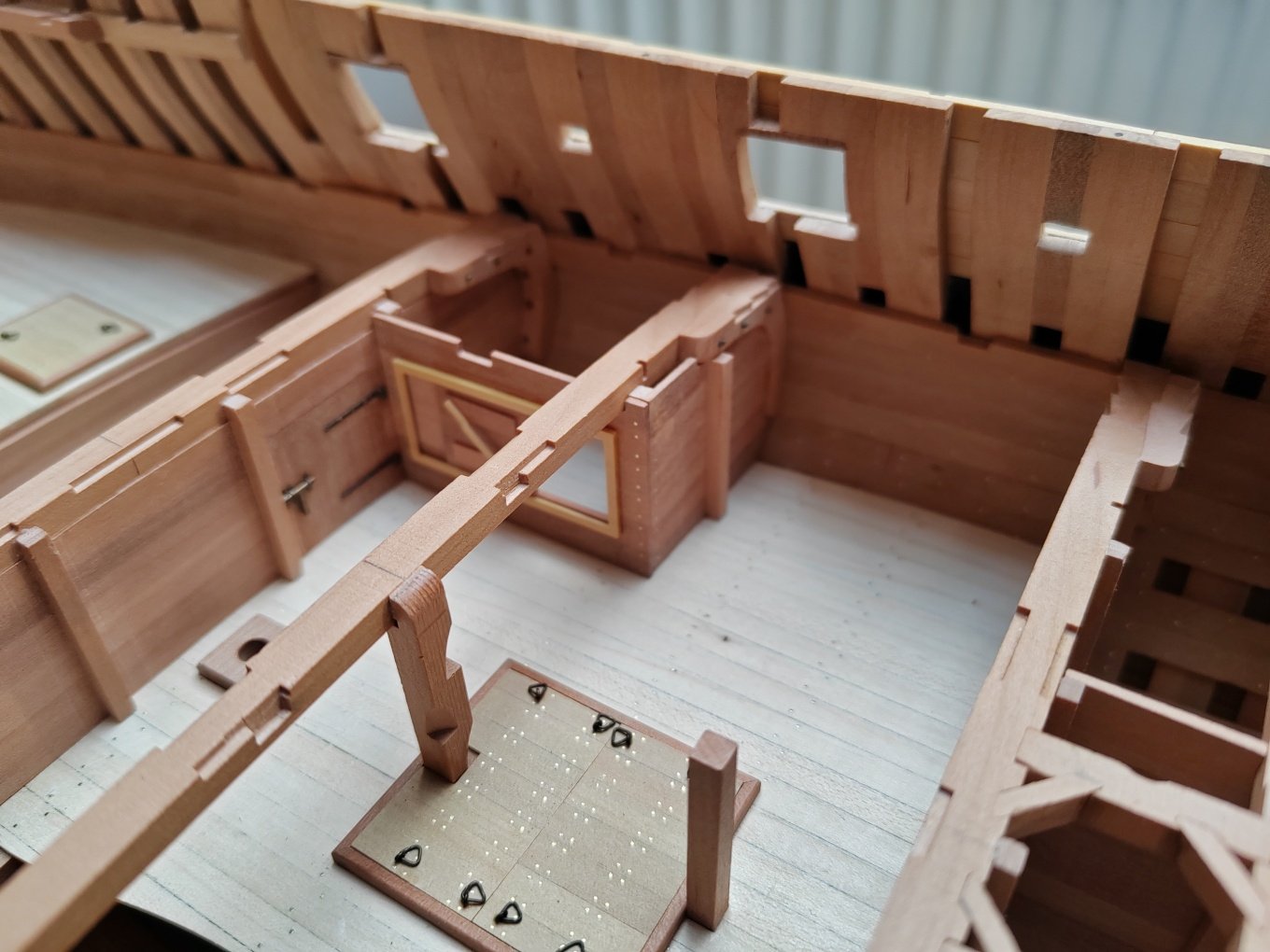

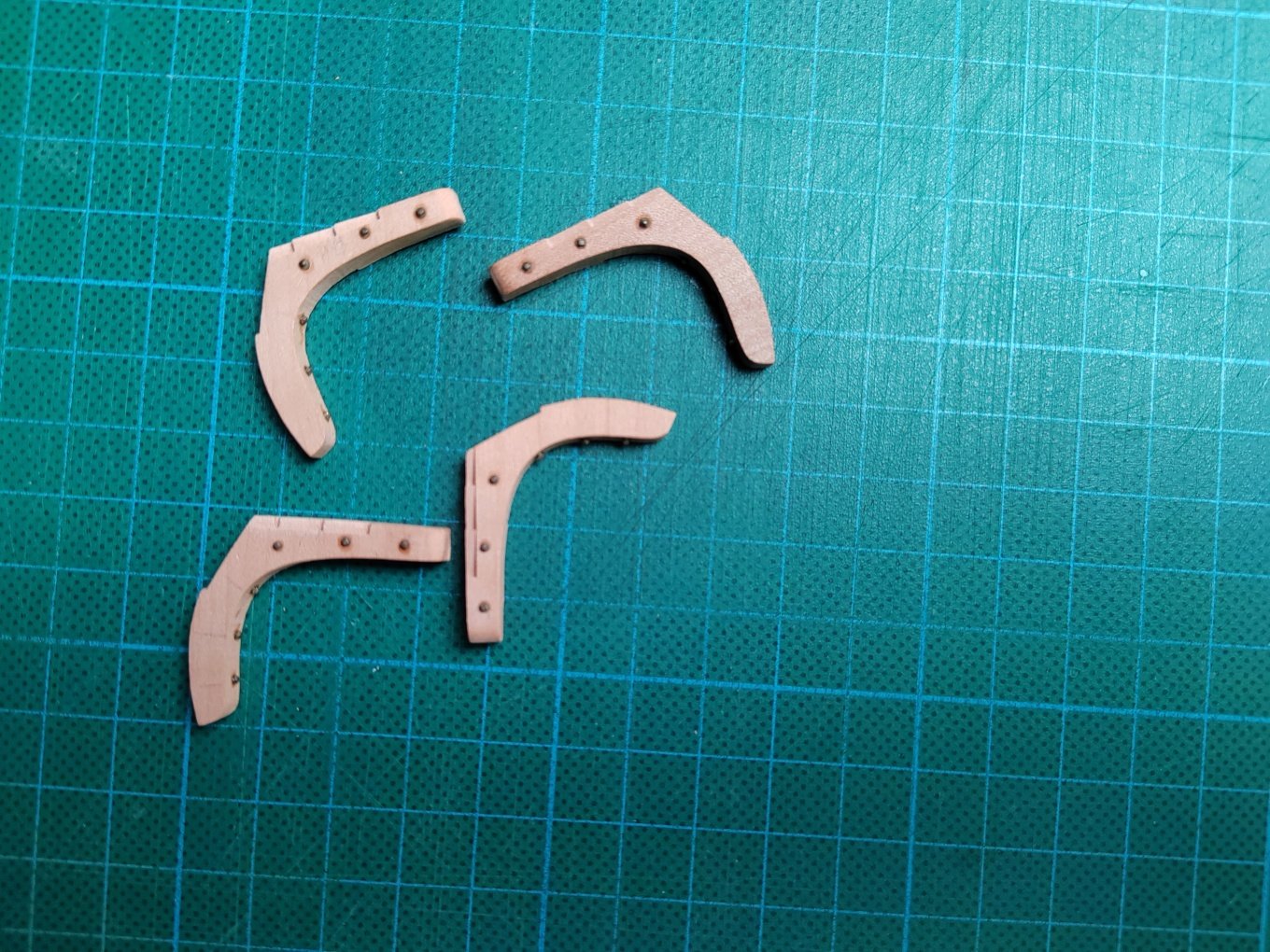

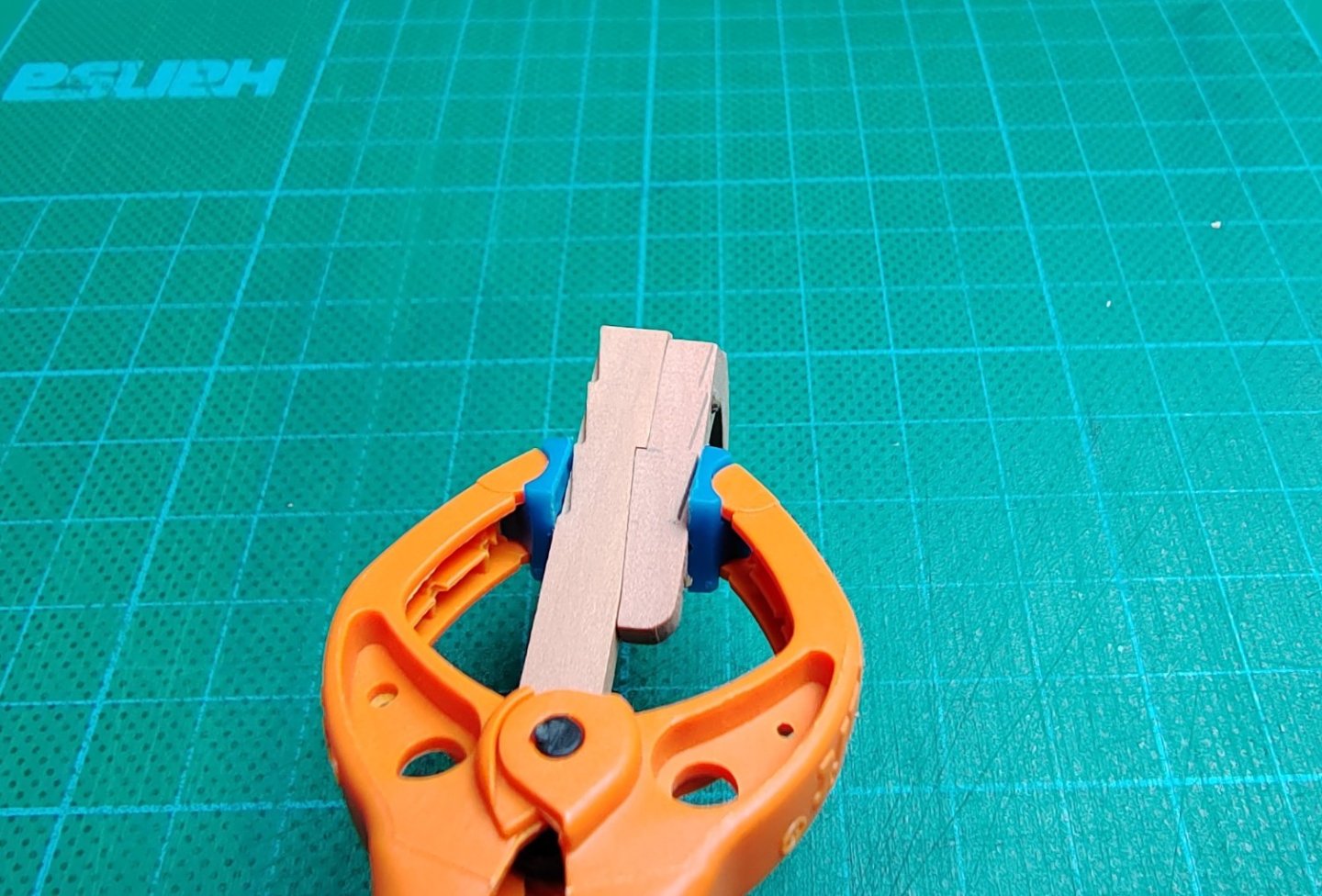

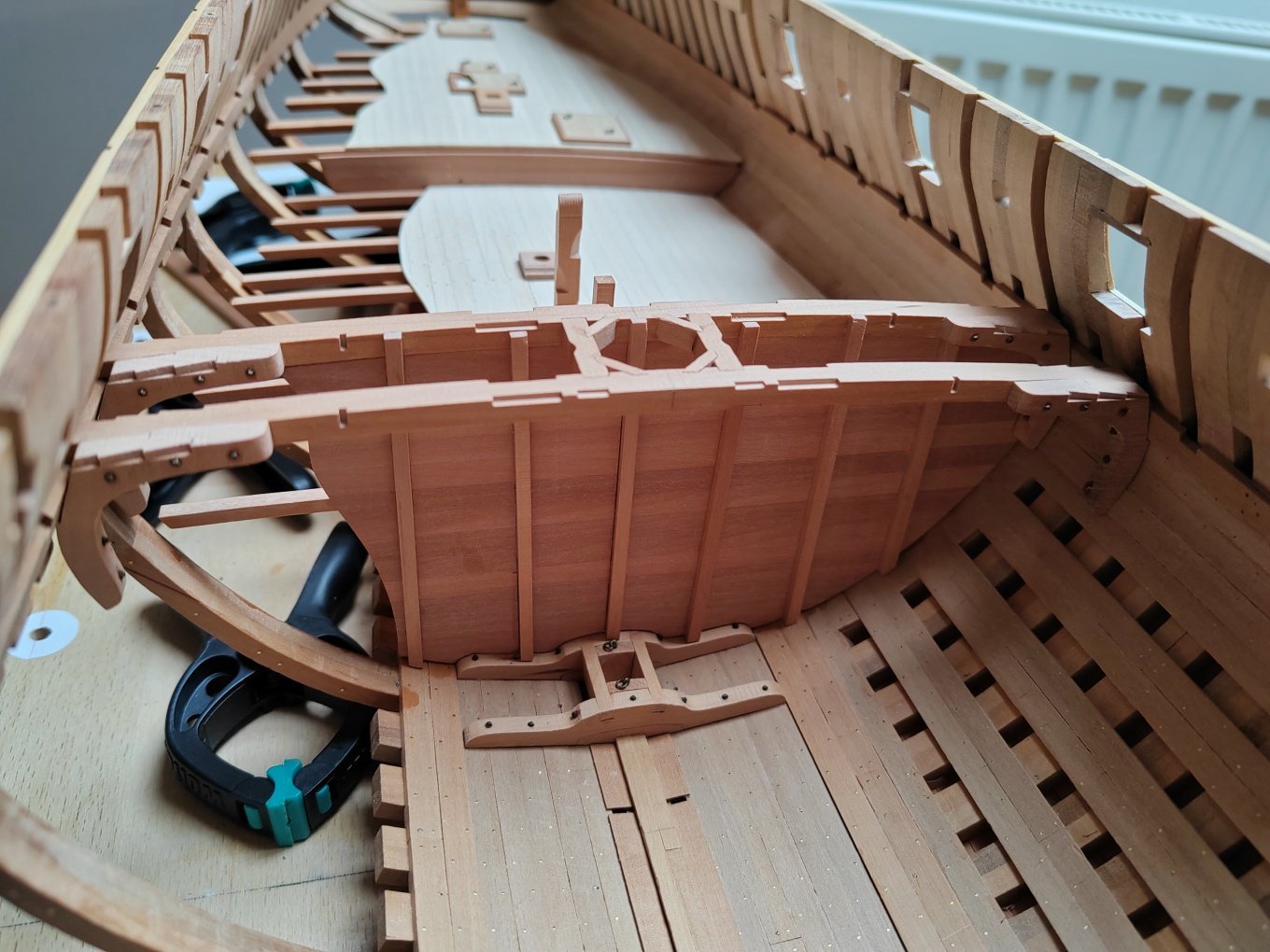

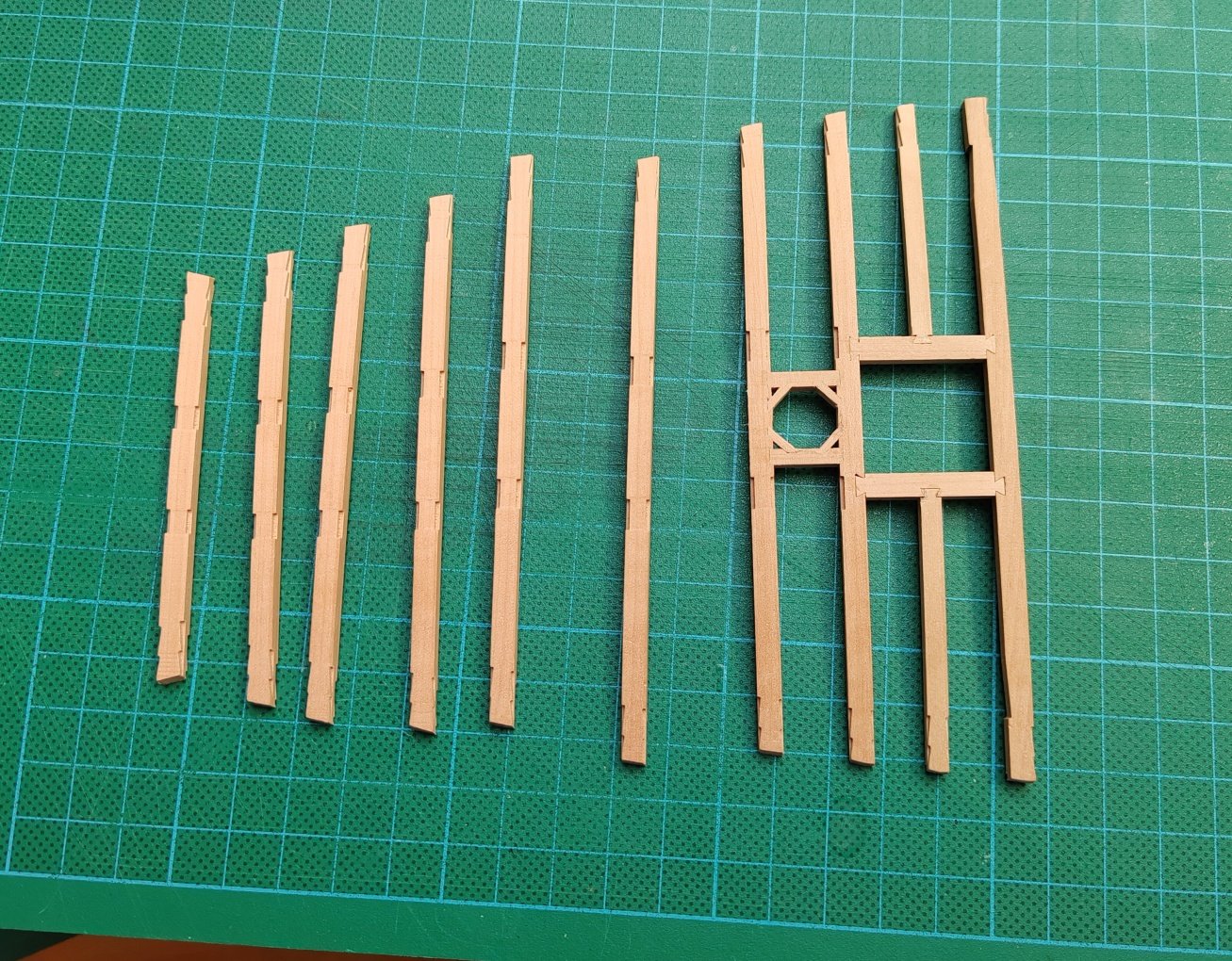

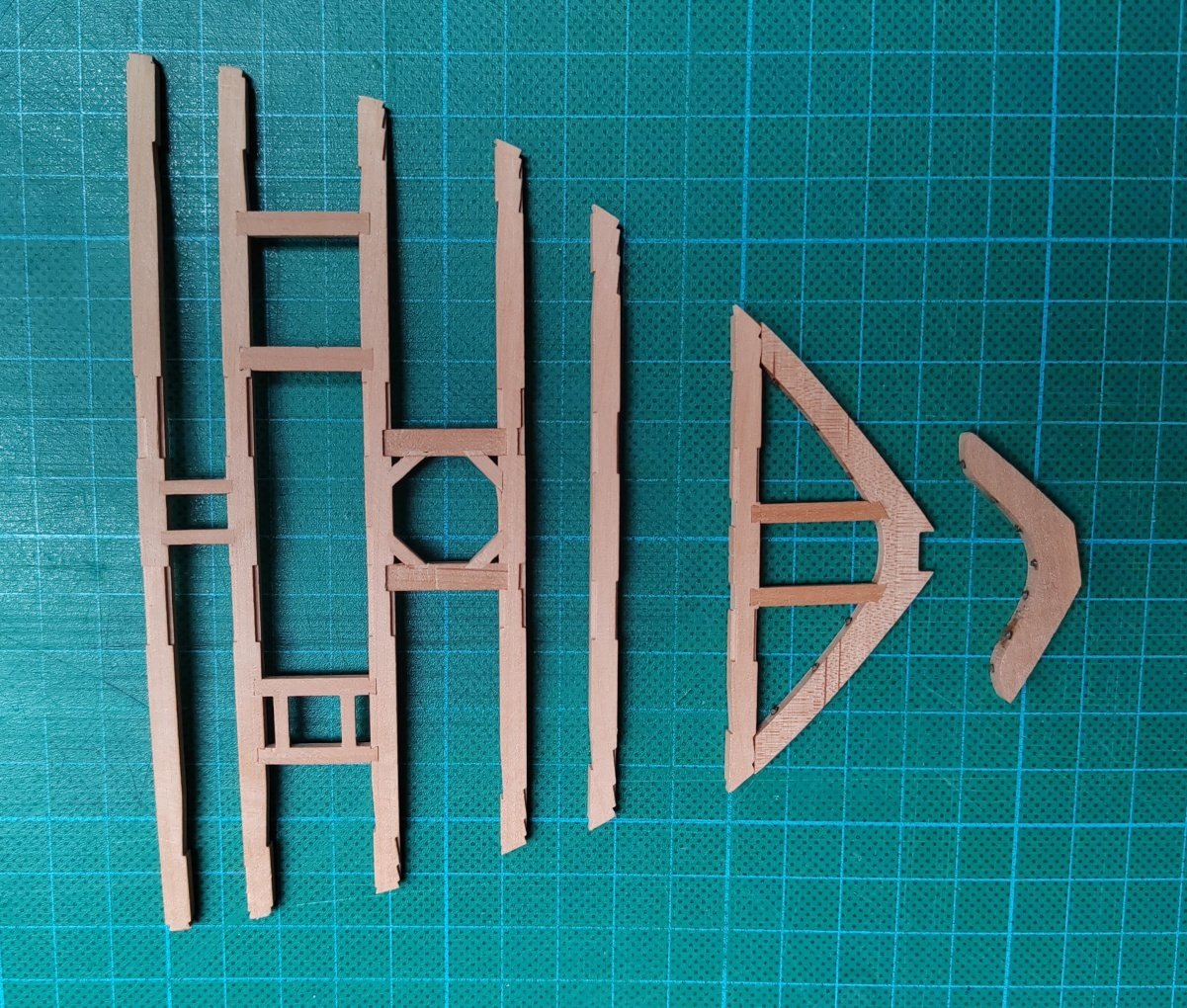

To Some Idea - Thank you for your very kind words. I agree with you that this is where the future of this hobby will go. I moved inside the hull. I made wooden knees and gradually started attaching individual deck beams, bulkheads and other internal structures. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

