-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CaptnBirdseye

-

Chris, the wife's going to kill me when i show her this 😄 I have to say she really does have beautiful lines. Just hope i can clear the decks for when she's launched .

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

How many kits do you have on the go at the moment?

CaptnBirdseye replied to CaptnBirdseye's topic in Wood ship model kits

I have to admit, the pleasure, for me, is in the building. However as different things pique my interest at different times, i can tend to stop and start a kit - but for me that's what keeps it fresh and interesting. Just my take.... That's a good job with the Amati Victory, as i REALLY want that but will need to make some room first 😱 lol -

How many kits do you have on the go at the moment?

CaptnBirdseye replied to CaptnBirdseye's topic in Wood ship model kits

You make a good point there Allan! I have done a lot of research into quality tools to have a go at scratch building, but there are 3 areas of concern: 1) Price...... given the chance/choice it would be a full workshop of Byrnes Model Machines, but living in the UK, the shipping alone is prohibative 2) Available space.....i would need my own workshop, not a spare room that i'm 'allowed' to convert. 3) Skill level.... and this is probably the biggest barrier. That and having the nerve to give it a go in the first place 😱 -

I’d second the one from Hobbyzone. I have both the large and small building slip from them, but rarely use the smaller. The larger is quite expensive but a worthy investment

-

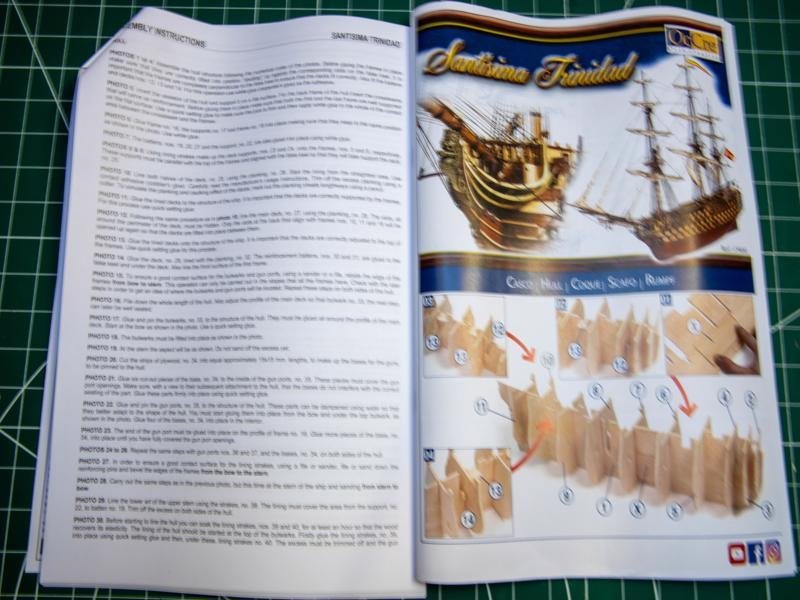

To be honest, Allan, the planking instructions supplied are woeful! I guess, at this level, OcCre thought everyone would have the experience to know how to plank without detailed instruction 😒 In this respect, the DA version is better. Admittedly, theirs is twice the price, and double planked.

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

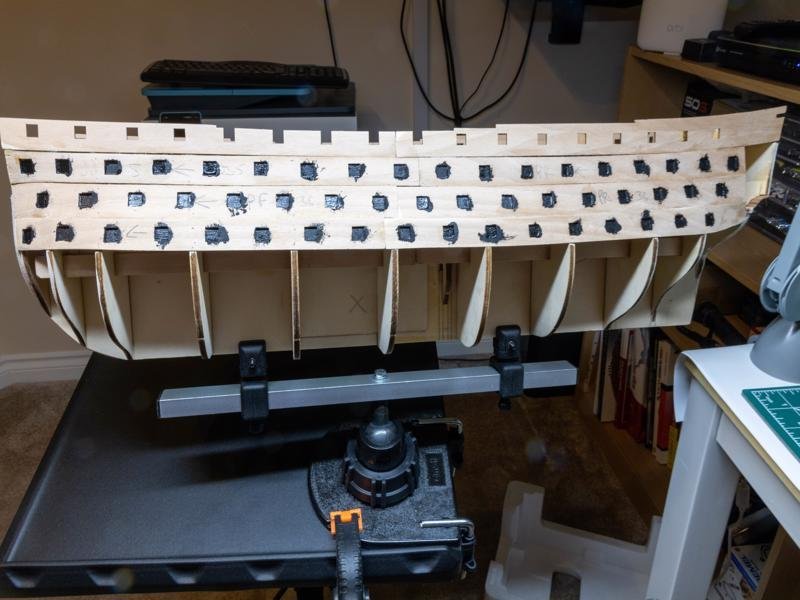

This update involves planking the counter. Due to the curve below the transom, i had to temporarily use pins to hold the planks on the lower counter in place while the glue dries. When cured, i will sand to shape. While waiting for that, i thought i would skip forward a bit in the instructions. I had read that once the upper planking was in place, the false gunports need painting black. As many have said, this has disaster written all over it, as the posibility of getting paint on the resulting planks is waaaayyyyy to easy! So i used some Tamiya X1 Black acrylic to 'black out' the ports before fitting the planks. I've found a noticeable drawback with the Amati Keel Clamp, shown in the last picture below. When trying to clamp it to my worktable, the front end has a habit of 'lifting'. So much so that i couldn't use it easily on my workbench so had to adapt my computer table This bring us up-to-date.

