-

Posts

258 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kscadman

-

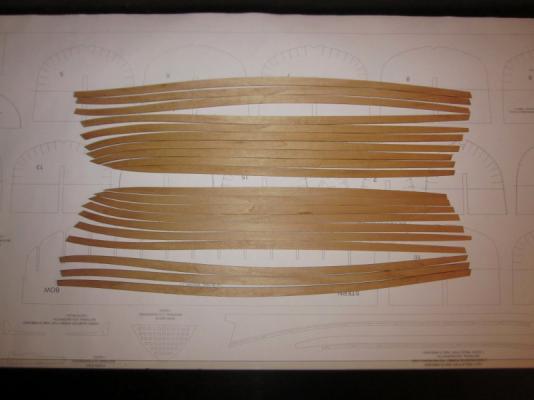

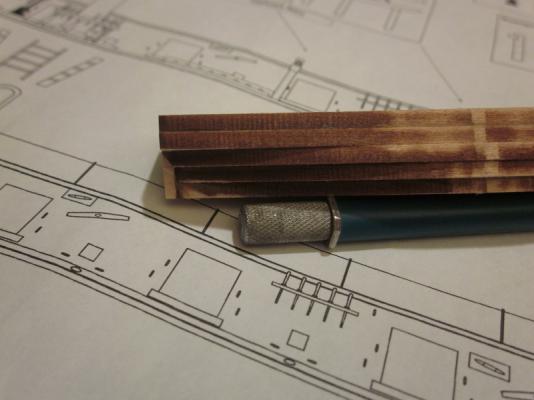

Thank you Tom & esion. Tom - last night I did as you did and sanded with the frames. I also re-read the instructions and there's 1 sentence about sanding with the frames. (duh on my part). I laid my batten along the plank lines as I went. The only part I don't like is I have a slight gap on the port side with mold #3 (the first one that doesn't have a frame) I've got a 1/64 to 1/32 gap but I think I should be ok with it since the frame will be canted. esion - I'll keep the PMs in mind should I run into any troubles. I projected the planking lines to the frames so I'll find out tonight how well I did. I'm going to try to get the first garboard bent & fitted. Richard

-

There are a couple of build logs for the Scotland so you could gain some knowledge from those builds. There are also tutorials that will help get you started. They are located in the shop notes, ship modeling tip, techniques and research section. I working on my first one as well so I understand how daunting it may seem, but once you begin and start learning then it will get easier. Richard

-

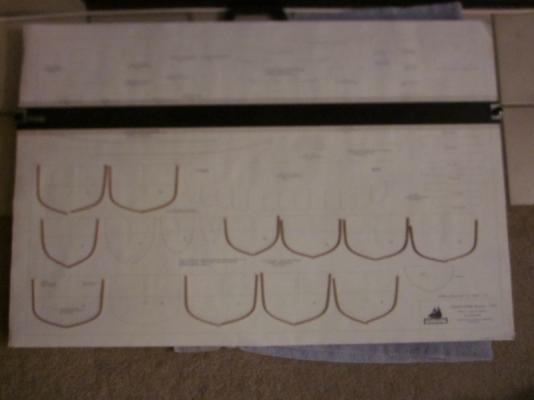

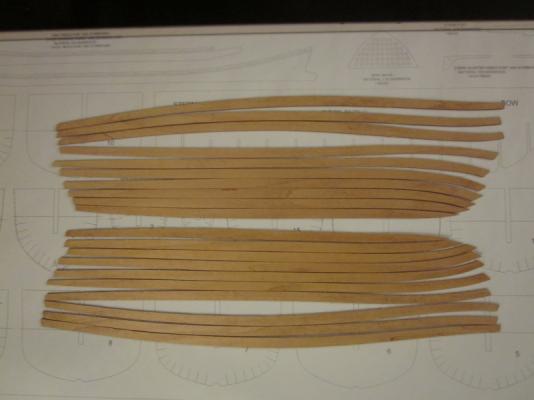

David Yes, the planks are laser cut. According to the instructions they are a little wider and are to be sanded down to the proper width. There are line off marks on the molds that are projected to the outer edges of the frames. The planks are supposed to be sanded down to those widths. You can see them on the third mold from the transom. Richard