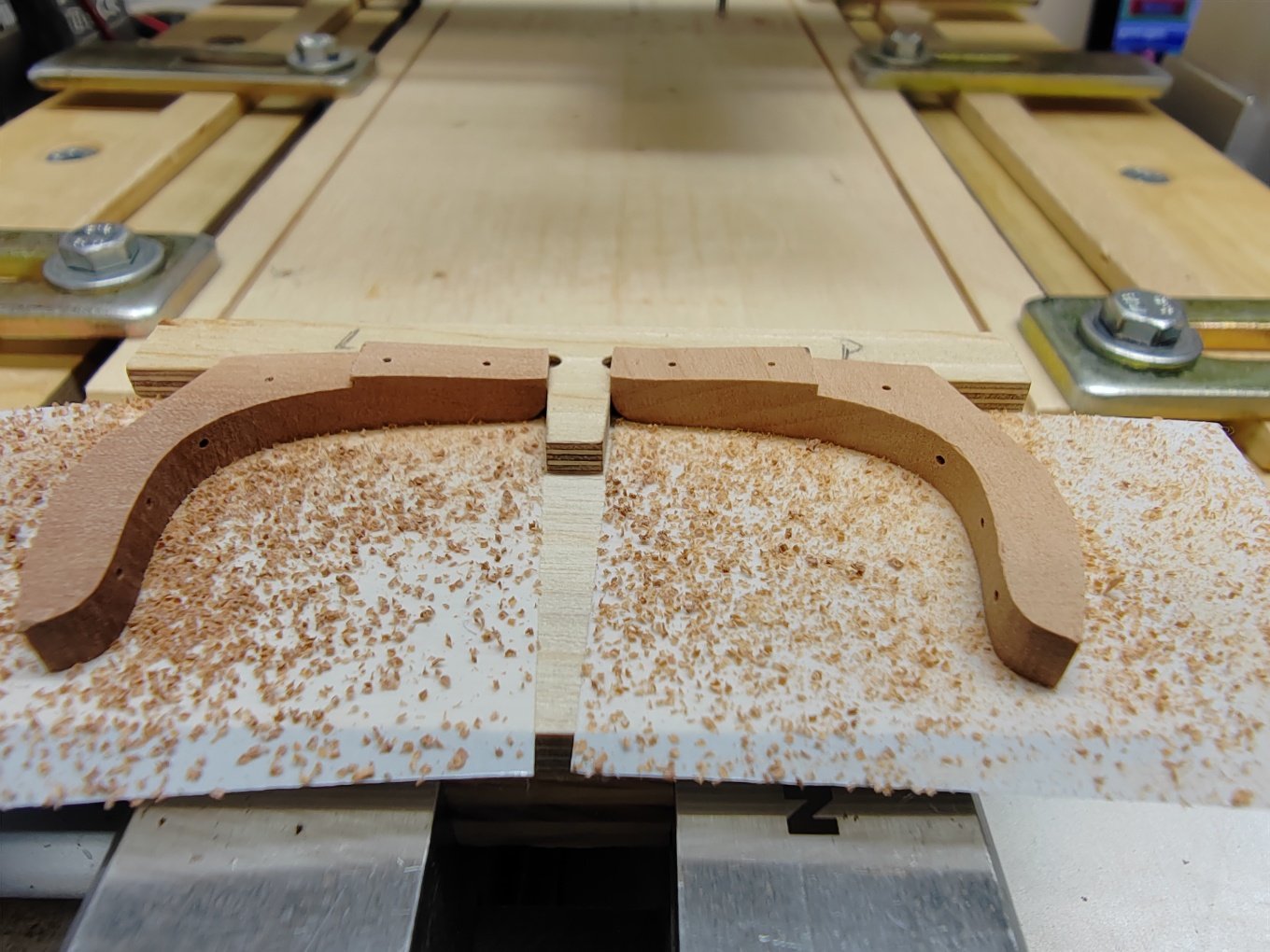

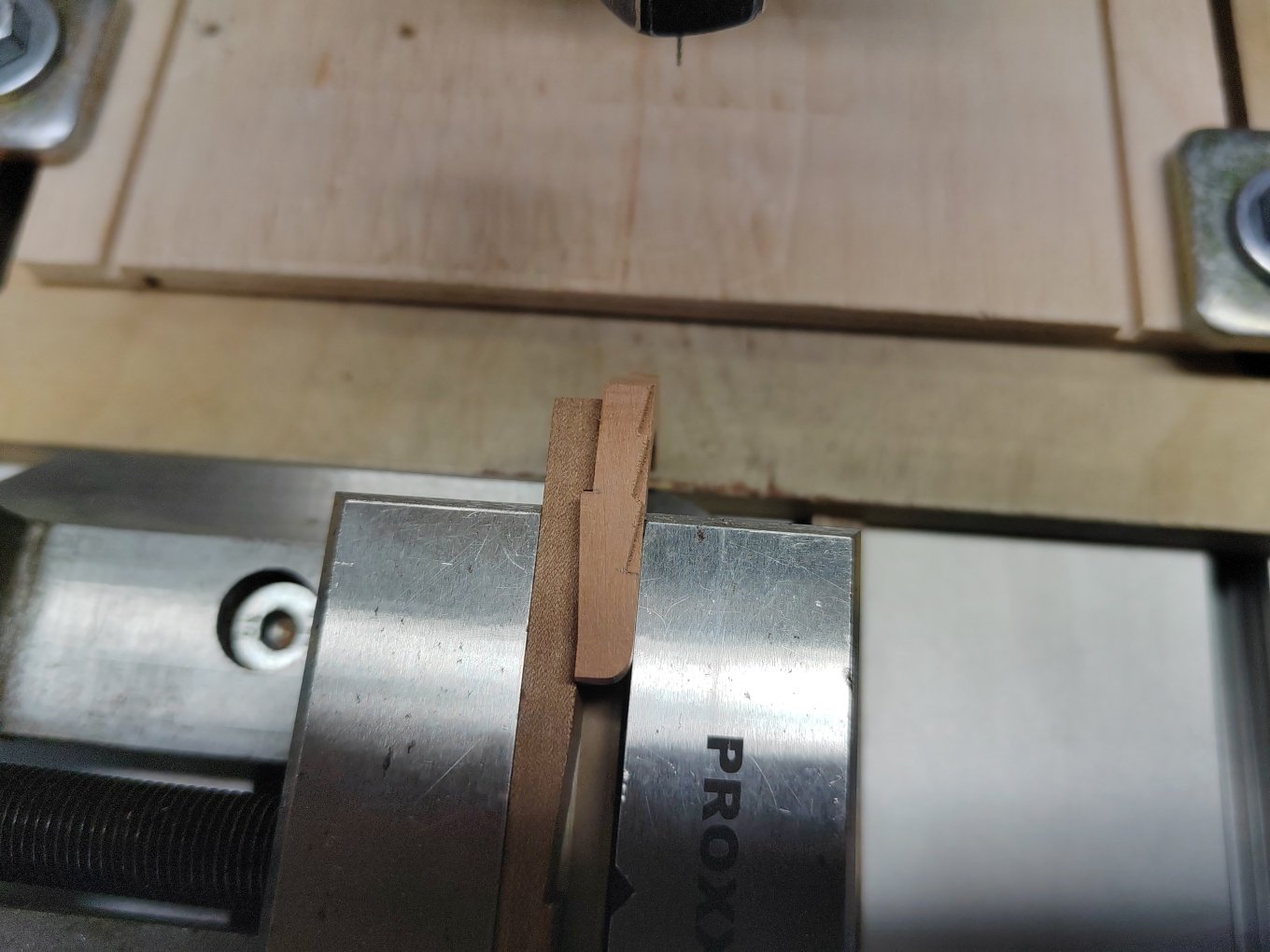

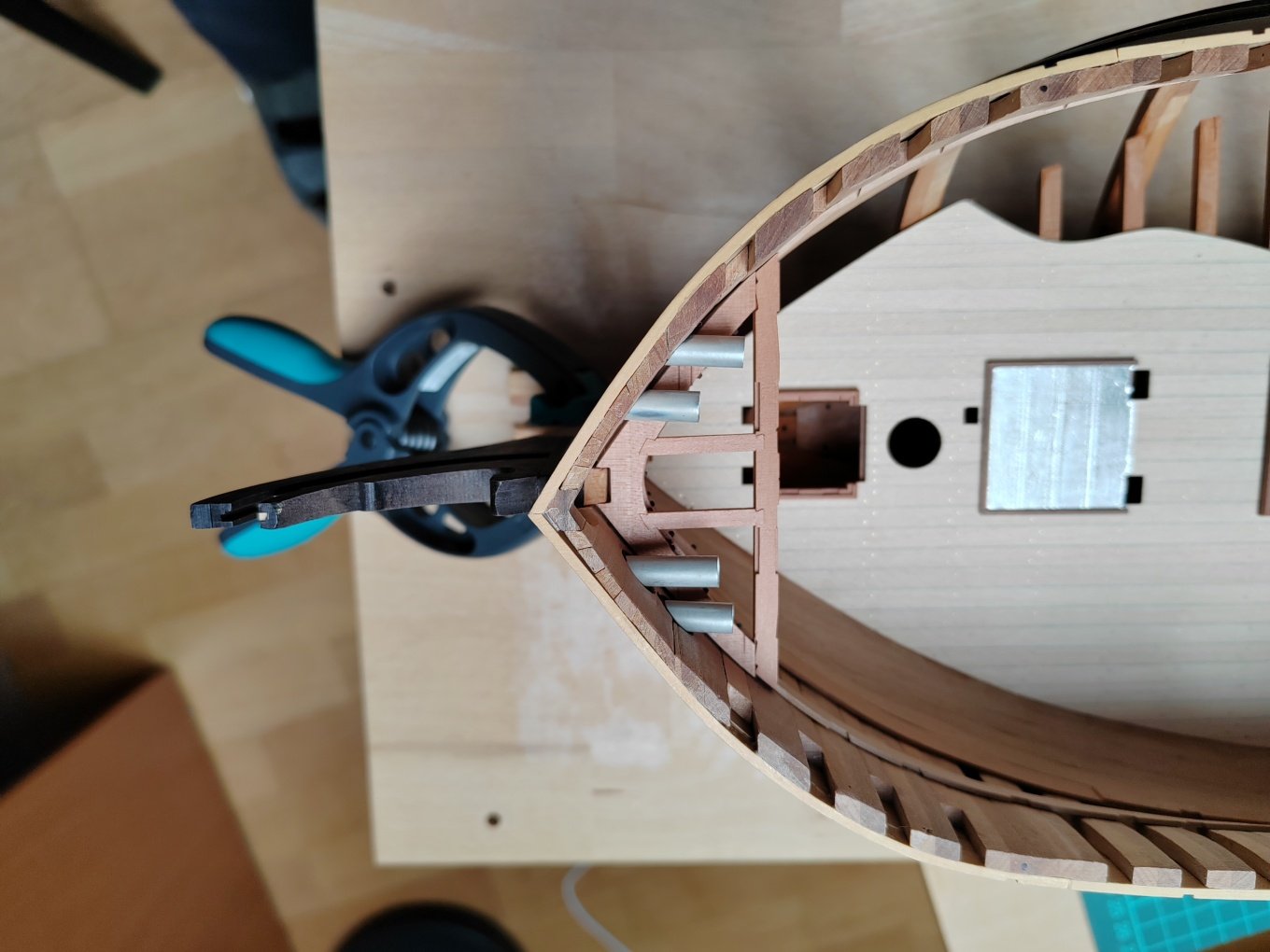

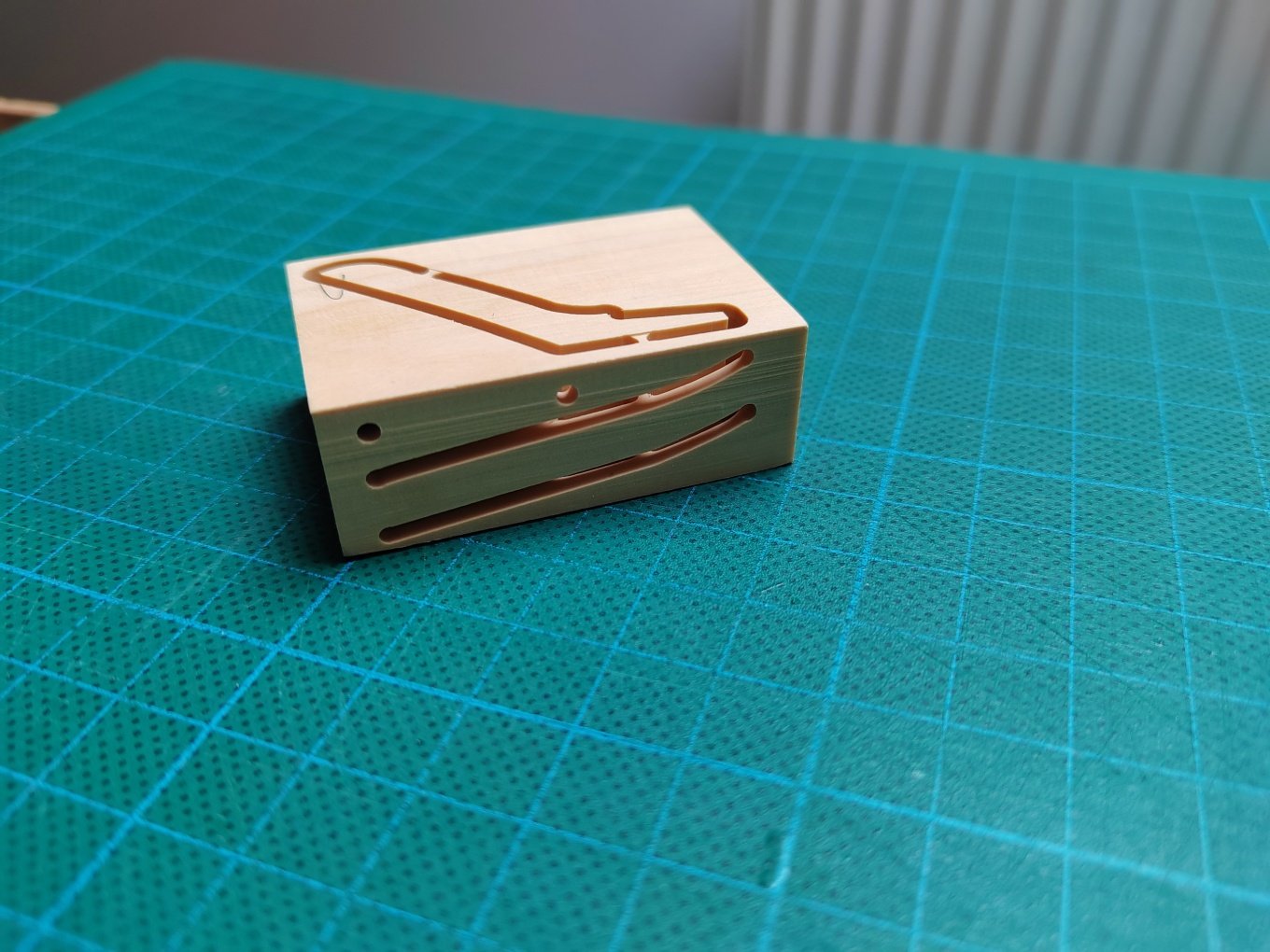

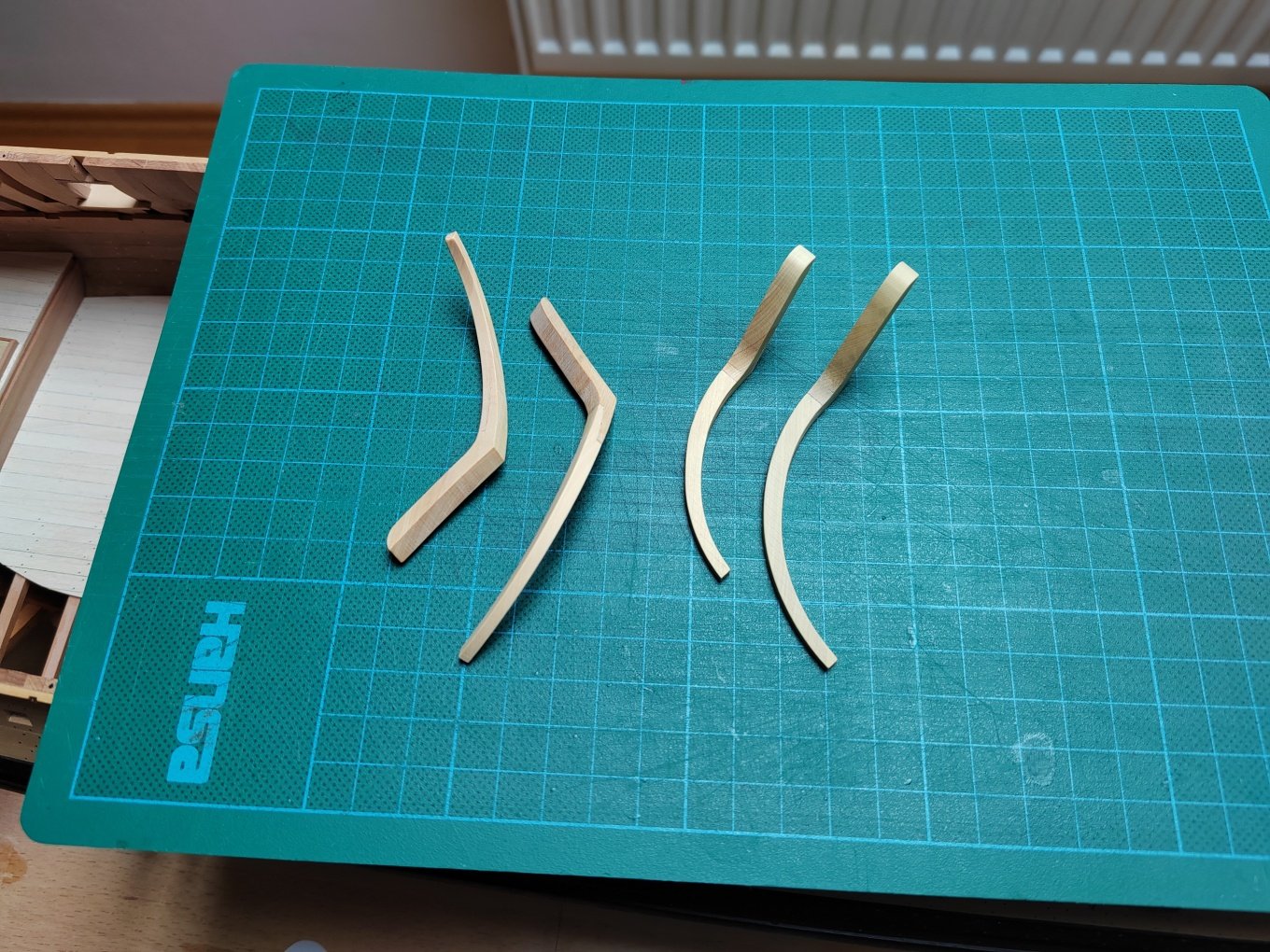

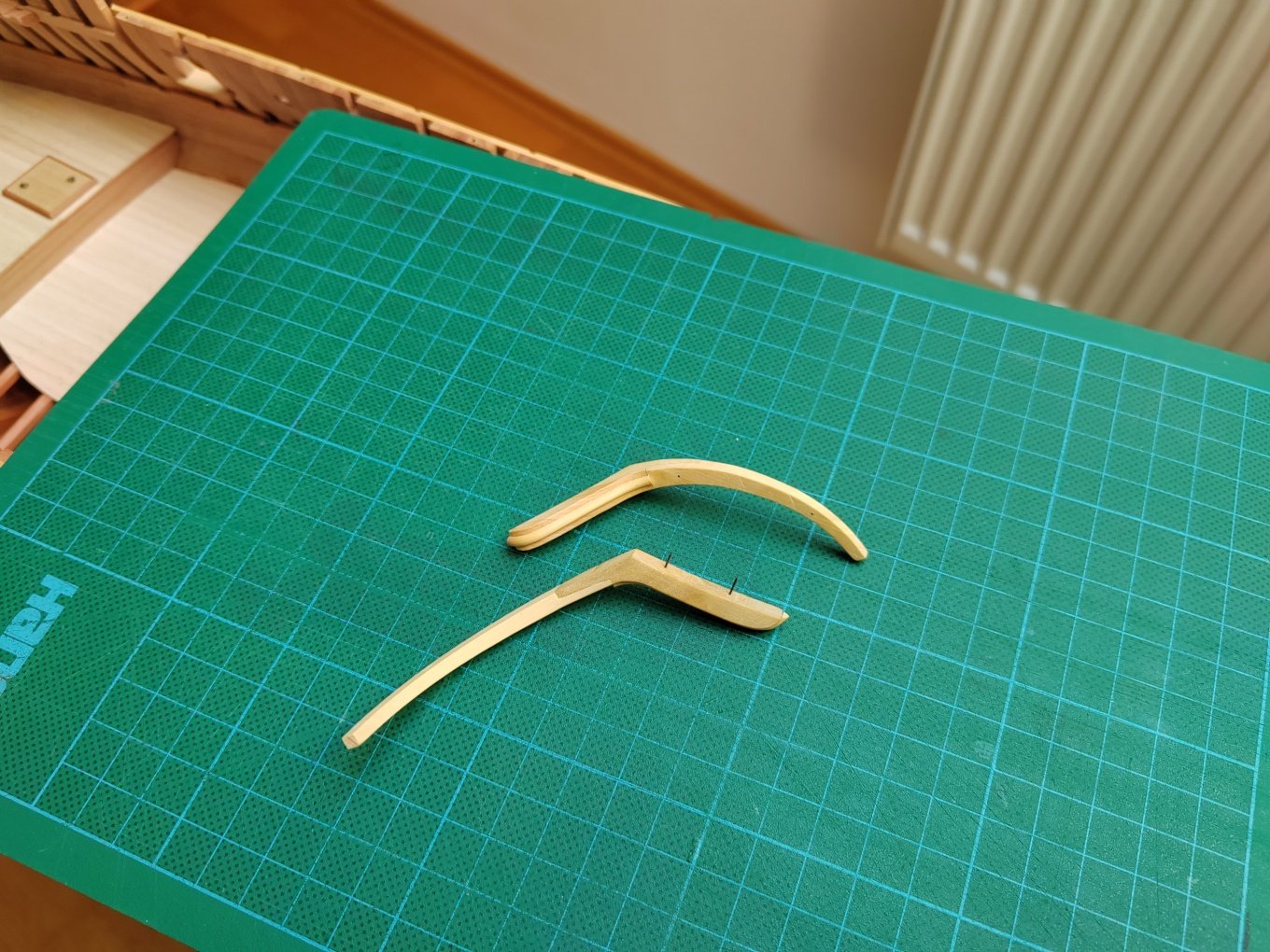

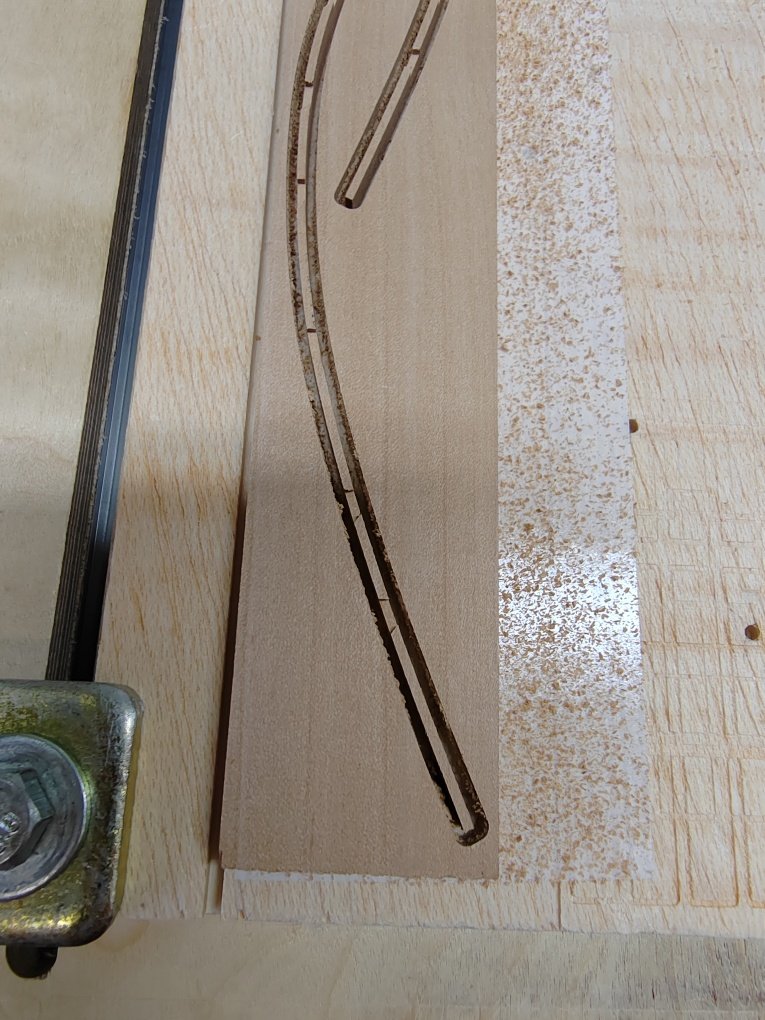

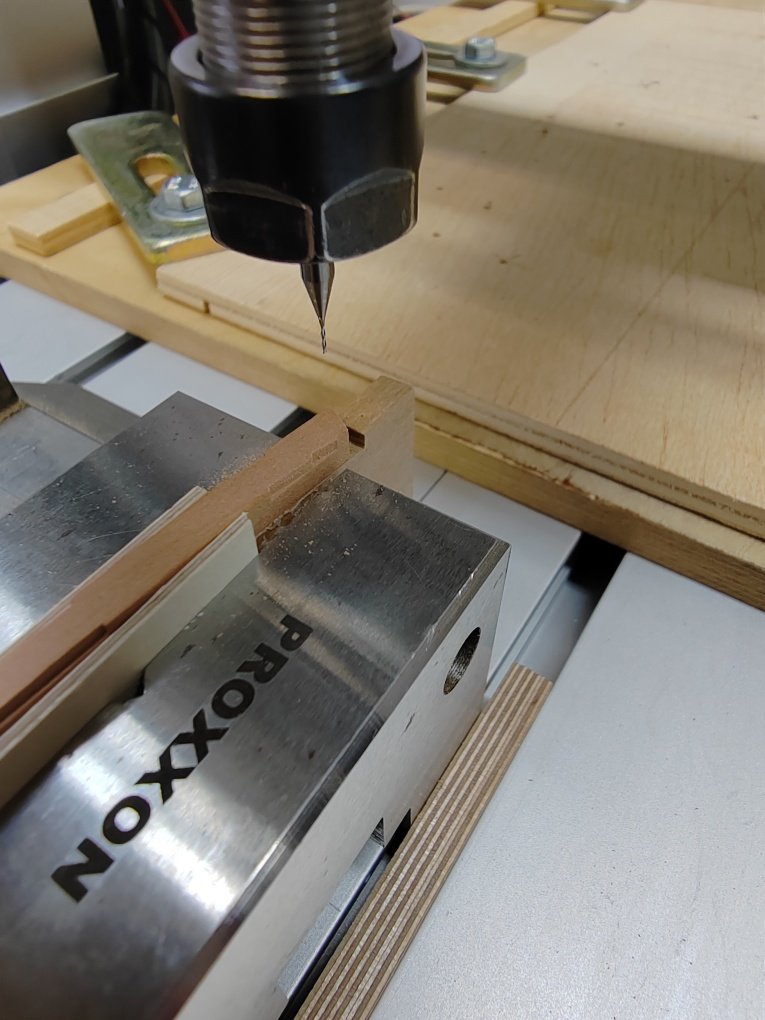

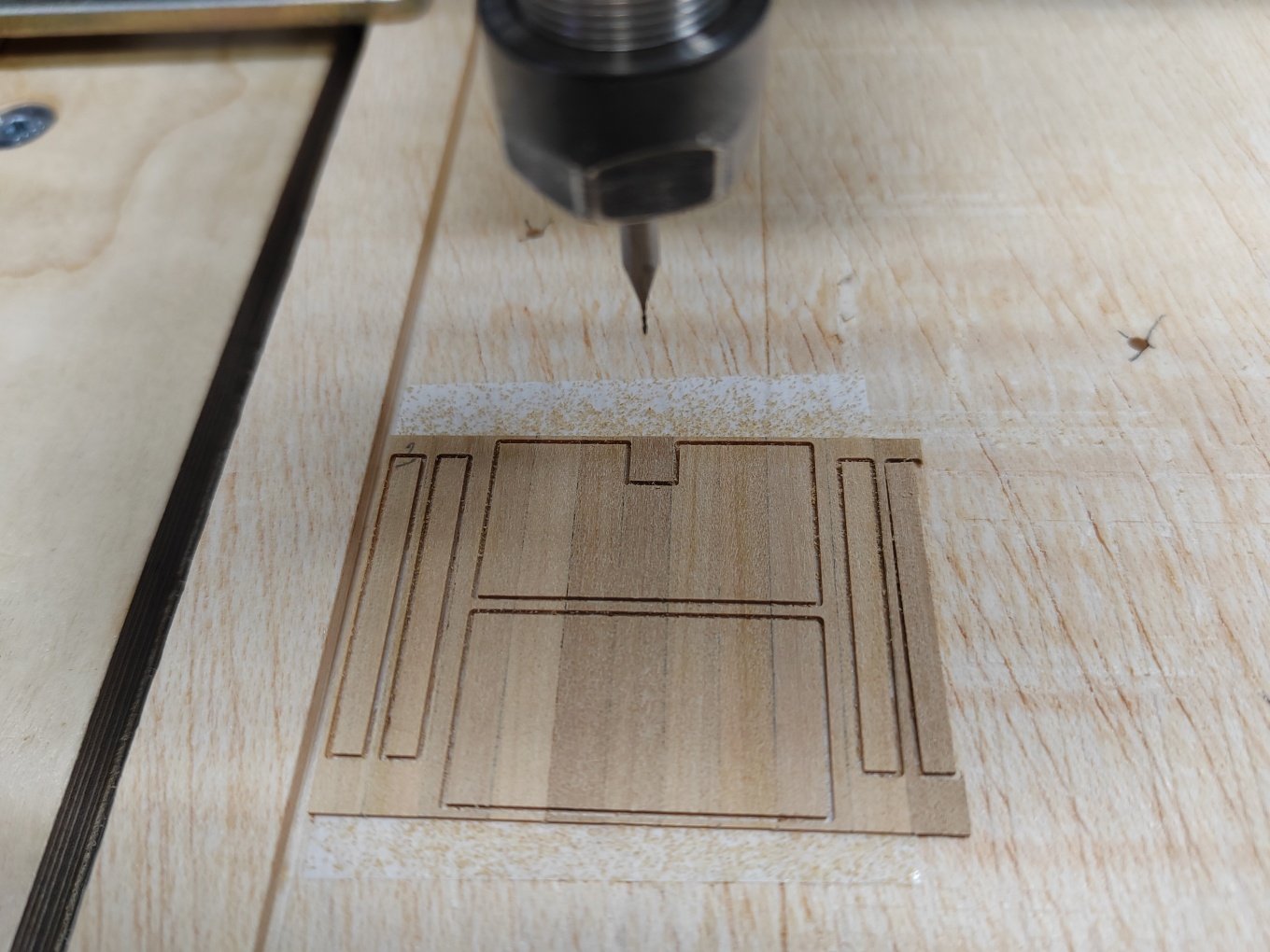

