-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

Keith, that is indeed true! Albeit, the first time after surgery I had troubles standing up concentrating for any period of time due some uneasiness in the "behind". Now I'm fine though. But as you guess, I have a lot of life to live now. Got myself a brand new mountainbike and the sailboat is also now in the water. The boat was on the hard the entire last season. I have actually contemplated over the build and realized what would have been "bobo" down the line. Anyhow, I'll see if I can get myself in the mood for building anytime soon or not.

-

Looking good Henke! I see that you keep the gun tackles to a minimum, which I think is a sensible choise. If not done exactly to scale, gun tackles can definitely bug up an otherwise nice ship model. There will be more than enough details when the rigging comes together to "oh" and "ah" over in the end 😉 Keep it up!

-

My guess is that they wanted a kit to be out as soon as possible. It was probably quite a hype when they found the ship in the late 1950:s. And for the first decades it was kept in a temporary location primarily used for conservation of the ship. Though it doubled up as a museum. It wasn't until 1990 that it was moved to its current location in the dedicated Vasa museum. That said, you're doing a good job on enhancing the old kit harbor johnny!

-

Good save and good job on that forward decking Vaddoc! Tricky is an understatement I think. Keep it up!

-

BE, who said planking was easy? Slow and steady will make it and it looks good now 🙂 Keep it up!

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well @KeithAug not much shop time on my part. Have been in hospital for the last 5 days. Back at home now though. It was en emergency visit and they kept me. Internal bleedings that needed urgent action. It was one of those s**t happens score cards that I drew. Note to self- don't be tempted to draw another card, even if it looks promising...

-

What every one else said @Django! We all have our ruck sacks with different kind of baggage. It's part of what we are in some sense. I'm glad that you could disengage the model from the baggage you carry. PTSD is a powerful spell! I have it close, and it is, as you state not the persons fault not being able to coup with it. People that suffers from PTSD needs therapy so they can come back to being "normal" functioning individuals. Again, well done on the restoration!

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

As others have said, it is amazing the amount of thought that goes into your creations @Chuck! I remember when you designed the Confederacy, extraordinary model that too. I'm in awe over the cleanliness and precision you deliver and that you make it available to the common people as well. Even tho I will probably never buy any of the kits, I still applaud you for taking the time and effort in making them! And why is that, one might wonder? Well, over here, on the other side of the pond it is just over my budget when shipping and customs/VAC is added. Keep it up!

-

Well thank you Andy 😊 I prefferably use white glue and is quick with a damp brush to wipe away any excess. @wefalck - apart from large steel ships I think the real vessel is "easier" to build than its scaled down counterpart. Given that there is adequate tooling and staff around. Tolerances are easier to manage in 1:1 than in 1:something I think. Work can be done on several places at once in 1:1 not so in scale. Of course it only is comparable as long as the scaled down version is an exact replica.

-

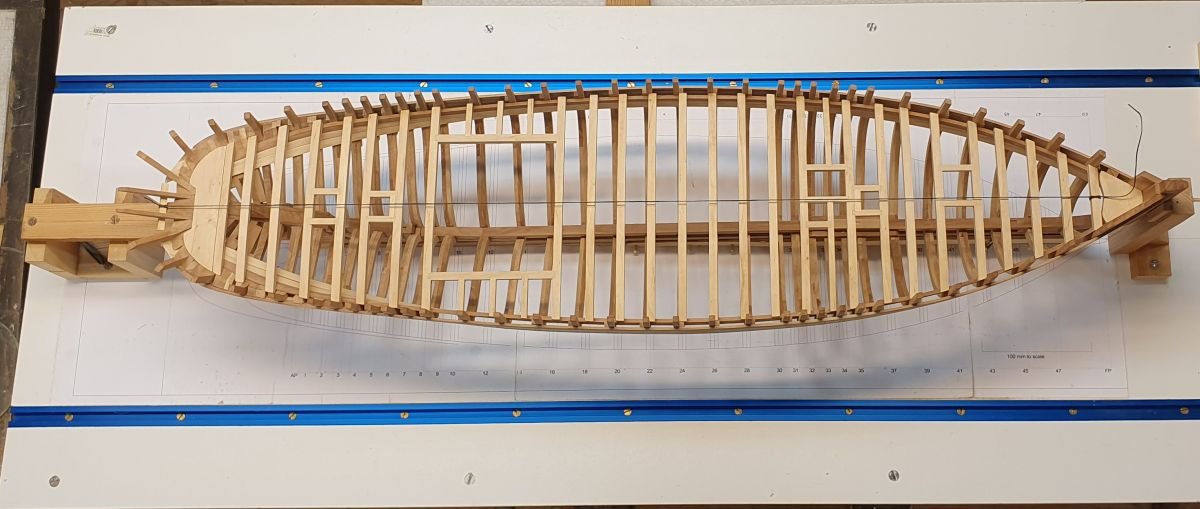

Finally feeling reasonable well to sit in front of the computer again! Without giving away any gory details - it has been a rough week. Period. Though I'd catch up my log with my actual progress as it stands Sunday before last. Deck framing is complete. All frames are secured to the beam shelf with a 19 mm screw bolt, aka 1 mm bamboo tree nail. Actually done after the photo session below. The entire deck will not need much fairing. The lighter carlings around the main hatch and the forward hatch needed a little shim to sit at correct height. Can not be seen in the photos below. What is left is to trim some of the timber tops. I will probably add some filler pieces to have support for the waterway and covering board. There will also be filler pieces/carlings where deck planks are supposed to end. Not all ends land on a deck beam. These will come later I think. So, this is where it stands at present. I think I will go out and crank up the heat again in the shop now... When I know there is a period where I will not be able to go out on a regular basis I set the heat to a minimum, which is 10 degrees to save energy. Otherwise it sits at around 15-16 degrees and with my 400V air heater it is quick work to get a descent 18-20 degrees out there. But starting from 10 is not okay since all the tools will be too cold for comfort. Pax et bonum!

-

EURYALUS 1803 by Peter6172 - 1:48

Wintergreen replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Indeed, and also, we wouldn't feel so special 😁 At work we tag it to our salaries, if it was easy - they wouldn't pay us 😄 Keep it up, Peter! -

EURYALUS 1803 by Peter6172 - 1:48

Wintergreen replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

I can't see how many pieces there are but it is a sizeable puzzle you've got your self into 😲 Keep it up! -

EURYALUS 1803 by Peter6172 - 1:48

Wintergreen replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Yep, all those frame pieces looked to be a chore for a rainy day 😉 Nice little library you've got there to. I guess Mr Underhills books are found in nearly all serious model boat builders library (I have them too) 😄 Keep it up!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.