-

Posts

1,272 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Thukydides

-

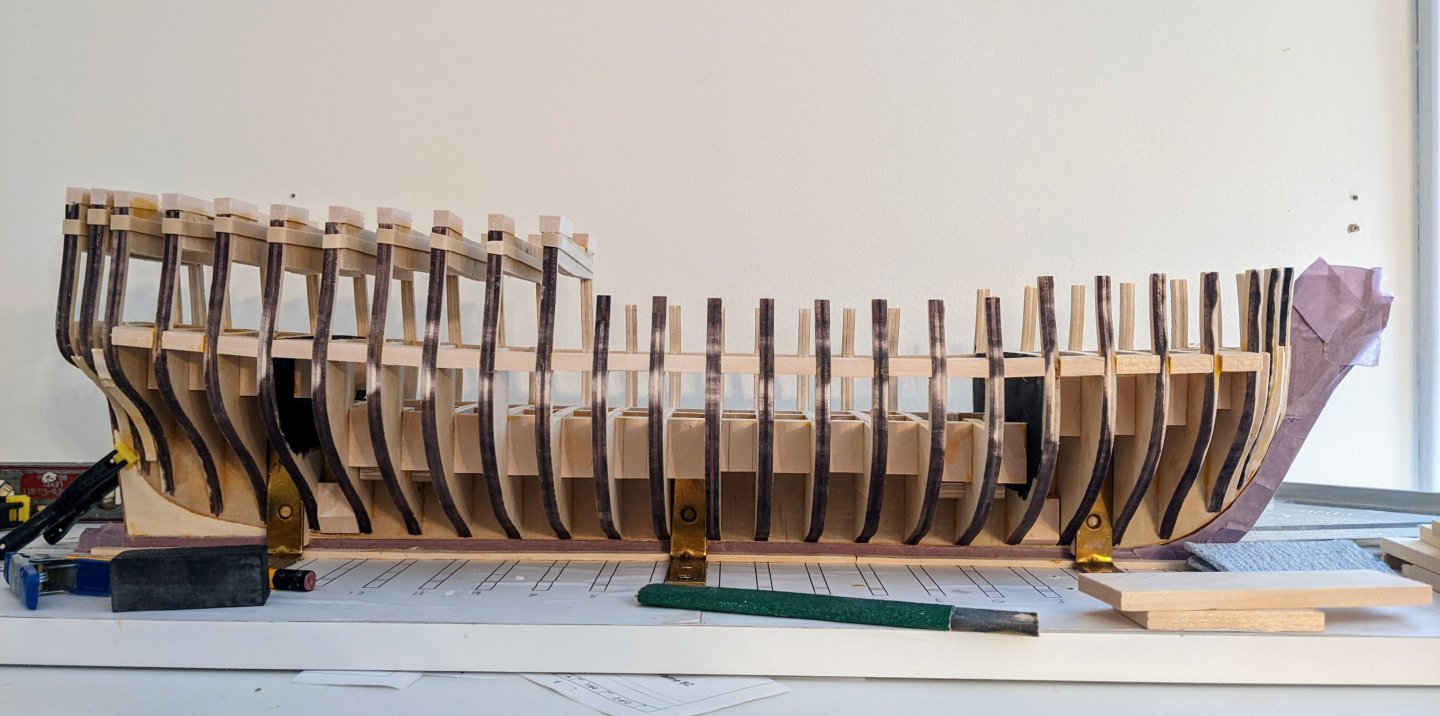

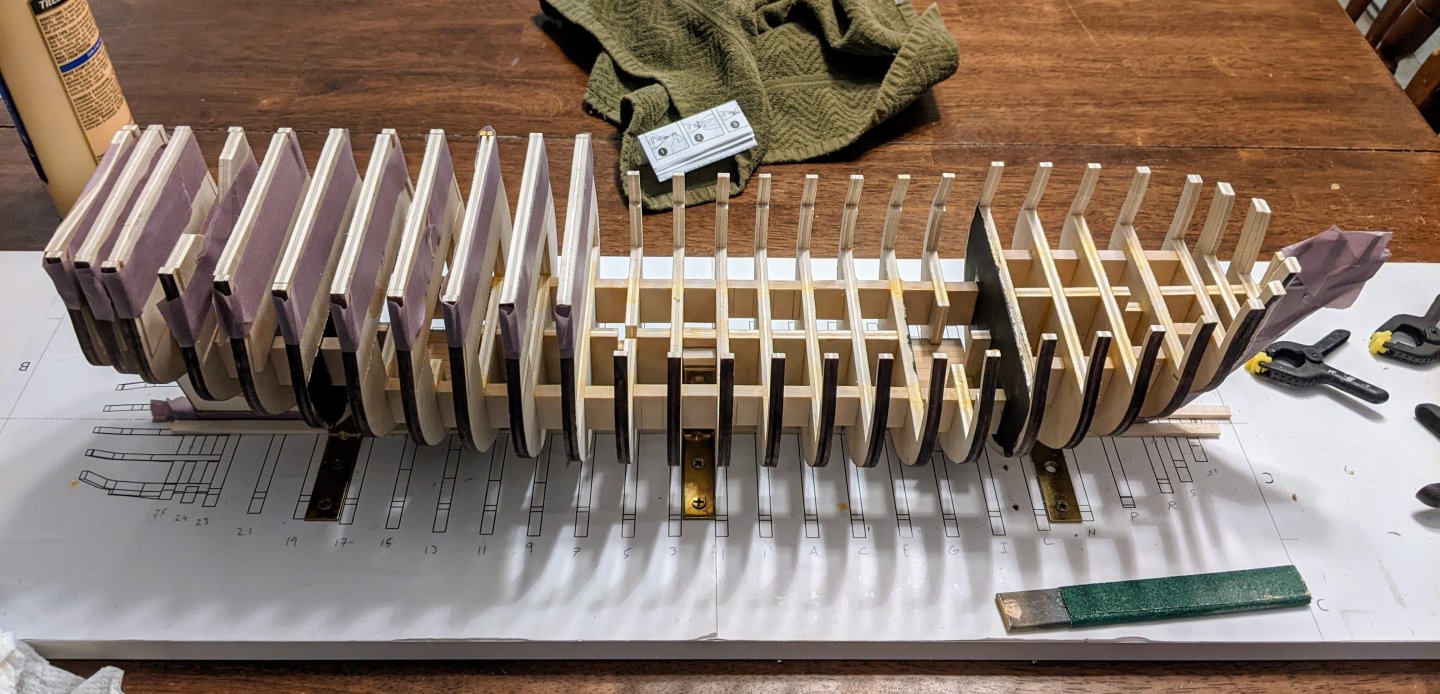

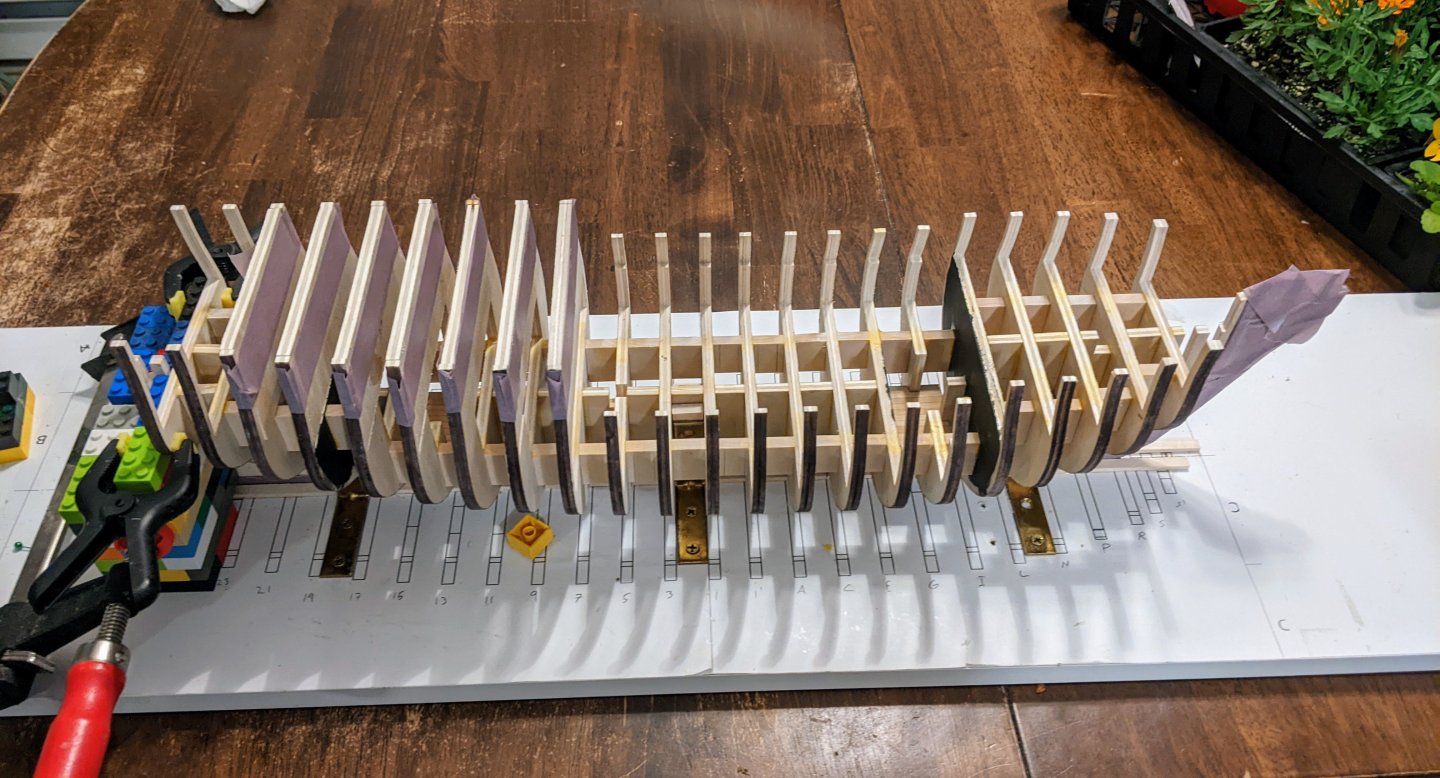

Log #25: More Structural Supports and the Deck Sheer It has been almost a month since I last posted as I have been busy with other tasks and though work has progressed, there had not been a lot of significant progress. One challenge is this work generates a lot of dust and so I have been trying to do it outside (I don’t have a dedicated workshop space). Between rain and the fact that most of my free hobby time is in the evening, this has slowed the process down a bit. Along the way I realized that the existing inserts I had taped in place to support the thinner bulkhead extensions were in the way and so I cut off the bottom of them and added glued pieces above them