Paul Le Wol

NRG Member-

Posts

1,047 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

Refurbishing an old model ship built from scratch.

Paul Le Wol replied to lawrence101's topic in New member Introductions

The rebuild is looking great Lawrence! -

Nils, happy to see you working on Elbe 1 again. Beautiful work on the railings!

- 307 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

Hi Jacques , the lobster smack is looking great! When I was building a Pinky, I looked at this video a lot. At about 3 minutes in you can see the pumps with the handles in a stored position. Maybe you could present whatever type of pump you decide on in the same manner. Pump handles always look like they’re in the way. https://youtu.be/E0XzgWVNZbU?si=WoRkcoJs2emlj9KV

-

Bob, your Harriet Lane is looking mighty fine! Take care

- 73 replies

-

- Steam Cutter

- Harriet Lane

-

(and 2 more)

Tagged with:

-

Cutters, Choppers, Guillotines, Slicers

Paul Le Wol replied to MintGum's topic in Modeling tools and Workshop Equipment

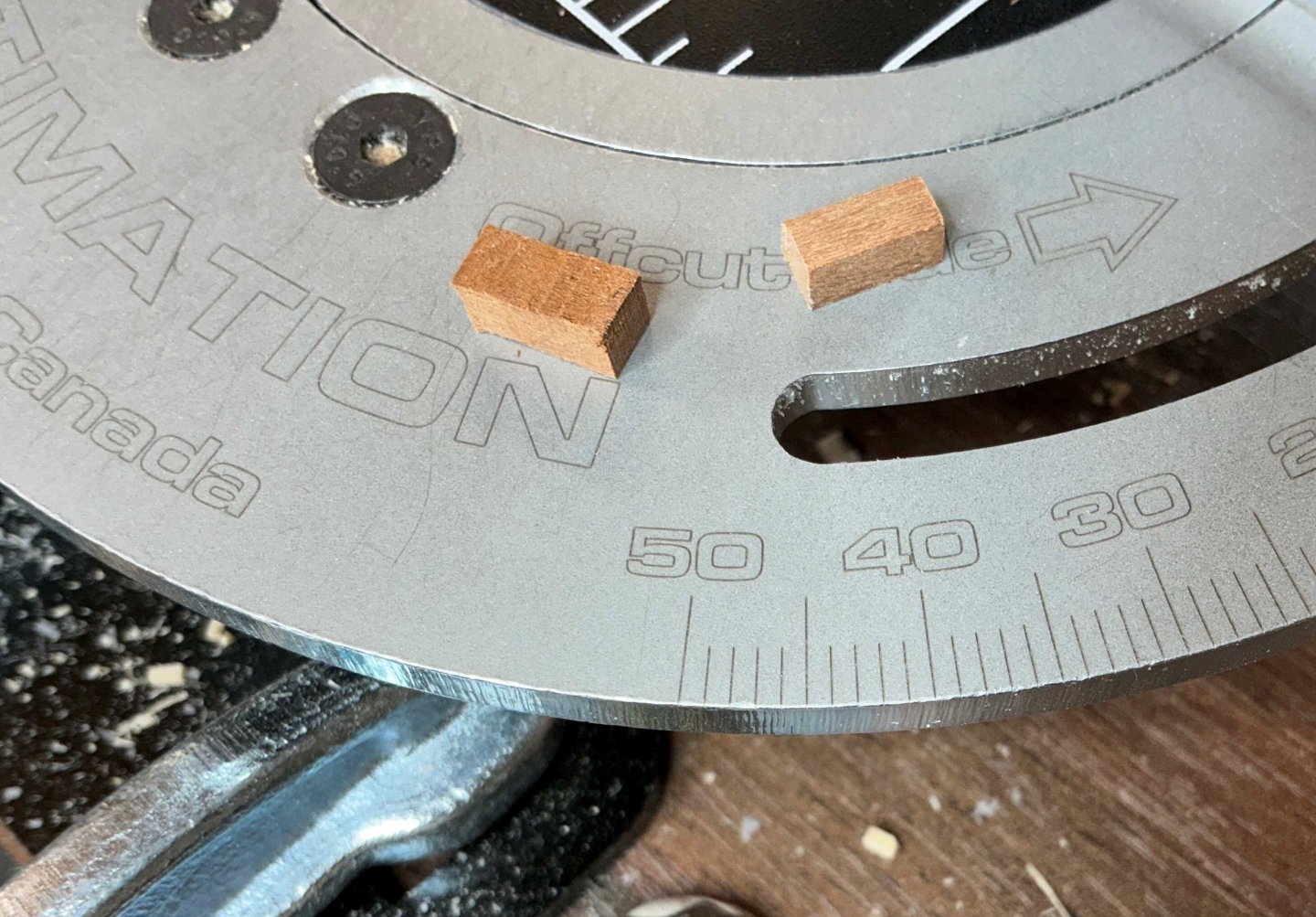

The piece on the left is 5/32"x 5/32" pear and the piece on the right is 1/8"x 1/8" cherry. It cut okay but I wouldn't want to try anything larger. I agree with @RossR's evaluation. -

