-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

Silly posts or not, it would of course be possible to do the tail piece using a lathe and controlled bed. It would take two clear passes with the dovetail bit. The pins, not so much because you get a rounded inner surface. Anyway, I only have a wood lathe and no usable index table (and no dovetail bit of mini size) so hand tools it is. The coaming came out pretty neat. Here it just sits in it place, not glued in. Two coats of water base matte lacquer applied to the sides. And finally a perspective picture of the build. As usual with all the debris in the background 😄 Pax et bonum!

-

Welcome back Mark! It is quite apparent that you enjoy the drawing business. Also, knowing that you are lefthanded means that you probably (but not necessarily) is quite apt at the artistic side of drawing also, and not only the engineering side. (We discussed work benches a long time ago and I envied, still env, your lefthand adapted work bench). Also, I like the reasoning about the false floor in the quarter galleries. It is just on another level of interpreting the original drafts and applying them to a somewhat virtual reality in 1:64. I hope that your nerves get back in working order and so, Keep it up!

-

Wow, that is next level stuff right there. Next up we will se frames with intarsia on the walls depicting some well known battle 😄 Keep it up!

-

Well thank you Gary @FriedClams 🙂 I totally agree that it is not possible to follow everything here on MSW, there are just too many excellent builds going on all the time. And yes, cancer can really give you mental ghosts to follow you along. But, being in my mid 50's I am focusing on living many years still! Cheers to you too and all the best!

-

Yup, it's a good feature that brain language isn't recorded anywhere outside said brain 😄 Very convincing deck, me like. Keep it up!

-

Yeah, space and tools... but on the other hand, learning to do it with less is beneficiary to the skill level in the long run 😉 Nice job so far. Keep it up!

- 99 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

Tool rants and sailing discussions aside, I said I was about to do the rudder. Did I? Erhm, no. After painting the hull a couple of times it didn't appeal to me to do the rudder (too simple). Instead I've opted for somethinge inherently much harder and more complicated - the coamings for all the deck openings! Truth be told, I have never done a fish tail corner in full size and now I attempt them in 1:30.. sane? No, not really. Buth then, amongst the kids I'm not known for being sane all the time 😄 So far, so good I must say. Only about 19 or 23 more corners to do 🙂 And here is my setup with tools to accomplish to work. Now a brake to watch some cross country skiing. Cheers!

-

@Mark Pearse, yes, Sweden and the Baltic region is totally shattered with islands and skerries like no other part on the entire globe actually. It makes for quite stunning trips in the archipelago. The Admiral has a sailing friend in Florida, where they only have shallow sand beaches everywhere. To his complete horror we send him films when we sail only meters away from solid rock islands on both sides 😄 My avatar picture is of a ship that sails in the Baltic sea, owned and maintained by a Christian organization. It has been a couple of years now since I last enlisted as first mate on it, but further back I was a regular for about 7 years. Fatigue through work and cancer did its best to take the fun of it for a while. As a first mate on it I was part in everything from sailing to finding the nearest power outlet and so on. Primarily though it is my own sailboat I commandeer. Picture below. It is called OE36 after its constructor, Olle Enderlein. He studied at Sparksman&Stephens in NY and the OE36 is very similar to the more known Swan 36. The Swan is a bit more slender around the waist compared to the OE36. 36 is the length in feet. The first OE36 is from 1969 and mine is from 1980. The Swan predates that with a handful of years if my memory is somewhat accurate.

-

Which just brings us further down the rabbit hole... there is a healthy restriction to fabrication with a limited set of tools, power or not. Of course there is a monetary side to it also. It's a matter of prioritization... I will not reveal how much I've spent on my sailing vessel, but it could have with easy bought me the entire Proxxon Micromot line of tools. And I mean the Entire product catalog. But then I wouldn't be able to go sailing, which I love...

-

I'm good, thank you. Getting every little detail to match in scale is hard work. I think you've made a sober decision re the dead eyes. Keep it up BE!

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Yes, I think that will work. I did similar with the stern stanchions on my build. Altho that is a complete different kind of boat.

