-

Posts

258 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kscadman

-

Still sanding on my long boat, but I have made progress on my jolly boat. The sanding looks good and its an even thickness using the calipers. So I stained the interior and sanded the stained the wood for the framing, floorboards, thwarts and thwart supports. I glued in the "keel" and first frames as well as did a rough gluing on the aft grate.

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Welcome Steve. I need all the support I can get! Thank you.

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I'll be glad to help. I've gotten a lot of advice from many members.

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Doug. I'll be following your Prince de Neufchatel. They are practically the same ship.

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

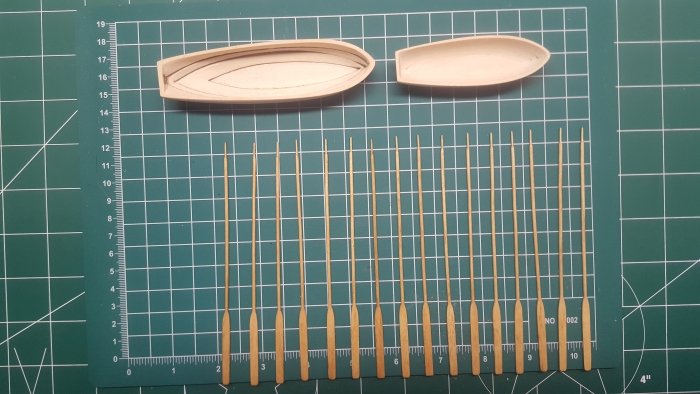

Greetings all. Sorry I've been away for a while. But I've made some progress on my ship. The long boat and jolly boat are coming along. In between sanding I decided to sand and stain the sweep oars. With that completed I can start on the boat oars. I went thru a move and now I cant find my hammock cloth so they have been put on the back burner for now.

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Your syren is looking beautiful Jesse. Nice work on the cannons and cannonades!!

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

She" beautiful Sjors, quite the ship to be proud of!!!

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Your Morgan looks great John!!

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Great work Rich, I'll being following with great interest.

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

I was able to get that kit from the local hobby shop. It was in their store for a couple of years and got it at a discount. It is a Amati/Modelshipways collaborated kit. Mainly Amati.

-

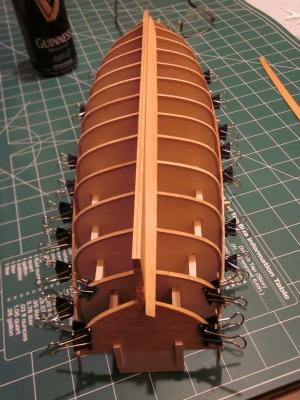

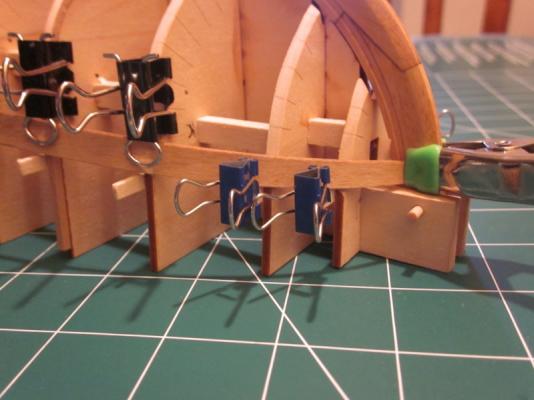

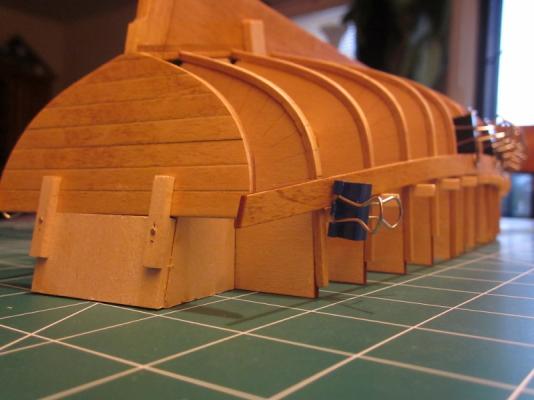

I'm halfway thru the planking and it hasn't been without its trials and tribulations. I was using the head post template but for some reason (me, of course) I didn't get the garboard and the plank next to it in the proper place. But I corrected this with the third plank. I tried to remove the garboard and second plank but I've been using carpenters glue since its stainable. Unfortunately its also WATERPROOF so I couldn't remove the planks and re-position them. (Hello wood filler) The good part is that my planks are aligning with the marks on the molds. Richard

-

I would like to have a copy if its ok with you. thank you for the offer. Richard

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Superb work Augie! And happy anniversary! She's got a beautiful deck now. Great choice with the pear. Can't wait to see it finished. Richard

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Beautiful work ChrisLBren!! Have you looked into the model shipways pedestals? They have wood screws and work really well. I used them on my Syren. I did pre-drill the holes but it wasn't too much trouble. Richard

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

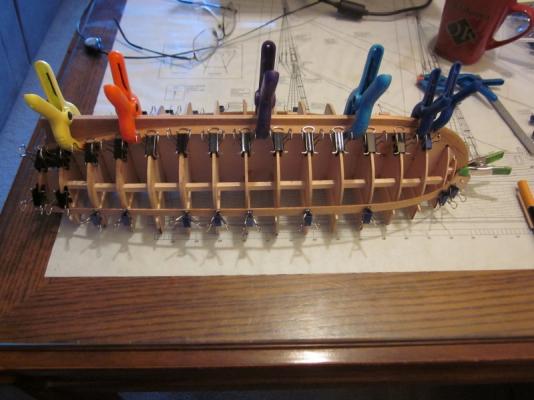

The first of the planking has begun! I have my sheer planks molded to the frames. So tonight I'm going to work on the garboards. I did find one thing curions about the kit. I glued the sheer tabs on to the molds correctly, but when I push the sheer planks flush with them the sheer planks wont line up with the planking marks on the molds. I think I should go ahead and follow the planking marks and not worry about the sheer tabs. Also when the planks are flush with the sheer tabs the planks are offset from the transom by 3/32 on each side. In pictures 4 & 5 you can see the planking lines and the distance from (top) of transom and (top) of sheer plank. Has anyone else run into this condition? Richard

-

Brilliant! Did you design it? If you did you need to patent it. I know I could of used it when I planked my Syren. Richard

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Beautiful work Tom. I'm curious about the spreadsheet. Does it give you a total length along the circumference of the bulkhead(s)? Richard

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.