-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HIPEXEC

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Your billowing sails look great! How did you do that?

- 234 replies

-

With all that friction you could start a fire! Nice homemade lathe. I'll try it.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm now in the eyebolt business with the purchase of round nose pliers. I loved the way all the ladies in the jewelry making department eyed me as I shopped in their domain.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm going to the hobby store today! No more dropping-the-part fears!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I spent the day going over the logistics of switching over to building and rigging the spars (yards). Good old Constructo gave me the exact amount of eye bolts to make the foot ropes. I can't drop one and lose it on the floor, now. I've also had to order more micro drill bits since I broke so many up until now. In checking the plans I realized if I placed the holders Constructo designed for the studding sails spars they would extend only a tiny bit, so I've redrawn the plans so they'll extend enough to actually hold a studding sail if I want to install one or more. Lastly I broke out my wood working gear so I can manufacture the spars. I do not have a lathe, so I shall taper the spars with a plane and sand paper. It's time consuming, but I can get good results.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Bill...have you thought about putting the hinge at the bottom so it just opens down and can be restrained to open to the horizontal by a light chain? Also, think about making a drawer so you can save your plans, notes and other construction history?

- 335 replies

-

- Constitution

- Mamoli

-

(and 3 more)

Tagged with:

-

I went to start on the yards and decided to take an accounting of exactly how much material I would need and how much Constructo gave me. Well...good old Coinstructo gave me material to within 2-4mm of what is needed, The sawdust will exceed that! So, I just went out and bought a lot more stuff since goodness knows how many mistakes I will make along the way.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I was going to originally stain the whole thing dark until I saw how perfect the stand matched the ship's colors. Sometimes I luck out. By the way, the moulding is doll house moulding.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I just did the same thing and made a stand. After I did all the measurements.Augie suggested a contour gage.Nice job.

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Here's the stand with a coat of varnish and a "Constitution" sign. I like the two tone effect. It compliments my ship's wood colors. You'll obviously notice I'm doing anything but starting on the yards, sails and running rigging?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

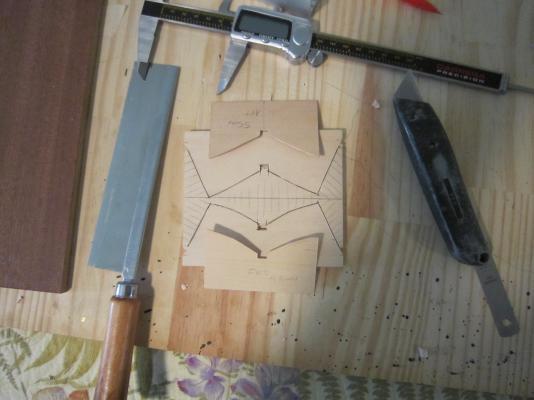

Well, I've been wavering on starting the yards, sails and running rigging while I study the best way to approach it. My first build was a fore & aft rig and I've had many years sailing experience on sloops, yawls and ketches so rigging it was quite natural. Square rig is totally different. So, while procrastinating I built the ship's stand. Getting the hull's shape was daunting but the contour gage helped verify my previous work. After building a working mock-up that actually supported the ship, I traced my work onto 1/4" stock and started to saw it out. Well, all my saws failed to give me clean cuts because of chatter and jumping out of the slot. I finally gave up with the saws and used a sharp set of knives. The knives gave me nice clean cuts right on my marks. It just took me two days of careful cutting to finish. If had a nice mini band saw it would have taken five minutes. Now all I have to do is some minor filling, staining and varnishing. Then I'll add felt pads to protect the planks.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

The cutout sheets the bulkheads came from were not very good. I must have altered the shape of the hull a bit during planking. Augie...now you tell me I could have bought a contour gage...boy that would have done the trick. My trial and error method took a day.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Constructo gives you a belaying plan...it's all numbers, so I have to match those all up with something I can work with.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

While I'm planning my attack on the yards & sails, I built a mock up of a stand to support my model when finished. It was a lot harder than I thought it would be. One of you gave me the idea to trace the shape of the hull where I wanted the supports to go with medium thickness wire. I did this, but it's not a perfect solution. I only got a close shape since the wire flexes too much. But, I took the wire and cut a thin sheet to that shape and tested it on the hull. Next, I saw what needed trimming or additions and re-cut the wooden supports. After three cycles I finally got a mock up that fits as well as supports the model. Now, I'll shop for some nice wood for the base and two supports.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks, Bill. I did all the rats, but there's room on the frontside of each mast to rig the spars (yards) and sails. At this point I'm even going to hang the sails (billowed out as if the wind is blowing) and as many sheets and braces I can hang on them. If I can pull that off, it will only be a matter of cinching down the sheets and braces, etc.I'll try one and see? Now, I'll start making the spars (yards). Each one seems it's like its own model there's so much on them. By the way...as I was debating whether to even hang sails...my Admiral intervened and insisted I hang the sails. That's good, since I want her to sew reefing ties on them. She did that with my first ship and the ties look very good.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Sjors...I'm planning my sequence of attack! It's crowded above deck so I want to put things together so I don't have to struggle later with small bits of rigging that will be easier to install before hanging a yard.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'd never be this far without all of you!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.