-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CaptnBirdseye

-

Ok having thought on this overnight ( yes I probably am over.thinking this), but I feel the best solution would be to lay the false gunport tight up against the upper one and build up the notch on the bulkhead so it sits tight. After all the planking will cove it anyway. unless anyone has a better idea?

-

I wonder if one of you kind members could give me some advice please? I’m building the Occre Santissima Trinidad and have reached the point where the false gunports are fitted. The port side fits in the notches of the bulkheads, but the starboard side is a few mm off, as shown in the photo. What would you guys do? Fit the lower edge into the slot on the bulkhead , or mate it to the one above and fill in with a shim? Thanks in advance.

-

Looking good so far 👍. I used some left-over Tanganyka for my deck planking. Will your stain mar the work done to simulate the caulking and treenails?

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

I Have this kit also, so i hope you won't mind if i follow along? Here's hoping the image issue gets sorted quickly

- 41 replies

-

- OcCre

- Santissima Trinidad

-

(and 1 more)

Tagged with:

-

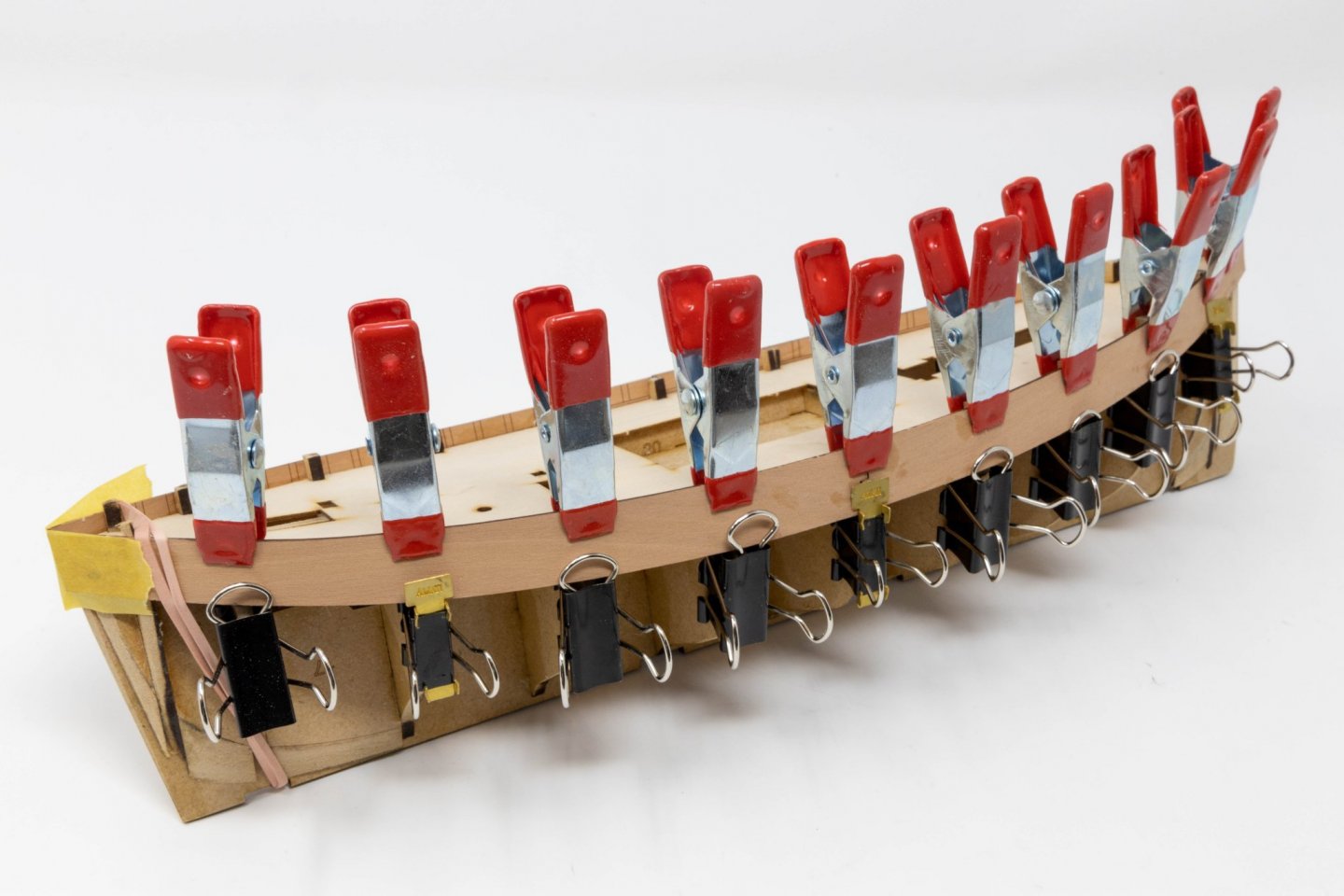

Oooouch! Mia Culpa, Mia Culpa! I’d left the port side to dry for a good 24 hours, but when removing the clamps I clumsily caught the bulwark and split a piece off! Luckily it’s in an area that will be covered by planking on both sides, so after gluing it back in place, I will cover with watered-down adhesive. After a light sanding I’m hoping all will be good and no one can tell. Hopefully….