- 99 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

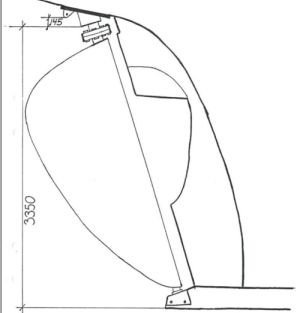

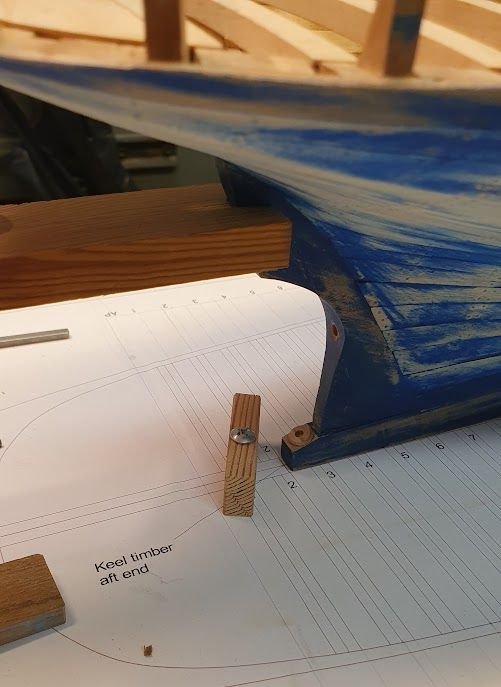

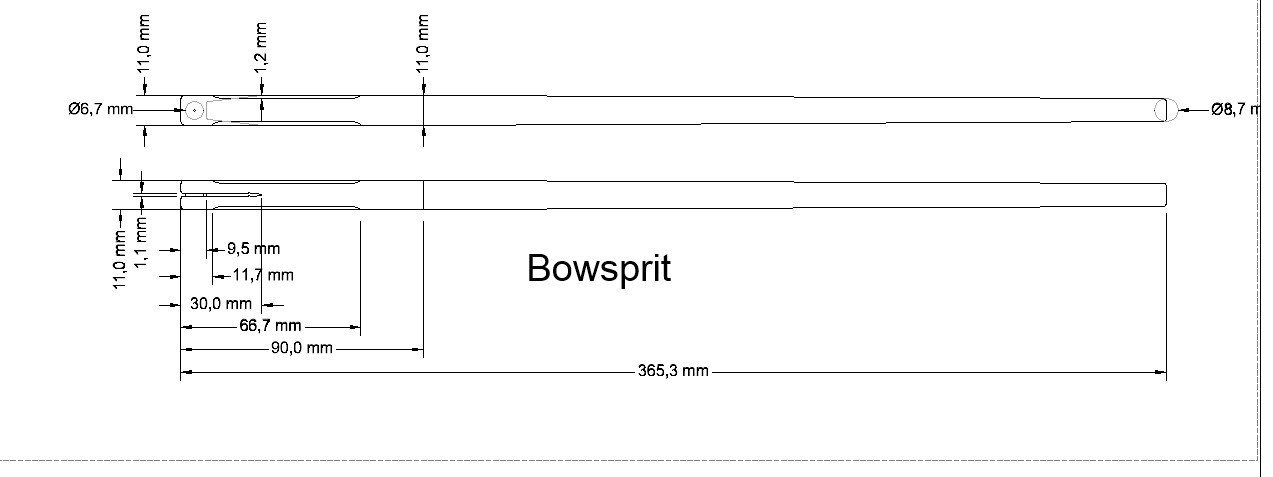

In an attempt to stay somewhat true to the original detailwise, I mused over how to fabricate the coppling between the rudder and rudderstock. Se the picture below. What I came up with I figure is an alternative way to make trucks for gun carriages. For those of us that do not own a precision lathe, that is. How then? Well, I used my bung drillbit, then swapped it for a regular drillbit without moving the stock. Then parted it off with the bandsaw. Apart from the coppling I also used it as bottom support for the rudder. 🙂 This was all for today. Now that the rudder assembly is figured out I can turn my attention to the bitts for the bowsprit. That also includes the bowsprit itself. So back to the plans and software... Yes yes, the measurements are to scale and not real world dimensions. My reasoning behind that is so that I not necessarily need to print them out, but instead just can look at the drawing and fabricate the spar from that. That's all for now, cheers!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.