-

Posts

604 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jasseji

-

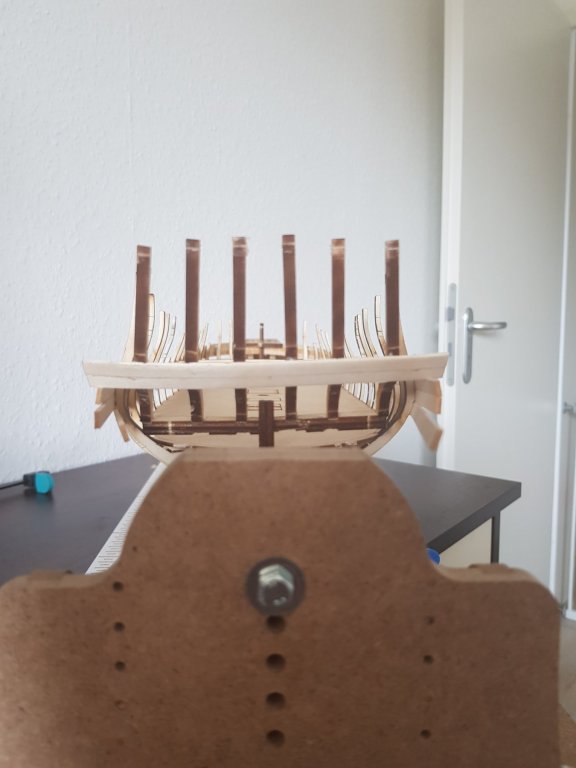

Main Wale, 3 strakes out of 4 done, ran out of glue 1.5x5mm Lime - I think it doesnt look that bad, will be Sanded to shape and covered with Walnut Veneer (or maybe Mahagoni even) Waiting for thinner Lime for rest of hull and internal planking (although i'm tempted to do all internals with Tanganika which is 25% cheaper...)

-

Those you marked are actually not a problem, it's the 3 bow frames which would require sanding/filing down to an angle but i tested on scrap Wood and each Time i try to file it, the plywood layers come apart even with a fine nail-file - i dont think it Will matter on the finished ship, it's Just a bad technique

-

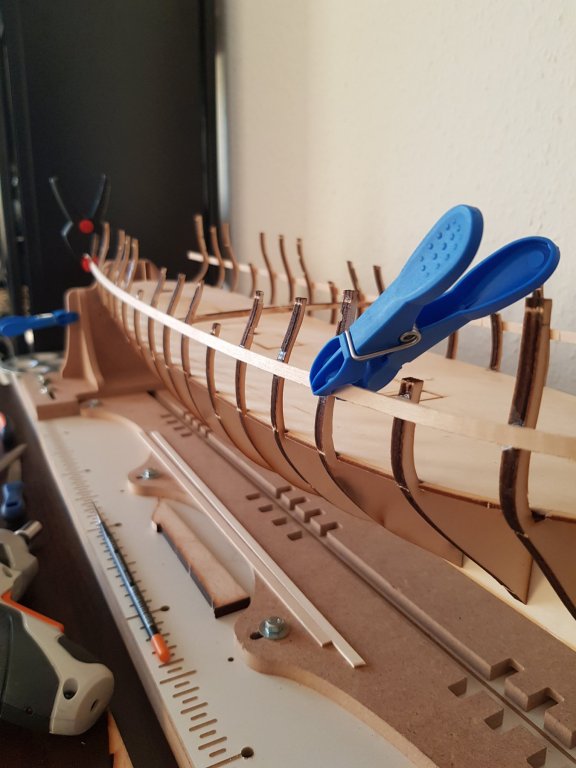

so, 1st strake of the main wale is in as a test, i am bending the planks with the wirecutters technique, although i found that the plywood i have for the frames is so brittle, i cant really fair them correctly so i'm left with gaps at the bow between the plank and frame 😕 Also it slighly affects the shape of the bow. I am waiting now for new wood to be delivered, will have to think about it if i can live with this or try to fix this somehow