-

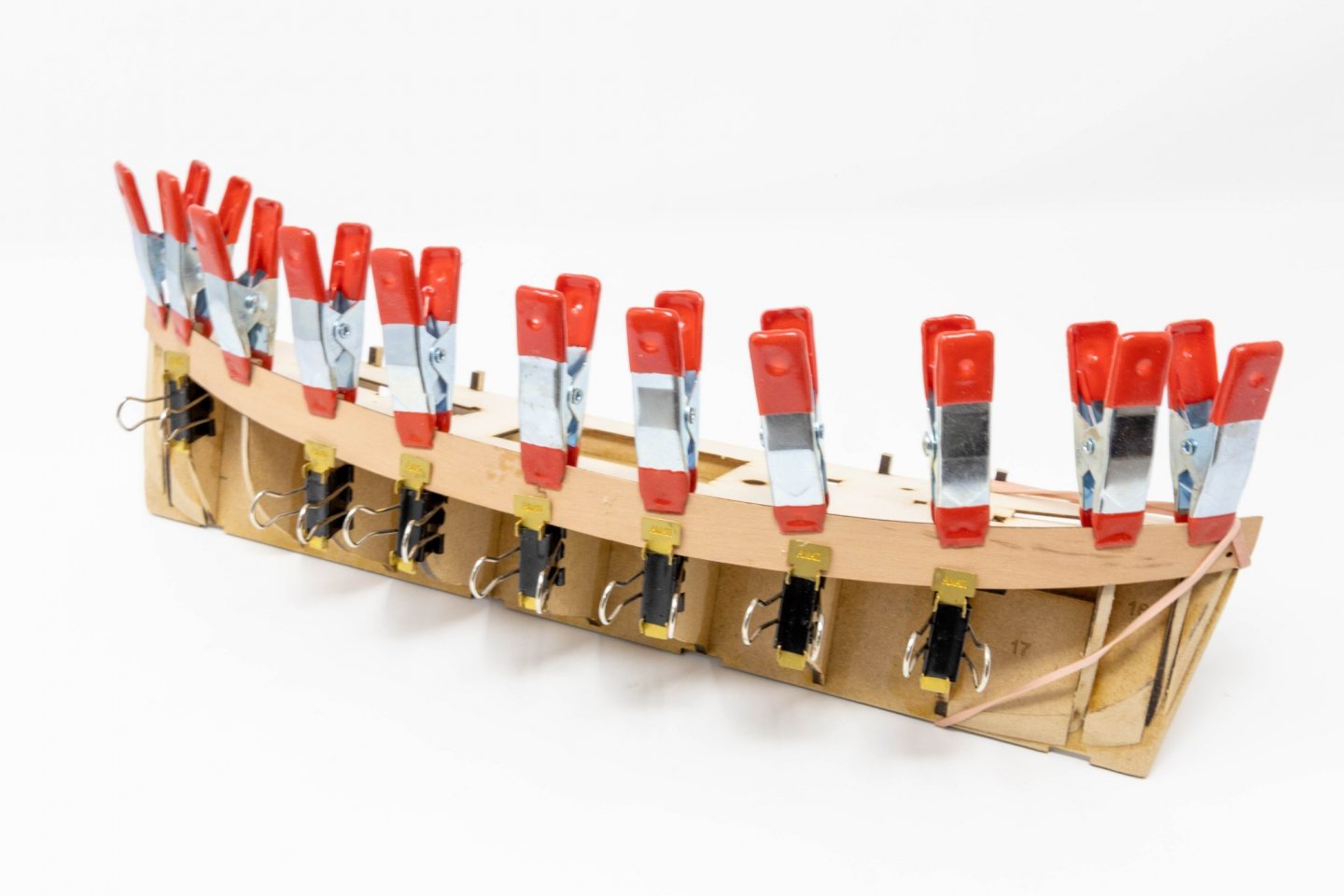

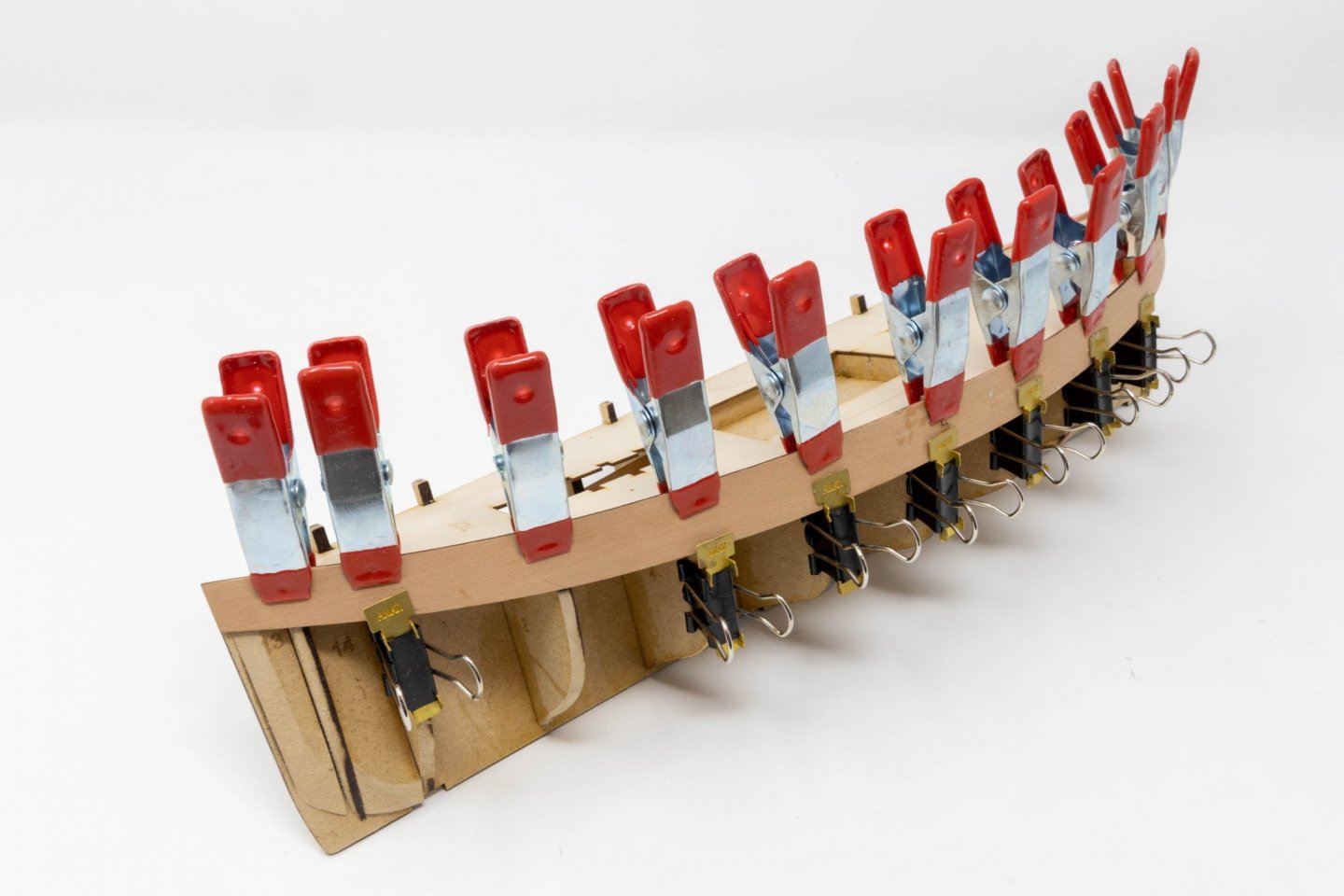

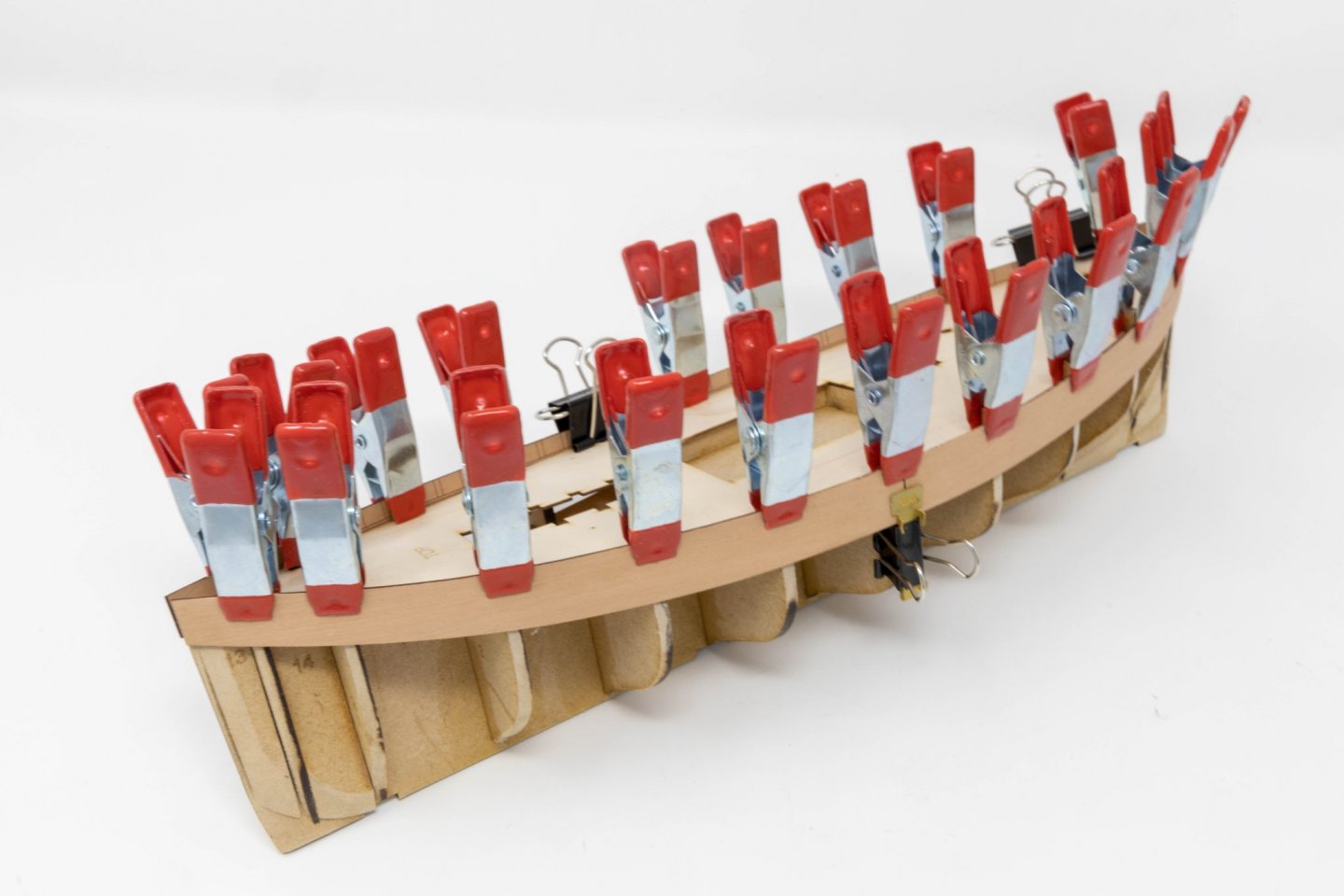

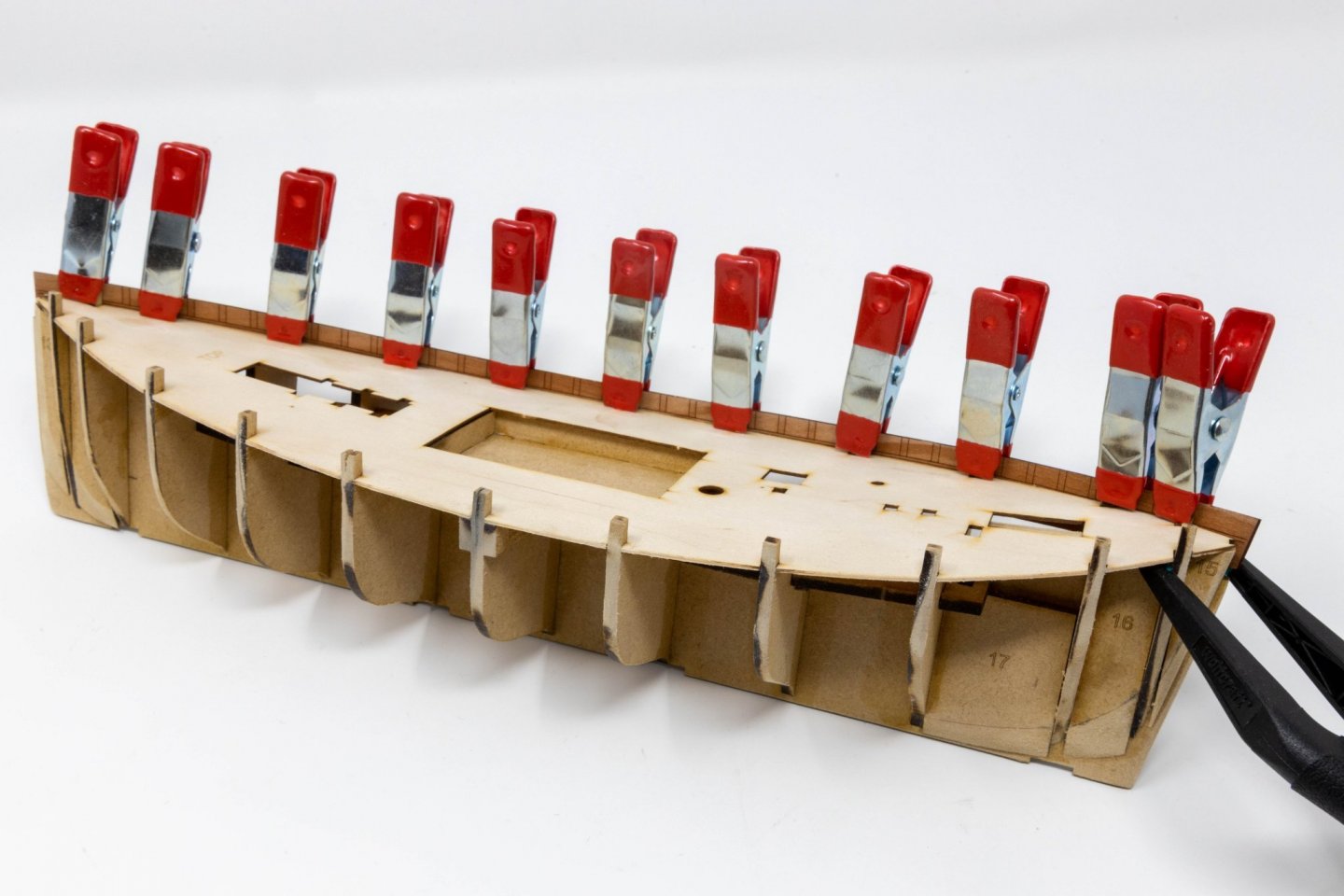

Pressing on with the build, i left the damp bulwarks clamped in place overnight to form properly. The next job, which i found harder than expected was to glue these in place. The problem arose because here i could have done with two pairs of hands! Even tough the bulwarks have lines on them to aid horizontal placement, i just couldn't get them to align at every bulkhead. In the end, i decided i was overthinking this, as the bulwark tops are sanded level in a later stage. Overall I am very pleased with the progress so far 👍

