-

Posts

1,963 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

If it's the brass wire that is too flimsy, you might try music wire. On my SIBs, I've used it for the funnel stays on sidewheel paddlers as well as tiny railing. Even at .015", it stays rigid and does not bend easily like brass wire. https://www.amazon.com/dp/B002WXPNB4?ref=ppx_yo2ov_dt_b_fed_asin_title Regardless, your Billy is coming together nicely. Can't wait to see how you make the paddlewheels. They are quite a challenge at that scale!

-

I like the red much better. Really eye-catching!

- 44 replies

-

- Scientific

- Billings Boats

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

Glen McGuire replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for the health update, Pat. So glad to hear that you are all clear. Full speed ahead with your Victoria!!- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

She looks great in her new home. Well done, Bob!!

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

I agree with John and Bob that printing on paper and then applying would be a good solution. You've got 2 different fonts to deal with and the lettering on the original has sharp lines which will be hard to duplicate freehand at this small scale, especially the serif font of the "Pittsburgh, PA". I believe you could easily create a graphic with the lettering on slightly weathered/off-white background for printing. You could even add that faint dividing line that runs thru BILLY if you wanted to get crazy! I'm also wondering what causes those wrinkles near the top. It almost looks like a stretched canvas that's not quite tight enough - like how my bed looks after I put the sheets on it! That's the cool thing about these projects of yours - trying to figure out what's going on by just studying these old photos.

-

Swigging and rigging. Does it get any better than that?

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

She looks fantastic, Gary. Superb craftsmanship. Congratulations on a fine build!

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

That is a work of art, Bob! So well done!!

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

That made me laugh! Very appropriate saying for this one, Pat! And thank you to everyone for your kind comments regarding how the project turned out. I greatly appreciate all of y'all. As for the next one, the Essex is certainly an intriguing idea. There's probably a lot that could be done with that ship and story. And I'm having a hard time getting Gary's suggestion (having a whale boat glued upside down to the inside of the bottle) out of my mind. But the next project may be a more standard SIB in nature. A local restaurant (very high-end chop house) has asked me to do an SIB that will be the centerpiece decoration for their "Mayor's Room". We are still working out the details on what they would like the project to be. I'm getting the impression that they may want something a little more traditional than my usual stuff, but we will see. Regardless, I'm really looking forward to creating something that they are happy with and will be a complement their fine establishment.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Where do you come up with cool things like this and why have you not told me about it before!! That looks perfect for my SIBs - a heckuva lot better than the pencil lines I've been drawing for a deck plank look. Oh, and by the way, what a cool project you are working on, Mike! Can't wait to see how you present it in a diorama (with a hanging locomotive I hope)! The Seishu Maru looks like the type of industrial vessel that @Javelin might model, albeit a vintage one.

