-

Posts

843 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by pirozzi

-

Hi Keith, I still have much work to do on the decks, like the railings, fixtures, stairways and such. That all will take some time to complete. I am starting now with the forecastle railings and catheads. Vince

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Welcome aboard mate! Nice work. Vince P.

-

Finished placing the trennels. There were over 2000. Next up will be to work on the forecastle railings and catheads. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

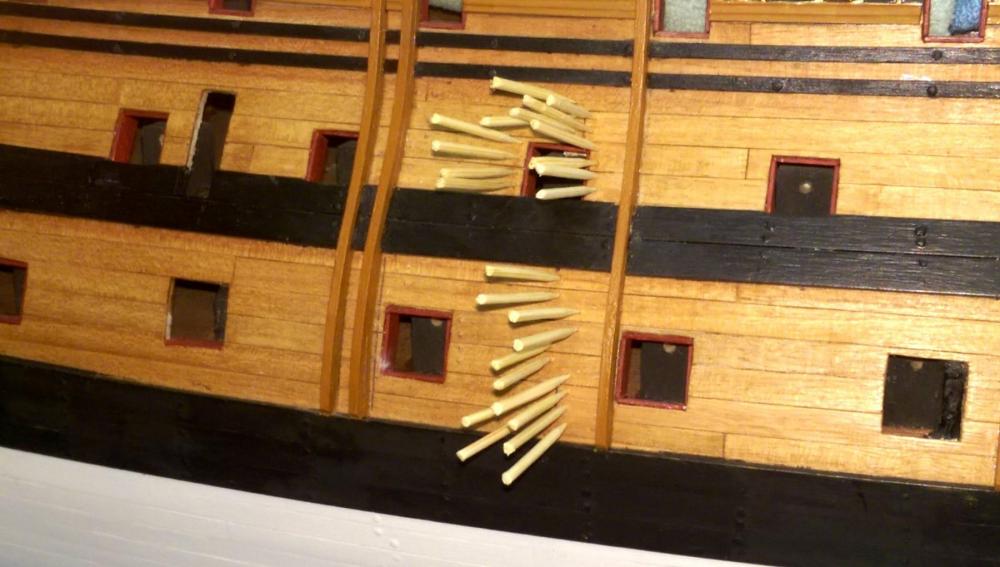

Now that the bow is mostly finished I decided to finish placing the trennels all along the unpainted portions of the hull. This will take a while since there are hundreds of them. Like before, I am using round toothpicks. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Thanks for the usual kind words and encouragement Greg. Vince

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

I have placed the timbers between the rails on the starboard side. I did not use the metal strips supplied in the kit, although they are fine. I made some decorative strips with wood from my stash and milled out the center by hand. I think they look more like the drawings and of other high quality models I have seen around. I found another blunder after placing some of the timbers at the forward end of the rails. When I bent the outward curves into the rails, I tried to match the drawings, and think I came pretty close, BUT, the stem is too thick and too high as provided in the kit. There is no room for the gammoning ropes to fit in between the inside of the lower rails and the stem. I would have to have known to shave the thickness of the stem piece, or cut it way down from the top beforehand. In looking at some scratch built models, the stem piece is cut way lower from the top to allow the ropes to run between. Nowhere in the plans does this seem obvious, but someone smarter than me would probably catch this. Anyway, if you are following this log, you can avoid this by fixing it before placing the lower head rails. I will have to run the gammoning outside the rails at the lower end and then feed them up inside to the bowsprit. I have seen other ships of the period do this, but not the RW. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Placed the gratings inside the head rails. As was already pointed out, they are lower than the drawings show because the curvature of the upper head rails is a little too low. I am however not too disturbed by this. Since my build log seems to be ahead of the others, I am the one who will make some mistakes for others to benefit. That is why build logs are so important, and one of the reasons I stick my neck out and publish my work for others to see. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Thanks Pete. I see where it would go now. However it looks like it would be awkward in place as it is cast. I might cut it down some to match the curvature of head rails and bow where they meet, or just leave it off. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