-

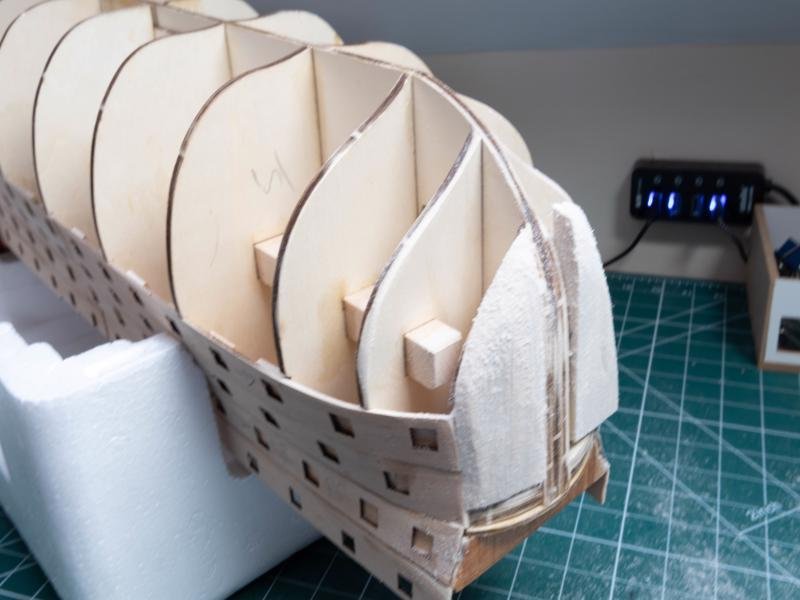

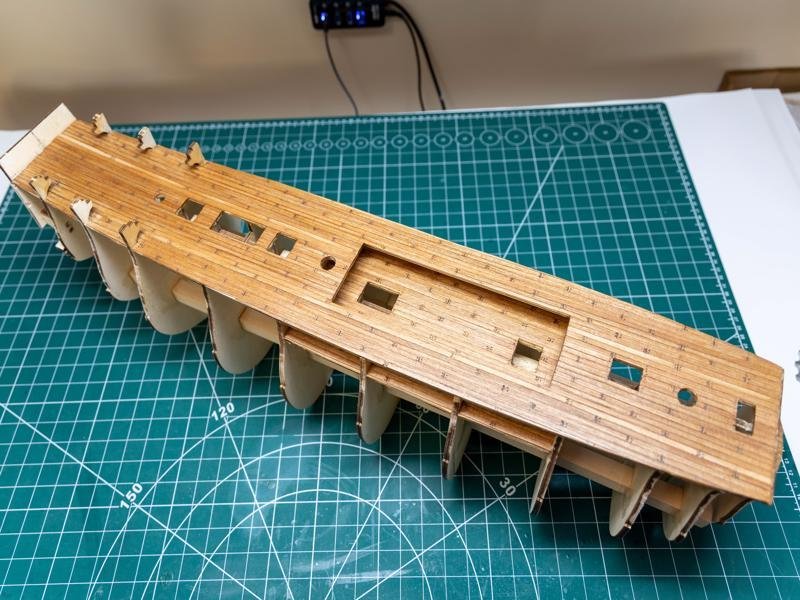

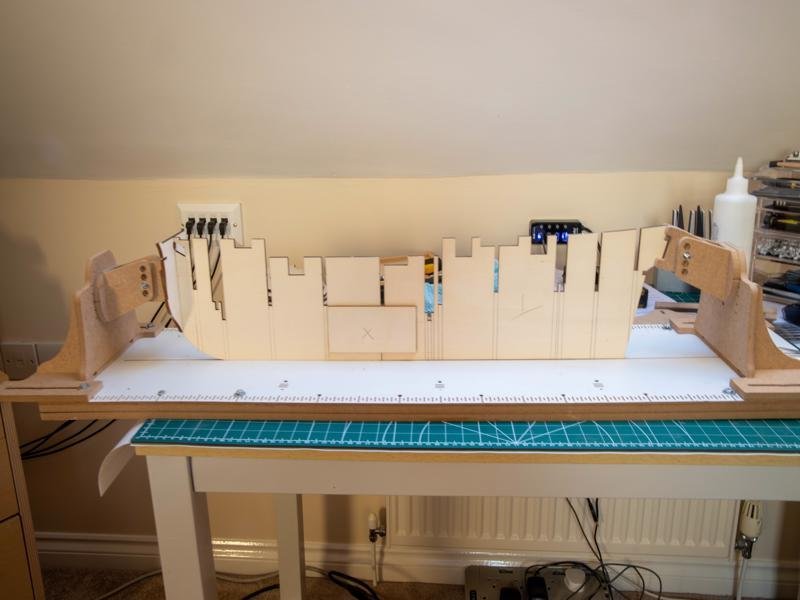

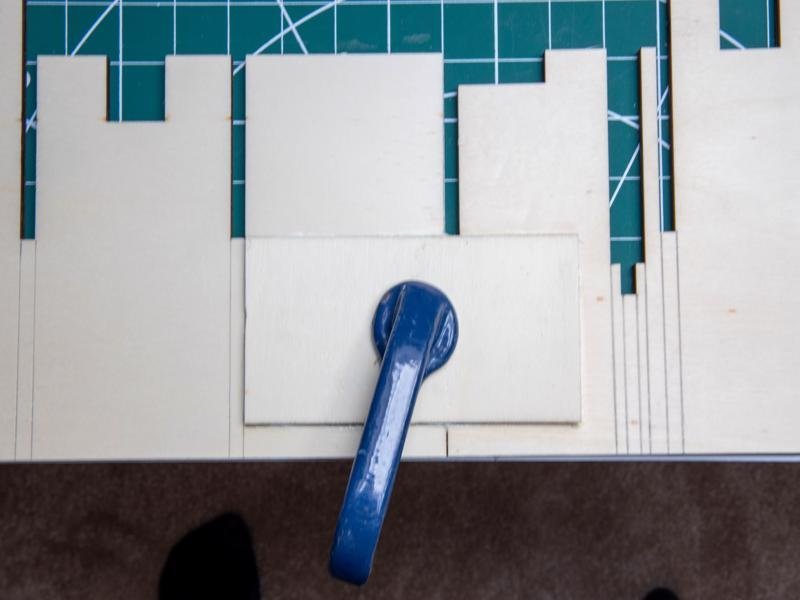

Once all of the bulwarks are in place, it is time to sand everything down, ready for planking I needed something that would alow me to turn the skeleton upside down without damaging the top bulwark. As luck would have it, i had just recently replaced our home printer and the polystyrene that came with it was just the right size for the hull to sit in Result! I also added balsa to the bow and stern to help with the lay of the planking.