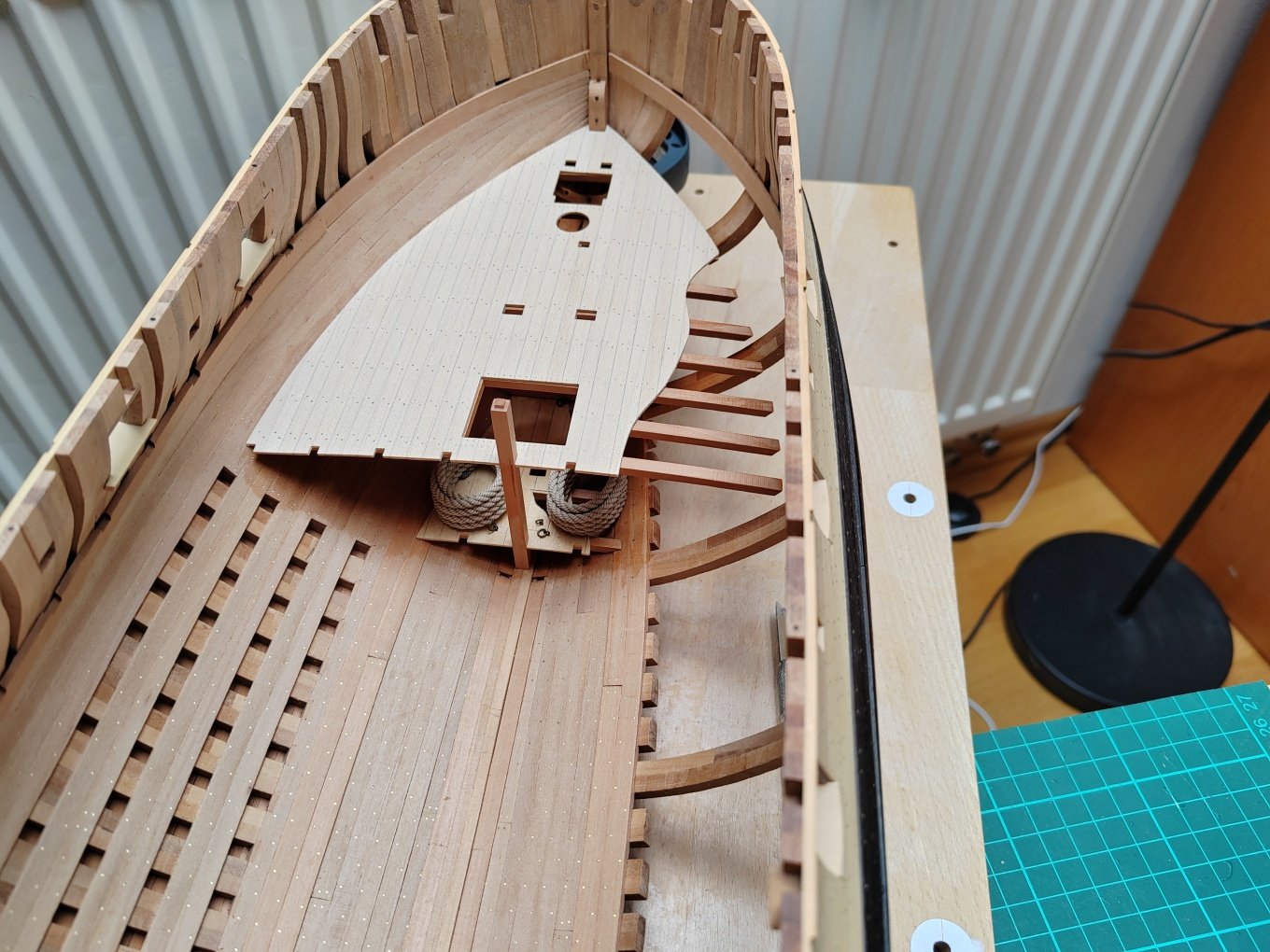

Thanks for the positive responses. The downside of using this technique is that you spend more time at the computer figuring out how to make the part as efficiently as possible. Added a few details on the bow - bolster, gammonig "pillow" and wash-piece. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