-

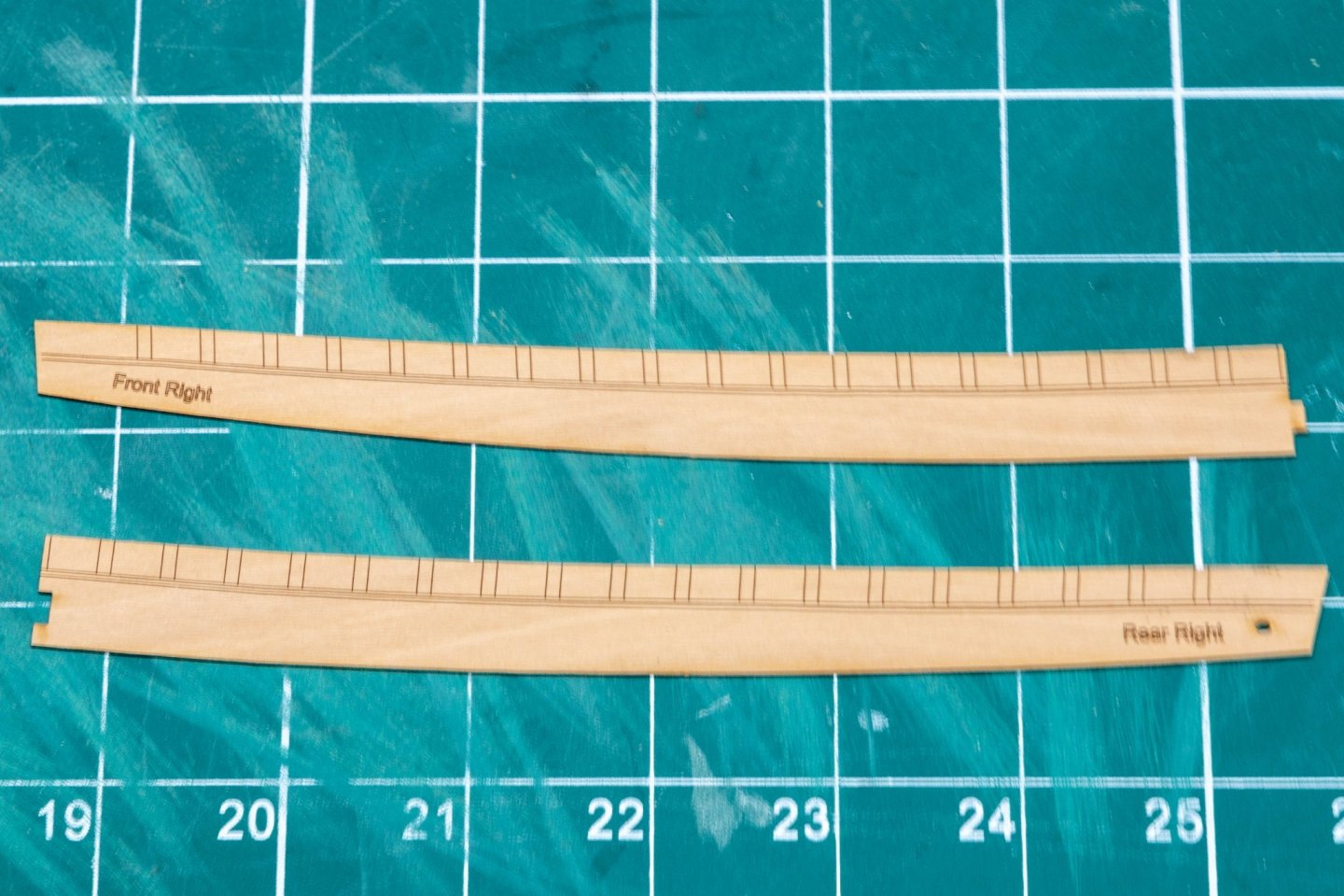

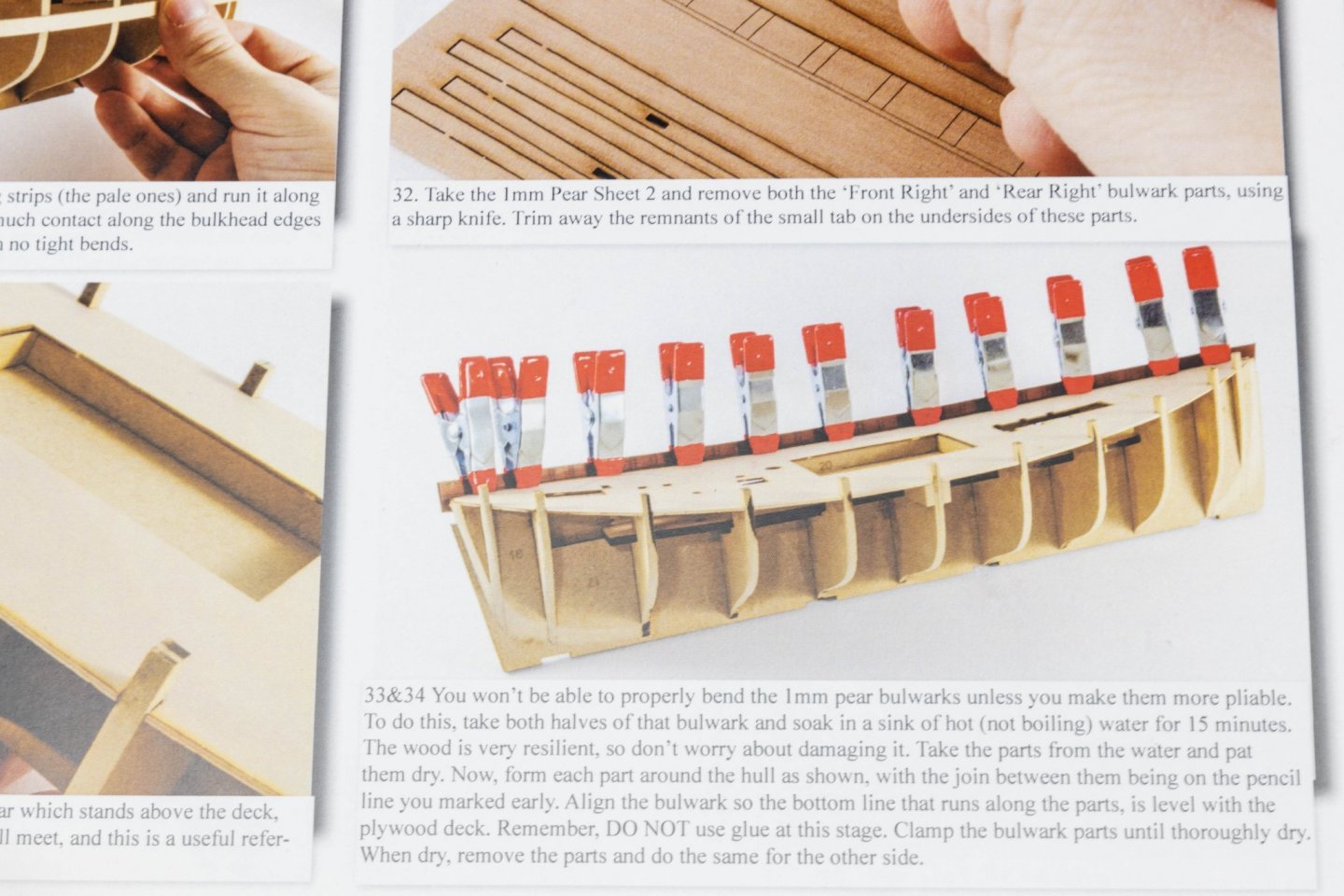

Er...looks like i may need that help sooner rather than later! I've given the bulkheads another quick sanding to make sure the bulwarks sit flush, and marked the meridian on the middle post. As per the instructions, i'ver removed the front & rear right bulwark parts, soaked in hot water for 15 minutes, and clamped them to the hull to dry. But have I done it wrong? JamesH’s photo shows bulwarks fitted to port side, but right to me would be starboard? Does it even matter?

-

3D Printed Plank Cutter

CaptnBirdseye replied to spill50's topic in Modeling tools and Workshop Equipment

If you can get it to cut straight, with no wobble with the handle, you might just have something there 👍 -

You know he might just have a point 😂 I agree Glenn, and to my eyes that looks about spot on 👍

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

3D Printed Plank Cutter

CaptnBirdseye replied to spill50's topic in Modeling tools and Workshop Equipment

Sweet! Are you going into production? 😀 -

Looking good Rick, that second planking really ‘pops’. Definitely see nothing wrong in your photos, but like you say, you know where to look. The rest of us will just be admiring. No the instructions are a little ‘sparse’

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

Wow that counter decoration really lifts an already great build to another level 👍