-

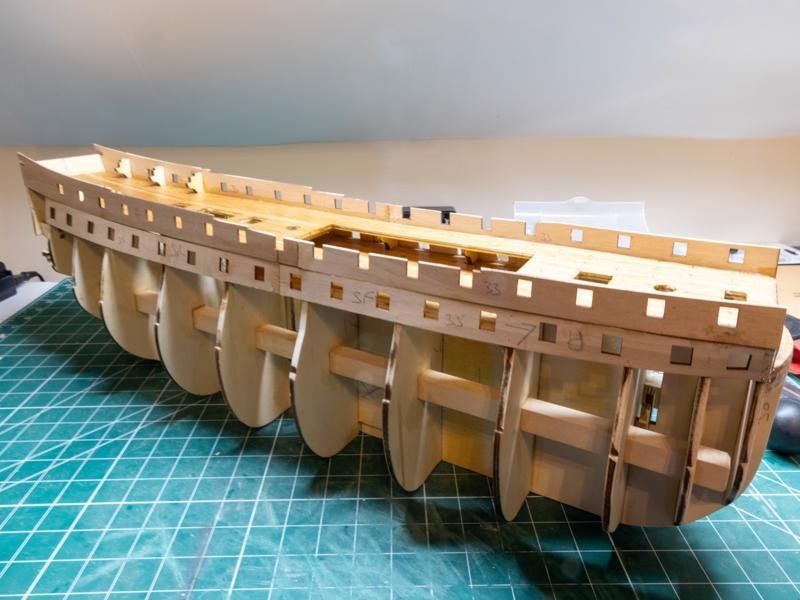

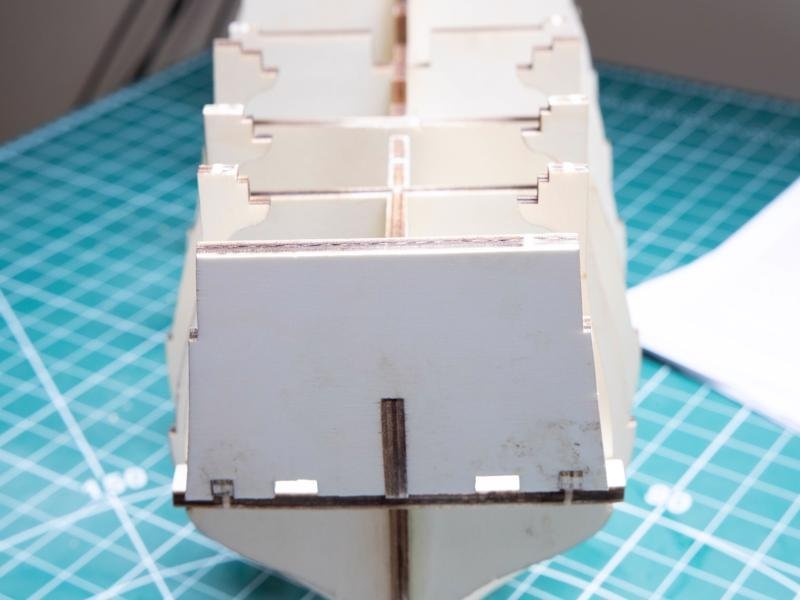

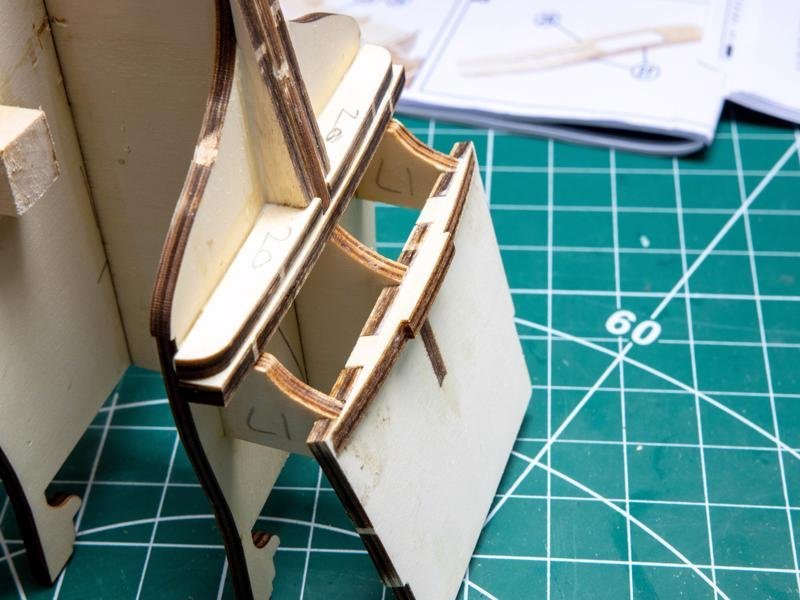

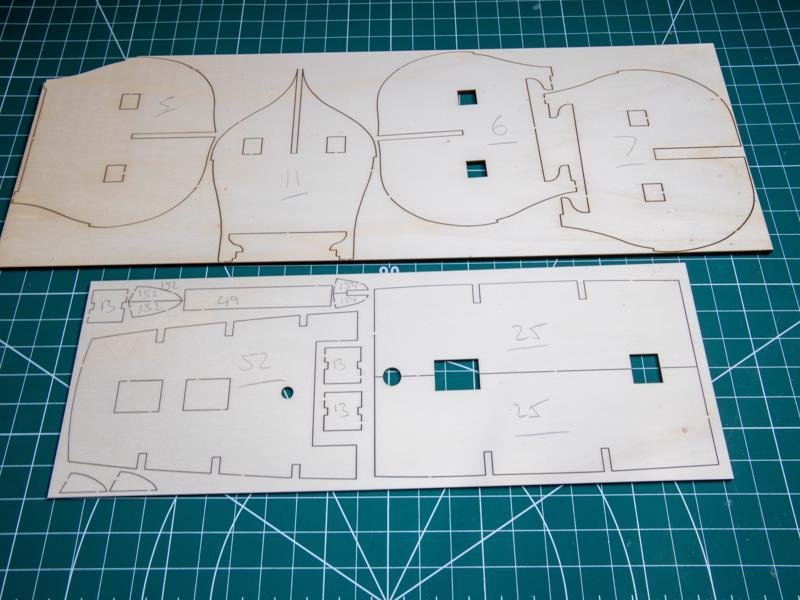

The Bulwarks are fitted next, but strangely to my eyes, you actually start from the top, working downwards This presents its own problems, like how do you get the upper bulwark to fit along the edge of the top deck? In the end i glued some temporary tabs underneath the top deck, which alowed the bulwarks to sit at the right height (tip i found on Youtube - thank you John Aliprantis). Once one side was glued in place, it was repeated for the other. However, i think if i was to ever build this again i would start from the bottom, ala the De Agostini version Each side has three rows of bulkarks, which terminate at the notch on each bulkhead. As each row is fitted, 15mm squares are cut and glued in place behind each gunport. Some of these can be a bit of a pain to get in place. Also because of the bulkheads, some of these will need to butt up against them. The bow end on the second row has to be shaped to fit. On the last row the bulwalk didn't avtually meet the notch in the bulkhead. After a little ponder, i decided i would leave it like that and rectify later.

