-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

I broke down and bought one of those denim aprons made for workmen. The Admiral wishes I would wear it. Bob

-

Lawrence, Glad to have you aboard. Well it's back to the drawing boards again. All seemed to be going well with the veneer as the first planking for two or three strakes and then I squeeze too hard and break them, tear them off and try again same thing, try again . . . Wait I know what they call people who try the same thing over and over and expect different results. So I will go back to my faithful basswood for first planking and cover it with the veneer. Now to make the bulkheads smaller to allow for the thicker planking. Ah well I learned something also. You need to be down to SIB size to use veneer as a structural member. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Hi Walt, I glued the paper to the wood with a thin layer of Elmer’s White glue covering the surface of the wood. After cutting the strips I planked from the outside in with the paper towards the outside. I did not try the other way but I doubt there would be a difference. Lawrence, thanks for the complement. Bob

-

Pete, I’m not sure yet what I’m getting myself into with this edge gluing of veneer. I’ve decided to make a minor change. I will place a narrow strip of the veneer over the edge of the bulkheads as something extra to hold it all together. George, I’m already having fun just figuring out what in the heck am I doing. Jparsley, welcome to ship/boat building. In most cases when bulkheads are set up in this way the planking is glued to the bulkheads and they become part if the boat. In my case I want an empty hull so I can maybe show the interior. In order to do this and hold the planks together they would have to be glued together edge to edge. Patrick, in my twenties I lived on a boat. Not too far away was a dragon. That is when I fell in love with them. Frank, the strips I mentioned above should add a lot of strength, at least that’s the hope. Igor, yes, I get into trouble all the time by making promises to her. Now It’s back to the boatyard hope to have more soon. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Sounds like you had a good day together, that's the way it should be. Many more happy days, Bob

-

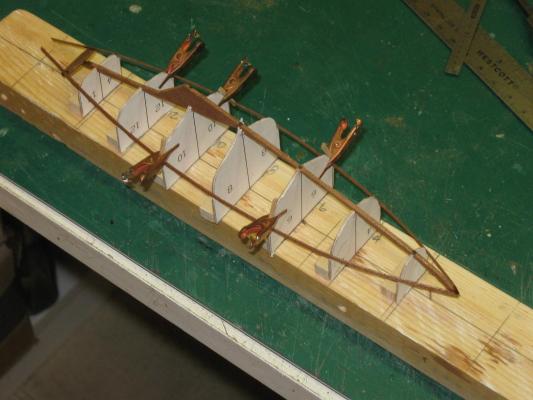

Hi All, Now to get started. I finished the drawings and cut out the bulkheads using 1/32” scrap plywood. The bulkheads were glued to 1/4” square stock and then glued to the build board. The keel was cut from 1/16” mahogany. I think its mahogany, its a little redder that walnut so I call it mahogany. I will plank with the mahogany veneer strips that can be found in most kits, the planks will be glued to each other but hopefully not to the bulkheads. Edge gluing the veneer strips should be fun (read as possibly frustrating), we’ll have to see how that goes. Anyway here’s a picture of where she is today. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Ben welcome aboard. If you are not familiar with the dragon you need to look it up. It was designed in the 1920's as a daysailer/cruising boat but sailed so well and fast that with minor changes it became an Olympic racing boat. There are still large fleets of these sleek boats. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Hi Jond, I'd sail it as is bet I certainly know that feeling to add more. She looks fin and should sail well. Your talk about Boothbay brought back fond memories of spending a couple days there in 1973 and eating lobster we bought form a shed out on the dock. Bob

-

I like your choice of sycamore for the planking and your thinking through the problems is very informative. Bob

-

Glad you're here Frank. Pull up a chair and enjoy the show. Made the first major change. Instead of 1:32 like the first Dragon I've decided to try this one in 1:48 to match my other boats. That means 1" = .020". Now to figure out how to make that 1/2" square stock. It's back to the drawing board for now. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Popeye, you're always welcome to come aboard. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

Don't worry Pete. The seats are filling but there's no limit. Welcome aboard. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

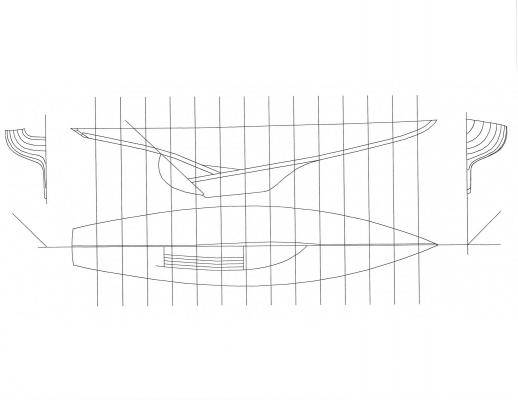

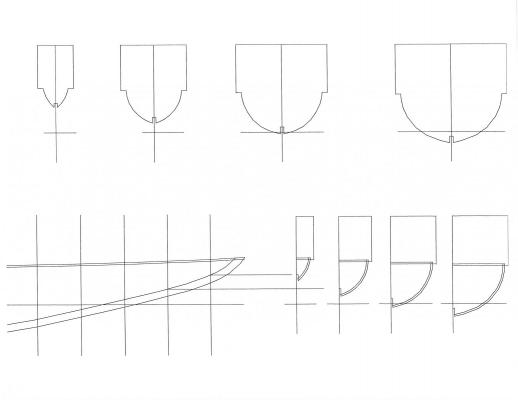

I want to thank you all for joining me on this build, I will make it as fun as possible. After all that's what it is all about. Chris this is how I do it. First is to trace the line drawing into the computer (or on paper) and separate the sections. These will become the bulkheads to plank over. Now at each station line draw a line from the top of the keel to the associated section drawing. This is the top of the slot for the keel to fit into. Draw the keel slot at half the keel width. Now decide how thick the hull and deck planking will be and offset lines to the inside of the section and erase to outside lines. Draw a base line above the section. I usually make it one to one and a half inches above the top of the section. This line is measured up from the water line and must be the same on all sections. From the top of the new hull line, draw a short line out from the hull and another connecting this up to the base line. Now by mirroring the half section around the center line of that section you end up with the bulkhead. Hopefully between this and the pictures the process is clear. I did show it in the pictures, but it is best to number the sections. Bob

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

I like the way you made your building board. The ability to mount the boat both ways is clever. For your planking, all you need is to do it and gain experience. You're doing fine. Bob

- 144 replies

-

- corsair

- bermuda boat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.