-

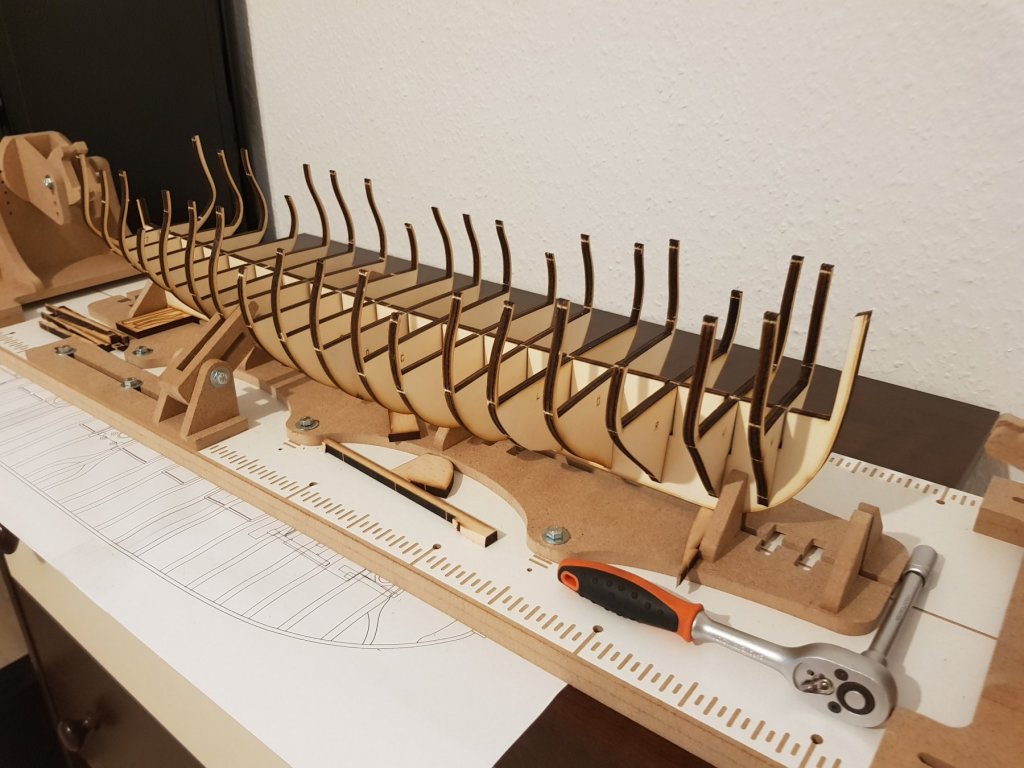

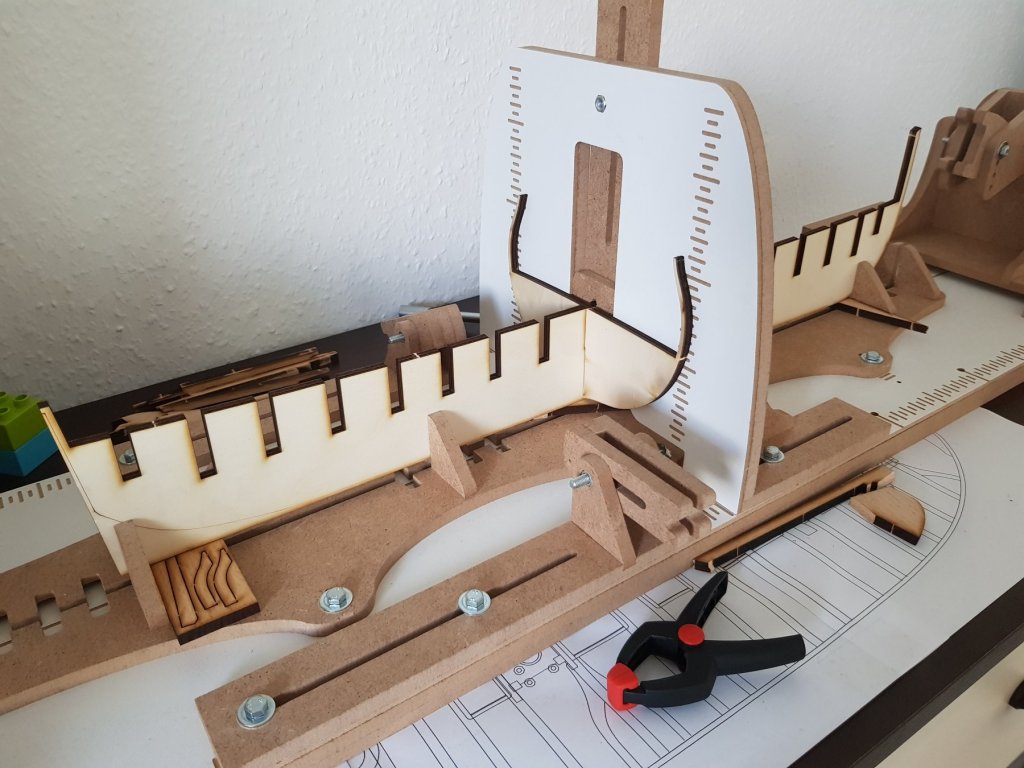

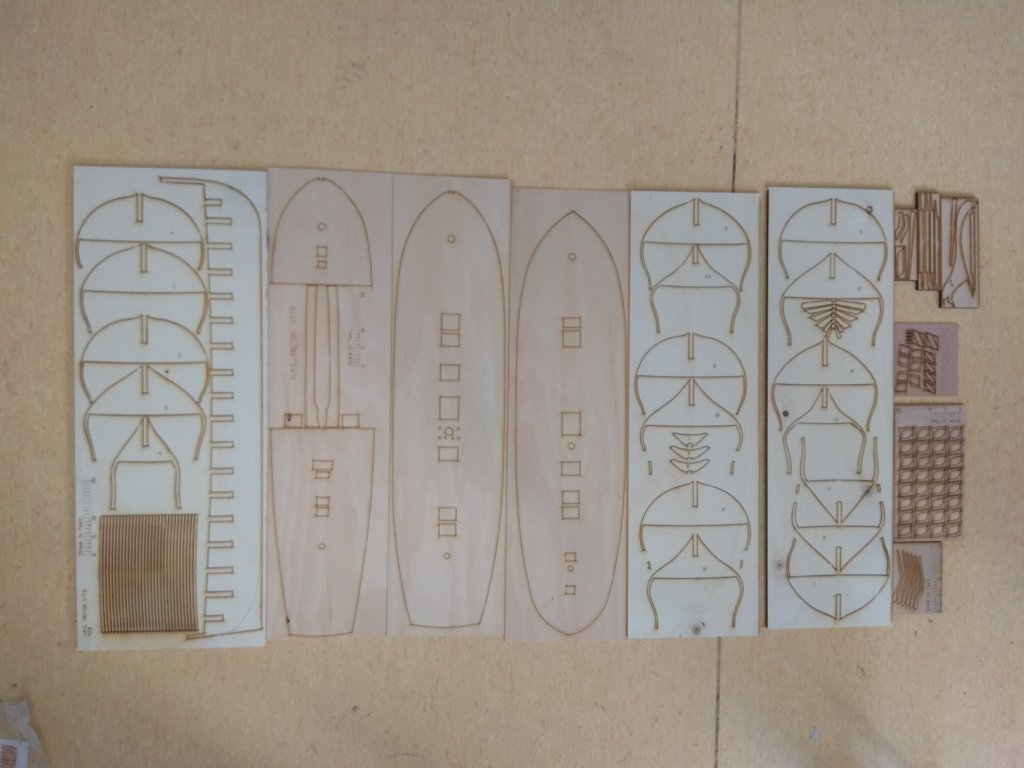

Nooo, not you Anyway, couldnt resist, frames are removed from the sheets and pre-positioned, the shorter ones are not damaged of course - that's where some of the Gunports go. Only one frame was damaged but managed to repair I also ordered AotS Pandora which is a very similar ship, only a bit shorter. BTW @James H, i can send you guys the DXF files i created for these from the plans - might save someone the trouble if they want to laser-cut and dont know CAD (to include them in the downloads section)

-

yes, i believe so, i got the 2mm blocks today, will see what i can come up with (hopefully i'll be able to use same thread)

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

near enough do you keep a web-gallery of all your paintings perhaps or only here ? Beautiful work

-

They are 3 or 4mm dont remember now but Daniel is sending me 2mm to try

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

hm, did you browse through the MSW ship kit Database ? http://mswshipkits.ampitcher.com/

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

Thank you, unfortunately this is only a kit, next Cross-Section will be scratch-build i hope (if i dont fail at the Triton scratch). I am actually thinking about a partial transverse - at least a cutout of the lower deck of the full Triton but we shall see.

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

Measure her and calculate There is a rope diameter sheet somewhere on the forums (in the rigging section i think) usually when you rig a ship, you start with the Bowsprit, then the mast shrouds, next the Stays - the bowsprit needs to be rigged properly first, because the stays are attached to it and it holds the fore-and-aft position of the masts in your case, you have like 90% of the standing rigging done (shrouds and ratlines) so propably only minor adjustments are needed on the stays and maybe lanyards If you dont like the color of the ratlines, you can always dye them a bit Ambitious projects are best

-

Yes, i have made the breeching ropes as described, wrapped around the knob (maybe not visible on the pic but they are) The coils i will do when i have made the rest of the Guns, however my concern is that the blocks are massively out of scale

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

Guys, really, honestly, please tell me if this rigging does look anywhere close to decent... i'm struggling with the thought to remove the outhaul tackles and just leave the breechings - it somehow doesnt look right in this scale

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

And here i would have made so many less mistakes if i'd found this thread sooner

- 75 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

I did not abandon her folks, despite being anxious to start the Triton, but with the HOT weather here (over 100F in Western Europe !!!), working on gun rigging is a no-go at the moment...

- 50 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

and you live where, Jim ?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.