-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Save me a seat. I love the old working boats. And this one looks good. Bob

- 170 replies

-

- thames barge

- billing boats

-

(and 1 more)

Tagged with:

-

Love the paper in the bottle. It will be great in wood. It is hard to get a size from the start of the hull. Please put a penny in the picture next time. Bob

- 170 replies

-

- ogallala

- praire schooner

-

(and 2 more)

Tagged with:

-

There is a topic “What do you use your mill for.” Check it out. you may not need a mill. http://modelshipworld.com/index.php?/topic/2755-what-do-you-use-your-mill-for/#entry75019

-

Michael, Beautiful work, but like Andy says watch out for that “fun” stuff . . . oh wait it’s supposed to be fun. Now what? Bob

- 2,215 replies

-

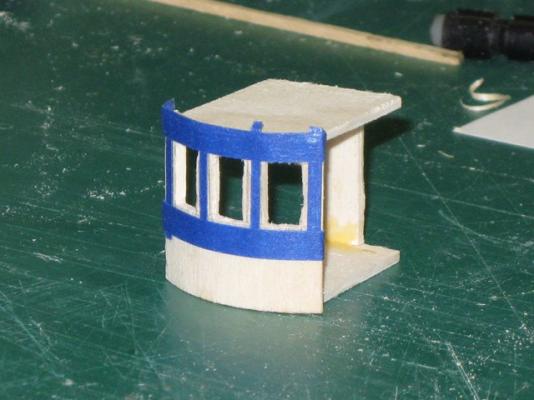

Guy, Thanks but I mixed up a light green and painted. The Wheel house is less than a one inch cube. That makes it fun to work on the inside but I’ll do what I can. Paul, Thanks for stopping by, feel free to browse any time you like. Bob

-

Green Graphed/scaled work bench mat

captainbob replied to Bill Hime's topic in Modeling tools and Workshop Equipment

Joann's Fabric also has them. -

What Knots on ratlines? (edited by admin)

captainbob replied to jd99's topic in Masting, rigging and sails

I know most MSW members say no CA on rigging, but at the end of the video he says when he is finished he will go back and put CA on each knot. Why not CA on rigging? Bob -

Michael, Glad to see you back on this beautiful cutter. Your work is superb as always. Bob

- 2,215 replies

-

I’m late to the party as usual, but it looks like you’re having fun anyway. That’s an interesting difference between the two boats, and both are correct. If five different builders built thier lobster smacks in the 1800’s you would have five slightly different boats, because each builder has his own idea of what is best. That’s part of the joy of building the small boats. Bob

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Michael, The white wood is bass wood, the dark wood is that .5mm X 4mm strips that comes in kits for second planking, I think it’s mahogany but I’m not sure. Thanks Pete, your lobster smacks are looking good. Bob

-

3D Printing - Not Just Yet!

captainbob replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Seven or eight years ago when I was working we would send 3D drawings to a company that specialized in 3D printing. The machines they used were as large as a refrigerator and quite expensive, so the parts were also expensive. (They had to pay for the machine.) The parts they printed were beautiful and the surface was smooth enough to use as sliding surfaces in our prototypes. Hopefully one day a company will make a low priced desktop printers that will produce the same hihg quality. Bob -

Yes, Michael. Stoop labor is no good, even if you love what you are doing. Bob

- 2,215 replies

-

Congratulations, John. The materials are gathered for the keel to be laid. I’ve always liked the hard working coasters and river boats, and the Francis Pritt is a fine example. Thanks for letting us watch your build. Bob

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Very nice, Allen. You're building a beautiful boat. Bob

- 86 replies

-

- schooner

- effie m morrisey

-

(and 1 more)

Tagged with:

-

Thanks John, Guy was on one of the Woban class tugs, hopefully he will remember the color. Bob

-

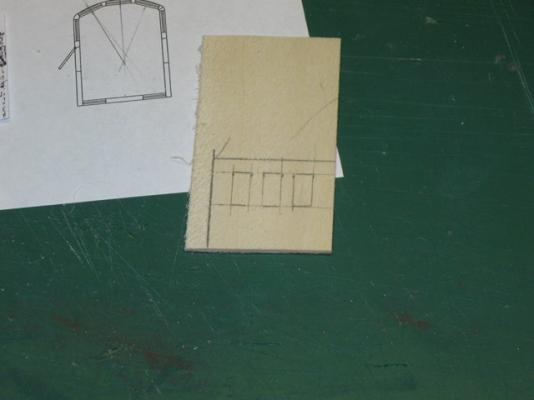

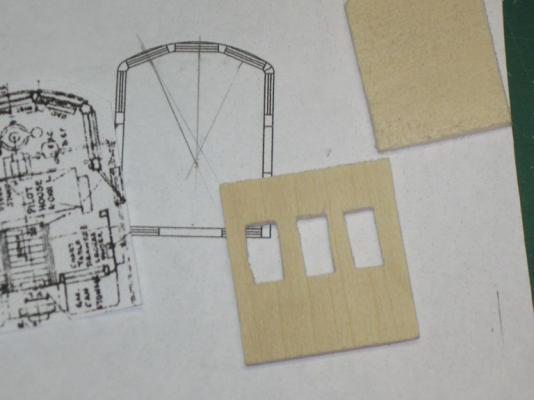

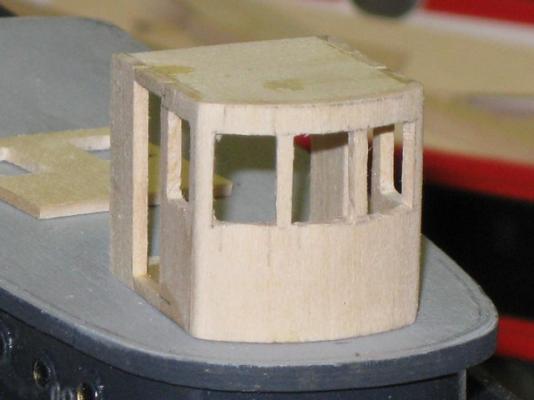

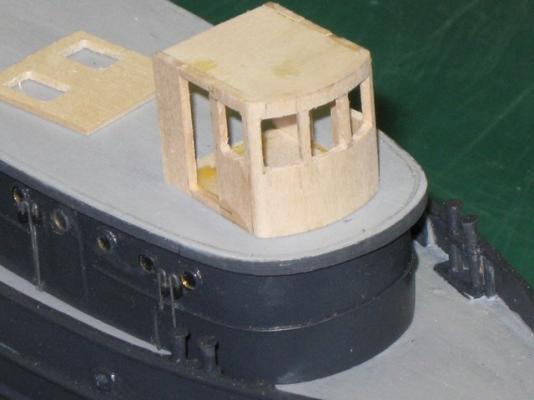

Now, on to the pilot house, it has a round front with three windows. First I drew a top view to get the spacing. The windows are .28” wide with .06” between them. The windows are flat while the structure curves. I cut the windows undersize and glued the panel to the curved top and bottom before I trimmed away the excess. I then put tape on the panel to show the limits of the windows and cut and sanded the windows to size. On the fourth try it worked. I made the side and back panels the same way. Now its paint and add the wood trim around the windows. Then add the interior furniture so I can glue on the back, which you can see on the deck, Ah well, one thing at a time. Guy, what color was the inside of the pilot house on YT 150 I suspect a light tan but I’m not sure. Bob

-

I wouldn't miss this fun build. Count me in. Bob

- 170 replies

-

- ogallala

- praire schooner

-

(and 2 more)

Tagged with:

-

Ah the joy of answering the question, "How in the . . . . am I going to make this?" Well done. Bob

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.