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

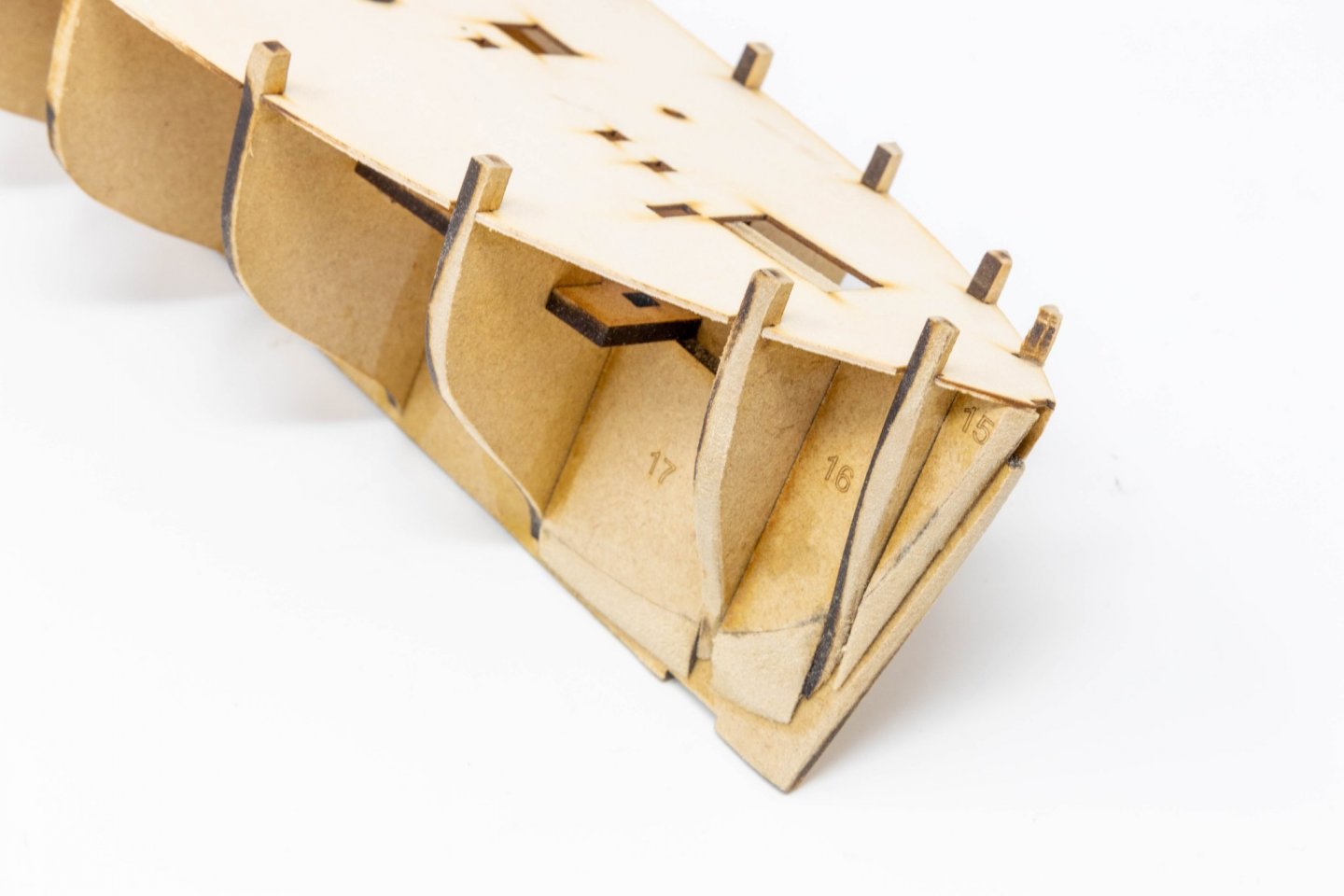

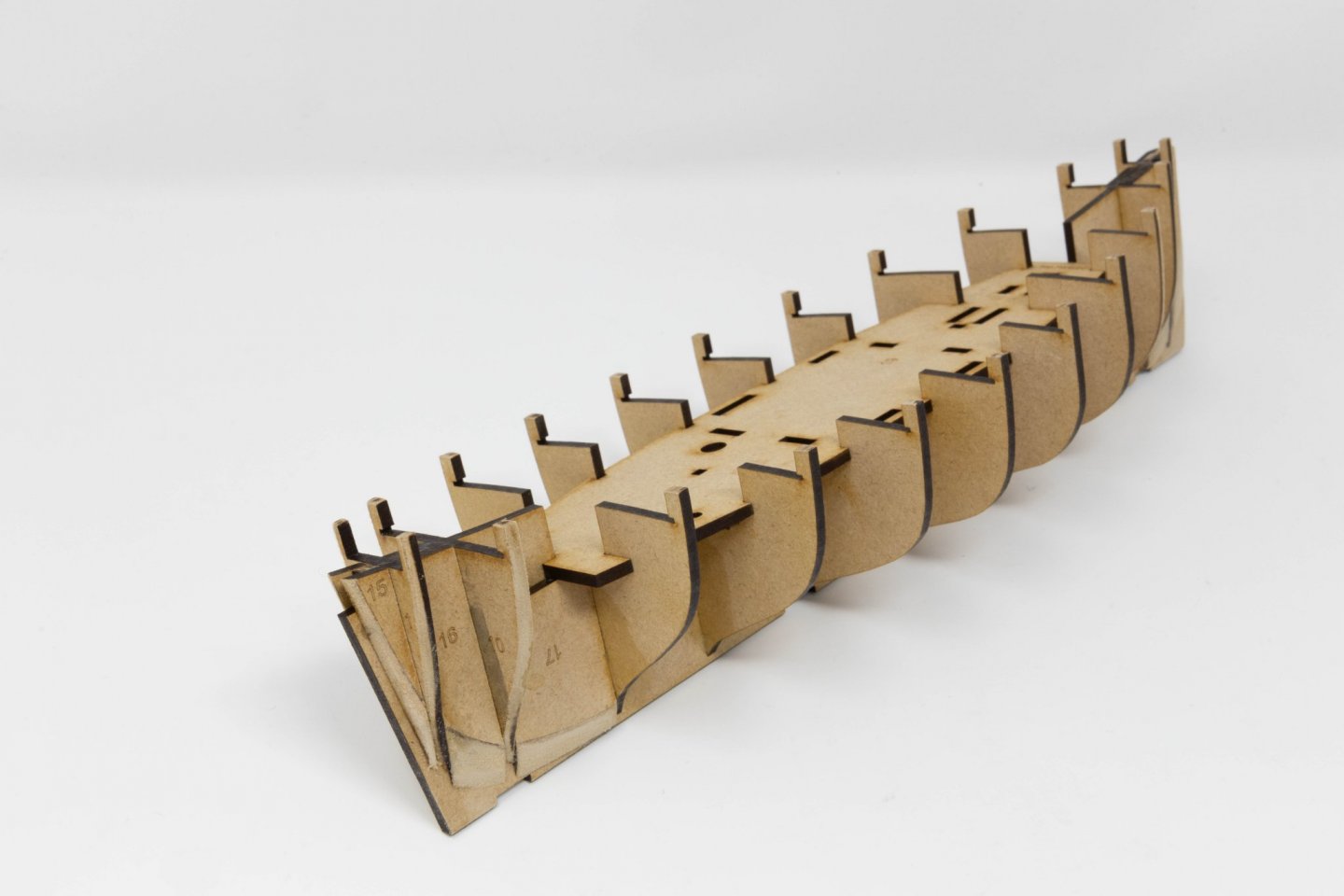

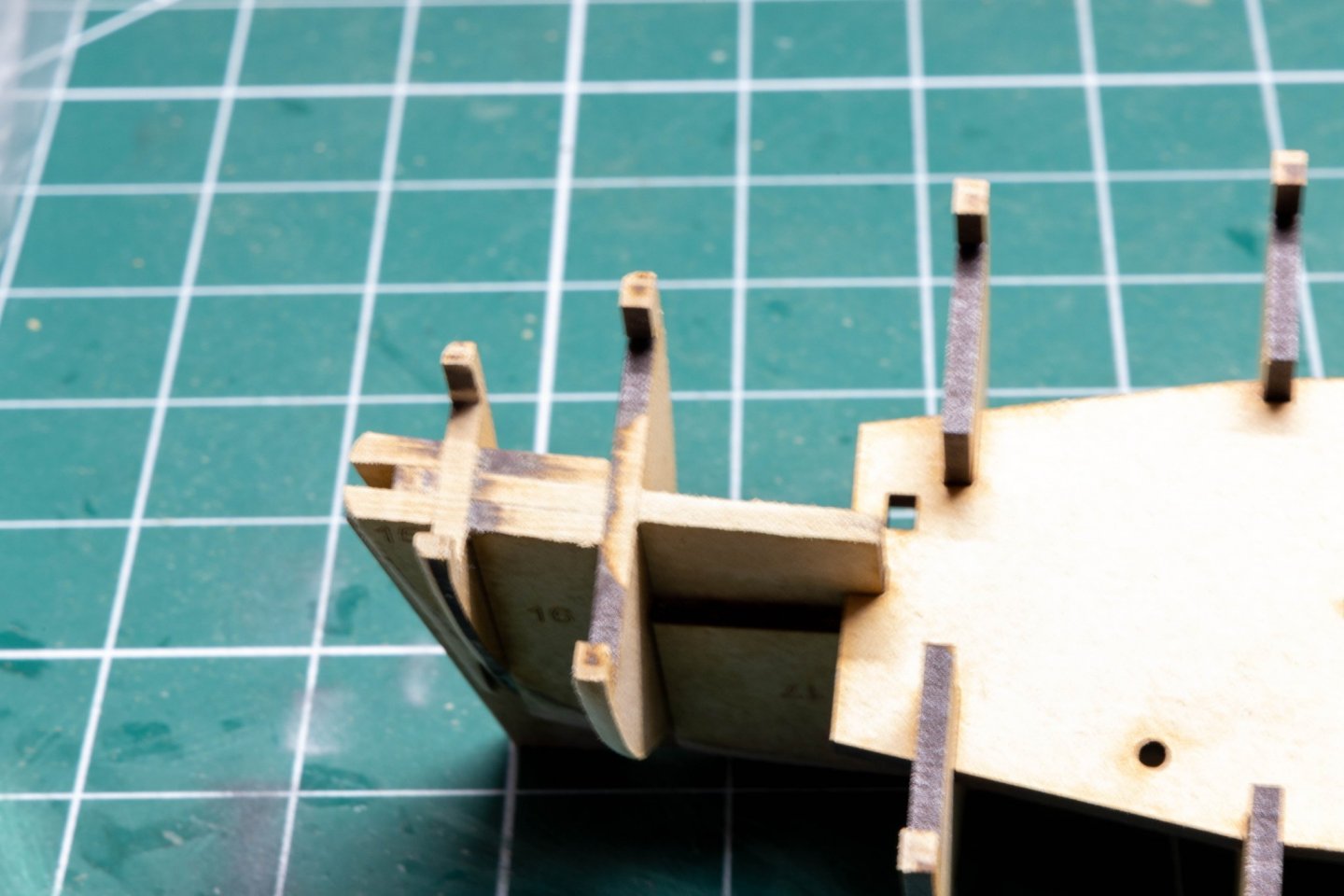

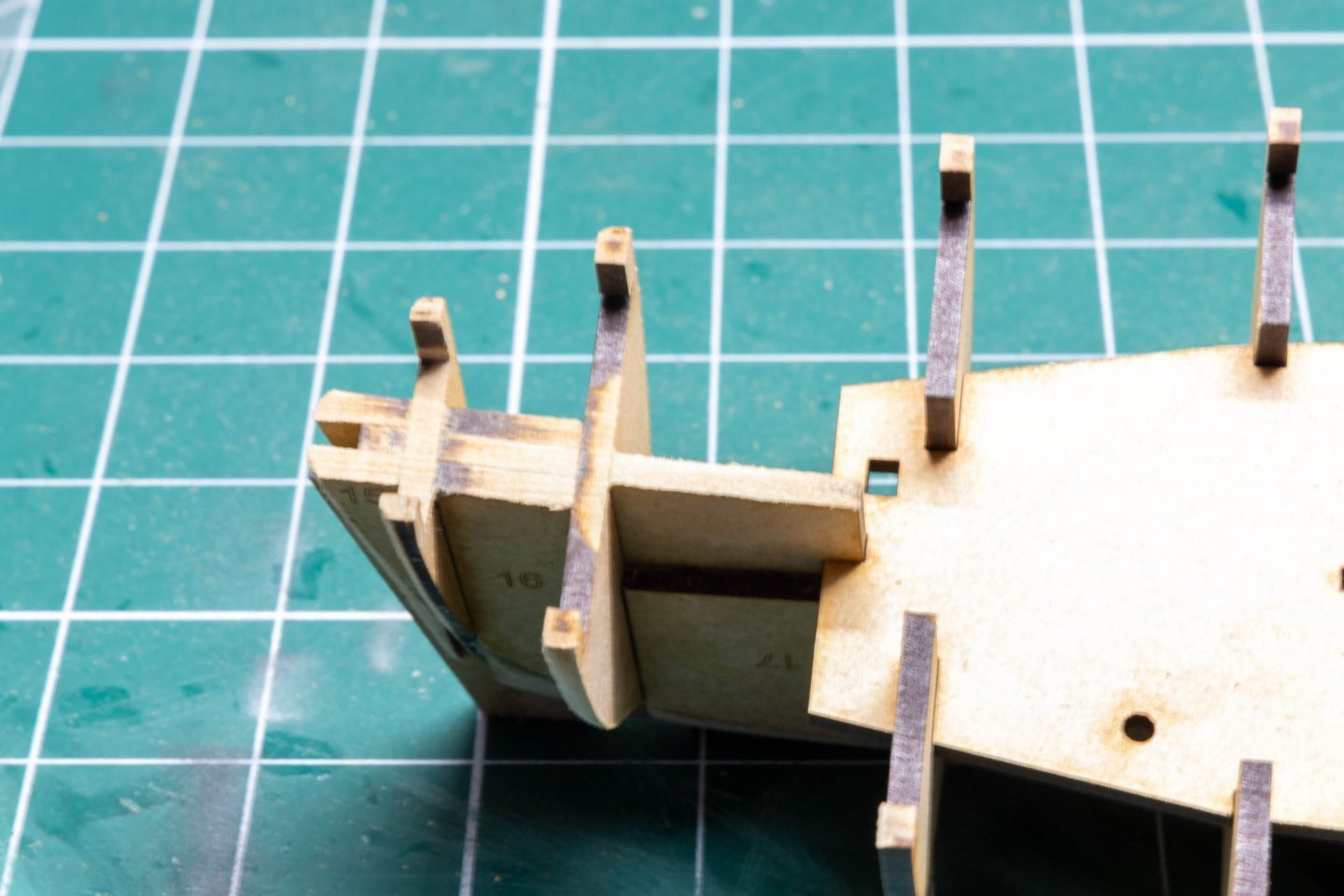

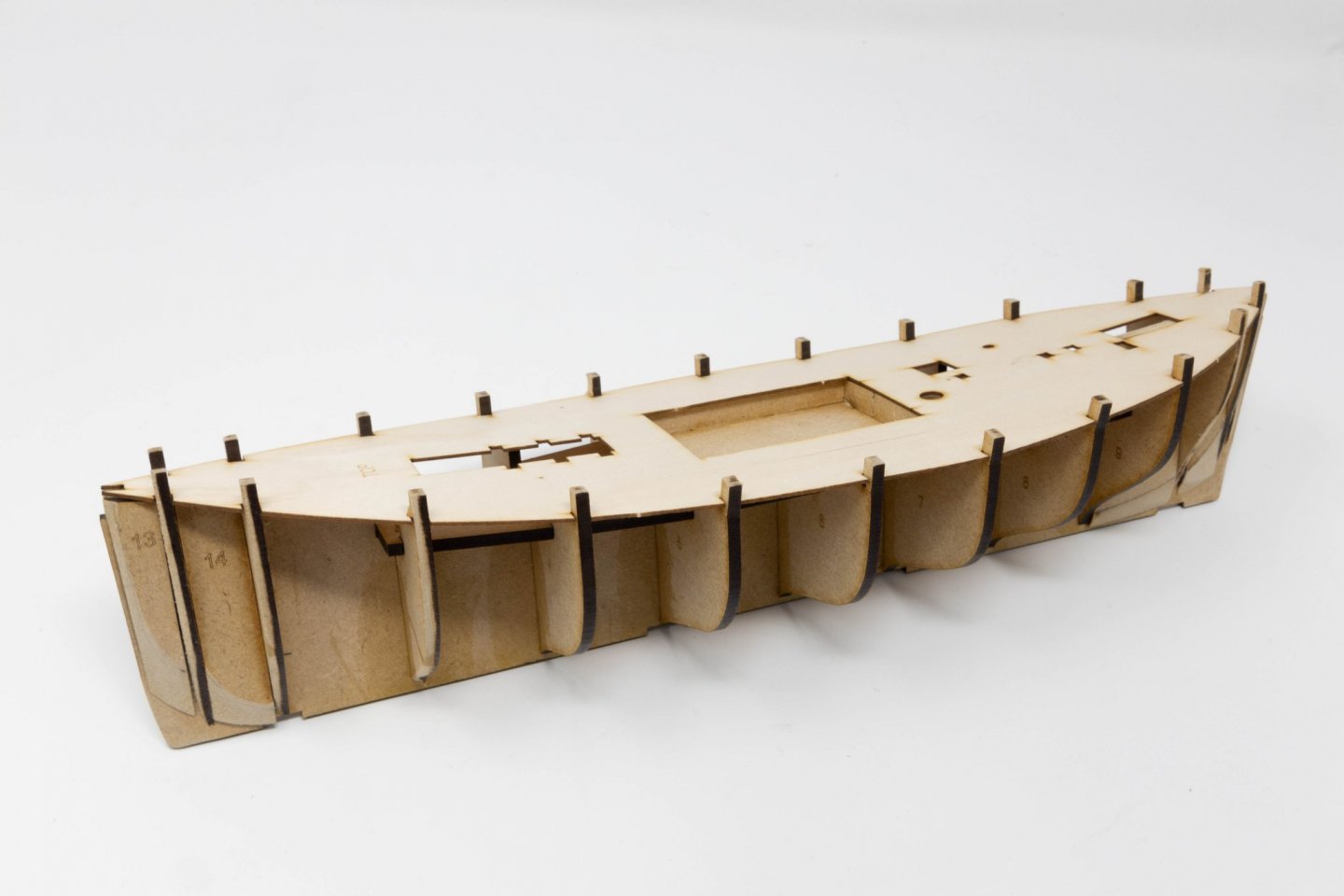

I'm sure you're not wrong there, B.E. 👍 Here's where i am up to at the moment. The Bulkhead patterns are fitted, but they don't sit flush with the edge of the deck. No worries, a bit of sanding when fairing the hull (which is the next stage) takes care of that. I think i've faired the bulkheads enough now. When i run a plank along it seems to fit ok?