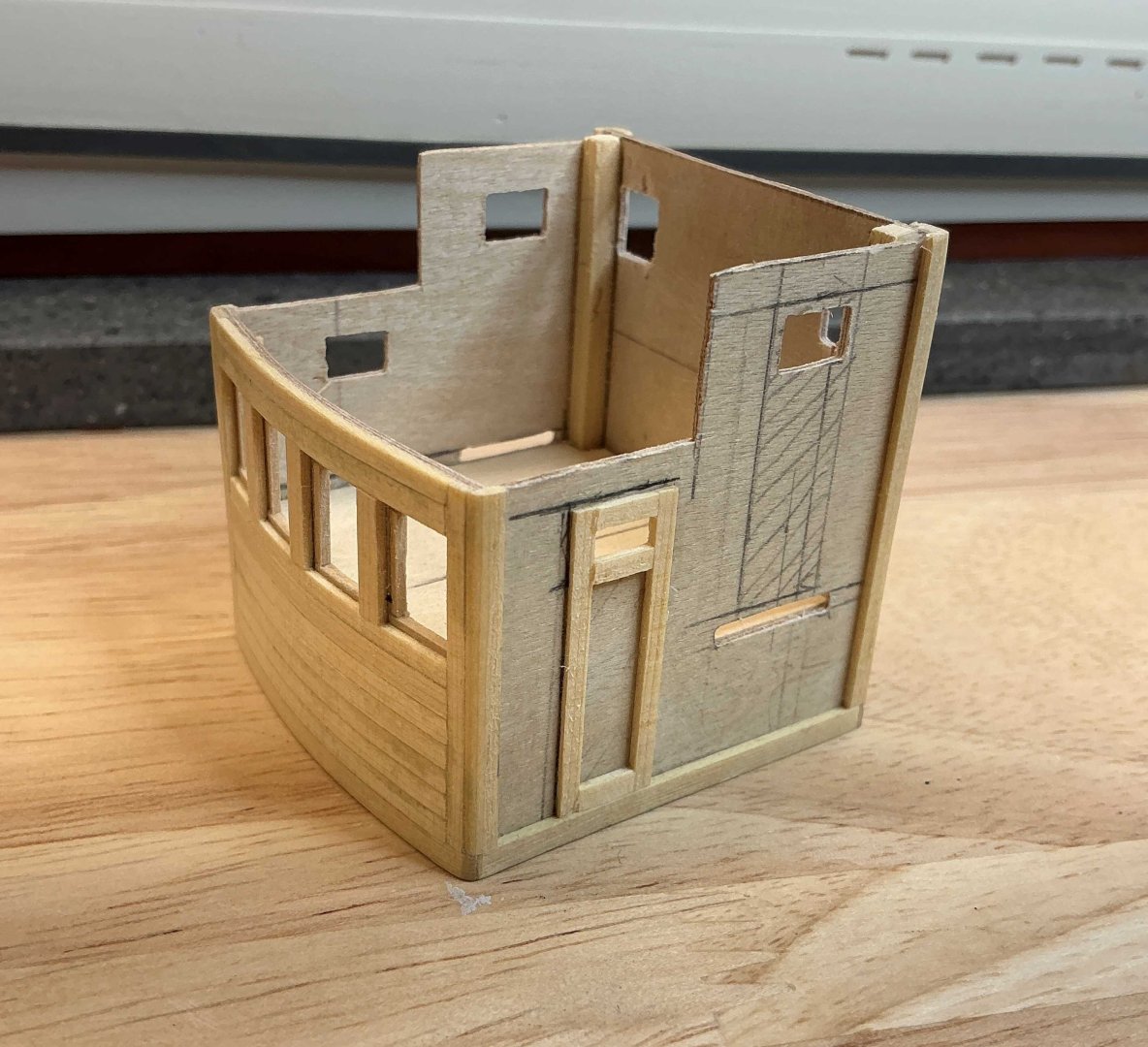

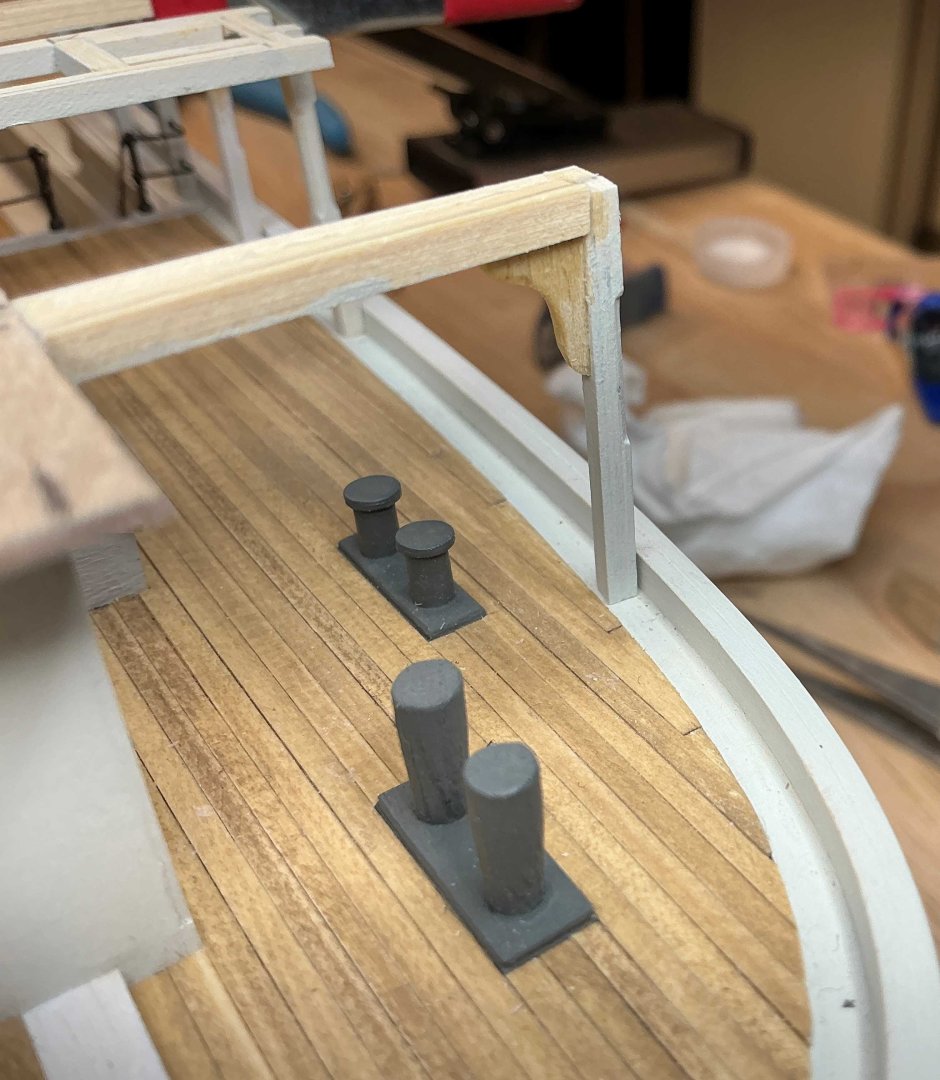

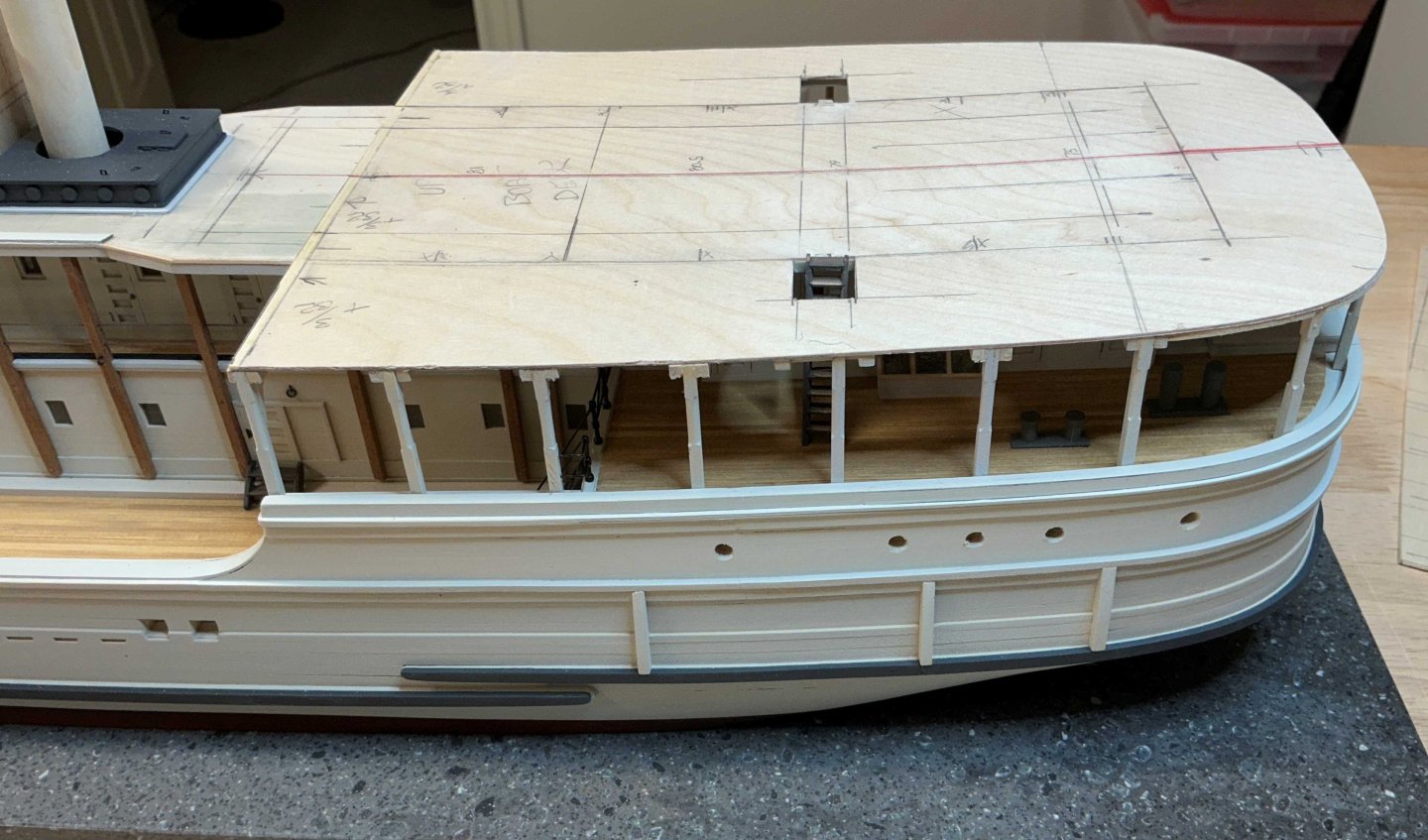

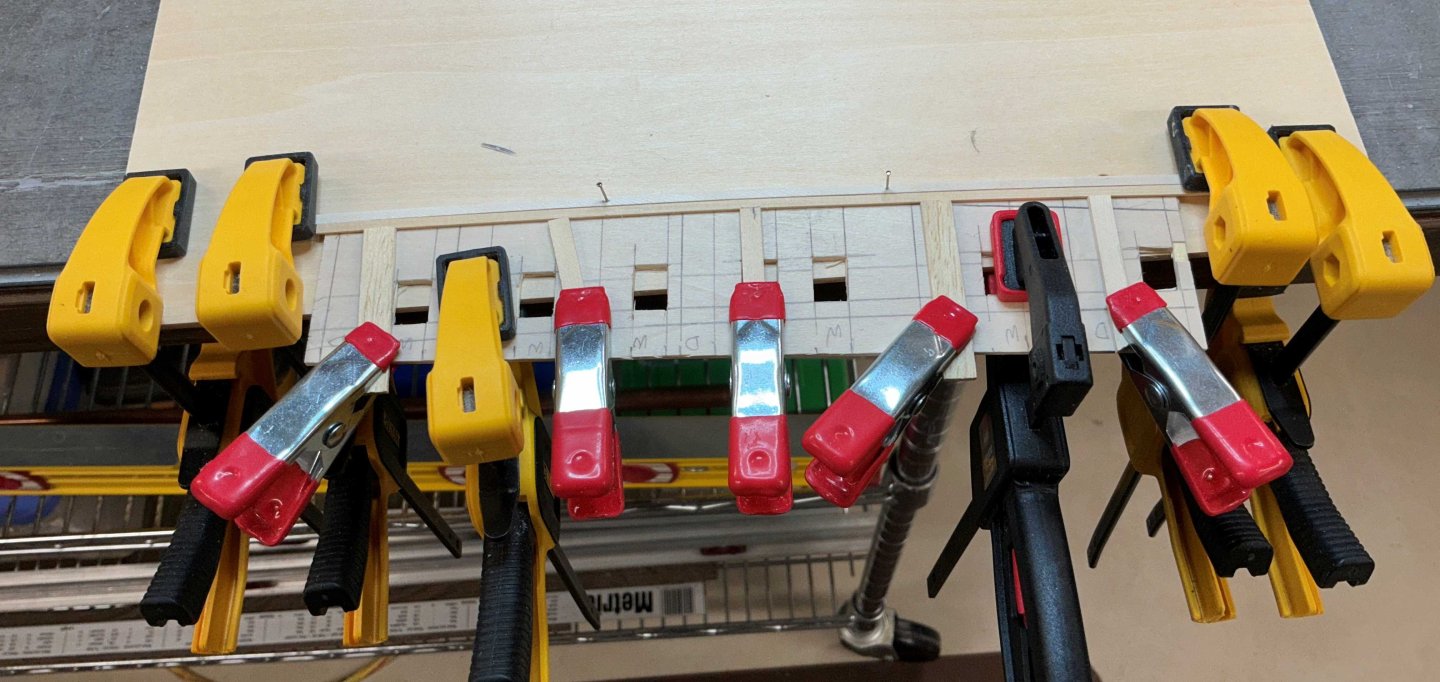

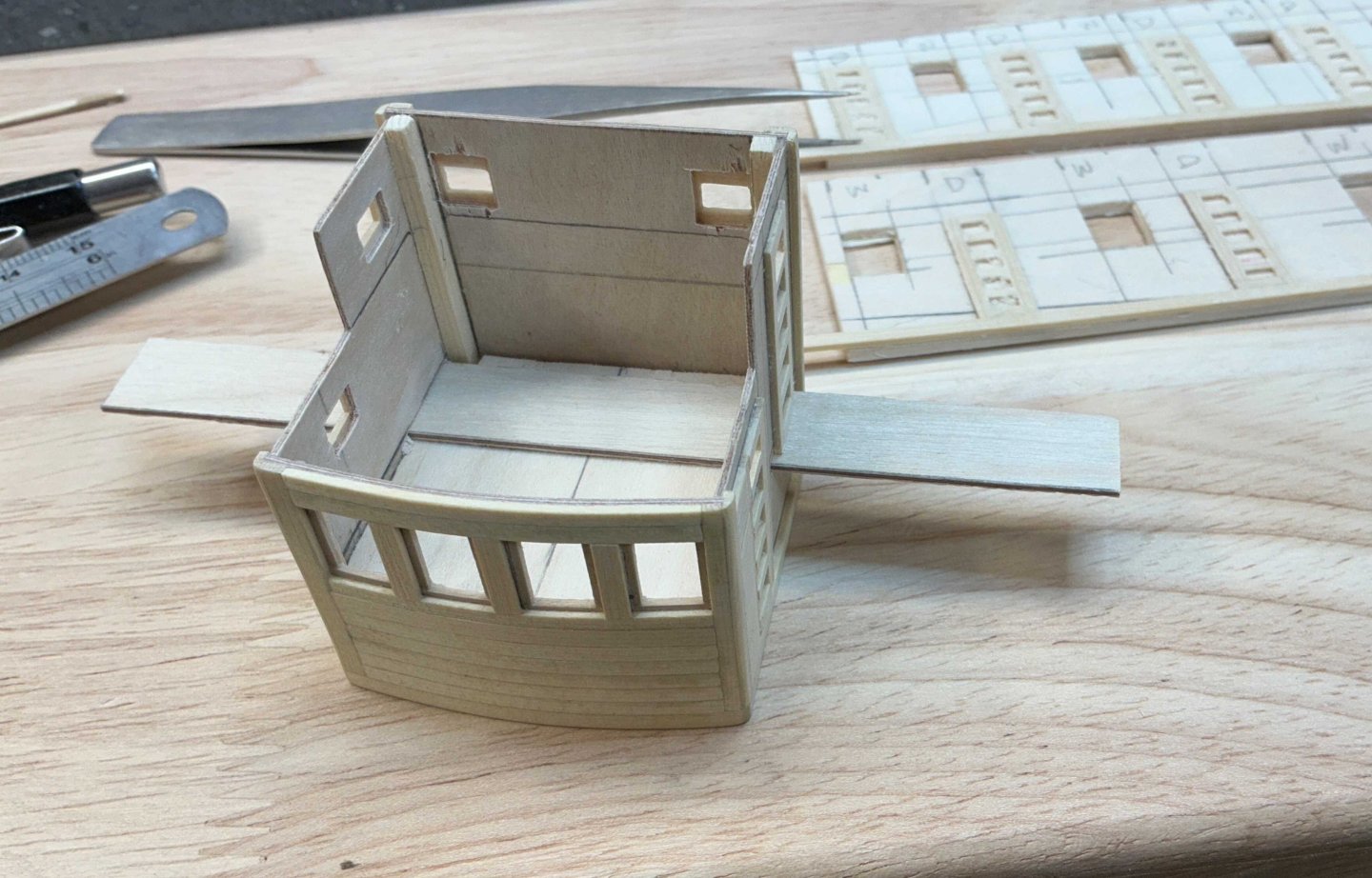

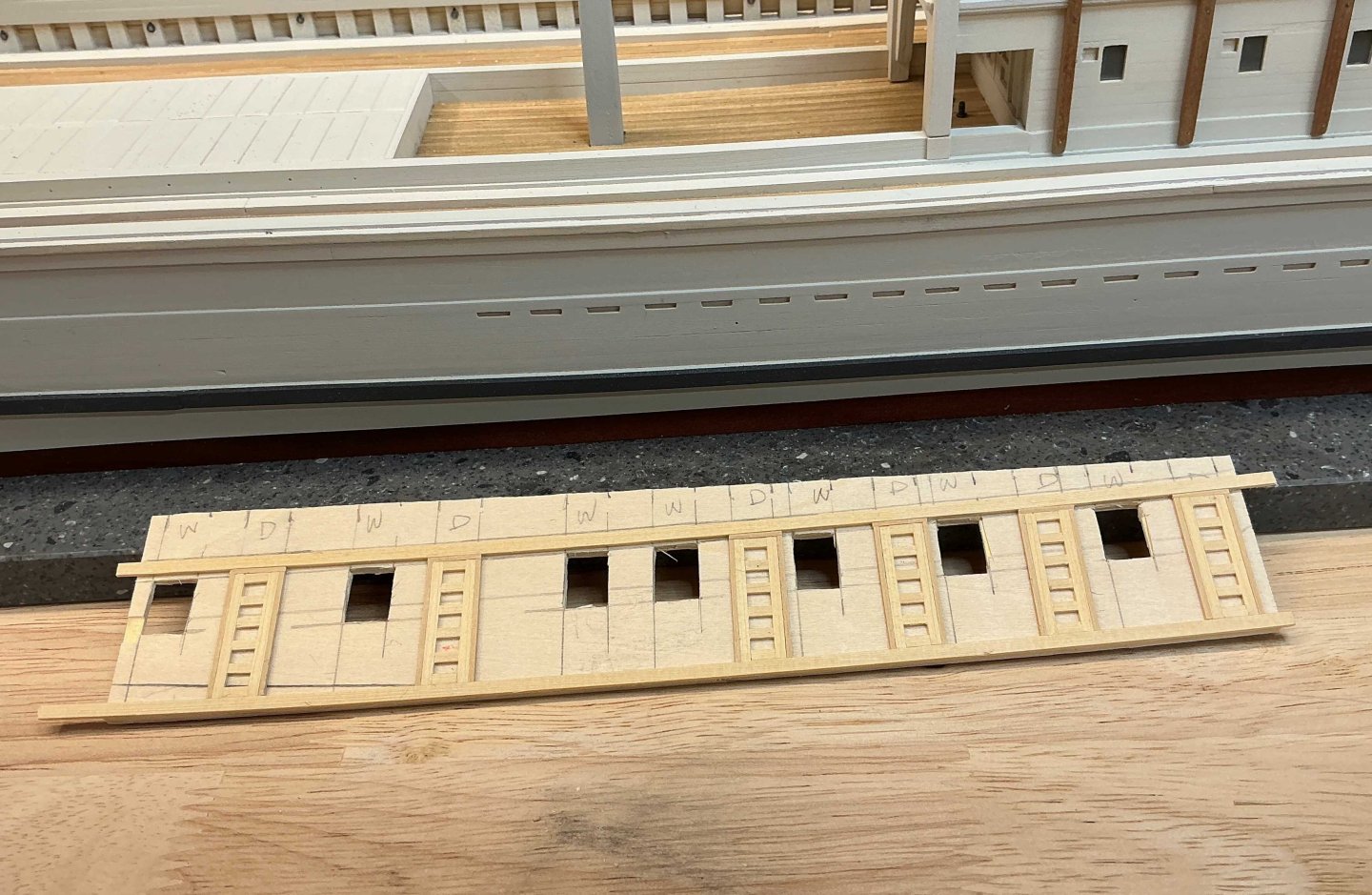

Hi Everyone, I hope your 2026 is going well. Thank you for the Comments, Likes and good wishes. The boat deck has been framed and the subdeck laid. The stanchion positions