-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HIPEXEC

-

Wow! You guys are great. I'll make CA needles. I've got about 60 of these to make just to rig the three masts upper and lower. The CA needles will save me one heck of a lot of time. Thanks!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

What's the secret to threading line that is almost the same thickness as the hole in the block? Just wetting and twisting the tip of the line is a hit or miss thing. HELP! As you can see I'm practicing.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

It looks like I can't make a mistake with gluing or not gluing the masts. Both ways seem to work. I like the silicone idea when I finally do glue them. Thanks everyone!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I just put a coat of varnish on the masts. Constructo's instructions for the standing rigging are not too detailed at this point. I'll be looking at your builds for guidance. Constructo wants me to permanently glue the masts at this stage. I'm holding off for now.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

George & Bill, thanks for your advise. I shall read a lot more before I get in over my head. Rigging my first build was easy since I have many years experience sailing fore & aft rigged sailboats. This Constitution might as well be from Mars. I have no natural instincts for this kind of sailing vessel.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Does anyone suggest I rig some of the standing rigging with the masts off the ship?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Sjors, Did you do any rigging with the mast off the ship?

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

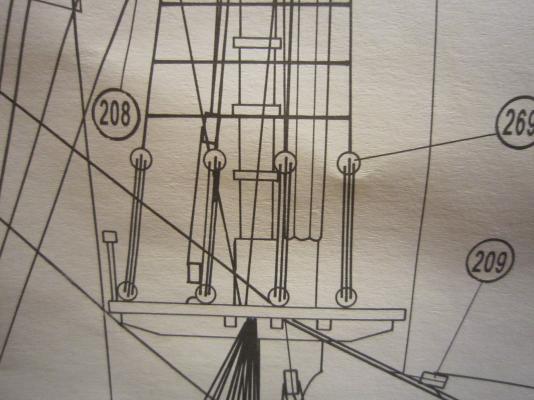

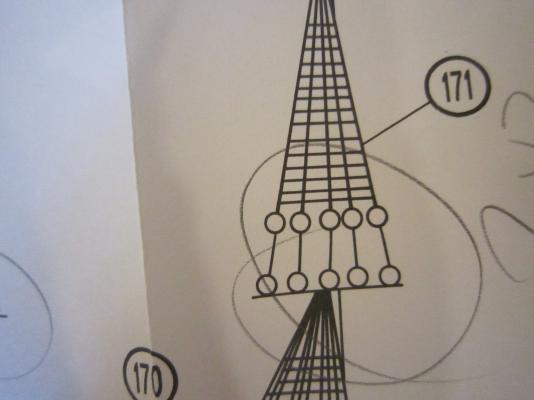

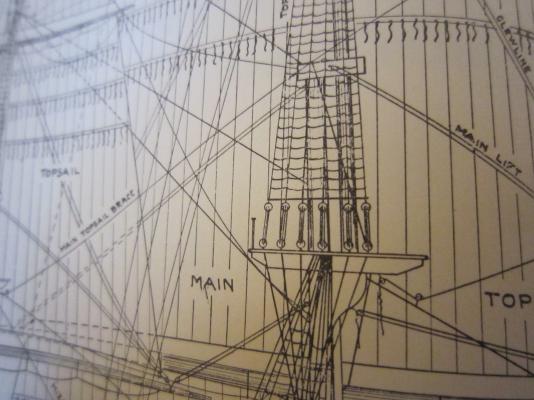

While I'm finishing the masts, I looking ahead at rigging and ran into this kind of problem: One Constructo drawing shows four stays for the upper main mast, then in the rigging plan Constucto shows five stays and on an official drawing for the Constitution it shows six.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks to all of you who suggested using painted paper instead of real brass for the mast reinforcements.....well done! The paper supports might not be the best,,,but when I clean them up, they'll look just fine. Thank you all again! In this picture they still have drying glue,hanging bits etc

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I can see it's going to be a challenge to line up all three masts and give them a 3 degree aft rake.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

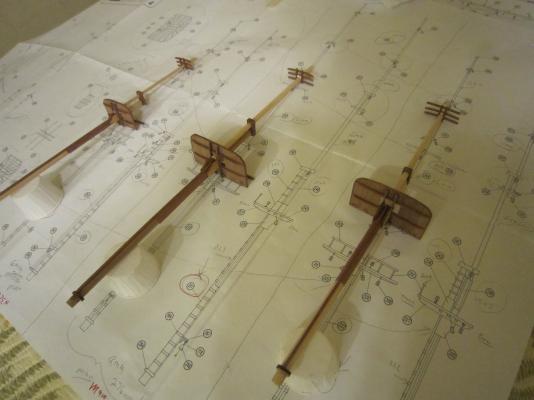

The plans are good for this stage, but I couldn't get the exact details where the lower mast phases into the middle mast. The stuff is "stacked" on the drawing so I had to slide pre built components up and down to get them to match the master drawing. Now, it's just making sure I position the rest in the correct place.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm starting to glue together some of the mast's components. Here they are laid up against the plans to make sure all is squared away and lined up. There's still a lot left to do on them

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Your planking plan makes me remember how my planking plan went. I figured out what would go were like your plan.....it all went according to plan until the 2/3 mark....then it seemed to work its way into Kentucky windage and make do at the end. The good news is....my planking job looks great...so will yours with your careful approach

- 1,348 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Having just rigged my bowsprit....I'm in familiar territory looking at your rigging of it. Nice work.

- 335 replies

-

- Constitution

- Mamoli

-

(and 3 more)

Tagged with:

-

The Swift was my first kit and I learned a lot building it. I bought the kit at a garage sale for $25. It came without sails, but I got so hooked on model building that I bought a full price kit just to get sails. It didn't hurt that I had a good supply of extra wood for my second build. Good luck! It looks great so far.

- 114 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

I've drawn a circle at the top of each mast to be tapered the diameter I want the tip to be. The picture is blurry, but you get the idea. Then I plane and sand the cylinder until,the taper is correct.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks to all of you, I'm running a test using paper strips painted brass for the mast bands. When the glue dries, I shall varnish it to see how it holds. Thanks...you all are great!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks for the great ideas. Yes, I'll be tapering them.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

My mast grow taller. I've dry fitted them to this point. I can't seem to master how to fabricate the metal straps that hold the masts together. No matter how I bend the pieces they wind up not laying snug to the mast? Any ideas?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.