-

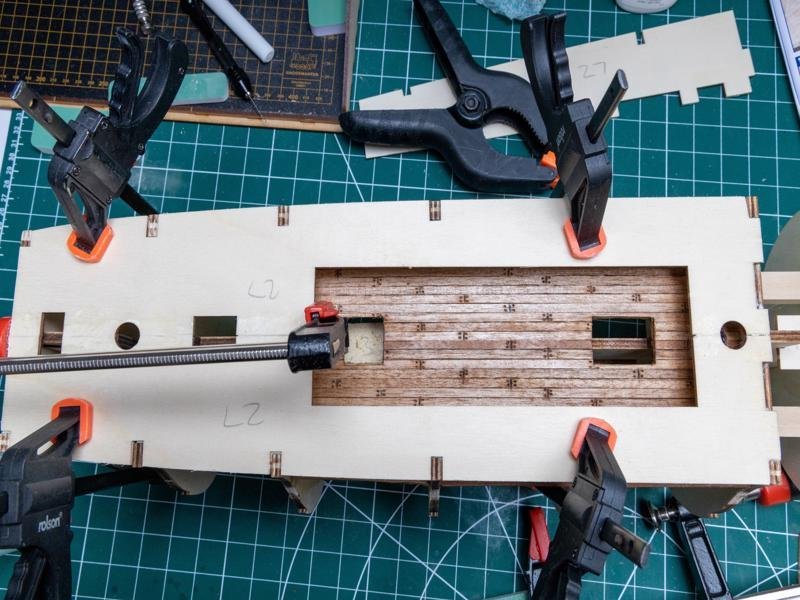

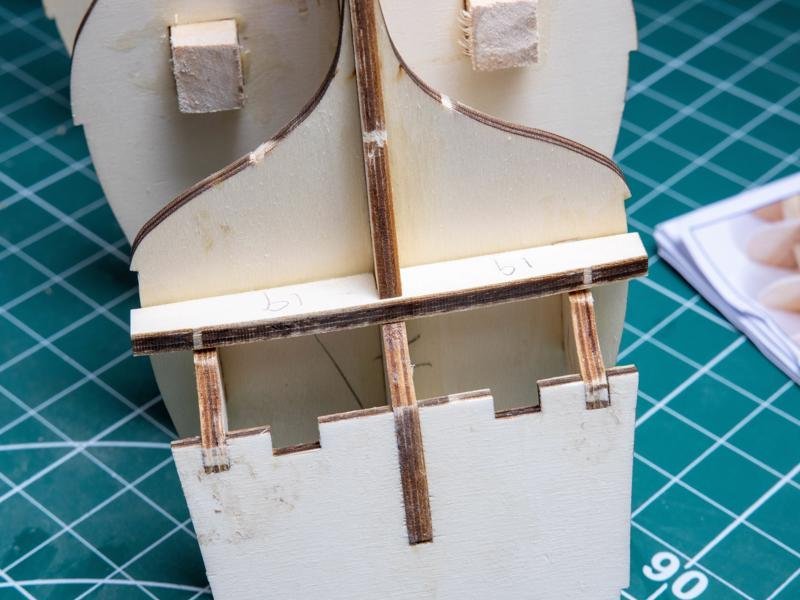

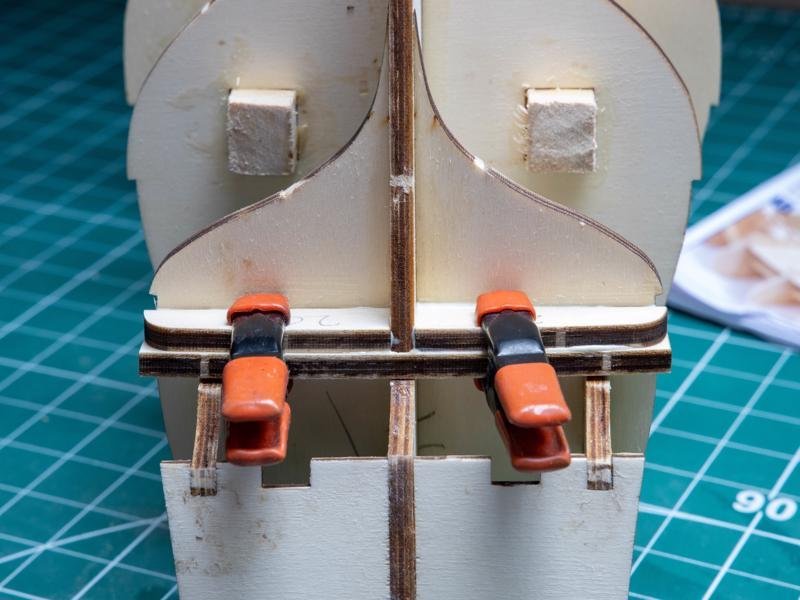

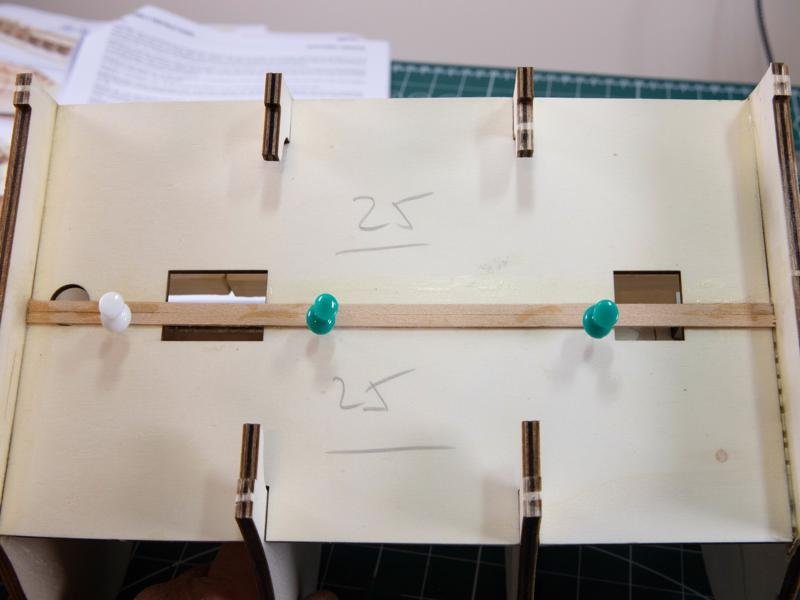

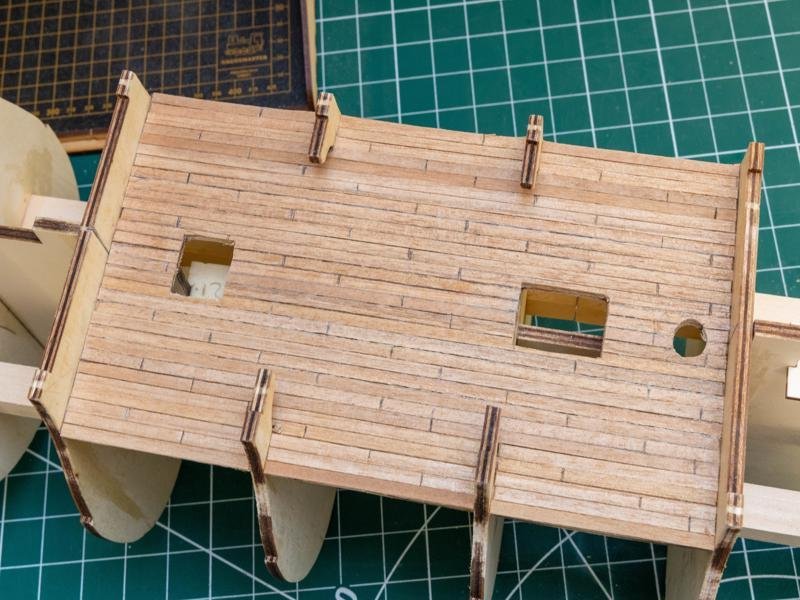

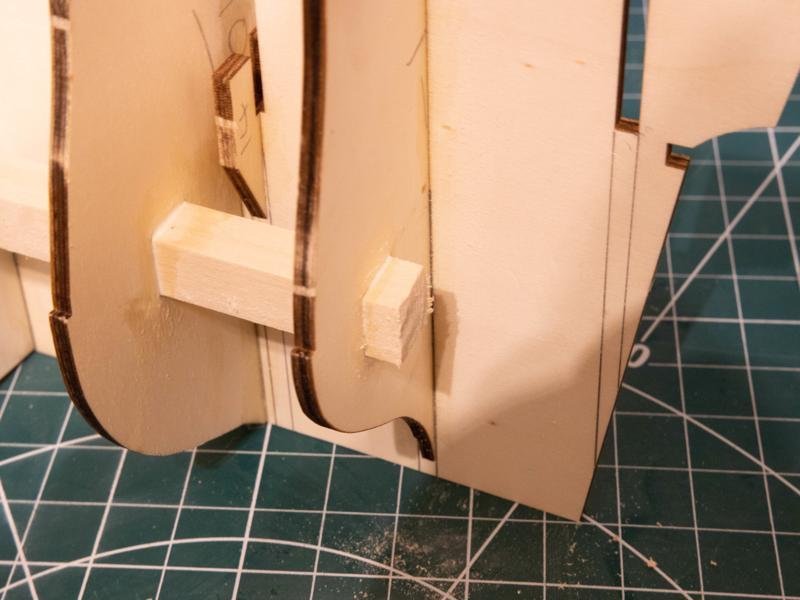

Next, i built up what will become the stern gallery. Straight forward enough, just adding the supports and the end panel. The instructions then ask that you add supports for the lower deck. These seemed a bit flimsy to me, so i used a few of the offcuts from where the hull formers came out of the ply sheet. These, i judged to be the right thickness - thick enough to offer better support to the deck, but not so thick that they interfere with the mast when installed (hopefully!). It is essential that these supports are at a right angle to the false keel, otherwise there are going to be problems when installing the deck itself. I used a set square for the first support, then a straight edge for the second. Seemed to work out ok Another deviation was to install the lower deck before planking. No other reason than for personal preference. My thinking being this way you can ensure better fit of the deck. Started laying the first planks. Decided to use some Tanganyka that i had laying around. The pins are there just to help butt them up against each other until the glue dries. I then gave the planks a coupleof coats of Danish oil.