to hold them in place. Then I place rubber bands around the whole upper part of each bulkhead to hold it together. This is actually more sturdy than what I previously had done and it also keeps the supports out of the way. I have been doing some preliminary faring as I add the bracing pieces along the sheer of the deck. The bracing pieces are now all in place, though the ones near the bow and stern have not been fared at all yet. As you can see from the below picture, the sheer is not perfect and so now I need to make small adjustments inboard to make sure the line of the deck is right. Then I can use that line to measure the gun port heights. The sheer will also allow me to measure and mark the height of the quarterdeck and forecastle and I will likely add bracing pieces to mark their locations before I start faring in earnest. I have also taken the opportunity to reinforce the area where the nuts are glued to accept the bolts that will attach the model to the base. To do this I cut pieces of basswood and then used my mini chisels to hollow them out. I then filled this hollow with a wood glue sawdust mixture. This was then pressed in place over the area of the nuts until the excess sawdust-glue mixture started to squeeze out indicating the area was fully filled. This is probably overkill, but as it didn’t take much time, I figured it was worth the effort to make sure that these don’t come loose. So that is all I have to show so far. Thanks to everyone who had stopped by to take a look. On the research side of things I don’t have much to report as I have only had time to transcribed a couple letters and they didn’t have any particularly significant info in them. Hopefully the next ones will have some more interesting information.