-

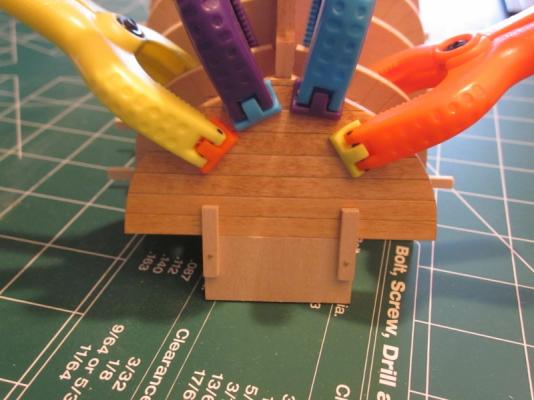

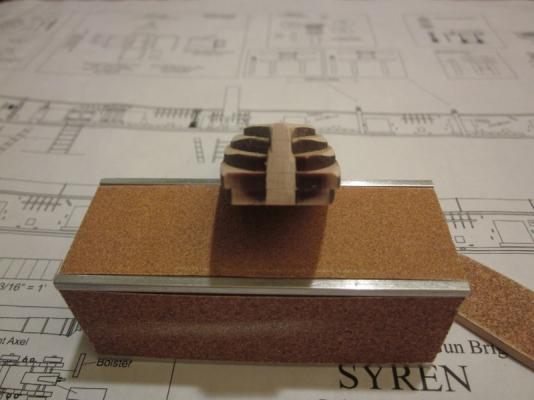

Hammocks are progressing. I'm really starting to believe the expert in expert modeler means you've learned how to make a jig for the task at hand. lol. Attached is a picture of the jig I made for rolling and tying hammocks

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Keith & Tom thanks for the advice it came in handy. I sanded down the transom to 1/8" then I took some 1/32" x 1/4" basswood and made planks for the transom and glued them on. I managed to get the transom flush with the sternpost so i shouldn't have troubles with the rudder installation. I like most others have decided to stray from the grey and white suggested by the kit. I'm going with oak but I'm going to keep the gunwales & breasthook cherry. I'll keep the white below the waterline and add blue to the sheer plank. I found some 3/32" X 3/32 basswood to use for the frames and I've stained them, the transom and keel oak. Should be starting the frame bending tonight. Richard

-

Thank you all for your comments! Keith - Its good to know I'm following in the wake of those who have gone before me. How did you go about sanding the transom down? I was thinking about using a block and large piece of sandpaper. Pops - I'll try to make sure to note when I divert from the instructions. When I get time I'll have to read thru your Longboat build to see if I can find some tips. Thomas - It IS a neat little model, but at 17 inches its bigger than the pictures represent. Plenty of room for added details. I would recommend it based off of what I've done so far. Plus I can apply what I'm learning from this to my Syren launch (still sanding the hull on that one) Richard

-

Thank you Keith, I hope to do her proud. I was working on my transom and it has the word "TRANS" on the outboard side. At first I thought that it would be planked over, but as I looked through the drawings and instructions I didn't see any instructions on planking. Then I looked at the relationship between the transom and rudder and noticed that there is no room for planking. I have the feeling I'm going to need to sand off 1/32 and then add some 1/32 planking. Richard