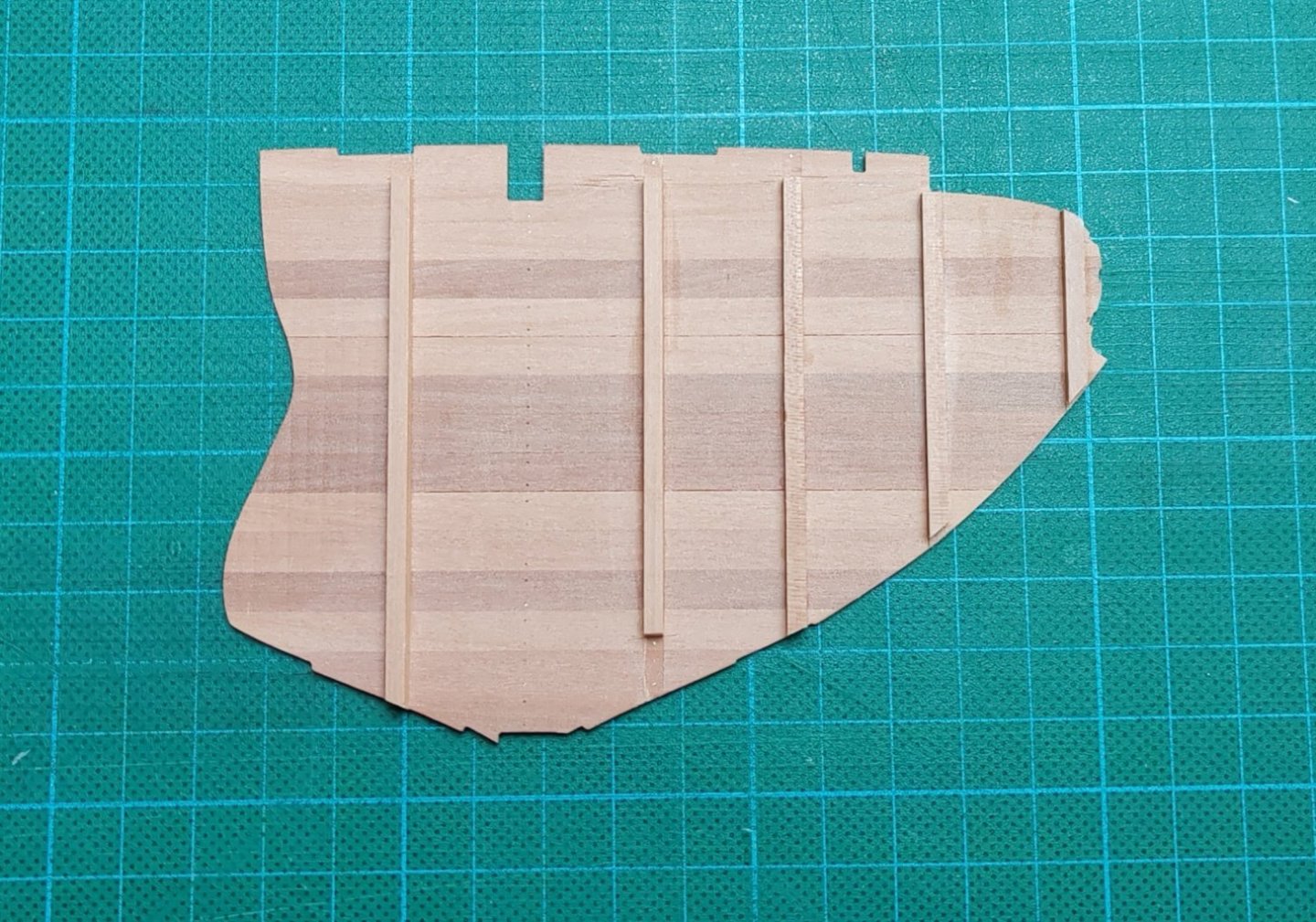

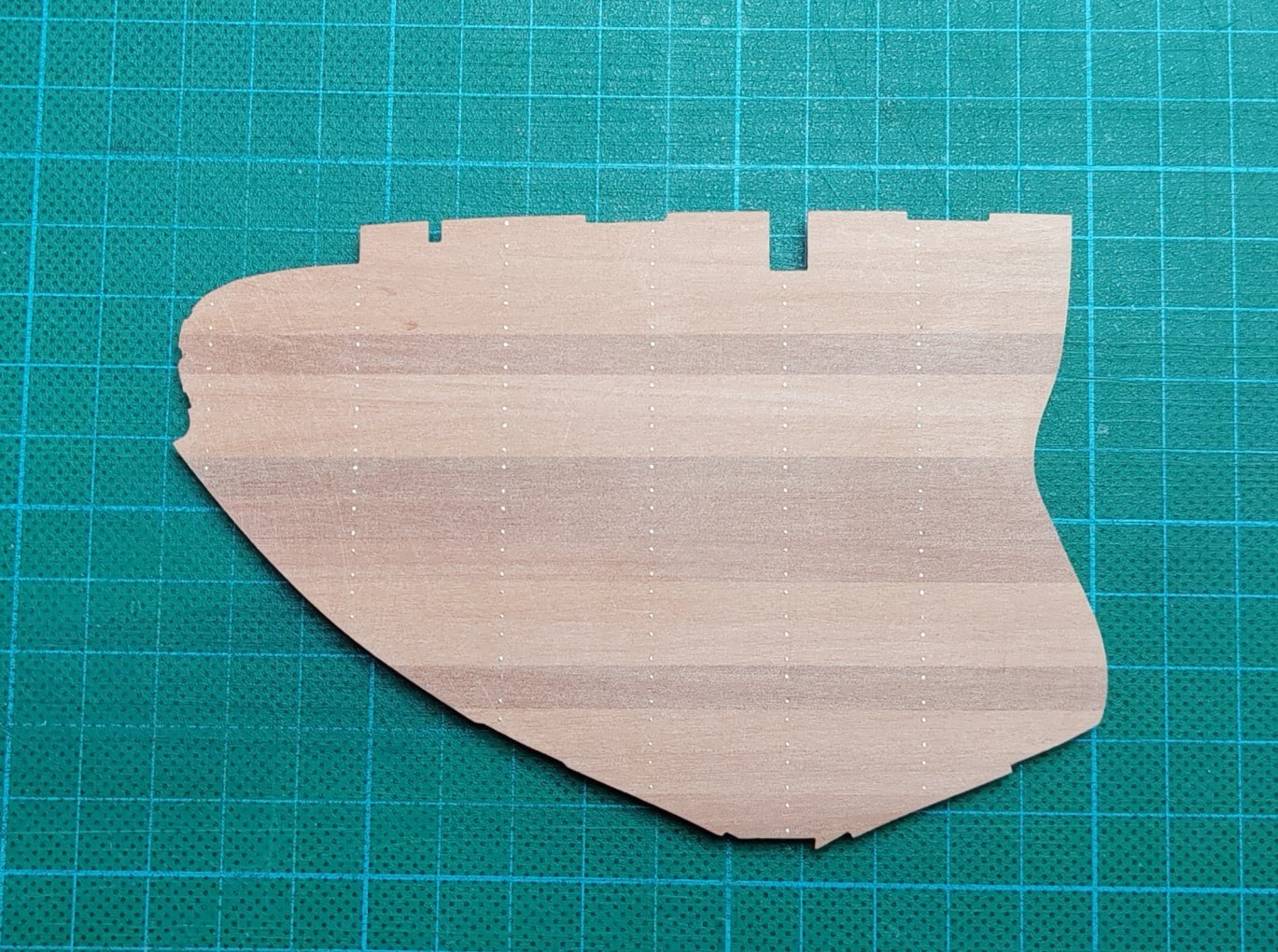

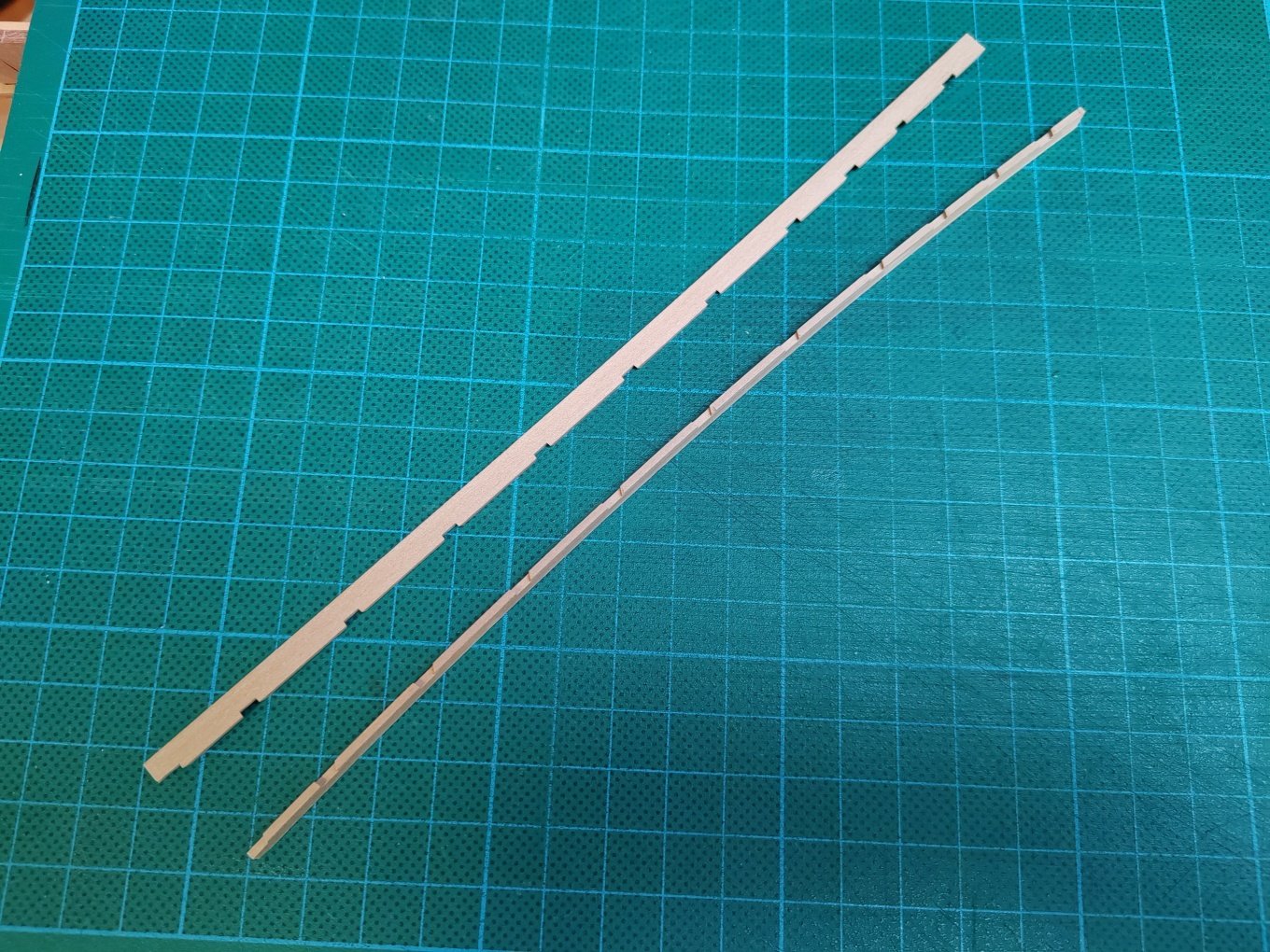

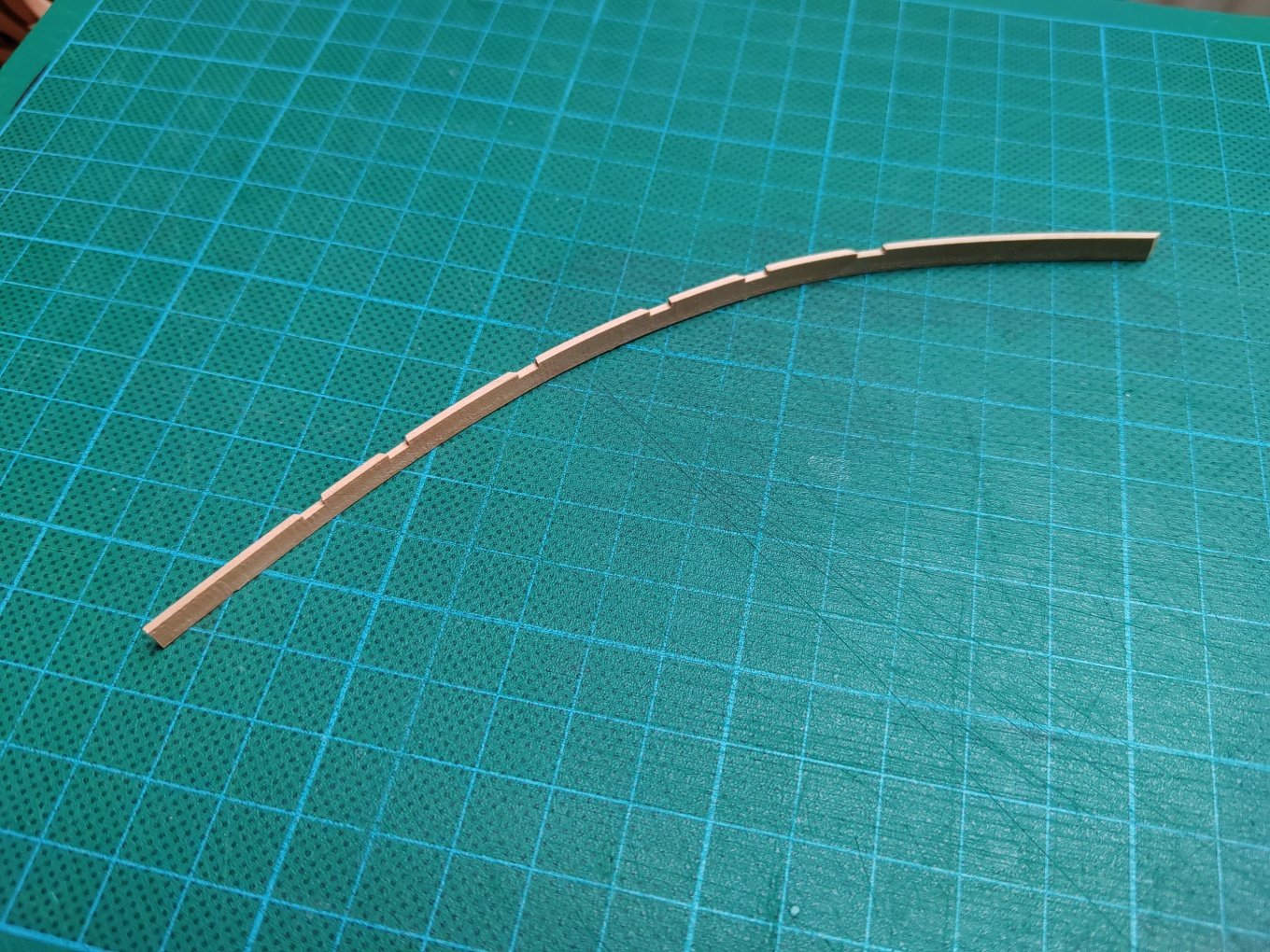

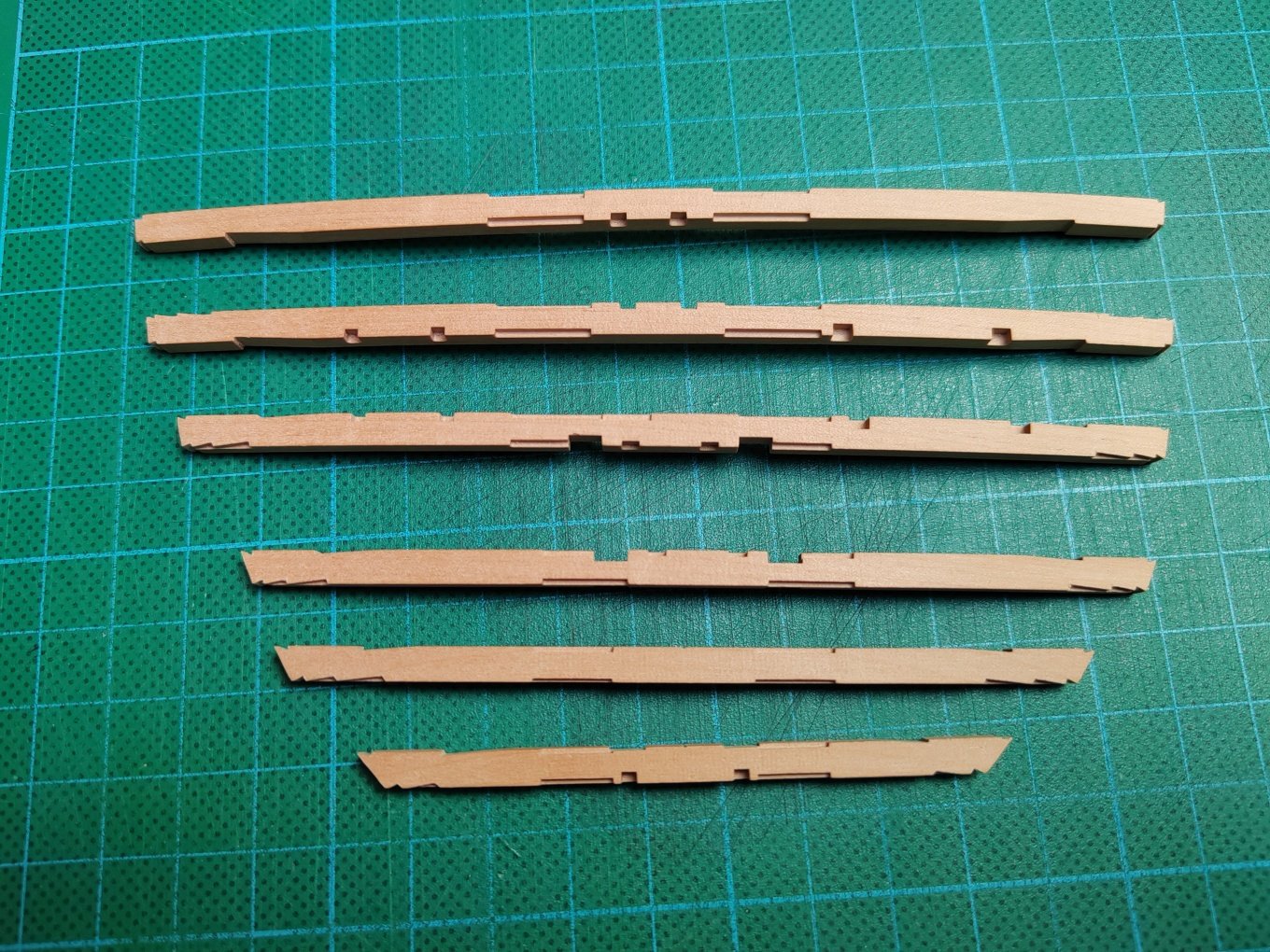

Thank you guys for very nice comments. But I definitely don't deserve such words of praise. I continue to prepare the deck beams for the aft upper deck in the same way. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

