-

Posts

1,978 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

Looking very sharp, Gary! Particularly the sheer trim on the bow with the elegant scroll. Nicely done!

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

Amazing work, Keith! I agree with Jacques C. I did not really grasp the scale until you showed it next to the dollar bill. Wow!!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

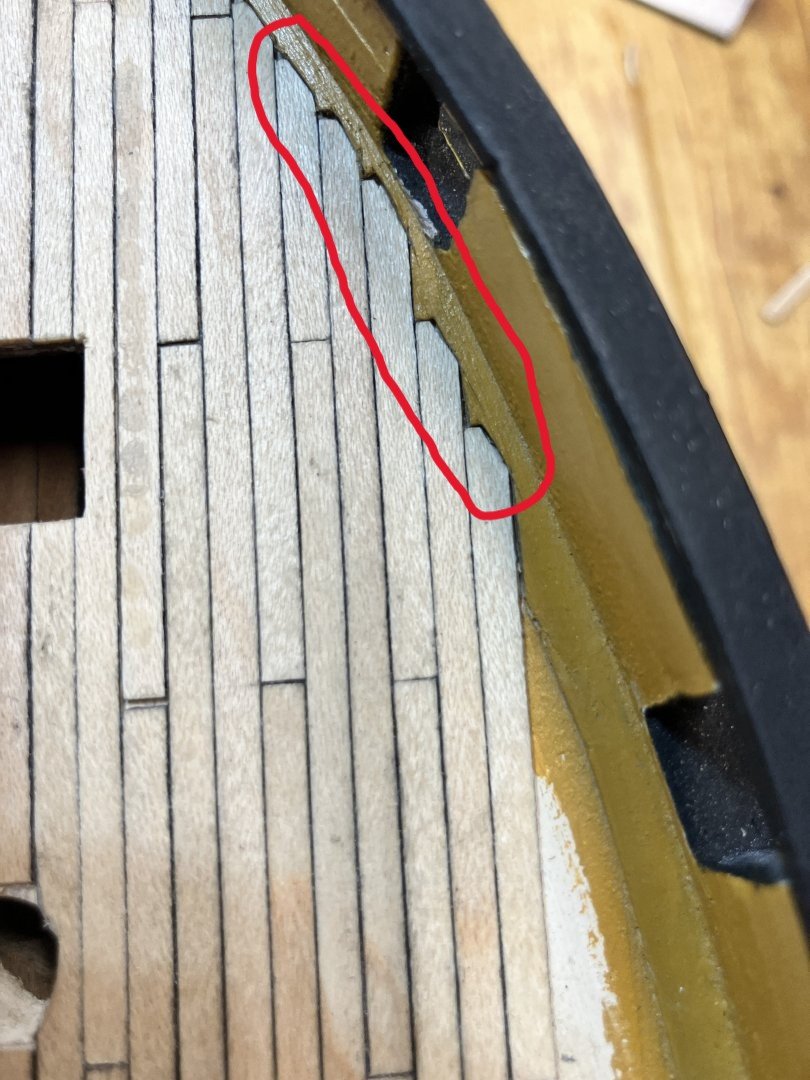

I'm not sure what nibbling is, Mark, but if this is what you are talking about, that's some very nice work!

- 257 replies

-

Hmmm. I was not even gonna try to incorporate any lighting beyond the Greek Fire. Never heard of "grain of wheat" bulbs, so I will have to look into those and see if they might work. I hope they are very small! Thanks, Johnny!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Before fully committing to this project, I wanted to see if I could actually drill a clean hole in a glass bottle. After watching several youtube videos, I found a technique I thought might work. I bought these diamond coated, hollow drill bits off Amazon for $15. The suggested technique is to run cooling water over the bottle and start the drill at a 45-degree angle till you get a small notch cut into the glass. Then slowly work the drill into a horizontal position. Once the vertical orientation is established, you gently rock the bit back and forth while applying light pressure letting the bit do most of the work till the hole is fully bored. It only took about 10 minutes. Afterwards, I had a pretty clean hole with no cracks and just a very tiny amount of chipping. The hole is 3/16 inches in diameter, so the chipping is only noticeable in these closeup pics. @Keith Black wants me to try and fit the ship thru this hole, but I’m not even going to try! I got some small, flickering LEDs from Amazon that run on a 9-volt battery. One or maybe 2 of these will go inside the fireball to bring it to life. Here’s the LED wire extending thru the hole and out the bottom of the bottle. When the time comes, I will be making the epoxy resin water a dark blue to hide the wire. Now that I’ve got a good hole in the bottle, we are off and running. Here we go!!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Time to get 'er in gear and start work on another SIB. I was tossing around a few different ideas and I just could not get rid of this one image that was floating around in what's left of my mind. In the 4th installment of the Pirates of the Caribbean movie (On Stranger Tides), there is a scene where Blackbeard is captaining his Queen Anne's Revenge when a mutiny breaks out among Jack Sparrow and the crew. Blackbeard appears on deck and raises his sword, bringing the rigging to life which begins roping and hanging crew members from the yards. Blackbeard decides to spare the crew but make an example out of the cook. He sets the cook adrift on a long boat, points the Revenge at it, then unleashes a ball of Greek Fire from the bow, engulfing the cook and long boat in flames. Here's a 5 minute video of the scene from the movie: https://youtu.be/fO4ZLQmcXMU My idea is to capture the moment where the Revenge is spewing out the Greek Fire. Here's a screenshot of the moment from the video. The scene is so dark that you don't get a good view of the ship, but you get the idea. And here's my crude artist's rendition of the SIB concept. Now, to bring the SIB to life, I want to actually light up my fireball. So I'm going to try and incorporate some flickering LED lights within the fireball and run the wiring thru the bottom of the bottle and into the base where it will lead to a battery and power switch. I think I've been reading too many of @Ian_Grant's build logs, which is why I can't get this crazy idea out of my head. Obviously, this is going to require doing some things that I haven't done before - making a fireball, drilling a hole in a glass bottle, rigging up some electrical stuff, etc. So put your helmet on and buckle up. This is probably gonna be a rough ride!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Ferrari 288 GTO by gsdpic - Fujimi - 1/24 - PLASTIC

Glen McGuire replied to gsdpic's topic in Completed non-ship models

That is incredible work, Gary! The pictures look like showroom shots for the real thing. Wow! -

That's fantastic news about your heart. So glad to hear it, Keith.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

The rope work on the rustic base is a really nice touch. It complements the ship quite well. Great job, Bryan!

- 44 replies

-

- Nave Egizia

- Amati

-

(and 1 more)

Tagged with:

-

She turned out to be a real beauty, JC. An enjoyable build to follow. Congratulations on your fine work!

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

The answer to your question is TBD! 😃

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

The stern deck looks amazing! Well done, Bryan!

- 44 replies

-

- Nave Egizia

- Amati

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.