-

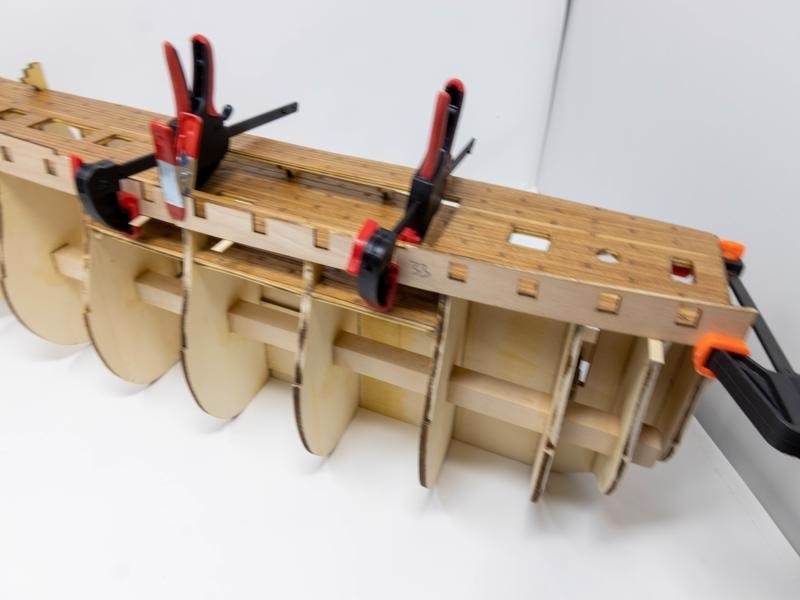

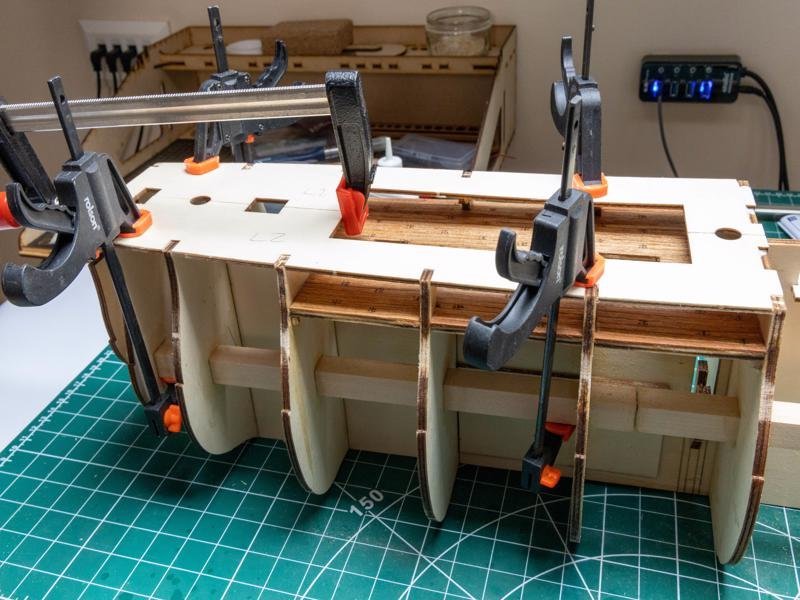

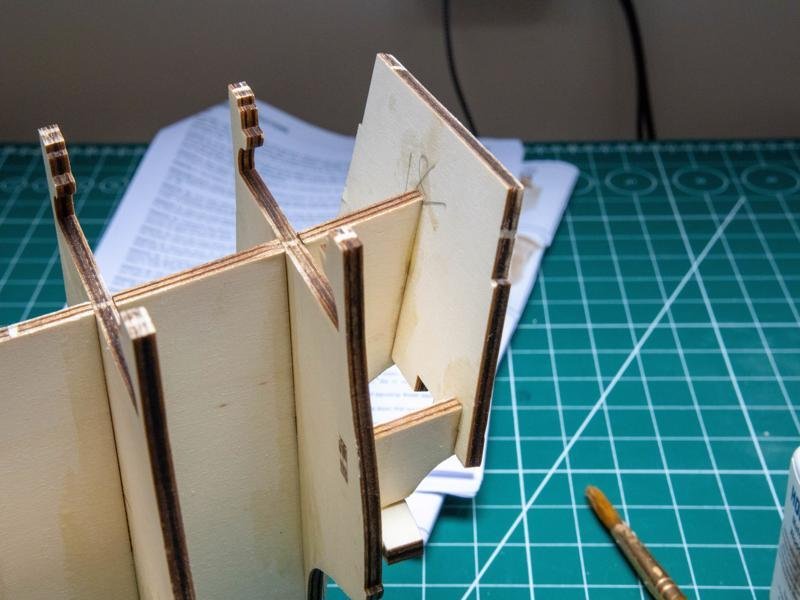

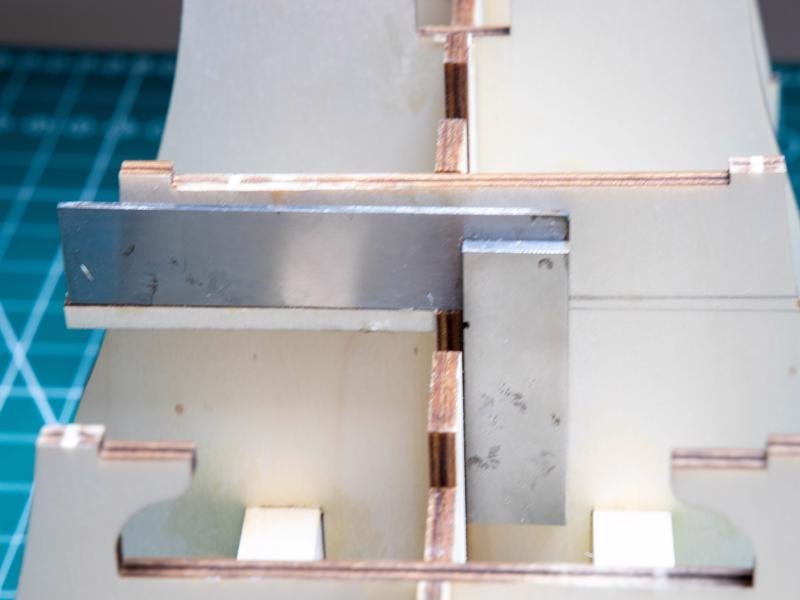

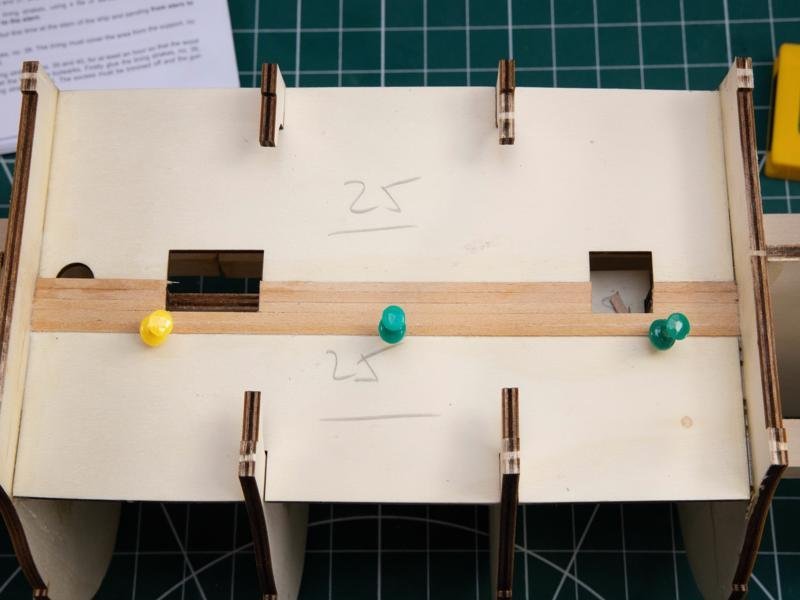

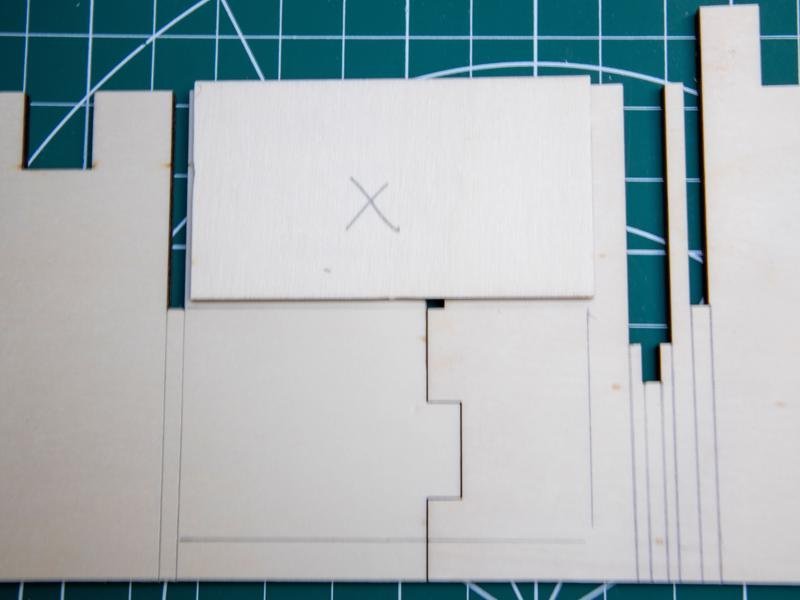

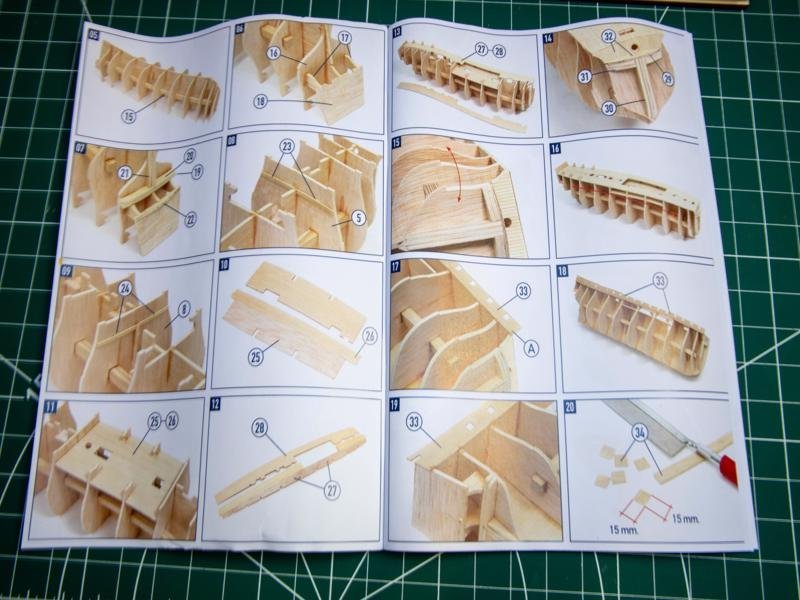

Another small update. The first photo shows all the formers installed, and looking mightily straight . Next came the task of fitting the 'bracing beams' for want of a better word. Inverting the skeleton of the hull, the four beams are prepared to slide through the square holes in the hull formers. It makes the job easier to give each beam a light sanding, and also to chamfer one end so it slides through easier. I superglued the ends of the two beams to hold in place, and then added glue where the beam and formers touched. This was repeated for the opposite side. The beam in situ looked too long to me, so , fearing it would interfere with the hull planking, i removed about 2cm from the stern end.