OK, a question for all Royal William builders. See the attached photo.... It is a metal part included in the Euro kit with a number of "11155". What is it?? Can't find anything on the plans or drawings even mentioning this. I believe it has something to do with the bow ornaments since the number is in the sequence for the parts there. HELP! Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Keith, You are correct about the level of the gratings. Having had to consider so many things in bending and installing the top rails more than once, I was bound to miss something. The gratings will be a little bit lower as a result. I am not going to remove the rails again and try to rebend them at this point. I think it will look OK in the end, I hope. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Finishing up with adding the remainder of the head rails. After placing the rails, I noticed that the top rail was curved so that it was way out from the lower rails. This would make the head timbers uneven and at a impractical angle. I had to remove the top rails and completely rebend them so they followed the curve of the lower rails more closely. Since they were already painted, using a torch was not a good idea. I had to bend them by hand, very carefully and slowly so as not to break them. The last photo shows the top rail hugging the hull more closely. Another mistake I learned from. Installing the rails from the bottom up would make more sense. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Still working on the bow area. There are 2 small utility ports that must be added before they are covered up by the head railings. I made one partially open. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi J, That is a little metal roller press that is used to bend planks and soft metal without the use of heat. In most cases you don't even need to soak the wood. Just adjust the rollers for the thickness you want and run the material through by cranking the handle. It does a very nice job of evenly bending. If the wood is particularly thick or hard, a little soaking first helps. For hull planks, you don't need soaking at all. I used it with the Royal William for all of the planks and even the heavy wales. I got it from Micro-Mark. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Keith, Yes I remembered to cut the holes. There are 2 holes, one in the decorations and another higher up on the stem. The one on the stem has not been posted yet. Thanks for looking out for me. It won't be the first time I forgot to do something critical until too late. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi JT, I was looking at a build log by Anja on this site years ago and noticed she had her ship clamped on a nice little stand and it was marked made by Dremel. I contacted them and was told that the mini work station was discontinued several years ago and no longer available in the US. It was however still available in Europe. I found a supply house in Germany through the Amazon website and ordered it through them. It is a great tool and I use it a lot. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Keith, I debated this too. While the gold looks rich, I think the color scheme brings out the actual figures better. I looked at several models done both ways and think the colors look more authentic. Vince

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

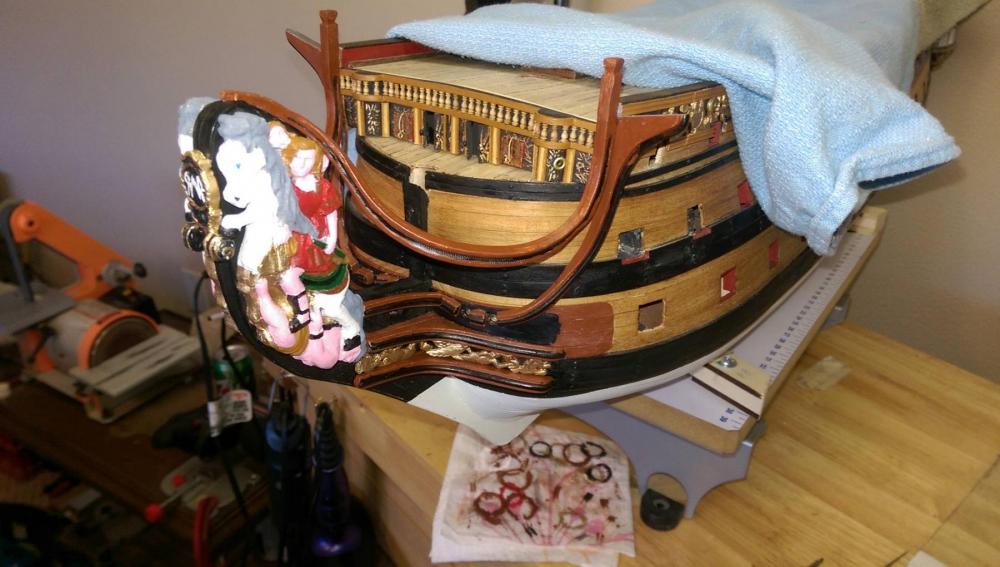

The metal figurehead panels are very heavy and will require some thick pins to keep them in place. I used 1.5mm brass rods. Also, part of the lower head rails have been placed. The figurehead panels will have to go on before the rest of the lower head rail can be measured, as well as the rest of the head rails and timbers. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

The outer bow reinforcement plates with the hawse holes drilled. I used some brass portholes (5mm) to line the holes. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

The heavy metal head rails need pins in order to hold them on to the hull. Just gluing, even with CA won't do it. The photo is of one of the lower head rails with the pin installed. A hole will be drilled into the hull to insert the pin and hold the rail in place. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

The upper and lower cheeks along with the decorative strip are added. At the very forward end of the decorative strip, a slot has to be cut into and through the stem for the forward gammoning ropes. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.