-

Posts

843 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by pirozzi

-

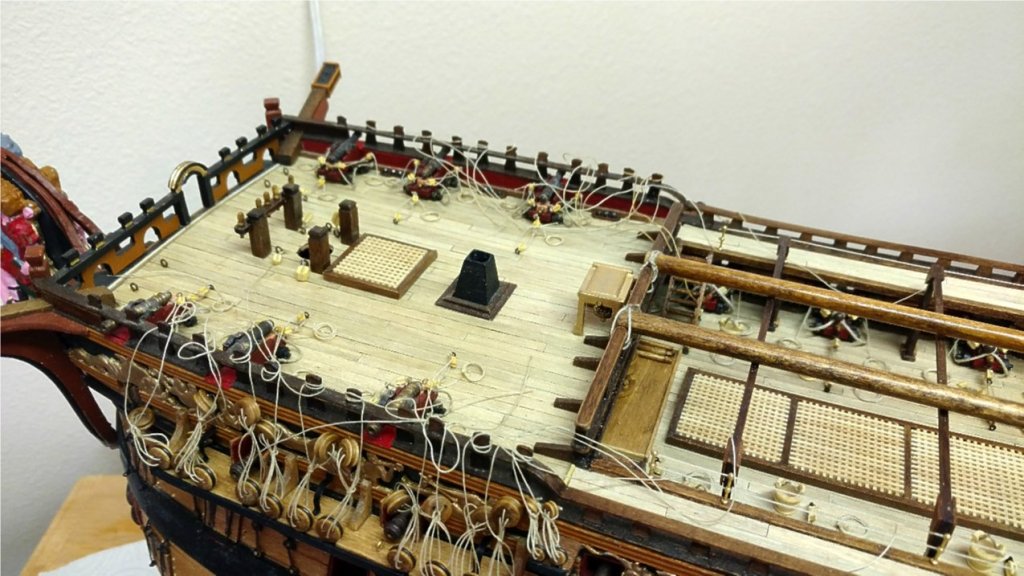

I am very busy these days with other projects and can only put in a few hours here and there on this ship. I certainly can't keep up with Mark. The advantage there is that I can use his log for reference, which I do occasionally (thanks Mark). All of the chain wales and stools with pre-rigged lanyards are completed. I also placed all of the eye rings and blocks on the decks for rigging later. On another note, I have a friend who is a seamstress, and she will created and sew the sails for me. One thing I am NOT is someone who can sew. The admiral does not like to either. Next up I think is to work on the ship's longboat. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

New member from North Sydney Australia

pirozzi replied to Fernando E's topic in New member Introductions

Welcome aboard mate! Vince P. -

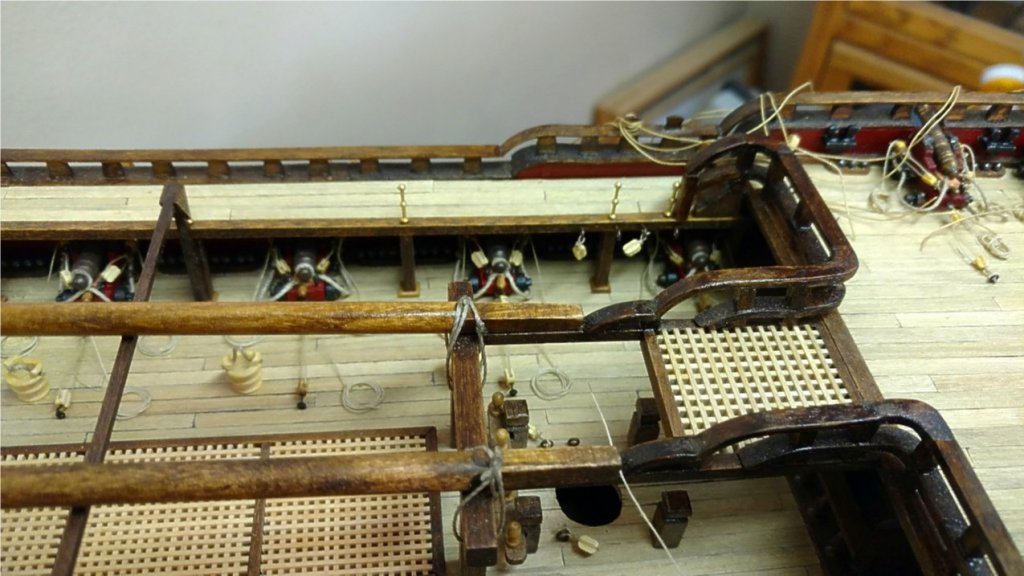

The port side chain wales, lanyards, and stools are completed. I prefer to rig the lanyards as they are placed on the wales. I find it easier this way to later on attach and rig the shrouds and back stays. Now off to the starboard side. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Everyone, Just an update on this build. Have been working on the chain wales and shroud lanyards. Since everything has to be made from scratch, it is a slow process. Will have some photos soon. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Ken, I am curious about what method you use to transfer images from plans to wood. Vince

- 424 replies

-

All the way from way down South ......