-

There is also a significant amount of evidence to suggest that the false keel was not coppered (at least with regard to British ships). Also some ships also had the uppermost layer of plates done after the fact running along the waterline to sort of finish off things. It seems that the upper edge of the covering was covered by a wooden batten or possibly canvas, but there is very little said on it and specifics are hard to come by.

-

Great progress jaques. The sails are looking really nice.

- 287 replies

-

- Chile

- Latin America

-

(and 5 more)

Tagged with:

-

You essentially have two options. 1) You can carefully remove the offending planks and replace them. This is the option I would go with. Note this is the only real option if you are planning on leaving the hull unpainted. If you used super glue to attach the planks then careful use of acetone can help with removal. For wood glue isopropyl works well. 2) you can leave as is, maybe add some more filler just making sure the shape is smooth and right. If you are painting it white then it shouldn't be that noticable. Good luck.

-

Great job Glen, I think you made the right choice. Just a little bit of green adds a nice bit of colour. It is a fantastic model with a great presentation.

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

Great work on the bottle. It looks fantastic.

- 287 replies

-

- Chile

- Latin America

-

(and 5 more)

Tagged with:

-

Congrats on a great build. You have taken the kit and made it your own. I appreciate all the little details you have added.

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks Jacques, Oh it was expensive, in many cases it cost almost as much as it cost to build the ship in the first place. For example Perseus was built by contract for a cost of £4,507, but her coppering cost £4,310. That said there were certainly some significant benefits. Many of the refits that you see documented often cost 50% of the ships original cost to complete. One document I have just finished transcribing is an analysis of the impact of coppering and he has this to say:

-

Log #24: Structural Supports & Fixing Mistakes Thanks to everyone who has stopped by to take a look at the log. I do find your comments and likes motivate me to keep pushing forward. Since my last log entry I have continued to work on the structure of the model. I will discuss that in more detail below, but I have also in the background been continuing my work on research. My current focus is on the coppering of Perseus. She was one of the first ships in the RN to be coppered and though I am not planning on coppering her, I am planning some aesthetic choices which will allude to the coppering. The handwriting of the documents I am currently looking at is not as good as some of the stuff I have previously looked at so it is slow going with the transcriptions at the moment. But I thought I would share an interesting tidbit I found. It is interesting to see how quickly the RN went from very few ships coppered to coppering a huge share of the fleet. You can see in the above transcription that from 1779 to 1781, 313 vessels were coppered. On the model itself, I have now got all the bulkheads in place. You will notice that the front two and stern two bulkheads do not have any bracing pieces as they are closer together. The reason for the omission is that I am planning on filling in these sections fully with filler blocks. First I cut the bow filler pieces and glued them in place. Then once that was dry I slid pieces of basswood which I had thinned to the appropriate thickness into the gaps between the bulkheads and marked off with pencil the approximate size they needed to be before cutting them out on the scroll saw. There is no need to be particularly accurate here so I have erred on making them oversized as this will all be sanded in the faring process. The most important part of this was making sure the bulkheads remained square through this process. However, it was around this point that I realized I had made a mistake with one of the bulkheads. Essentially the slot was not deep enough and so it was not far down enough on the center bulkhead. It was only off by about a mm, but this is enough to throw off the lines of the ship. So I had to break out the isopropyl and slowly work it free with a knives and solvent. It was particularly unfortunate that the offending bulkhead was at just about the worst possible location (the stern platform also had to be removed). However after a few hours of working slowly and carefully on it, I managed to get it out. Then I sanded and dry fitted it back in place, making extra sure of the positioning this time :). Finally, I have also been starting the outer structural supports. This is a line of bracing pieces which run along the upper deck line. These serve three purposes: To allow me to correct for any warped bulkheads which might be square at the base, but are not square at the upper deck bulwarks. To strengthen the overall structure. To allow me to better see the line of the main deck to determine if I need to make any adjustments. These pieces are inserted square to the bulkheads, but at an angle such that they follow the sheer of the deck. I will then use a combination of planes and sanding to trim them back in line with the frames. Getting the sheer of the main deck right is crucial as it will determine the height of the gun ports. It feels like this structural work is taking a really long time, but I am trying to avoid future problems by making sure I am constantly checking to make sure everything looks good now while it is easier to fix.