were laid out and holes were drilled into the waterway inside the coaming. A .020" brass rod was CA'd into the bottom of each stanchion but the pins are not glued into the waterway. The beams are 3/32" x 3/32" and are glued to the underside of the overhang on the cabins. There are three knees Port and Starboard that look to be positioned to add support for the lifeboats. They were made from a strip of wood that measures 1.8mm x 7.2mm. Not sue what type of wood it is but it is from an old Billing Kit. It stayed together well while each one was cut off with the Slicer. To make clamping easier every other stanchion was installed and then I went back and filled in the rest. Pieces Of 1/32" plywood were glued between the beams to add support to the subdeck joints. After some sanding and tweaking the remainder of the subdeck was ready to be glued down. I decided to cut it in half on the center line at the stern. I thought I had a photo of this but I forgot to take one. The fascia board (?) was glued to the perimeter using a combination of PVA and CA. The board is 3/64" x 5/32" AYC that was left over from Cheerful's wales. The area under the lifeboats was canvas over tongue and groove deck planking so it was painted with the Vallejo Deck Tan. The covering boards were cut in one piece from a sheet of 1/32" plywood. I concentrated on getting the inboard edge shaped correctly and then sanded down the outboard edge after it was painted and glued down. The coamings for the davit support brackets were partially painted and glued in place While this was going on I got a bit of work done on the Wheelhouse / Pilot House and the boat deck cabins. The Pilot House bridge wings are a piece of 1/32" plywood that slides through the slot under the doors. And this is what she looks like today. The smoke stack is there just to jazz it up a bit. Now it's back to finishing the siding. Hope to see you soon!

-

Sal, congratulations on completing your Nordkap. Beautifully done!

- 79 replies

-

- Nordkap

- Billing Boats

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6c632b0906bfb6395254bafb4fb935bd.jpg)