-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rfolsom

-

The planks do taper, and yes, to build an accurate model, you'll have to taper them. Or just throw wood on, sand the living daylights out of it, throw on some automotive bondo, sand again, and paint a nice glossy mirror fiinsh on it! (Ready for the Battle of Lake Erie! ) The planks in the bulwark area are slightly thinner, if I recall.. Photos show the tapering (hopefully)

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

-

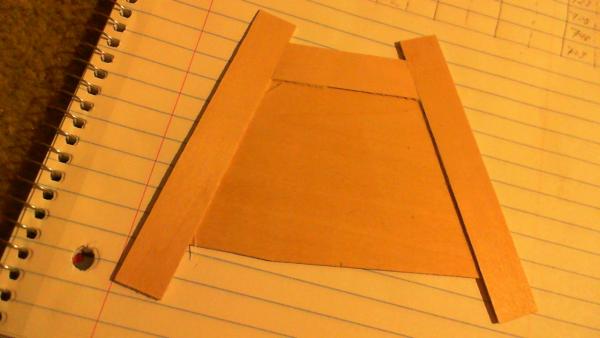

During test fitting, I noticed my bulwarks were going to be a little short when the strips were installed; I'll be adding a 1/32" shim all along the edges to compensate, then sand everything even in preparation for the topgallent rail. (View is from the outside, showing the strip overhang) "...reckless is he, now matters are worse"

-

It's good that Nenad gets us to think! Well, now it is finally panel mounting day for Bob. After 8 months of fiddling and ignoring these things, off and on, they are going on the ship, regardless of what they look like. I must say, with the many dissatisfactions of the build that I can live with, this one is the worst so far. Without mechanical help, however, I could never make these accurately, even if I practiced for 100 years. Some are better than others, and I plan on targeting the worst 5 or so and cutting them out for remaking, but then I will be done with it. Pictures will follow, and yes, some will be macro, just to show you why this is driving me crazy... But like I said previously, at least the build (hopefully) will be enjoyed, mistakes, blemishes, imperfections, and all; and not sit in a box to rot in an attic, forever incomplete... "Don't give up the Ship!!"

-

Quick note: those notches on the rear (poop) deck are not necessary; the bulkheads need to be trimmed there as well. (If you haven't already done so).. Decking looks great! ~Bob

- 151 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

No, Nenad; not the hencoops; I've done the pigpen and paint locker. According to Campell's plans, the dimensions of the top of the coops would be 7' 4" x 29", which at 1:90 scale would be 24.75 mm x 8.18 mm. Top of the coop is 34.75" off of deck, or 9.80 mm at 1:90.

- 74 replies

-

- del prado

- cutty sark

-

(and 1 more)

Tagged with:

-

Also, there is a grey area between "kit-bashed" and scratch-built" My Cutty Sark started as "kit-bashed". It is now 95% scratch-built.. But my Niagara is (so far) straight out of the box...

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hello, Brian; Battens are temporary planks that sit on the bulkheads to provide natural curvature reference lines when planking the hull. They are usually removed during actual planking. A strake is one continuous run of planks, from stem to stern. (A "row" of planks). The waterline of a ship is where the water comes up to on the hull, in ideal engineering conditions, on a perfectly calm sea, with an even keel, and a normal and perfectly balanced ballast, cargo load, and crew accompaniment. (with some allowance of cargo variance, ship's designers will set this) Hope this helps... ~Bob

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

-

Consulting Campell's plans; the bulwarks in this area are still made of iron, with plain varnished teak panels on the inside. Giving thought to where this extra thickness would "reconcile" , I could not see a point on the exterior; but consulting Lou's photos, the interface between the inside teak panels and the sternmost vertical uprights on the oval panels would account for the thickness.

-

Cutty Sark by NenadM

rfolsom replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hmm, Yes, I didn't expect to see a post from you yet, as your time is 8 hours ahead of mine, and figured you were still sleeping.... Makes sense now... Good Morning, BTW.. (Nenad says: "Good Morning, my %$*&, Bob!")- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Outside curve of the stern topgallent rail has been cut and sanded to shape. I am very satisfied how it follows the curve of the hull. Now I just have to get the courage up to cut out the inside curve, and hope my structure is strong enough to survive the cutting process... Out comes a new #11 blade...

-

Nenad has excellent advice; I did my first tests on this in November; I'm now planning on installing my strips sometime this week... I have made some progress on other areas in the meantime, but the fact that I cannot get these ovals all equal has haunted me for the last eight months. Time for me to just live with the inaccuracies; (most of which will be hidden by other details anyhow) Great job so far! ~Bob

- 151 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

These tangents, by the way, (catheads, rails) will all have to be (in my build at least) simultaneously assembled with the oval augmentation strips, all capped off with the continuous topgallent rail, assemblies painted or stained, then masked off and coated with protective finish... I can then proceed in any direction I like, (deckhouses, freeing port covers, scrollwork (how the h#@# am I going to do that??). Nenad; I see you are also pondering scrollwork; maybe I'll sit back and see what you come up with... ~Bob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.