-

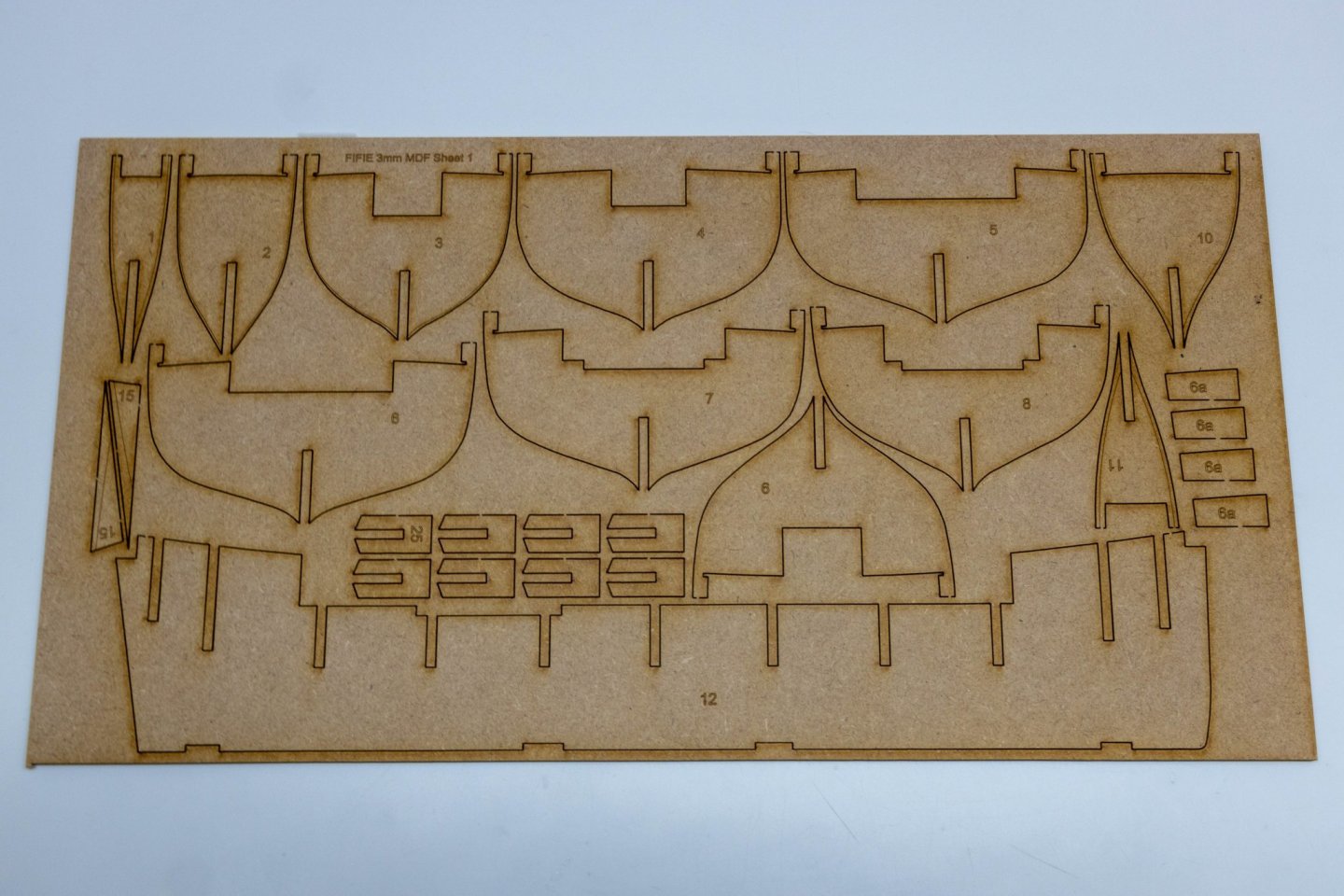

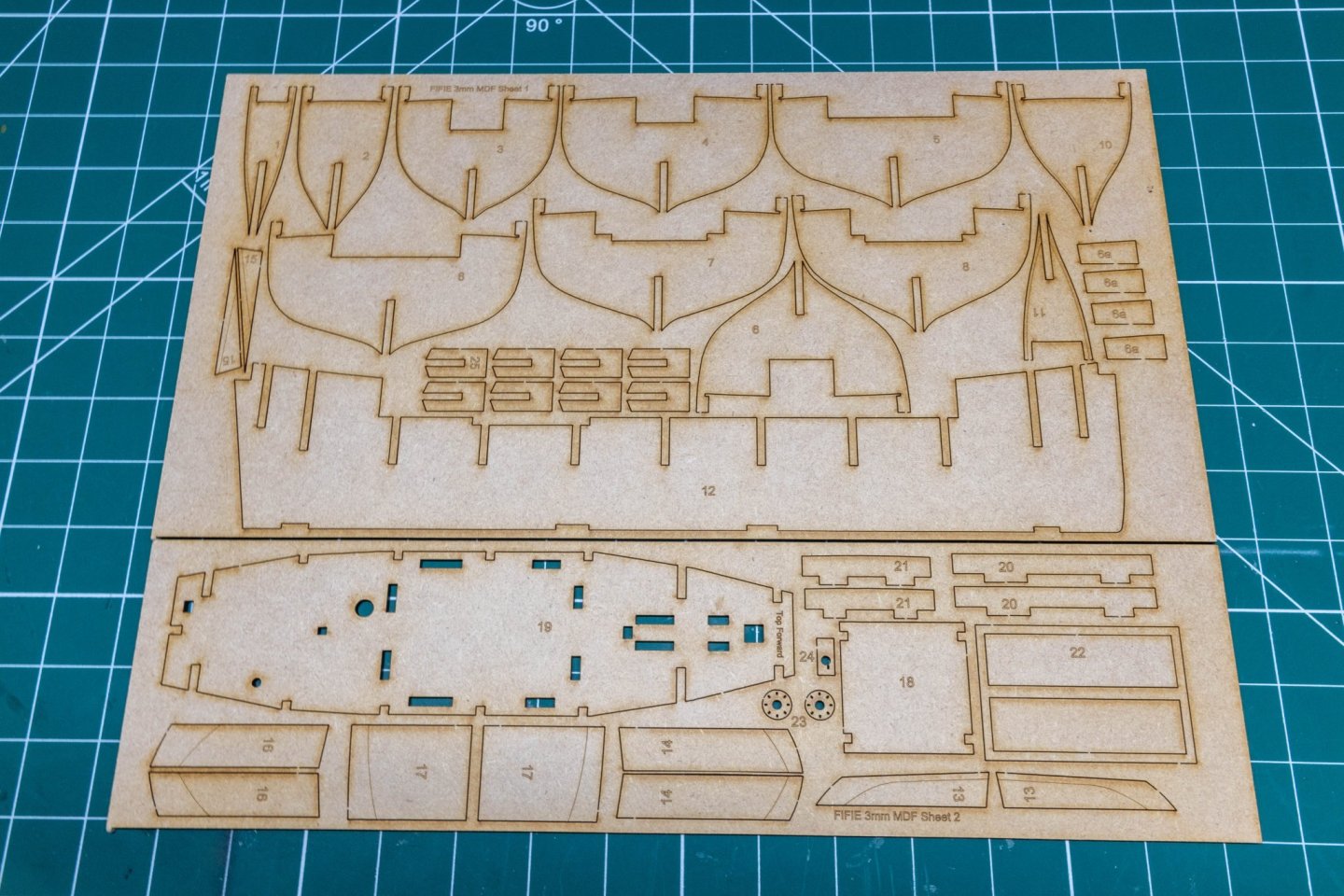

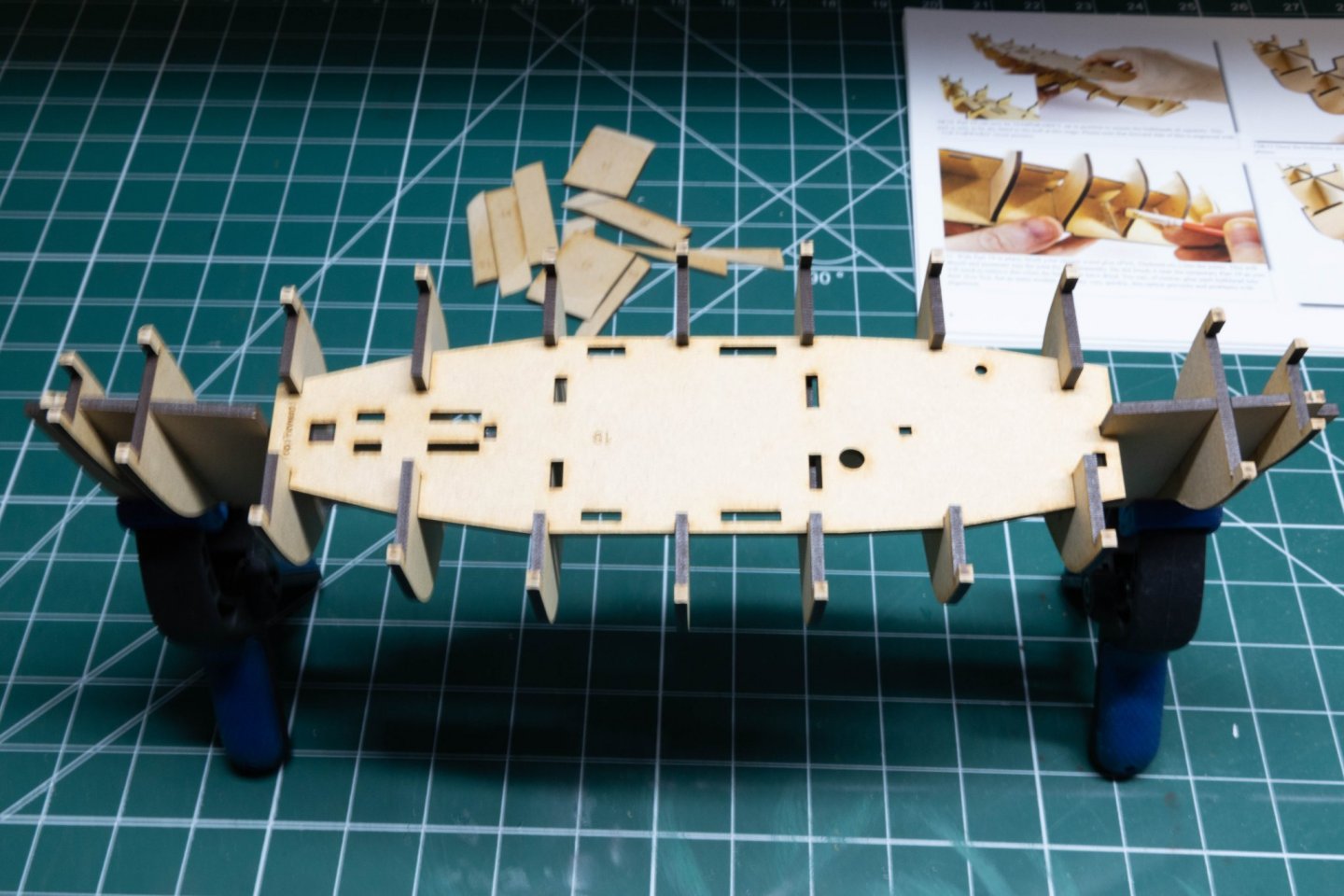

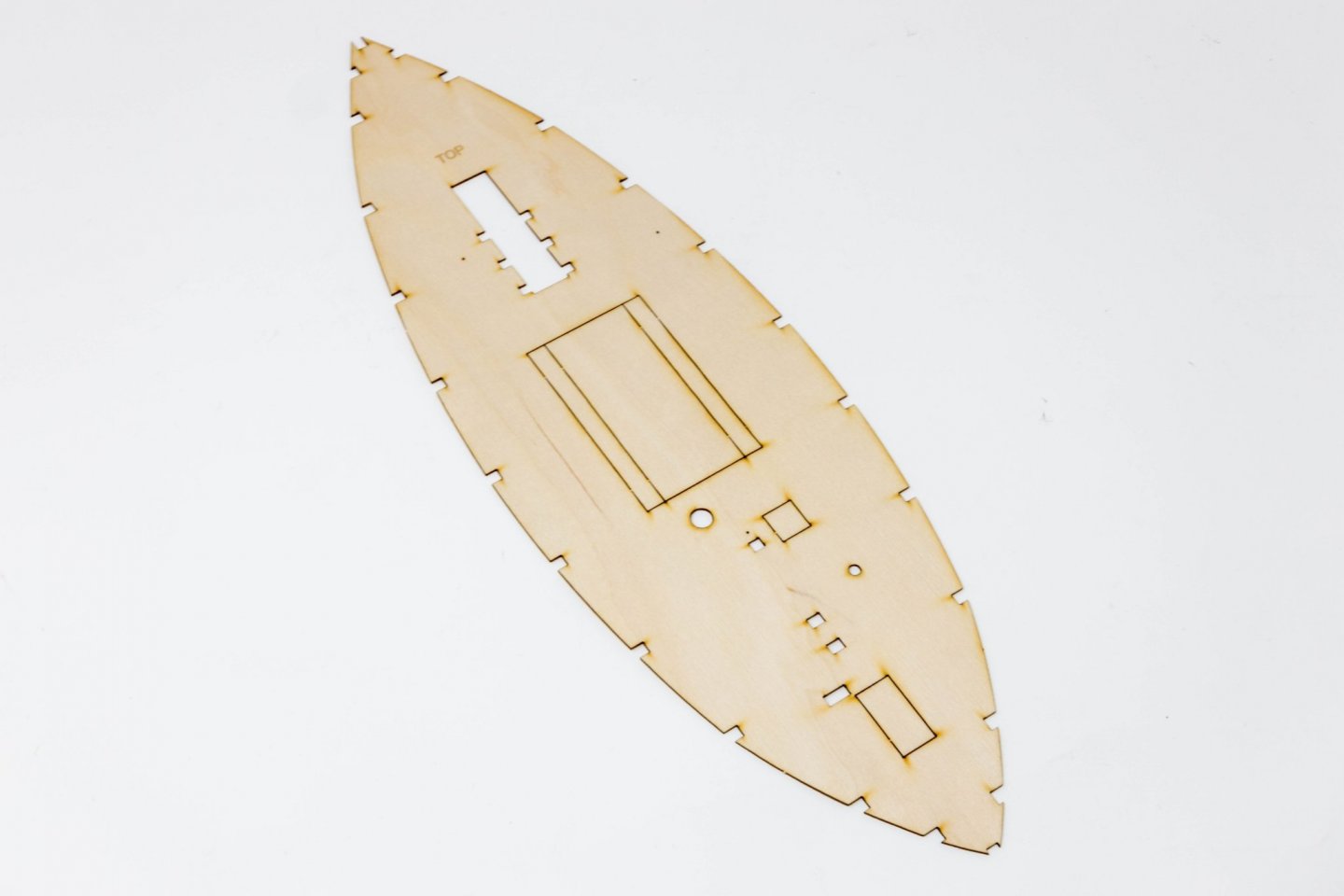

Hi everyone. I have been wanting to try one of Chris Watton's 'Vanguard Models' kits for a while now . As i have several ongoing builds, and not wanting to overspend, i finally decided to take the plunge with this one. Now i won't be doing the usual 'kit review' as i feel i cannot extol the virtues better than have alreday been written on this site. I will say that i'm so impressed by the quality of what i have seen so far to be already eyeing up my next purchase from Vanguard! So, first job after checking over the parts, is to build up the hull skeleton. Once all the parts are removed from their frets, and given a very light sanding to remove any burrs, I prepared the bulkheads by bevelling their edges prior to fitting them (unglued) to the false keel. I just used sanding sticks as i didn't trust myself with the Dremel 😀 The bulkheads fitted perfectly, requiring no adjustments at all. Once fitted, the lower deck slid into place and i was then able to apply waterd-down glue to just the bulkheads, using the deck to line everything up. Once the bracing was glued in place under rhe lower deck, I glued the deck to the bulkheads. The filler patterns were added next, then the box created on the lower deck. Once the sheer is sanded, we can fit the plain decking. This I just fitted dry, bending (😟) the ply into place. When i was happy with the positioning, i applied glue to the joints from below.

-

Typical Vanguard kit.... well packaged, well documented and well thought out build process with quality parts to boot! Win-Win Following with interest 👍

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.