-

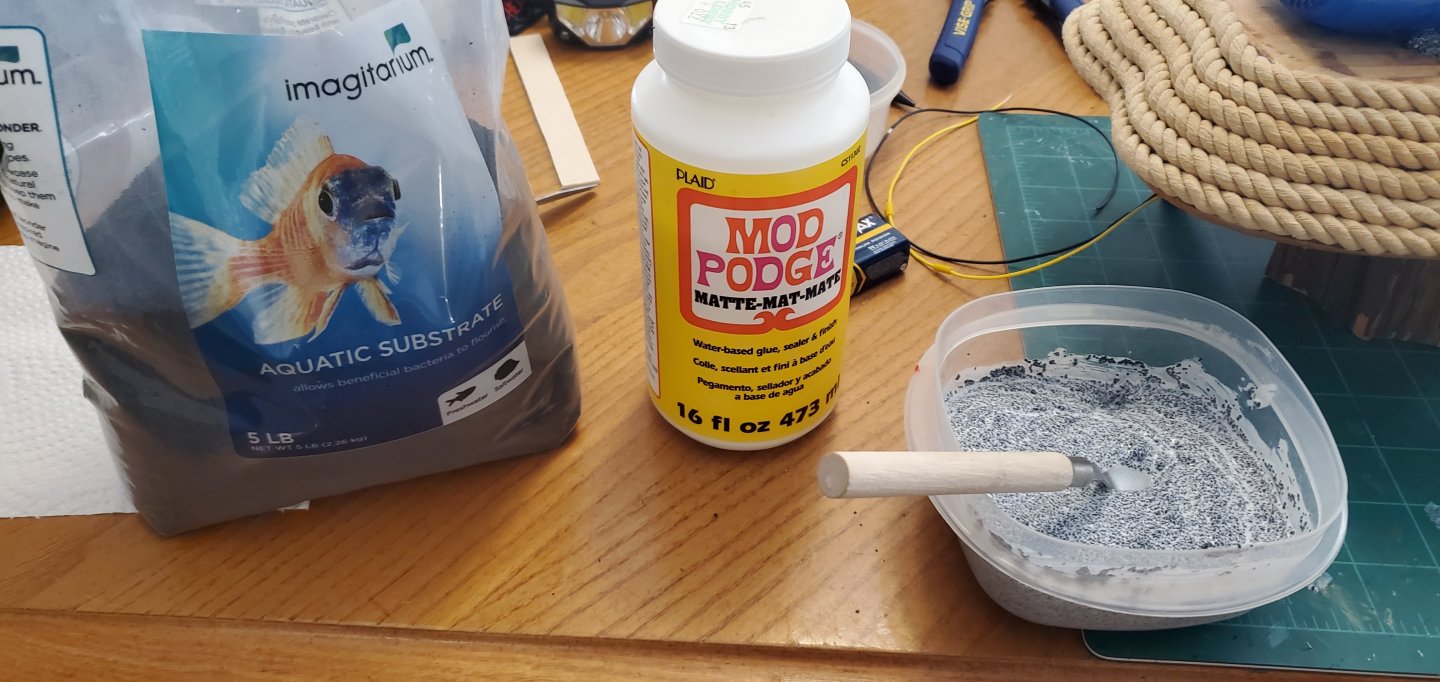

I got all the wires soldered together and the connectors connected to the switch. The last step was mounting the bottle on the base. The bottle is flask-shaped, but the sides are curved so it does not lie on it's side with any stability. Also, it's got kind of a female body shape with a gentle waistline in the middle. After more hand-wringing, I decided to mount the bottle on a "black sand beach". The thought was that I could push the bottle slightly into the sand and it would conform and adhere to the side of the bottle providing stability to the mount. For my black sand beach, I used a mixture of aquarium sand and Mod Podge. After a day, the Mod Podge dried clear and provided a solid adhesion to the bottle and the base, I also made a nameplate and attached to the front which you can see in the final pics below. But before I post those final pics, I want to give a sincere thank you to everyone that participated in the fun expedition. Whether you read every post of just popped in on occasion, I greatly appreciate you being part of the journey from idea to completed project. So a huge THANK YOU to @Keith Black, @Ian_Grant, @Coyote_6, @Snug Harbor Johnny, @Knocklouder, @Javelin, @KennyH78, @Canute, @Bryan Woods, @Baker, @gjdale, @gsdpic, @Paul Le Wol, @BANYAN, @JacquesCousteau, @SaltyScot, @GrandpaPhil, @John Fox III, @popeye2sea, @hollowneck, @tmj, @CiscoH, @FriedClams, @Desertanimal, @ccoyle, @BLACK VIKING, @Siggi52, @robdurant, @Landlubber Mike, @Kauz, @Kenchington. Here are the final pictures: And here's the same in low light: What you can't see in the still shots is that I used a flickering LED inside the fireball. So if you want to see what that looks like, here's a 15 second video: https://www.youtube.com/watch?v=PQxOmC4wIFM. And with that, this fun ride comes to a close. Thank you again for all your comments, help, humor, and inspiration! It's an amazing community we have here in MSW.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.