-

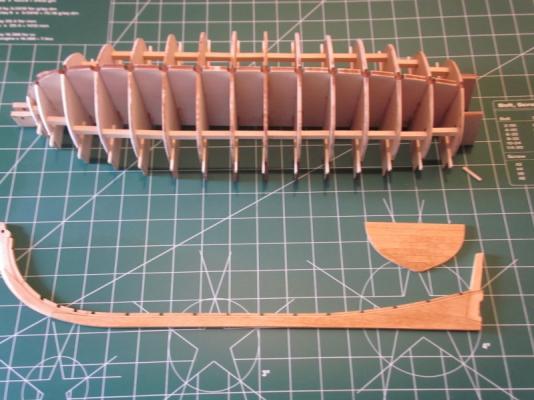

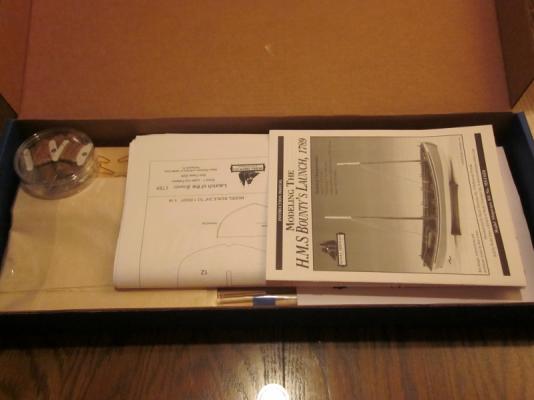

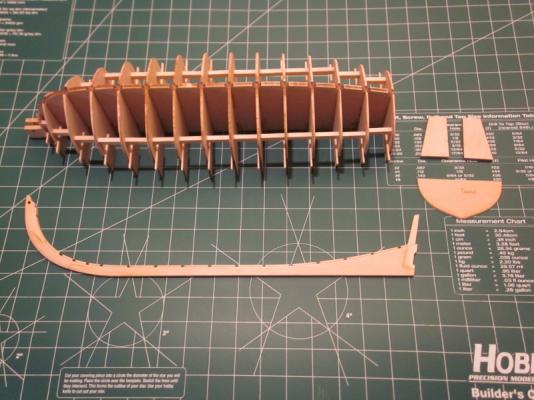

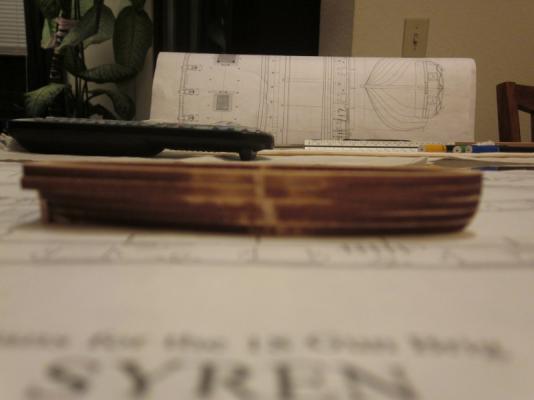

Welcome to my second build log.After several months of work on my U.S. Syren I've come to realize why many here on MSW work on several builds at a time. Currently I'm at a point where I need to do some wood working (rolling & tying hammocks is a tedious thing). My work so far has gone easily and quickly. The keel is assembled, Rabbet is cut, and the building jig is assembled and faired. The stem alignment blocks are spot glued and the keel has been dry fitted. So far I've had zero problems. The holes to pin the stem lined up perfectly. Now its time to roll a few more hammocks then install the transom horses and transom. I did a quick dry fit and it looks good. Attached are some pics Richard

-

Just sign in to your account with model expo. Go to customer service (at the bottom of the page) then go to tech support then parts request then you can tell them what part you need. Richard

- 139 replies

-

Augie, you are correct. But in this case I'm not going to do the 24' Pinnacle. I'd like to get to my masting and rigging sometime this decade, lol. Thanks for the link to Waynes' build. I wonder if he was referring to the deck slats surrounding the capstan or he's taking a dimension from a different plan sheet. I'll keep an eye on his build. Richard