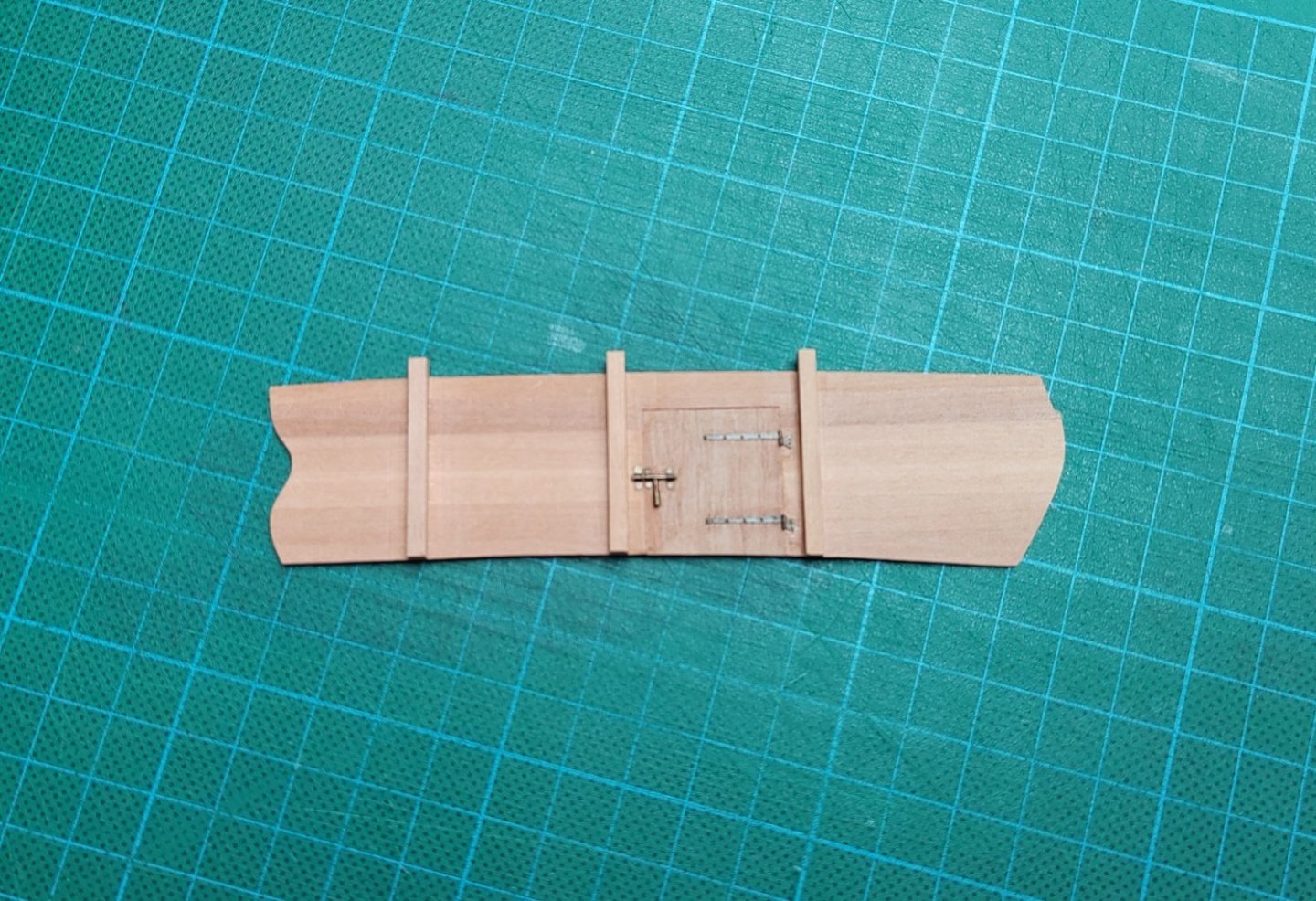

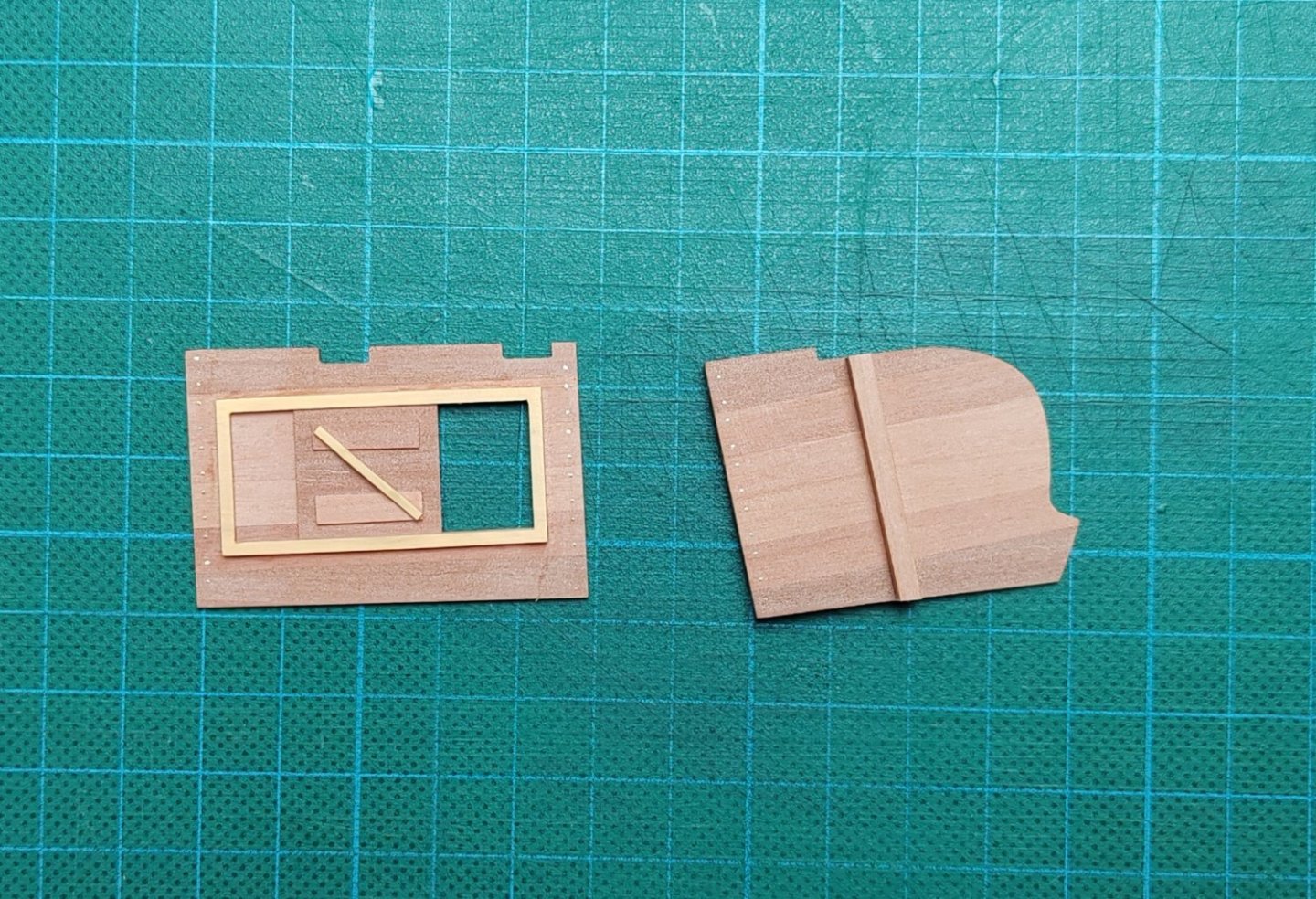

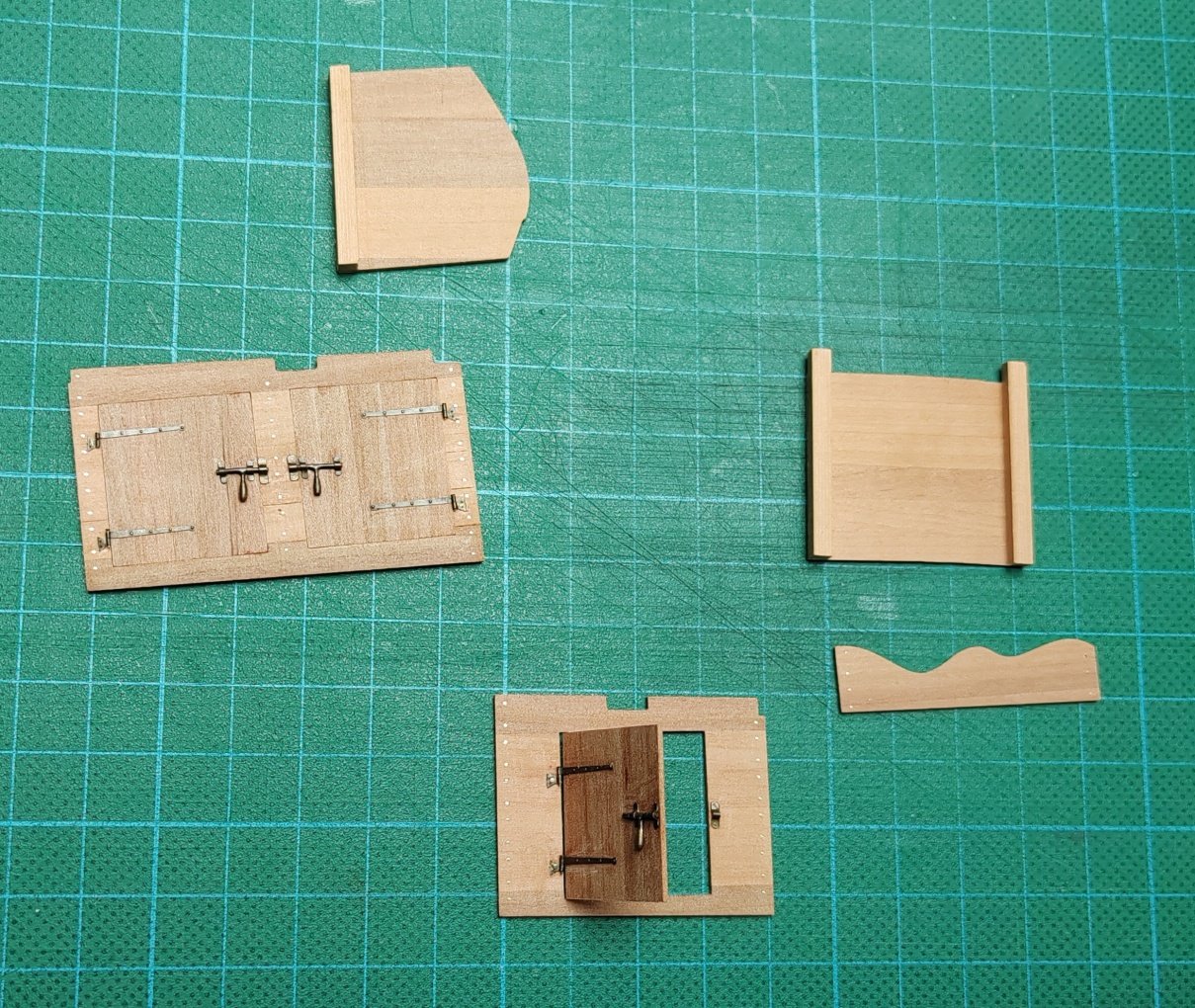

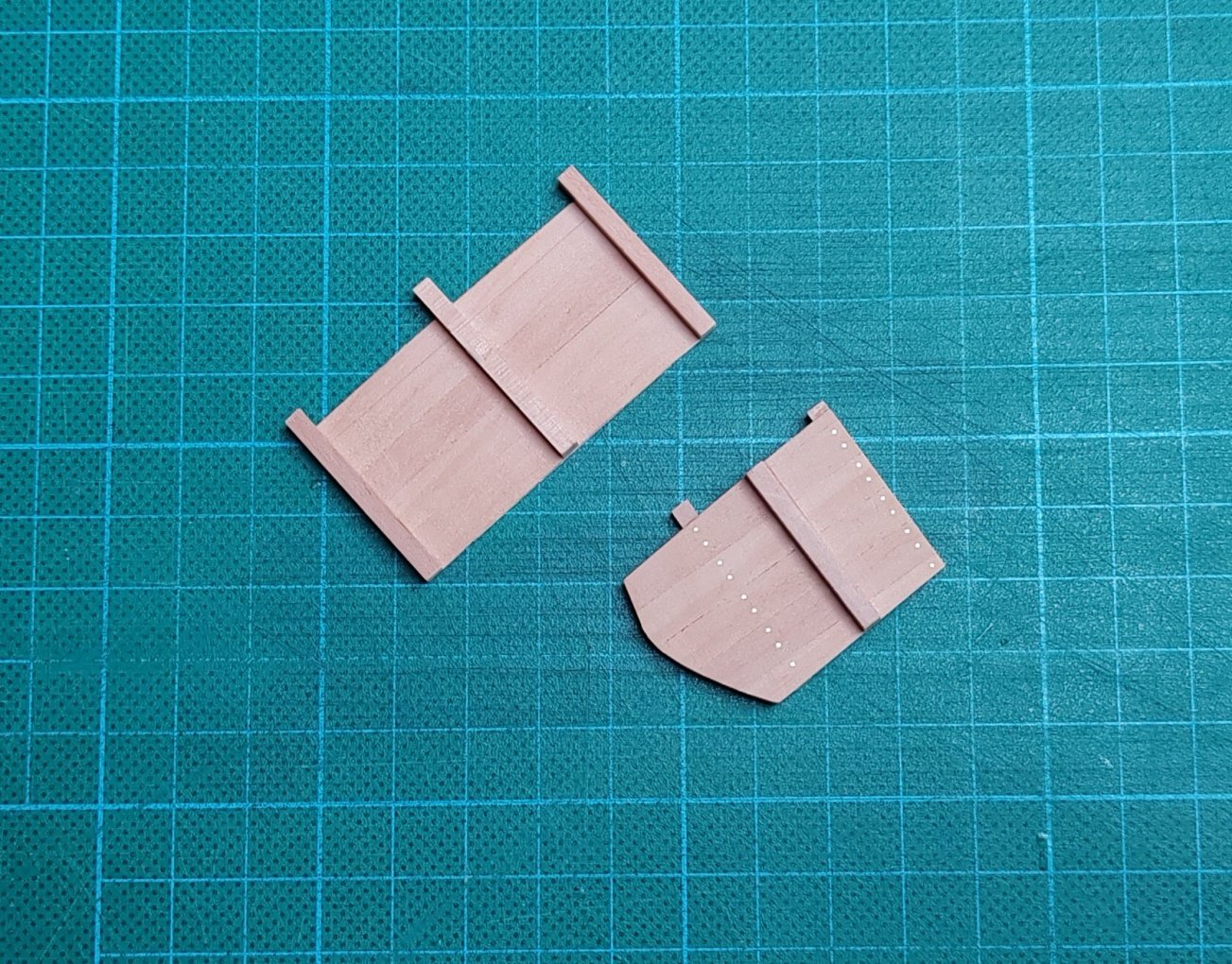

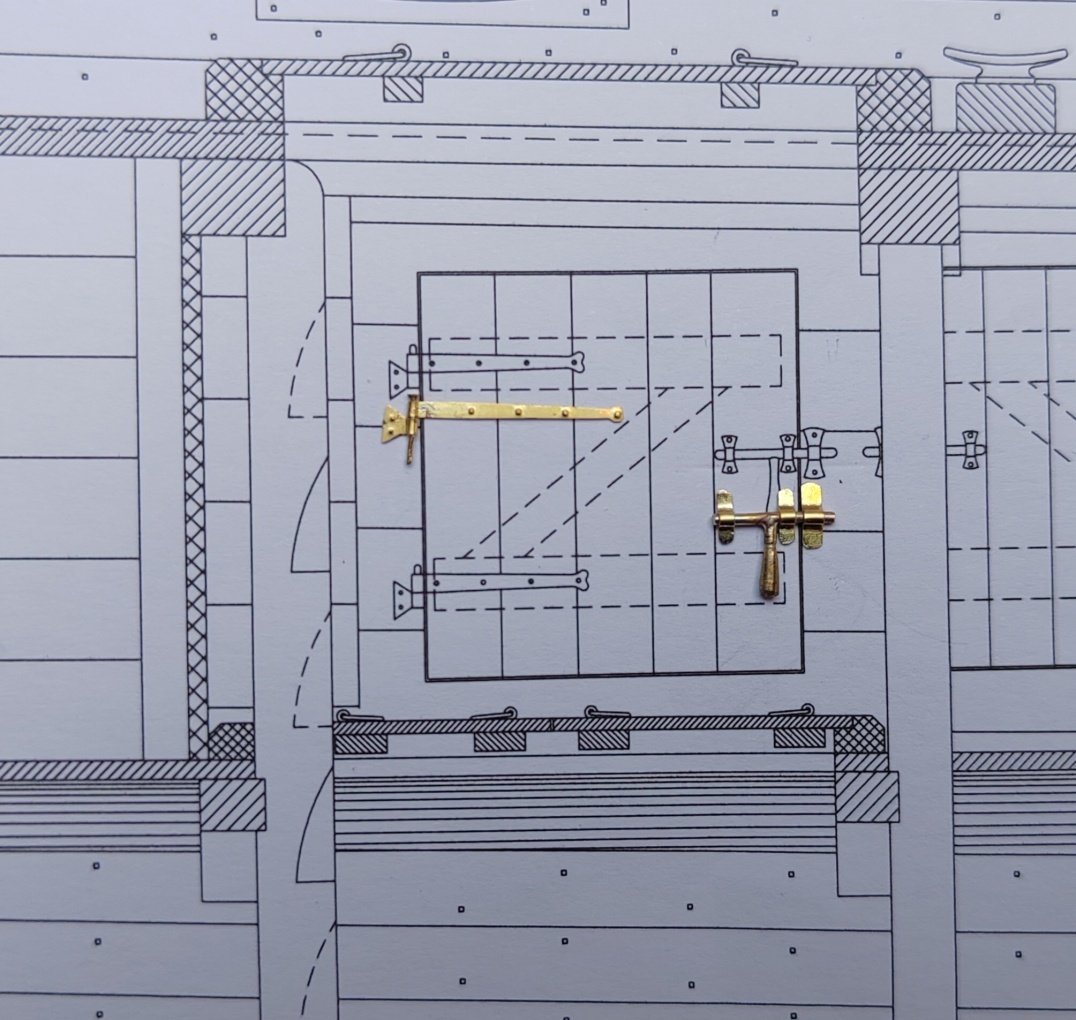

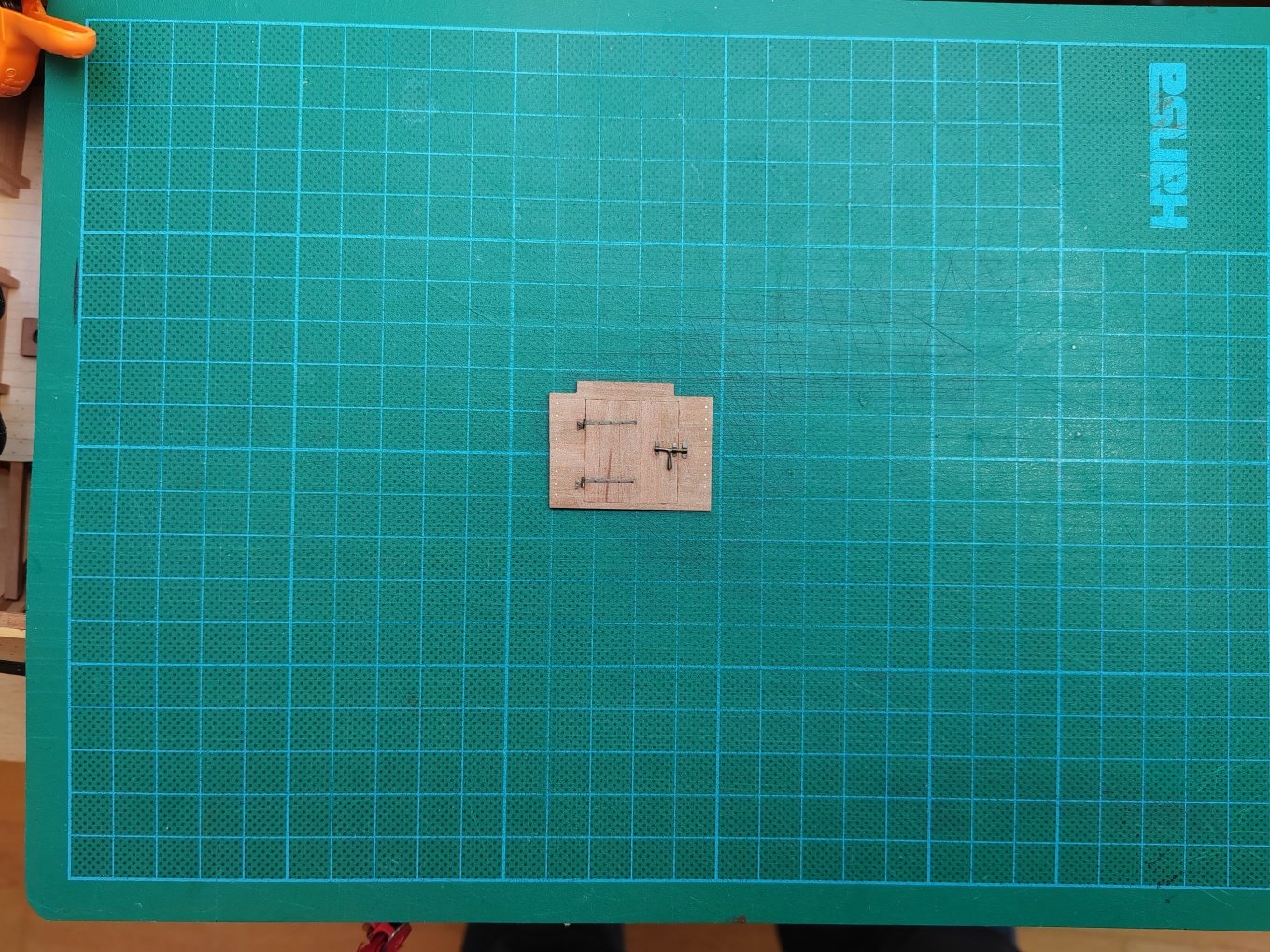