-

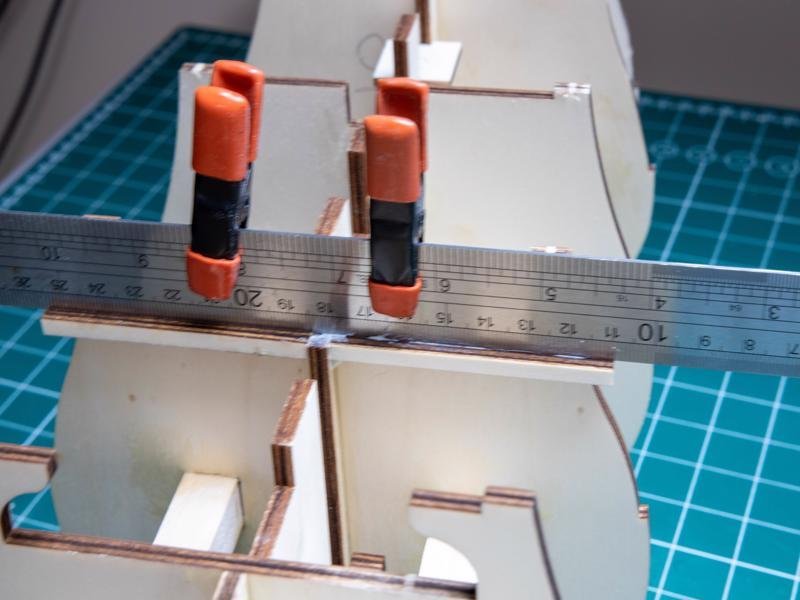

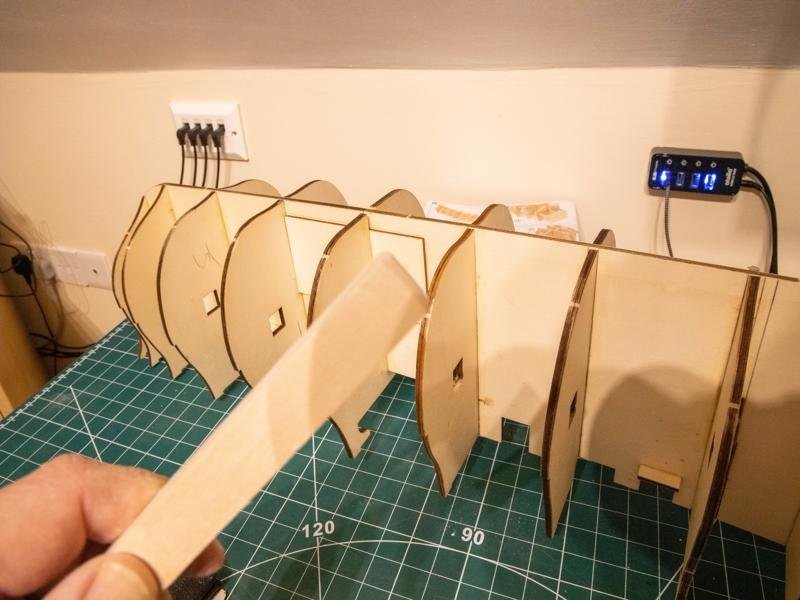

Next task is setting up my Hobbyzone jig, making sure everything is square. The hull formers are then sanded for ease of fitment, and glued in place. Two things noticed here: no warpage on the keel, and the formers nearly all sat square without having to clamp to a set square! (oddly enough only the first and last former need squaring). It is important that the hull formers sit suare to the keel, and seated fully into the keel slots, otherwise problems could occur later when fitting the decks. Once the formers are dry, the mast and deck support braces are fitted. That finishes this first update.

-

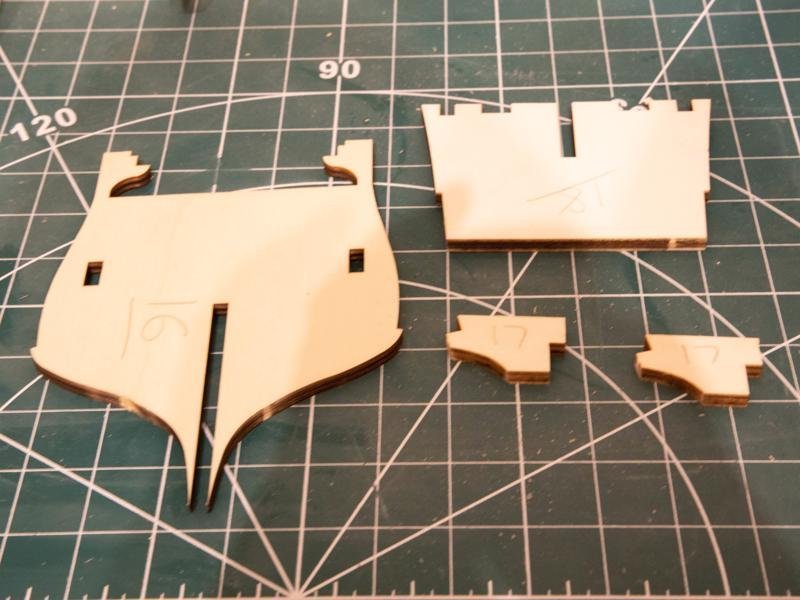

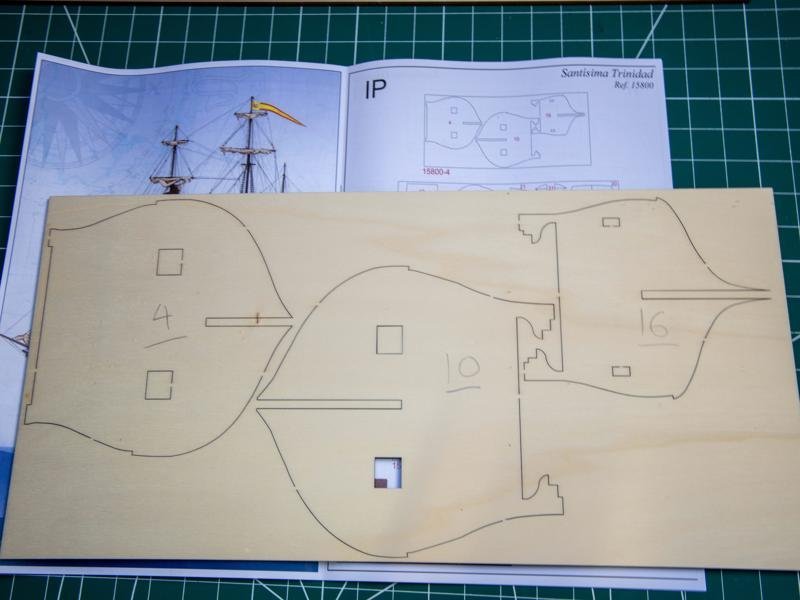

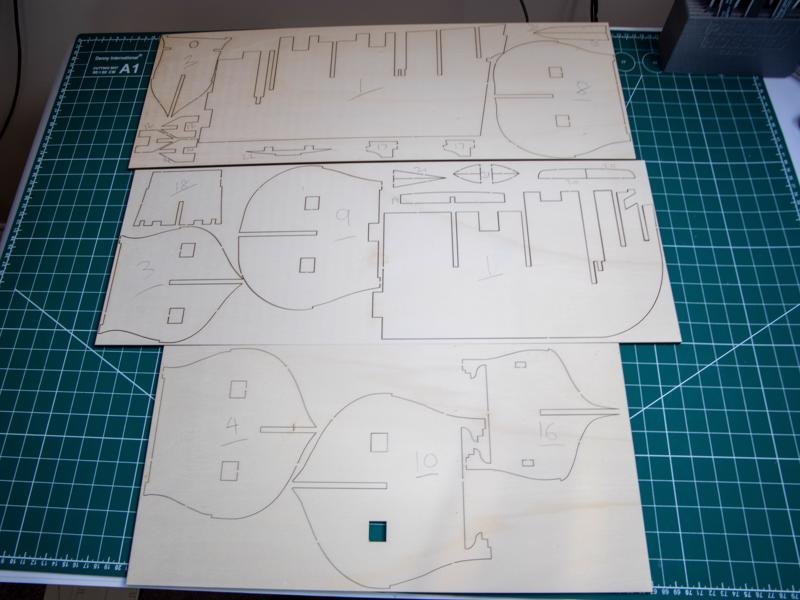

First job, remove all the bulkheads (hull formers) and false keel, clean up the edges and number the parts. I also drew vertical lines on the keel to aid alignment of the bulkheads. The false keel is in two sections, so using a flat work surface, these are glued together and braced over the join on both sides.