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

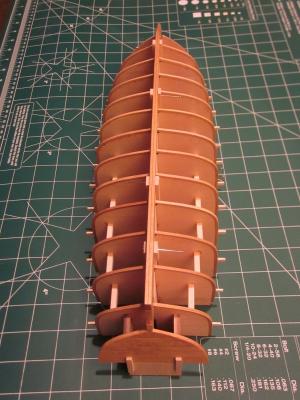

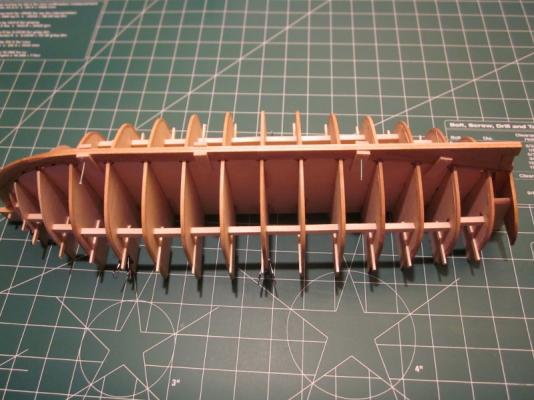

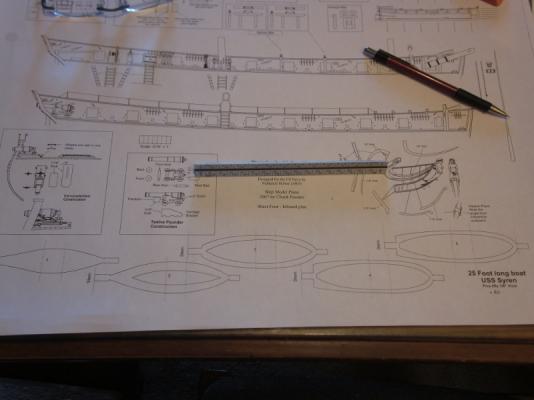

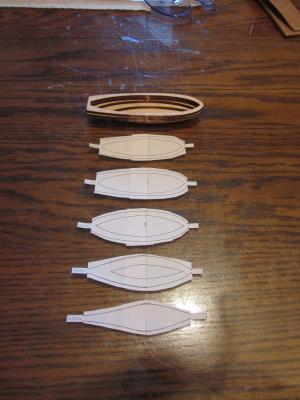

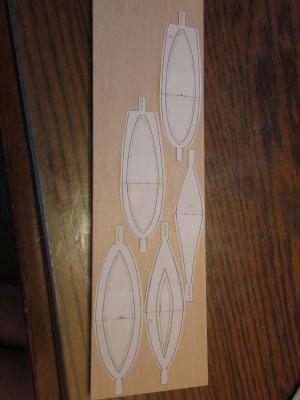

Well, I'm continuing to cut hammocks (I'm starting to rethink this hammock thing). I've been working on my long boat but I'm still a little skiddish about the curvature from midship to stern so I decided to make a jolly boat. I reduced the plans by 15% which gave me a beam of 6'-0" then I cut a section out and feathered the curve to get an overall length of 18'-0" once I add the keel. I kept the draft the same since I haven't found any information on what the draft should be. The way I see it, if it works out then I'll have a jolly boat to add to the stern davits. If not, then I I've learned what not to do on my long boat. Attached are some pics. I still need to fair the lifts a bit more before I glue them together. Richard

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I'm looking forward to seeing it! Richard

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Augie, your sample turned out great! But do you think it will be too dark compared to the hull color? The only reason I ask is because I haven't seen deck planking made with pear but I have seen plenty of deck furniture made from it. It could just be the picture that makes it look dark. Either way I'm sure it will turn out great! Richard

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

I used the same fair a frame when I was starting and you should be able to slide the bar over to be snug with the bulkhead former. Also make sure to check that the bulkheads and bulkhead former (what I think your calling the keel) are straight without any warping. (It looks like its warped a little in the 1st picture) I'm not familiar with Corel kits but typically the top edges of the bulkheads should be flush with the top of the bulkhead former. I would check the plans and overlay it if there is a plan view. When dry fitting your bulkheads check and make sure they fit at perpendicular to the former. If its too tight it will twist the bulkhead. Hope this helps. Richard

- 139 replies

-

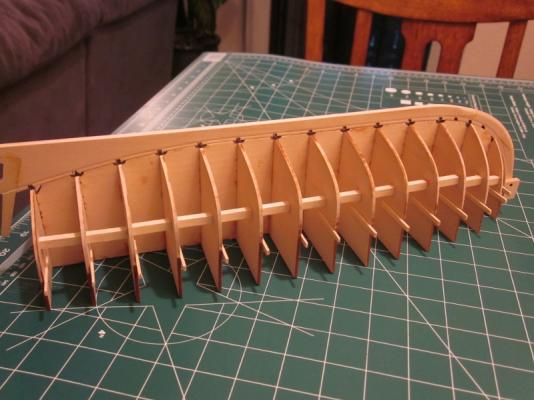

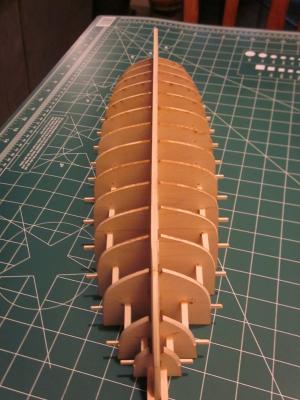

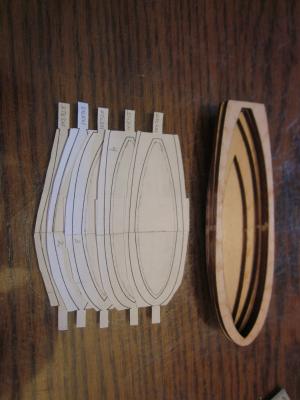

Ok, in between cutting cloth for my hammocks I've started on my ships' boat. Lifts are glued, tabs are cut off and I sanded the basic profile shape. My question for those who have built a boat using the lift method. Am I getting the fairing right, especially toward the stern? I know I'm just getting started but I've learned that if I don't start off right then it will cause problems later. Also its my first time so I'm a little unsure about this step. Attached are a few pics. Richard

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.