-

Great job Chris. The buoys are well done.

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I think that looks much better than your previous versions. Great jobQ If you would like some suggestions to make it really pop, I would still go up a little higher in value on the highest highlights of the red. Maybe mix a bit of orange in with your red to get that highest highlight. On the gold I would use pure white or maybe white with a little yellow in it and try and pick out the upper edges of the monogram and any sharp upper edge points such as the tips of the cannons. This would be really small dots/lines, but it will push that contrast just that bit higher.

- 73 replies

-

- Christiania

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I agree with the others that the second is probably the better option. What I would suggest is there is a bit too much of a hard transition from the bonsai to the rock. To alleviate this you could add some moss around the base of the bonsai to allow for a transition to the rock. Not much, just a little to make it less of a hard line between the two.

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

Great job on the anchor. It does look like rusty metal.

- 287 replies

-

- Chile

- Latin America

-

(and 5 more)

Tagged with:

-

I don't have a tonne of progress to show, but as it has been about a week since I last posted I figured I would give a short update. I continue to work away at the bulkheads and am now nearing the end. The only bulkheads left to put in place are the final two at either end. I have left these till last as the stern ones are the most fragile and the bow ones need some pre-fairing before I glue them in place. Still lots of structural work to go, but she is starting to take shape now.

-

This is what you want to do. If you have to force the planks into place they are not shaped right. The best advice I can give you it to treat every single plank as its own project. The planking is one of the more consequential parts of the model in terms of determining its look. So it pays to take your time with it.

-

Great job, both the research and the execution.

- 165 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Time for a minor update. I continue to add bulkheads and am getting close to the bow at this point. You may notice some of the bulkheads have been painted black. The reason for this is I am as of yet unsure how much of the main deck I will open up to being visible and so on the off chance that these parts are seen I want them to fade into the blackness of the lower deck. They represent areas that would actually have been open and so we need to create the illusion of space. One thing I don’t think I appreciated fully until now is how much minor errors or slight alignment issues can have significant impacts on a model when it comes to the main structure. I ran into one issue (though I was able to correct it) and since have been much more careful about checking everything in all 3 dimensions. This all makes me very thankful that the Vanguard Models kit I used for my first model was so precise. Really I took the structure of the model for granted. It is much harder when you have to cut and align everything yourself and even parts being a millimetre off can make a significant difference. Thanks to everyone who is following along for all your encouragement.

-

Great job. I like the top one the best. It just needs a bit more, it feels like it has the most depth. The issue is the mid tones need to be brighter so you need to extend what you have for highlights down over more of the surface and go for even higher values on the highlights. In general it is better to make too much contrast as opposed to too little. You can smooth it all together with a thin glaze of your mid-tone once you are done if you think you went too bright. If you do this be careful that you don't let it pool in the recesses. It will have the consistency of a wash, but you don't want to use it like one. Glazing over the transitions using the darker colour pulling from light to dark will also help with smoothing out the transitions if you are concerned about them.

- 73 replies

-

- Christiania

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Good luck, you seem to have made a good start.

- 9 replies

-

- Vanguard Models

- Sherbourne

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.