pirozzi replied to ctclock's topic in New member Introductions

Welcome aboard mate! Vince P. -

The starboard side hull entry port with planking ladder installed. The metal parts supplied in the kit were fine and just needed some cleaning up and painting. The 2 columns supporting the roof were metal wire in the kit. I used 2 small cannon wheels and toothpicks to create columns that were tapered and looked more decorative. Next up are the chain wales. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Ken, that looks fabulous. Great comeback. Vince

- 424 replies

-

This is an incredibly interesting place!

pirozzi replied to Dilbert55's topic in New member Introductions

Welcome aboard mate! Vince P. -

Hi Ken, I see what you mean. Another thing that helps to get the bleach into the wood pores evenly is to mix your bleach at a 1 to 10 solution, bleach for just 30 minutes (time it). Rince thoroughly and then put it in an oven on white paper towels with the temperature set at the lowest setting possible ( 150 degrees or less) . The wood comes out pretty much the same shade, even in different batches. The key is the timing and drying. Good luck, Vince

- 424 replies

-

Hi Ken, While I agree that the decks could be lighter, don't get too caught up in having all of the planks the same color. On real ships the planks were often of different shades because lumber just came that way. When I planked my decks, I had all different shades because that is how the bleached wood came out. I tried to mix it up so the different shades appeared random. It came out nice and really gave the effect of a weather worn surface. As for the blackened edges, try a soft lead pencil. It looks good, is easier to apply, and won't bleed into the wood. Vince.

- 424 replies

-

Welcome aboard mate! Vince P.

-

Welcome aboard mate! Sorry about your brother. When she is finished she will be a living testament to him. If you feel up to it, post a build log for us to enjoy. Vince P.

-

OK, I mentioned that the rudder pendants in the plans were not exactly authentic. I removed the ropes I had installed. Using actual photos of the HMS Victory in England, I determined how to rig them. The pendants are actually chains and ropes. The chains are attached to the rear edge of the rudder above the waterline with eyebolts and rings. Then up to the transom and fed through 2 more eyebolts and rings. Here the chains terminate. A heavy rope pendant is then spliced to the end of the chain with an open hook and ring and the hook is seized with rope to keep the pendant from slipping off the chain. The pendant then continues up through another eyebolt in the hull and through a hole in the hull just under and towards the rear of the mizzen channels. According to research, this arrangement would allow the rudder to be used if the tiller were damaged, and also helps to keep the rudder from being washed away should damage of the gudgeons and pintles occur. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

I have installed the closed gun port lids on the port side. They were created from walnut plywood and strips. The hinge plates were not the ones included in the kit. I used larger ones for the lower ports and smaller ones for the uppers. I made the hinges out of small eye bolts and brass wire. I determined that 2 pull up ropes were needed for the lower ports, since these ports were large and heavy. Single ropes are used for the uppers. When I make and install the open port lids, I will use the same configuration. Now on to the starboard side. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Welcome aboard mate! Just pick something you like. Vince P.

-

Ok, Pirate Pete and I did some research on rudder pendants of ships of the RW period. It appears that the plans are not exactly correct, but close. I decided that I will remove the rope pendants I installed and do it the accurate way. I actually got the idea from photos of the actual HMS Victory currently moored in England. I have to order some supplies in order to complete this, so more to come as soon as they arrive. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Ken, That was a great way to build the staircase. I did it the hard way. I wish I would have thought to do it your way. Very nice. Vince P.

- 424 replies

-

Hi Steve, I believe your problem stems from using contact cement and not getting an even layer before placing the planks. Using a PVA glue such as Tightbond is the way to go. Make sure the false deck is clean and free of dirt, splinters, and glue. Apply a few spots of PVA on each plank and spread evenly with the blade of a small screwdriver before placing on the deck. Use your finger to run across the top to press it down. Also, make the planks longer using the model scale. About 100 to 120mm. Use the 3 plank shift pattern for the seams, as was used on real ships of the period. After completed and dried, sand lightly and apply a clear matte coating to seal it. It will be smooth as a baby's butt and look great. Vince P.

-

Welcome back aboard mate! Hope to see some of your work Manuel. Vince P.

-

The rudder assembly has been completed and placed on the hull. Pretty straight forward, but bending the metal brackets to follow the hull was tricky. The metal is very soft and the bends needed are quite drastic. A little heating with a hair dryer and bending ever so slowly is small increments is critical to prevent breaking them. Also, the safety lines on the rudder according to the plans are ropes and not chains. There is no chain supplied in the kit, so I just used the correct size rope (1.0mm). Next up will be to continue with the outside hull fixtures such as gun port lids, chain wales, doorways, and ladders, etc. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Ken, to go to the bottom of your log, click on the 2 little arrows to the right of the page list (if more than 1 page has been posted), and then the END key on your computer. That will take you to the last post in your log. Vince P.

- 424 replies

-

Hi Ken, welcome to the RW crew. There are several us, now including you, who are building her. You are quite right about this kit being different from others. It is a very challenging project to say the least, but you will enjoy it very much. You say you are just going to build the basic kit without adding enhancements. That is what they all say. As you go along, you will find yourself adding a little here and a little there. The kit makes you want to improve it. Looking forward to your log. Vince P.

- 424 replies

-

Welcome aboard mate! Vince P.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.