-

Posts

3,254 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NenadM

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Oh what a day ... 15°C outside, first gardening works this season, cooking, visiting Old Lady, going to swiming pool to swim my weekly 1km, helping Hothead to wash and start preparing his bike for season, at evening kids went to downtown, and after a few hours, Her Majesty is at Her working throne, at last The best colateral thing is, that throne can enter into Her dust protecting wall shelf And I am happy to go forward to finish aft deck one of this days- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thank you for nice and supporting words, Piet. In my life, I graduated improvisation for many reasons. Also, when I make something, I have a irrational fear that structure will be weak, and usually I made it more stronger and complicated than it has to be. I remember when kids were babies, year 1993. full force of hyperinflation, and no money for anything... we just moved in our semi-finished house, with no furniture. I found some cheap pine lumber and made beds for babies ... thinking ... they will jump on beds ... they had to be very strong ... you just can not have any idea what wooden fortress I have made ... Also, our double bed in sleeping room has hidden metal structure and can withstand weight of one tone !!!! You can easily hang yourself on any bookshelf I put on walls ... every concrete I have made in and around of house is much stronger than it had to be ... That is just - me, and my irrational approach to everything I make/made . This time, transposed to my model Thanks again- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

I added extra ballast earlier, my friend, so I think whole thing now has a little less than 1 kg- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

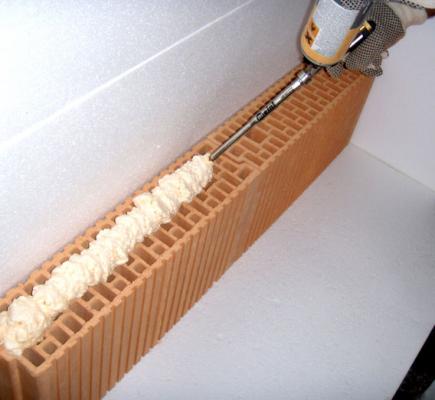

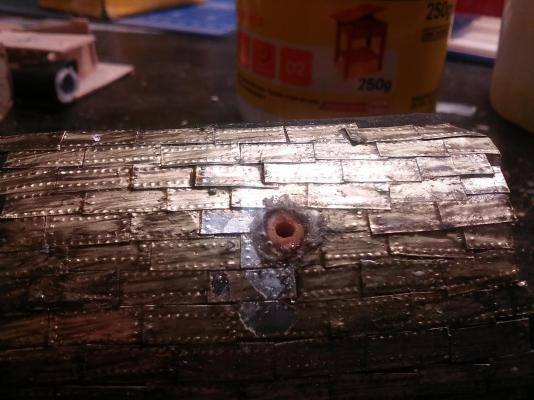

Here are me again. Couple of days I was pretty quiet, because I have got a little flue, and also there was not visible progress. Today I can proudly pronounce that my four "black holes" losed their "black" atributes, and have turned in regular holes, with bottom I can reach. Filling is slowly coming to end. I know it Dave, but it needs a time for filling material to dry, and I have to work in thin layers, to avoid danger of leaking glue etc etc through deck planking. Her Majesty is turned upside down, I suppose - a last time in Her life time, and holes are opened to up during filling process. So, put one relative thin layer of material, and must wait for it to dry. And on that way, every day. about hour for four holes. The end is on horizon ... Helo Jud, I have readed your post before you deleted it. I used rolled paper sodden with glue cleated to bottom of hole, and covered with thin layer of BBQ strip pieces, with another thin coat of glue. Idea with wire is something valuable to think about. So, bunch of strips rise over time, and now it is only 1-2 cm under hole entrance, so final filling can start I was thinking about epoxy, Michael, but I gave up, because I was afraid of leaking through the deck planking. Particularly, I can not find in near shops adequate epoxy. In Belgrade there are not shops like "Hobby-lobby" and another such a type I have read on MSW, there are only a few similar, but with poor choice of such a things, materials tools etc etc ( mainly plastic kits, acrylic, brushes, cheep Chinese scalpels etc etc). So I have to manage with things I have My idea is similar Denis : to fill hole with material to the top, when dry and harden, drill through a new hole for 4mm dowel, drill 1-1,5mm hole in dowel, glue dowel in new hole and align it to the surface of hull. And after that mount stand with screw or a new thin dowel, or wire. Just for remind, main problem is balsa 2x5mm strips used for hull planking Hello Nils. That was my first idea, and I made some testing with such a solution, but I was scarred of possibility that balsa strips can not withstand direct force. That was a reason I decided to reduce that direct force giving some "meat" to hold dowel and to distribute direct force from hole entrance to whole "meat" in which dowel will be embedded. Problem is in fact that I know with whom I am dealing with ... un patience, and awkward Nenad, and I just have to make something strong enough to keep me and my work from - me So, another booooring period is coming to end, and I hope soon to continue with deck stuff challenges- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

WOOOOW !!!!!! What a work !