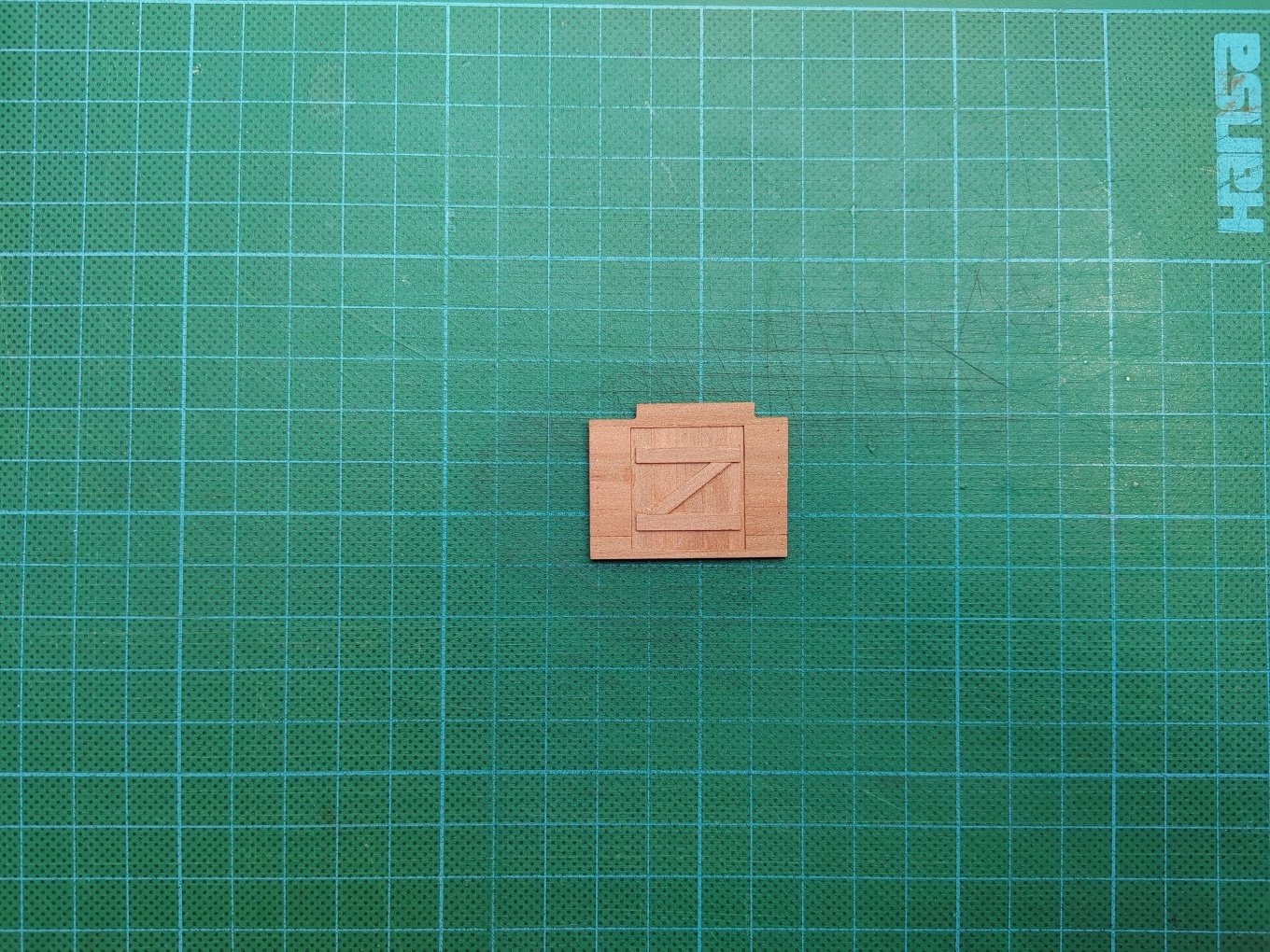

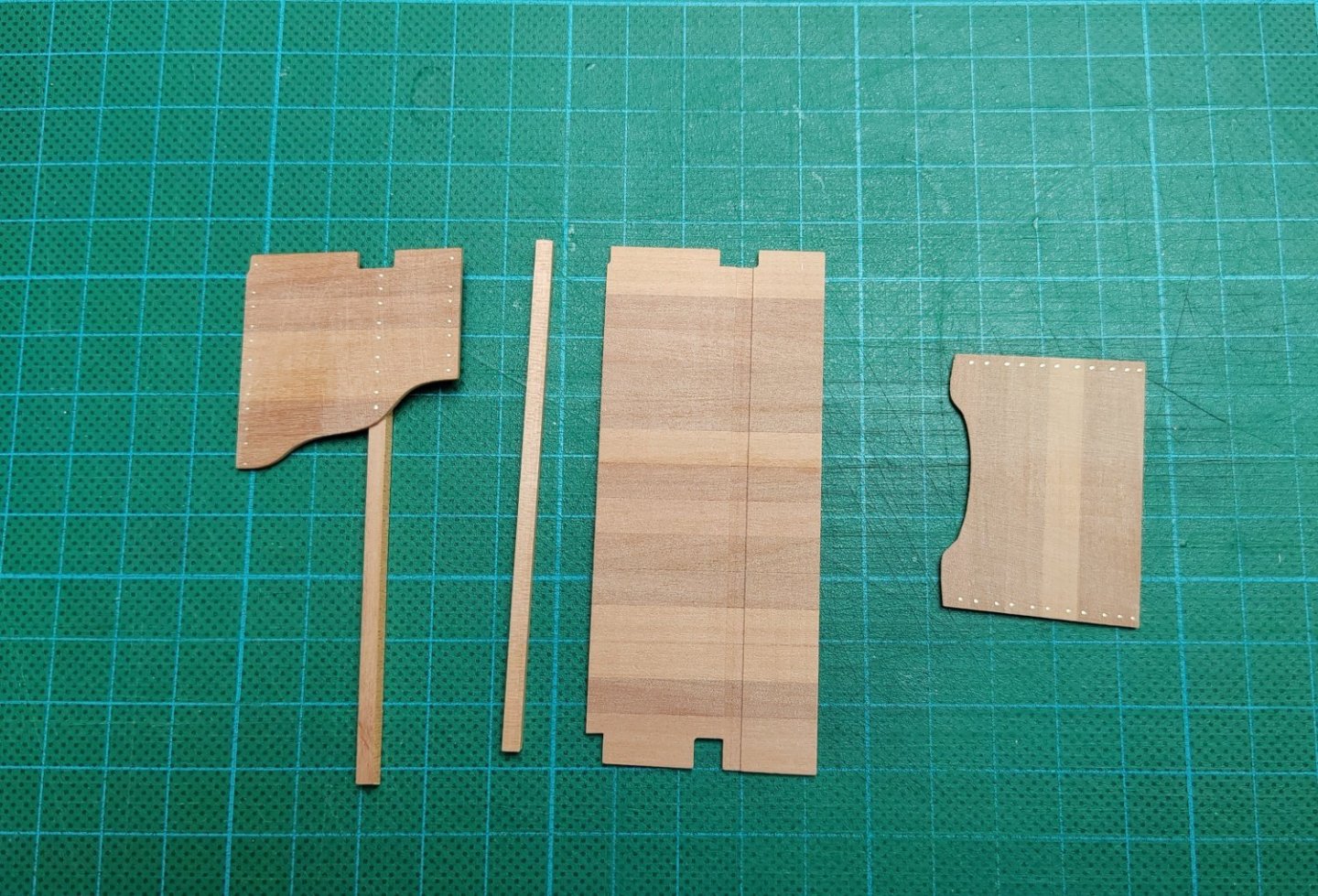

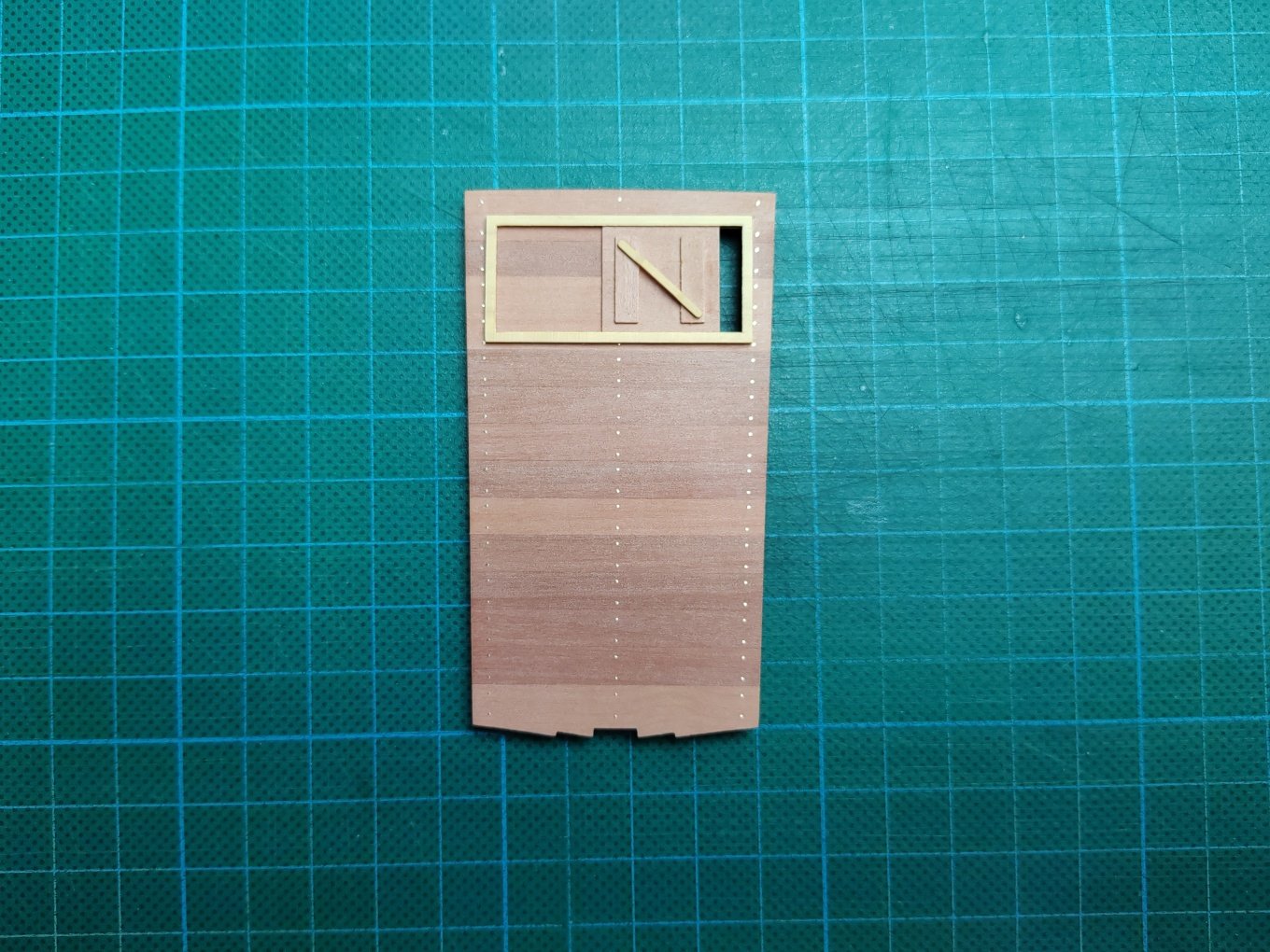

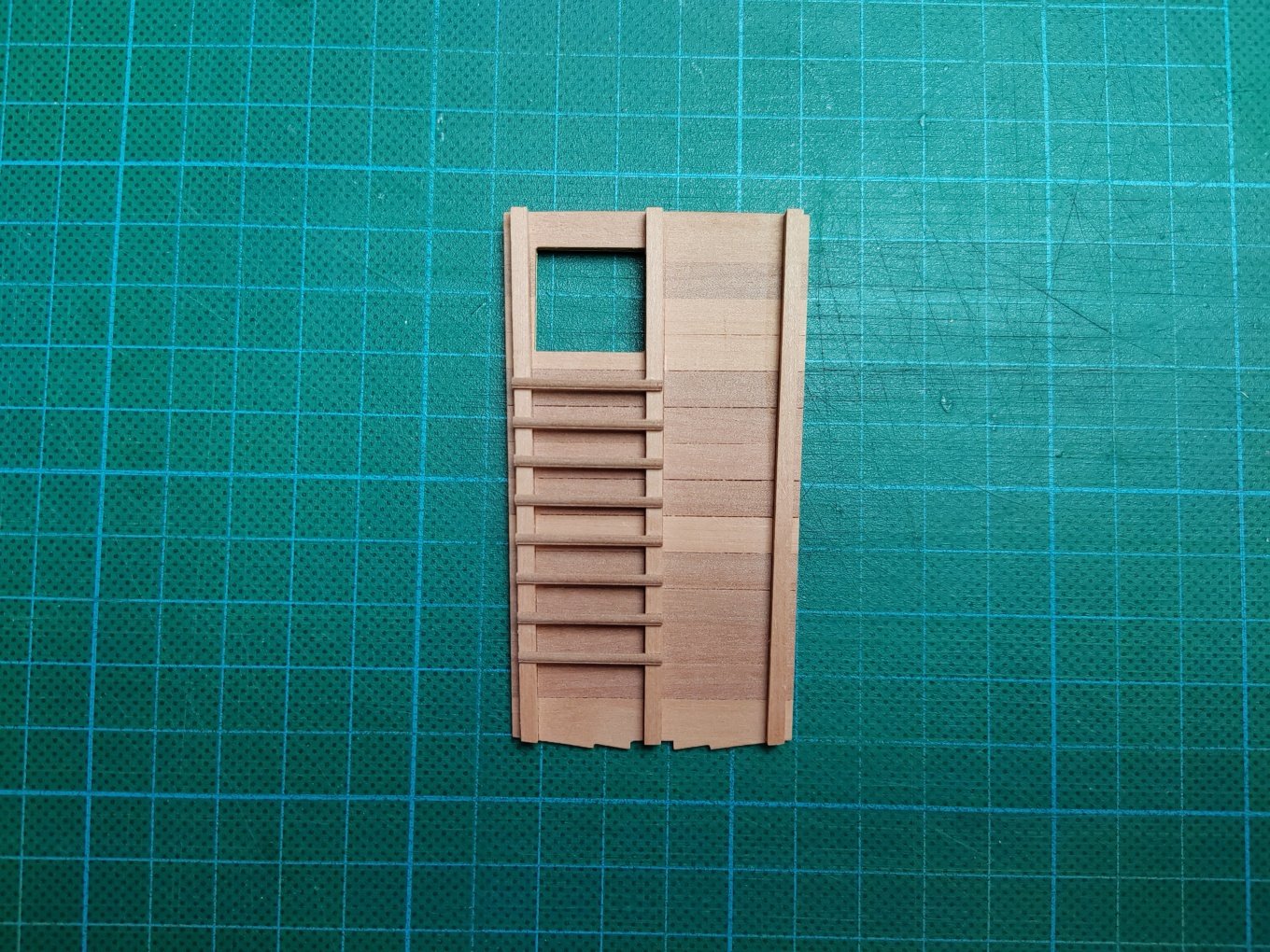

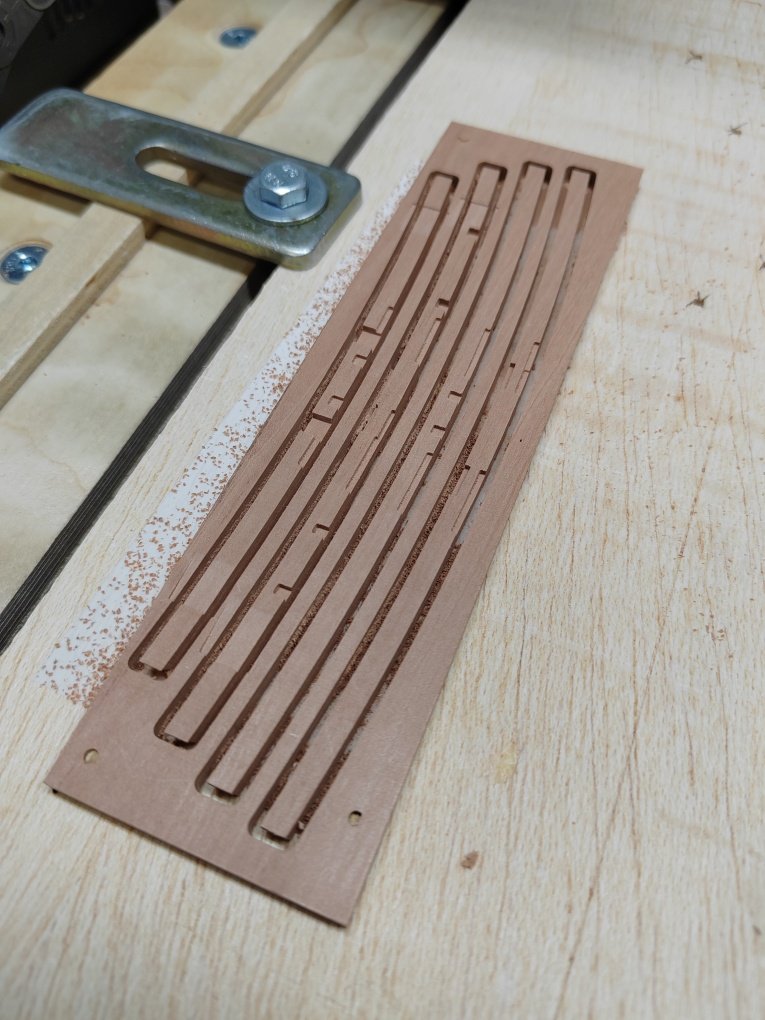

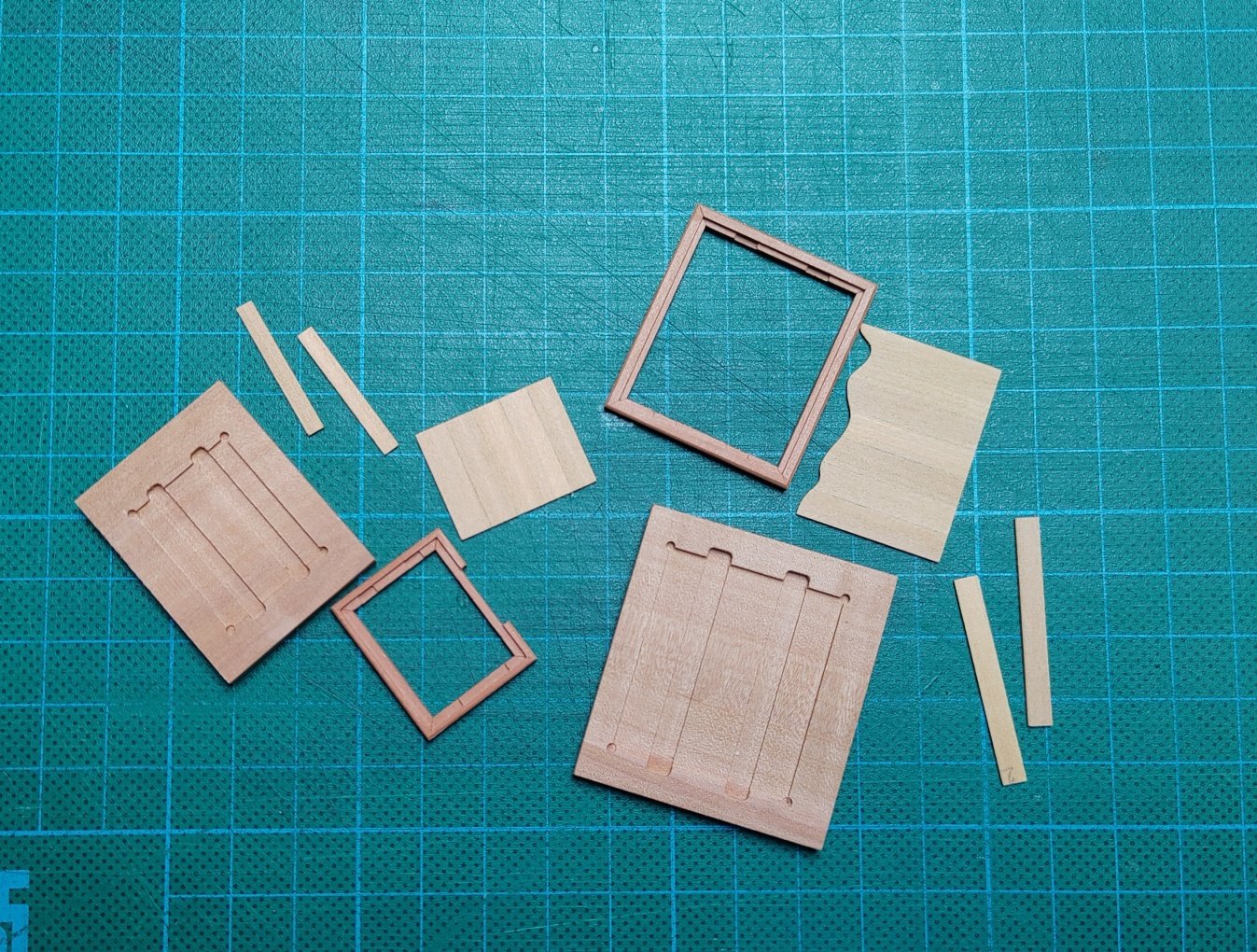