-

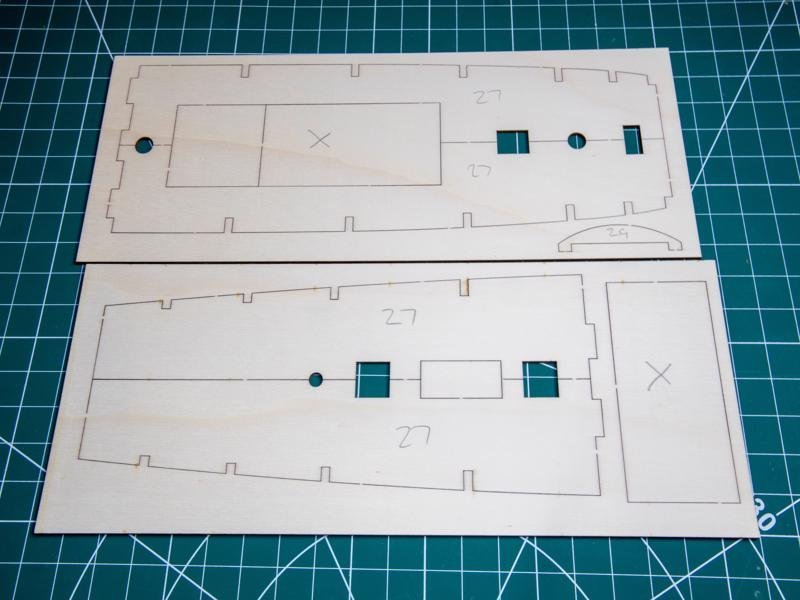

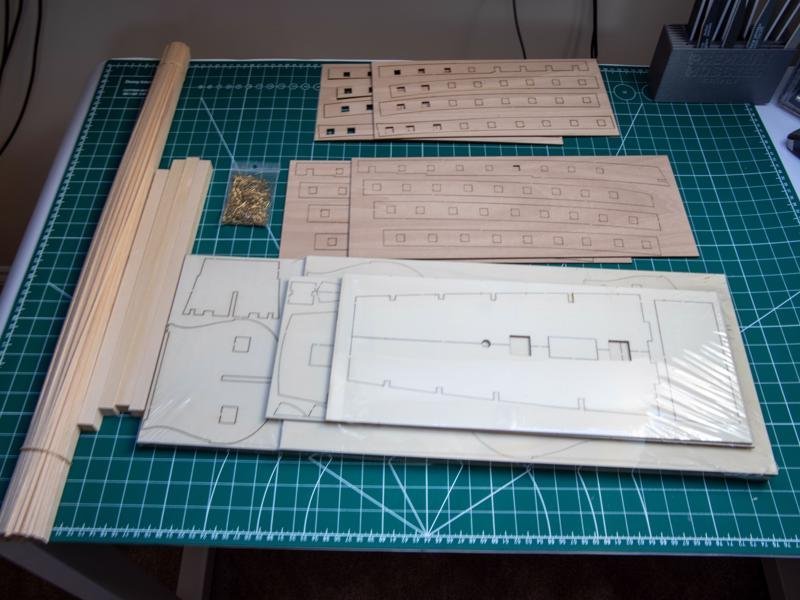

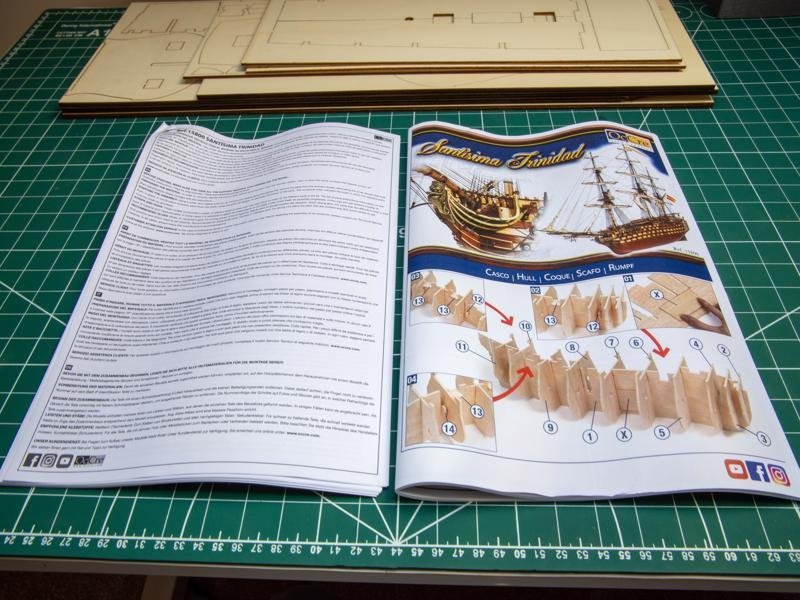

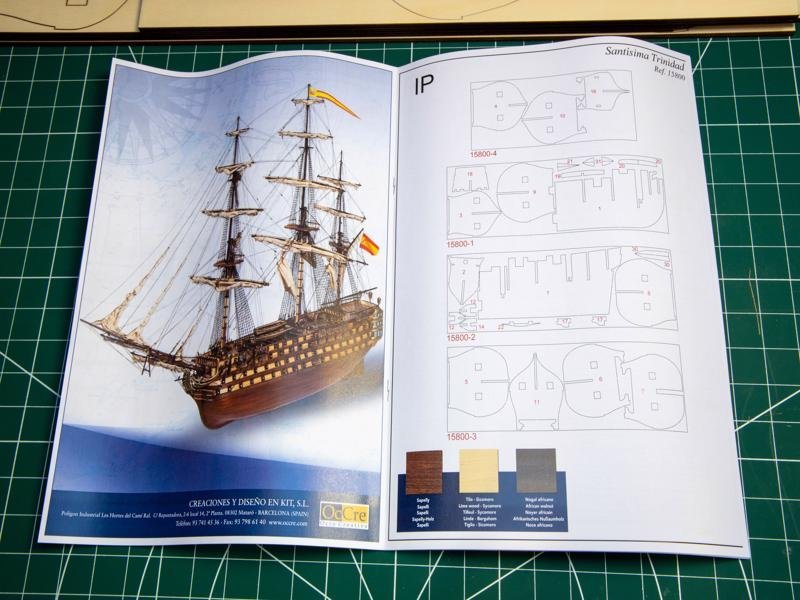

Pack 1 - The Skeleton. As mentioned, i am buying this in Stages (never knew you could do that with these kits). This will help with storage, but does cost a little more than the full kit though. First impressions? The initial box is huge, and well packaged. Pack 1 comprises of 2 false keel sections, Keel brace parts, the bulkheads, 4 rib strengtheners (not in the MS version), pre-cut gun-ports, lower and middle decks, 2 types of wooden planks and a bag of pins. The instructions come in two parts: one full colour and the other numbered instructions. So Far, so good

-

I thought i would share with you my journey to build this leviathan of it's day. I had tried twice to build it with DeAgostini, but theirs has some differences to this one. One thing they both share though is the fact that you can buy them in installments. Well sort of, in the case of OcCre, as it comes in 7 packs instead of 33 with DeAgostini. I wasn't even aware that Occre did this, but in my case it makes sense, as i can buy the packs when i need them and not having to store packs unnecessarily. Anyway, i started this back in February last year, but i hope it will be of interest to some of you, so i would like to share my build with this forum. Any hints, tips and general advice welcome as always. I will try to bring this diary up-to-date as soon as I can. In the meantime……enjoy!

-

You might want to think about doing a production run on the name plate 😀 Boiund to be takers out there! Very well done 👍

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Looking good Eck 👍 I was wondering about double planking. What do you think?

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

Am i the only one who has multiple builds on the go at the moment? All at different stages in their build. I do a bit to one, then put it aside while the glue dries or whatever, then pick up another, etc... I counted them up last night. 1) Hachette 1/200 Bismarck (wooden original) - awaiting hull planking 2) Occre 1/90 Santissima Trinidad - planking again 4) Hachette U96 - unstated as yet 5)Caldercraft 1/64 HM Brig Supply - another awaiting hull planking 6) Vanguard Models Scottish Fifie - ditto 7) Vanguard Models Scottish Fifie ( yes i have 2) - yep, awaiting hull planking 8/ Vanguard Models 1/64 HM Flirt Master Shipwright Edition- second planking 9) Artesania Latia Arab Dhow - planking Is that enough to be going on with 😂😂😂 Can anyone see a pattern emerging here?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.