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Dowel is main idea. I am fighting now to make some "meat" for dowel inside large space under holes. It is necessary because I used balsa planking (?!?!)/Considering possible angle of holes in stand, simple one dowel can not be mounted, so here will be kind a "dowel for dowel" or "dowel in dowel"- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thanks for your support, dear friends Do you know who will win next Nobel prize for astronomy ? I found a black hole, here on earth. More correct, four of them They swallow everytging I put inside Filling continues- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by samson - Billing Boats

NenadM replied to samson's topic in - Kit build logs for subjects built from 1851 - 1900

Briliant work, Jens !!!- 188 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

Cutty Sark by samson - Billing Boats

NenadM replied to samson's topic in - Kit build logs for subjects built from 1851 - 1900

So do I, Denis- 188 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Maybe this is shortcut to Ver. No 2, Mark- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Resin ... hmm ... there could be something ... Not only with glue, Mark. Pieces of BBQ strips with a drops of glue over just to slip through and connect them to each other Hi Peter. Caution reasons lead me to do make first layer of glue/BBQ pieces very thin ( I was afraid that glue can find a little hole inside and to enter to deck. Fortunately, this did not happened) . Idea was to use this first layer to impregnate lower inside surface of deck). Actually, I think there is no danger here for planking, because my deck has three layers ( plywood, first planking, and re-planking layer) covered with matt acrylic varnish. And the fact is that Nenad did not think about chemistry issues how glues work ... need some air ... For now, I am thinking about first move in this situation - to be to careful and to put inside holes some hot air from hairdryer ... or to put inside very thin layer of alabaster dust to pick up excess of moisture from glue Or maybe foam ... But ... it also need air ... Here are we ... in a swamp again ... and I like challenges .... very much ...( lying)- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

@#$@#$ first layet of glue do not dry and harden whole two days..... @$@$#$ not enough air? Bad glue? Obviously there will be no progress until I resolve this- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Feel the taste of white glue! Filling process started. Layer of pieces of BBQ strips, layer of white glue, next hole, repeat, next hole .... Deep holes, as black holes, swallow everything I put inside, so testing piece which I use to spread pieces and check progress did not show anything going forward Patience, Nenad, patience- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by samson - Billing Boats

NenadM replied to samson's topic in - Kit build logs for subjects built from 1851 - 1900

And real fun begins! Good luck!- 188 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Forward ... Princess recovered and go to down-town, and I steal some time from office for myself First I take out Hotheads bike under stairs in garage from it`s winter house, to get approach to old pieces of plywood which remains from my furniture carpenter works, to find adequate piece for temporary stand .. this beast has 175 kg ... Dust, dust, dust ... I must clean that space ... one day ... I have a habit to cannibalize and keep every piece of shackle from old furniture, and have found in my man cave a piece just what I needed to realize my idea Drilling a hole in a throne ... and mount throne on temporary stand At this stage, my idea with a "box" in stand becomes clear. Box fuse will hide screws, and at the same time, I shall be able one day to remove throne from temporary stand, and to mount it on final place without any damage. Connection is very firm After that, I continued with drilling holes in upper arms of throne, to use that holes for marking place where to drill in hull Two ideas arises here one - to use screw another - to use BBQ bamboo Something to think about during filling hull spaces If I use bamboo, connection will be a bit more elastic, and I can level outer surface of arm to zero, and paint it a bit just not to be visible. This kind of connection is a bit weaker, which can be better. Or not If I use screw, I must wide inlet to hide head of screw, which could get a bit weak arm, But connection will be stronger. and less elastic. Or not Hmmm Always there is something to think about- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thank you for nice words to everybody Proud to announce that "scientific" experiment is a success ! Nothing moves, every single plank (and a pipe of course ) is on it`s place So, Nenad , found some courage, and bravely start drilling real holes in hull !!!- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Proud beautifull lines appears !!! You can be satisfied

- 71 replies

-

- cutty sark

- mantua

-

(and 2 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hole ~4mm drilled and filled with white glue, then testing anchor ~4mm made from rounded molding turned in hole When glue started to dry, testing screw get in Have to wait until tomorrow for glue to dry , and to apply final weight and force test over night Testing shows that anchor must have larger dia (~5mm), and that whole structure get more stronger Yes, Piet, it seems that this will work. Send my regards to your dentist In mean time, I discovered that SOMEBODY get my precise measuring tool and sent it to hell ... Enough work for today, I'm going upstears to nurse ill Princess. Nothing serious, stomach flue, but Ill doctor? Strange...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.