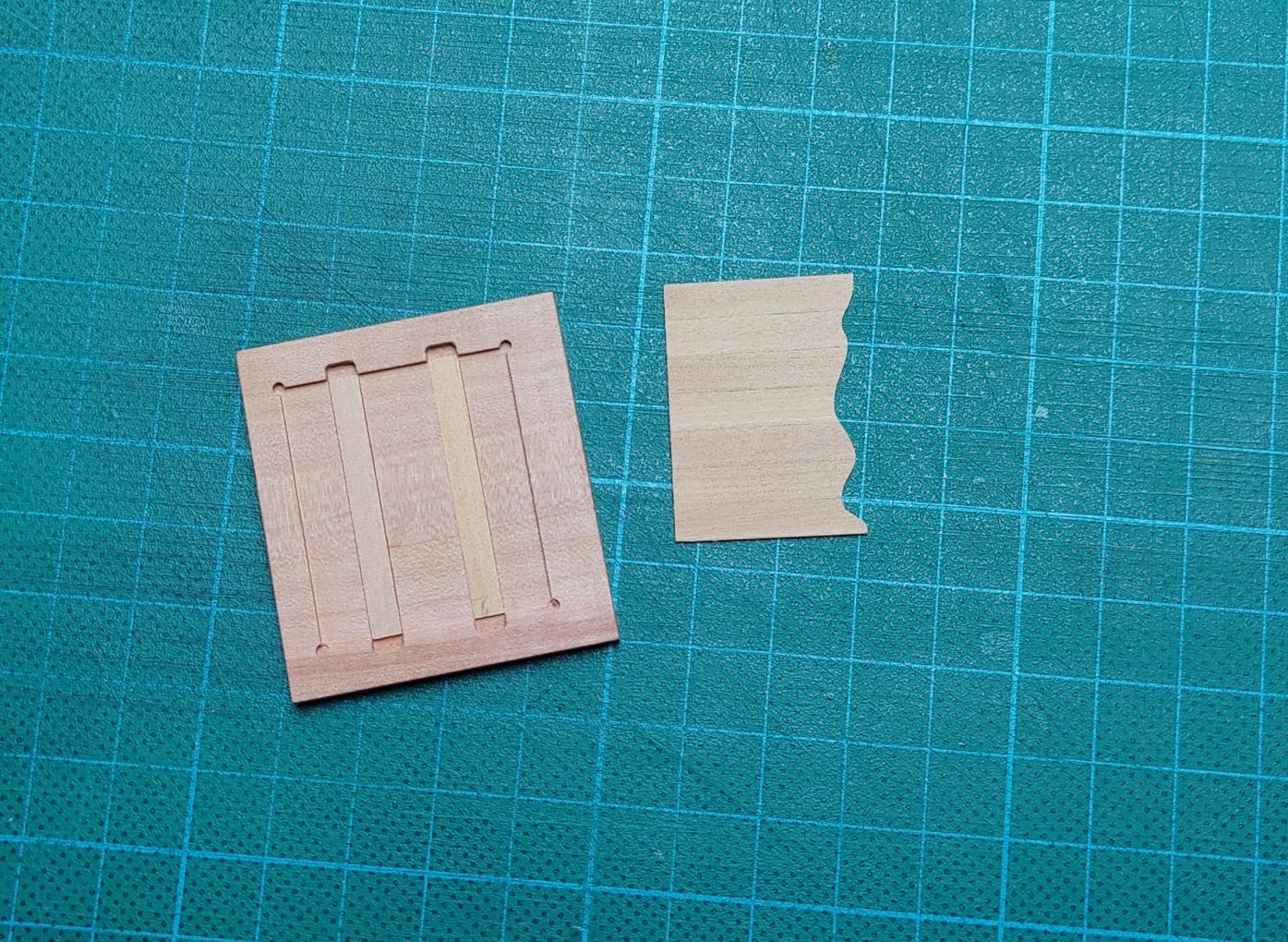

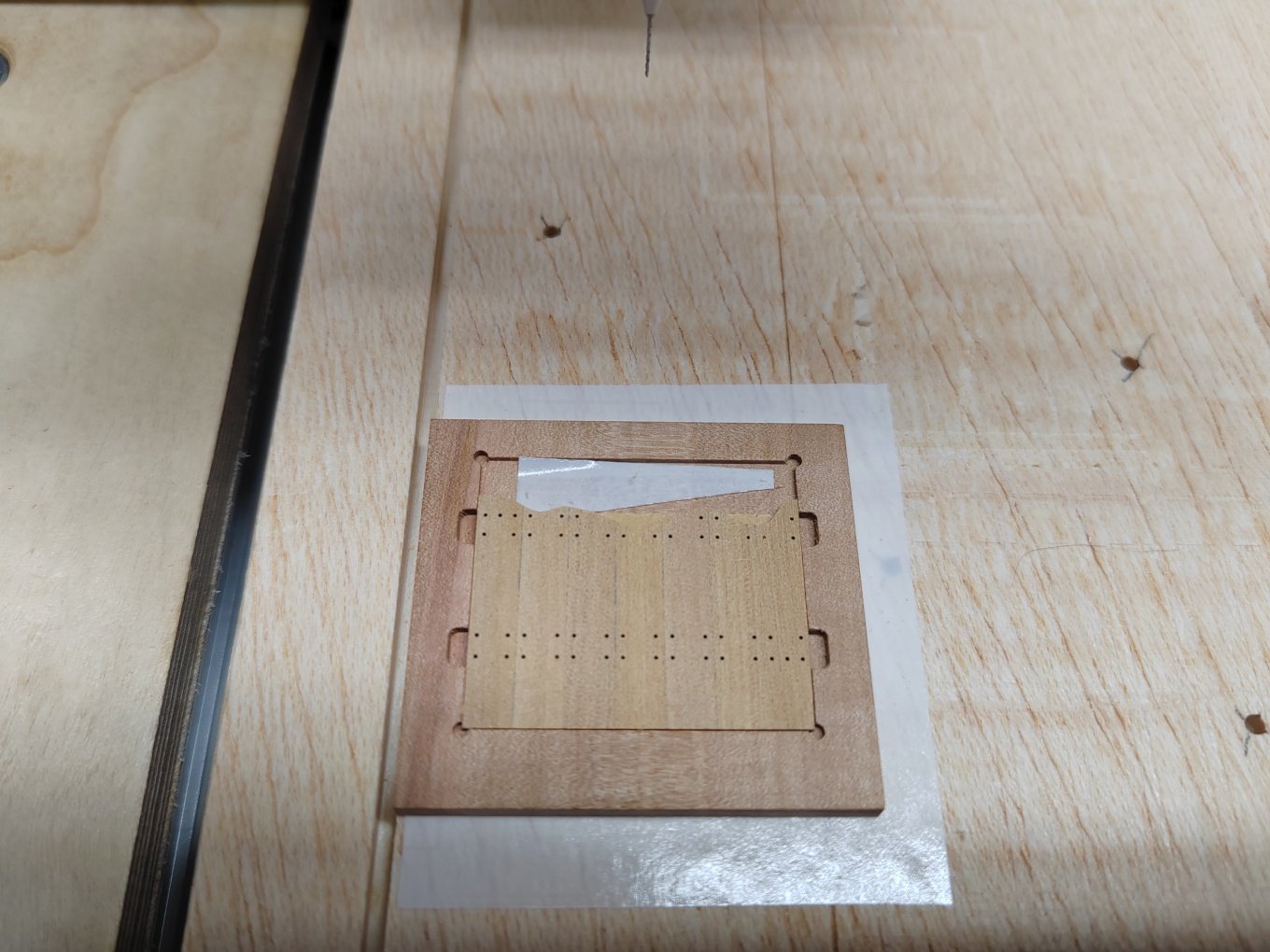

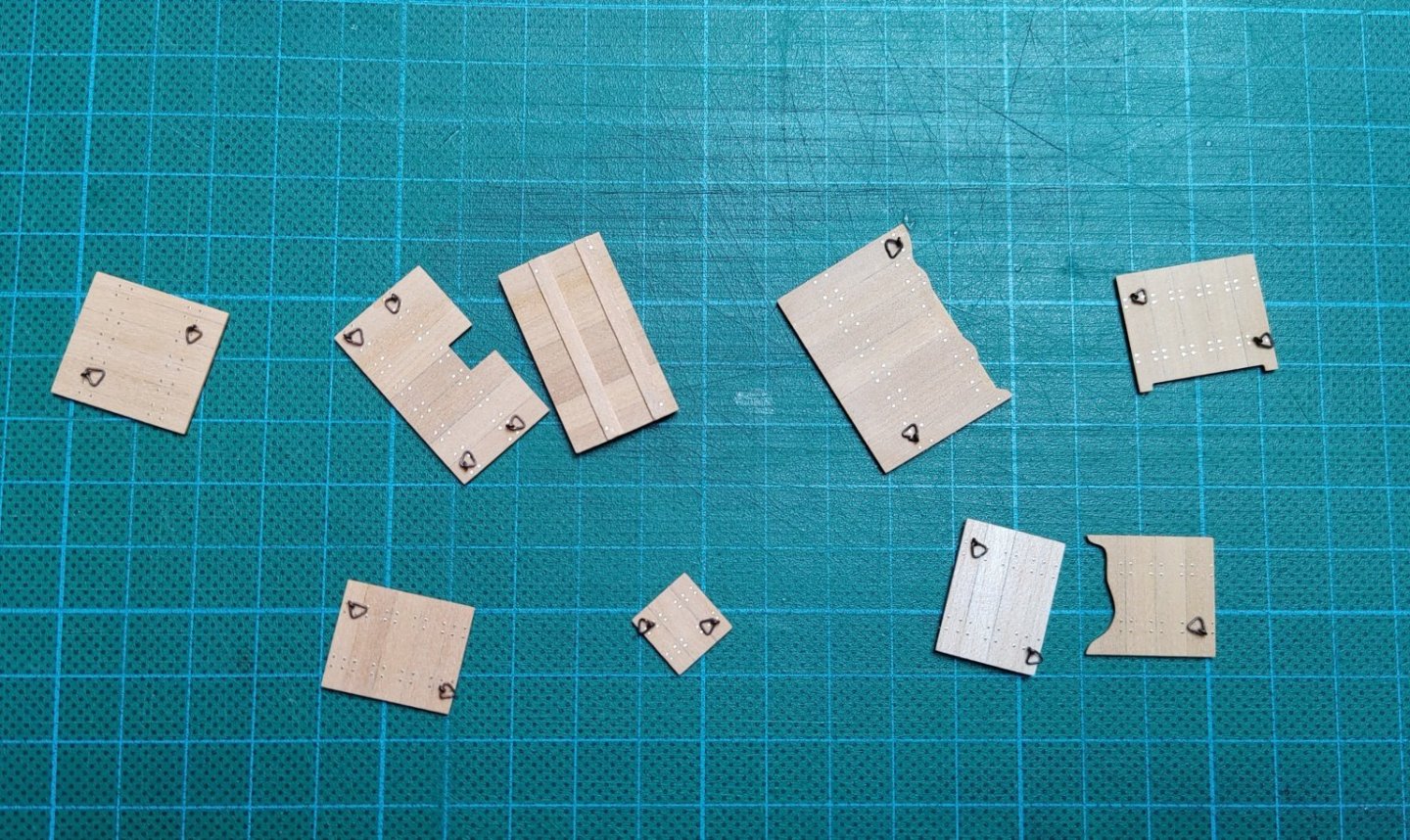

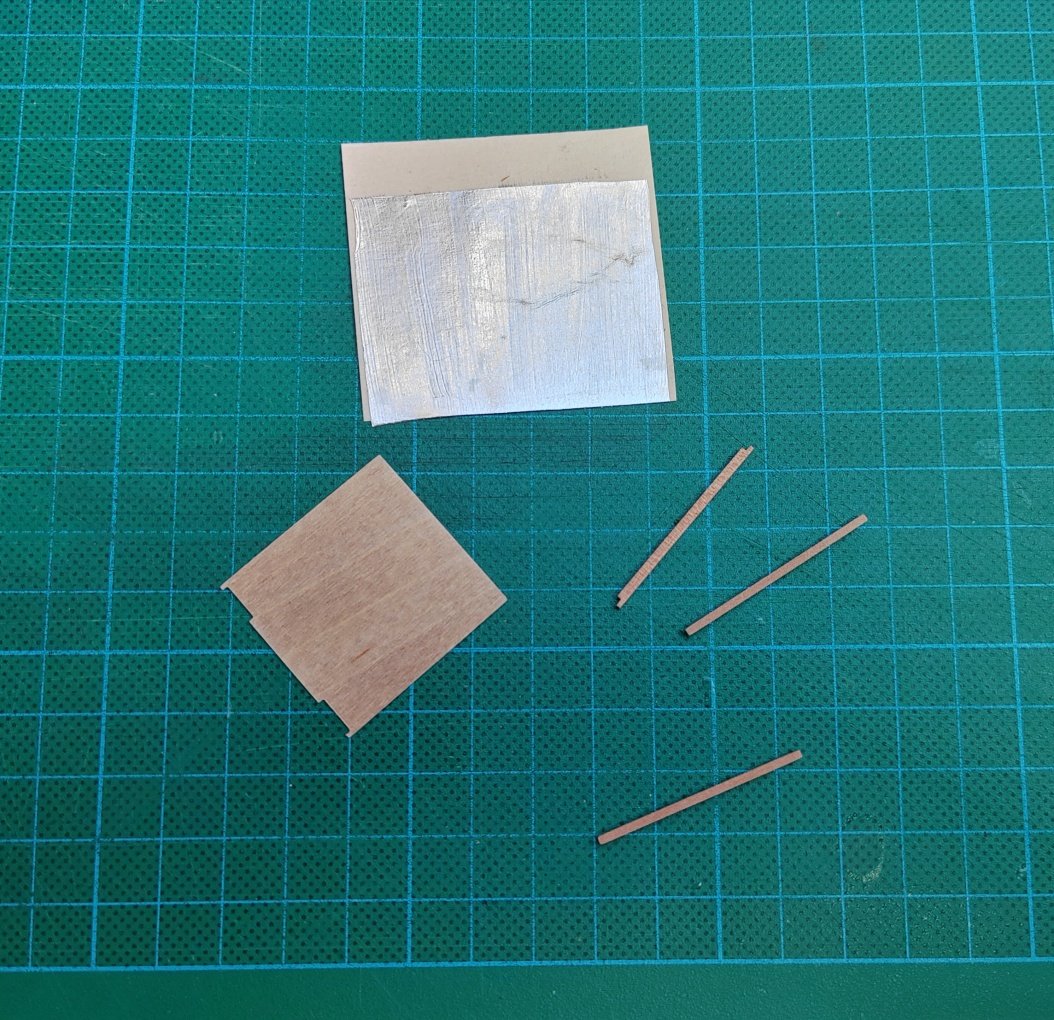

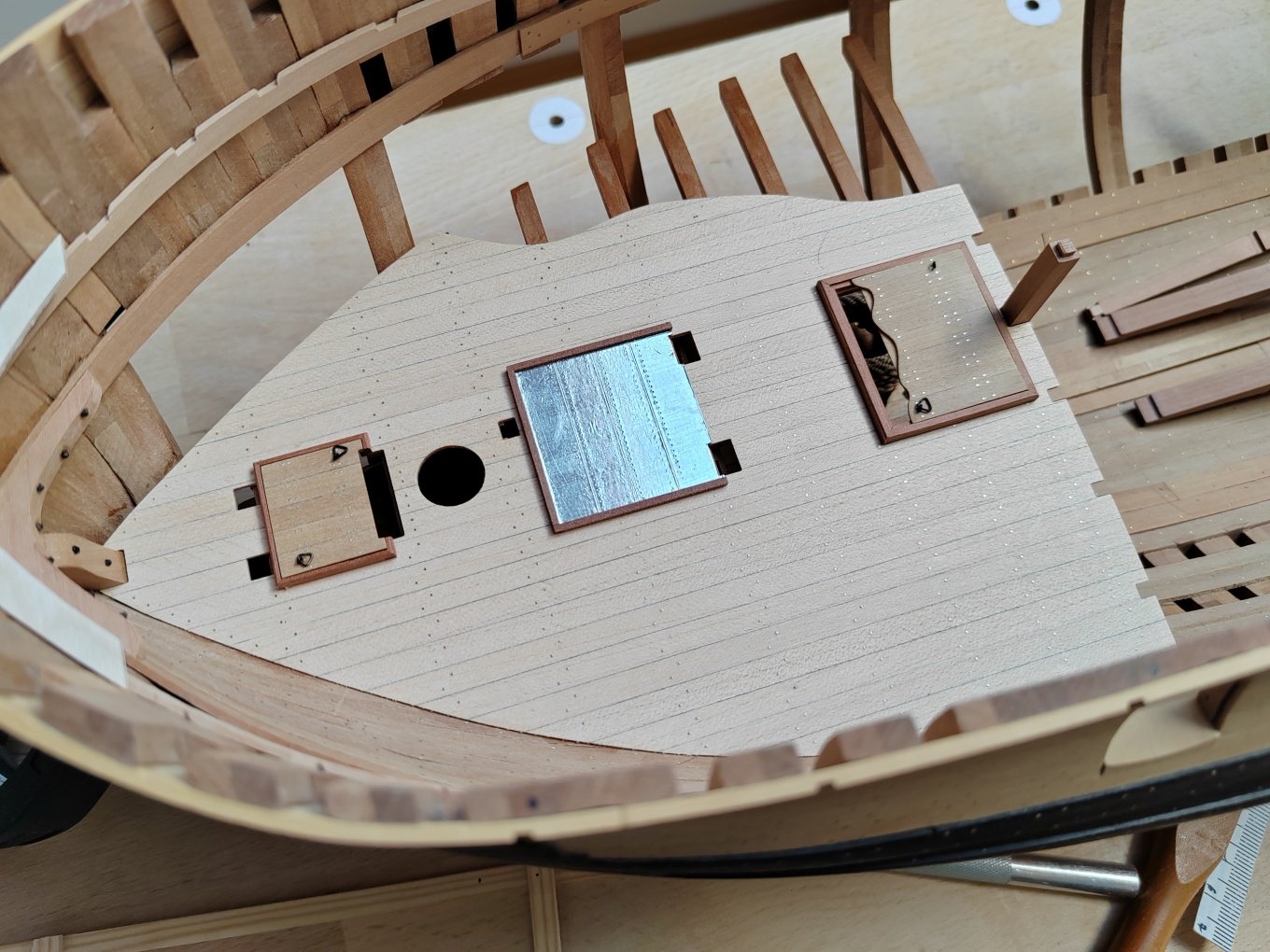

Hi Chris, thank you for compliment. I must say that the work you are doing at Le Renommee is fantastic. You probably have a good teacher . So that the decks don't look so "poor", I started making hatches. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.