-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

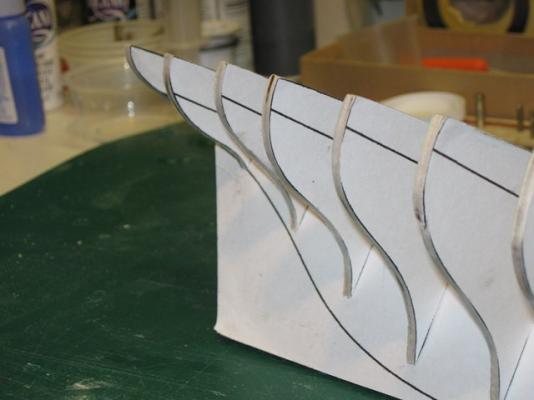

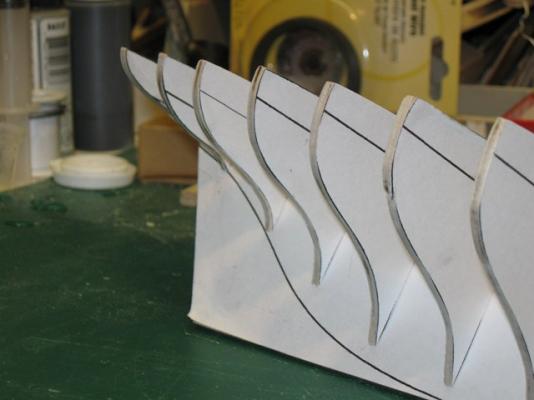

What a great time of the year, not only the holidays, but all the college football games. I’m not going to get much done on this build for the next three weeks. I did manage however to clean up the bulkheads and dry fit them, that’s when I found out #14 (third from end) was bad. You can see in the first picture #14 is not big enough. So it was back to the drawing board, so to speak, I use DraftSight, and I did find the error. Picture two shows both #14 bulkheads and then how the new part lines up. And with that I’ll say Merry Christmas to all, with wishes for a great 2014. Bob

- 420 replies

-

A schooner with two topsail masts has spring lines from one to the other. When tacking does the fore topsail have to be lowered and reset on the other side of these lines? Bob

-

I always did my first test in the bath tub. I didn't have to go anywhere. Bob

- 76 replies

-

- fantail launch ii

- midwest products

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

captainbob replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Tom, congratulations on a job well done. The molding is great even with Andy’s dentures, I mean dentals. Bob- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Looking good, Shawn. Can't wait to see it in the water. Bob

- 76 replies

-

- fantail launch ii

- midwest products

-

(and 1 more)

Tagged with:

-

Steve, I've never signed my boats, but maybe I should start. Bob

- 420 replies

-

Fine work, Michael. And it's about time you got around to making the foreman a chair. Bob

- 2,215 replies

-

Wow. I'd be pleased with all of it not just the deck planking. Good work. Bob

- 170 replies

-

- ogallala

- praire schooner

-

(and 2 more)

Tagged with:

-

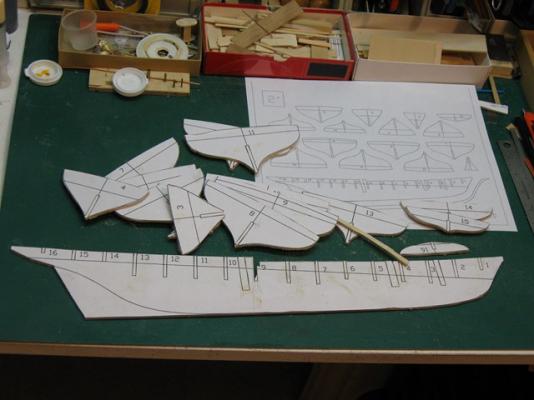

Keith, I was going to answer but John and Frankie beat me to it. Thanks friends. Tom, I bought 1/8” plywood for the profile and bulkheads. As for the larger slots, yes they are the masts and the foremost is for the Sampson post which would not have to go below decks on a model but I put the slot in anyway. The rake of the masts is shown on the inner profile drawings. Popeye, Michael & Augie thanks for the well wishes. And yes, Popeye I have copies of the bulkhead drawings I made. Bob

- 420 replies

-

Pavel and Keith, thanks for stopping by and for the good words. Keith, in entry >5 you see the Lettie under sail and from the shape of the sails you can tell the wind is cuming from the starboard side. But looking at the fore jib, it is still sheeted on the starboard side and the clew is on the wrong side of the main jib. Backing a sail is forcing it against the wind so as to cause the boat to go backwards. The jib in this case is not large enough to reverse the boat but the term still applies. Bob

- 420 replies

-

Finally! I made sawdust today. I cut the parts out on the skill saw now I need to go back and sand to the line, but it feels good to get started. I should mark the date somewhere, like in the records of ships where you see, “KEEL LAID ON:” Dec 18, 2013. I decided to go POB for this boat. You can see my CAD drawing on letter size paper in the picture. The box with the 2” inside gives me the size to enlarge to. If anyone wants a copy let me know. Bob

- 420 replies

-

Thanks for showing your work. As I said I had never tried it myself but had heard it was good. And yours looks fine. Bob

- 76 replies

-

- fantail launch ii

- midwest products

-

(and 1 more)

Tagged with:

-

Isopropyl alcohol makes a nice thinner. I’ve used it many times, of course in those days nobody heard of epoxy thinners. A warning. If you are not using fiber, (glass, nylon stockings, . . .) you need to build up the thickness of the epoxy for strength. I have seen the wood of the hull swell and shrink with moisture and/or weather enough to open the seams between the planks. Bob

-

Shawn, It is the glass that gives the resin strength. But I have heard of using nylon stockings instead of glass. That would also be strong and I would think easier to apply. I never liked fiber glassing either. Bob

- 76 replies

-

- fantail launch ii

- midwest products

-

(and 1 more)

Tagged with:

-

Steve & Stan, thanks for stopping by. Haven’t had a chance to get to town yet for the wood. Hopefully tomorrow. Bob

- 420 replies

-

Beautiful job, I'm sure she'll love it. Bob

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

You’re going to have to build a diorama of a fishing dock to keep them all. They all look good. Bob

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Clare, Glad the nerve is feeling better. You’ll have to do a tutorial on how to etch brass. I’ve never been able to come close to your quality. Good work. Bob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.