-

Posts

82 -

Joined

-

Last visited

About fmartins

- Birthday 05/19/1985

Profile Information

-

Gender

Male

-

Location

São Paulo - Brazil

Recent Profile Visitors

-

KARAVOKIRIS reacted to a post in a topic:

Royal Louis by fmartins - multi-media

KARAVOKIRIS reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

KARAVOKIRIS reacted to a post in a topic:

Royal Louis by fmartins - multi-media

KARAVOKIRIS reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

GrandpaPhil reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

fmartins reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

fmartins reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

scrubbyj427 reacted to a post in a topic:

Royal Louis by fmartins - multi-media

scrubbyj427 reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

JacquesCousteau reacted to a post in a topic:

Royal Louis by fmartins - multi-media

JacquesCousteau reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

fmartins started following La Belle 1684 by Gregor – Finished - 1:64 scale and Royal Louis by fmartins - multi-media

-

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

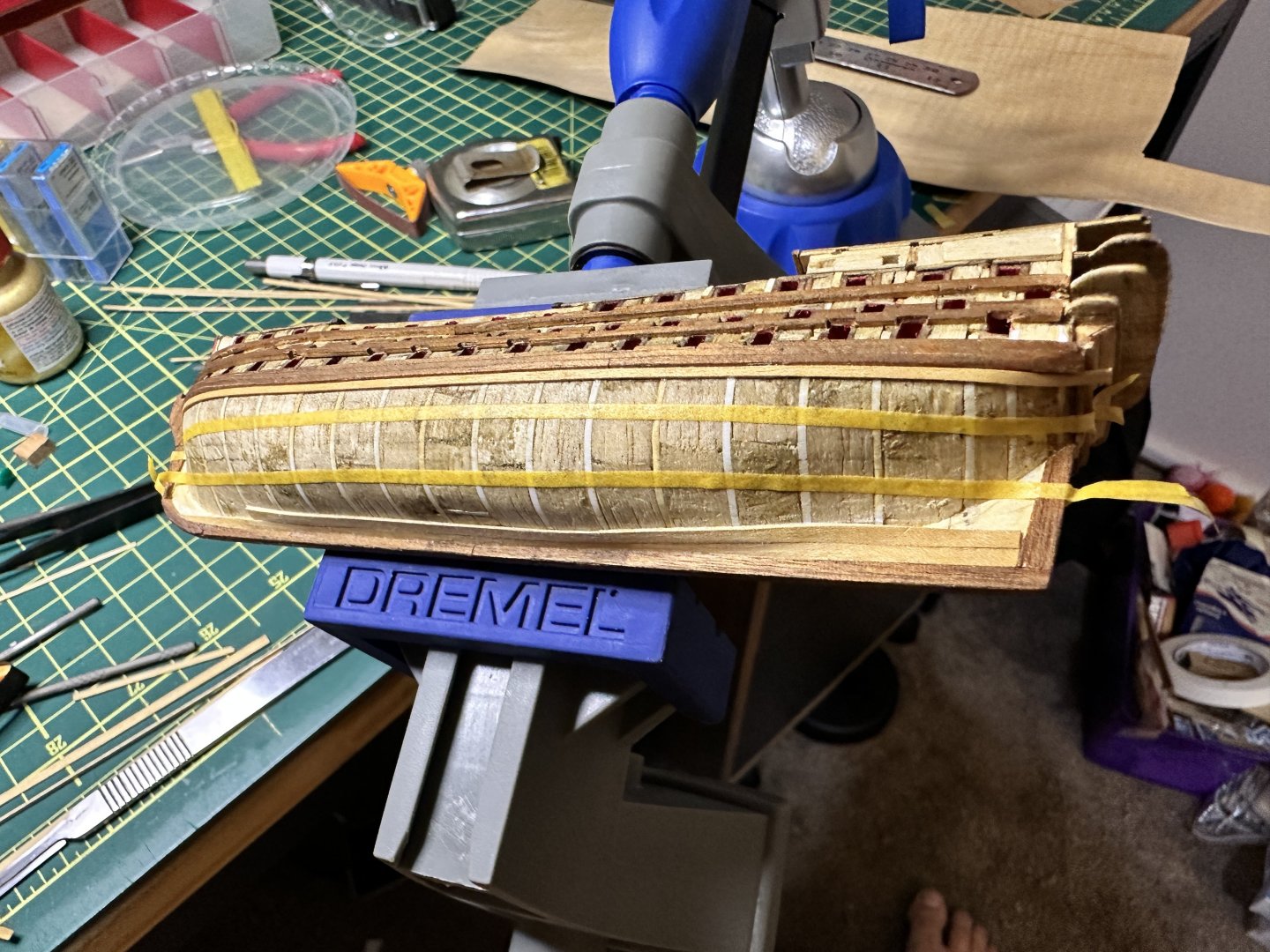

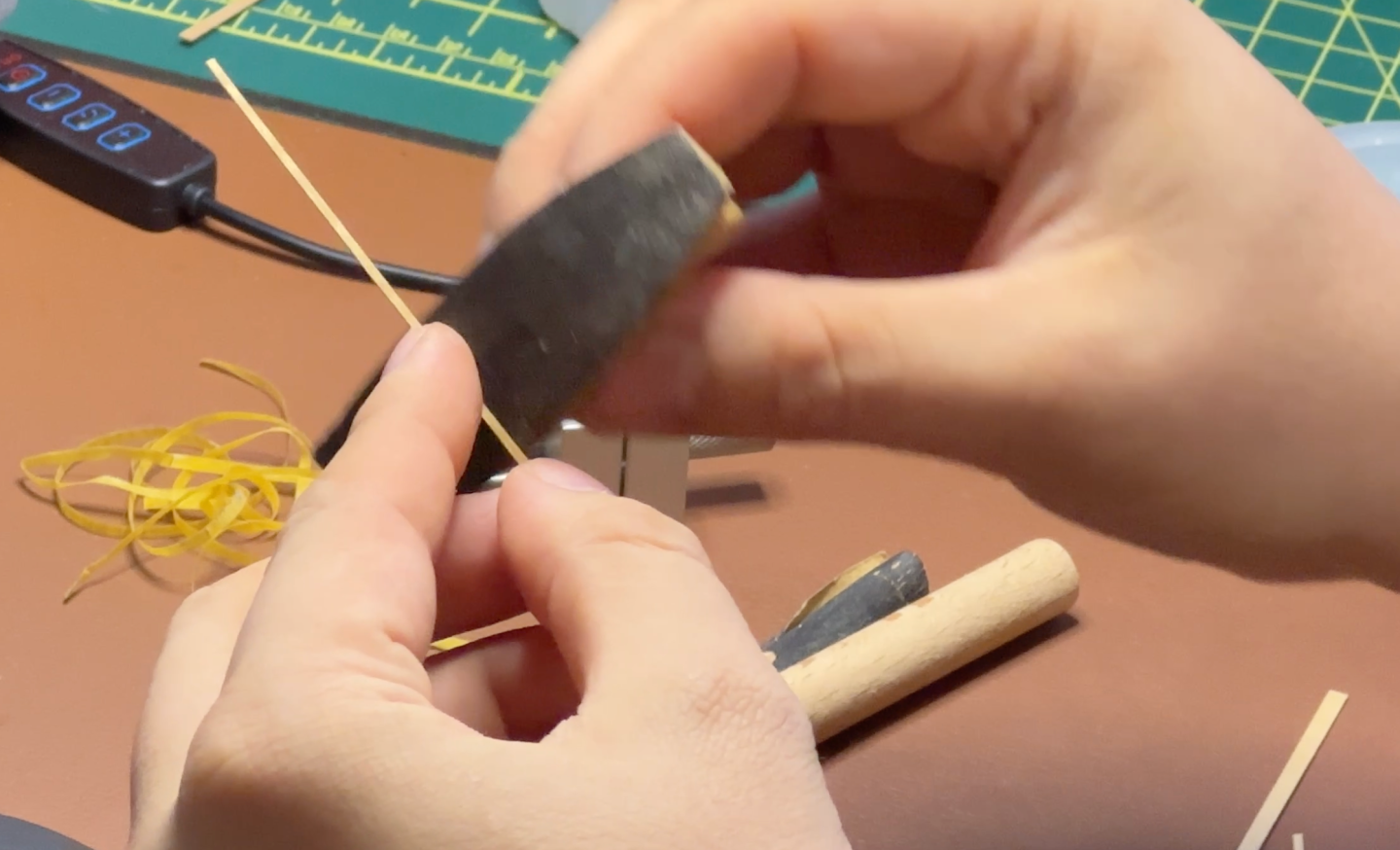

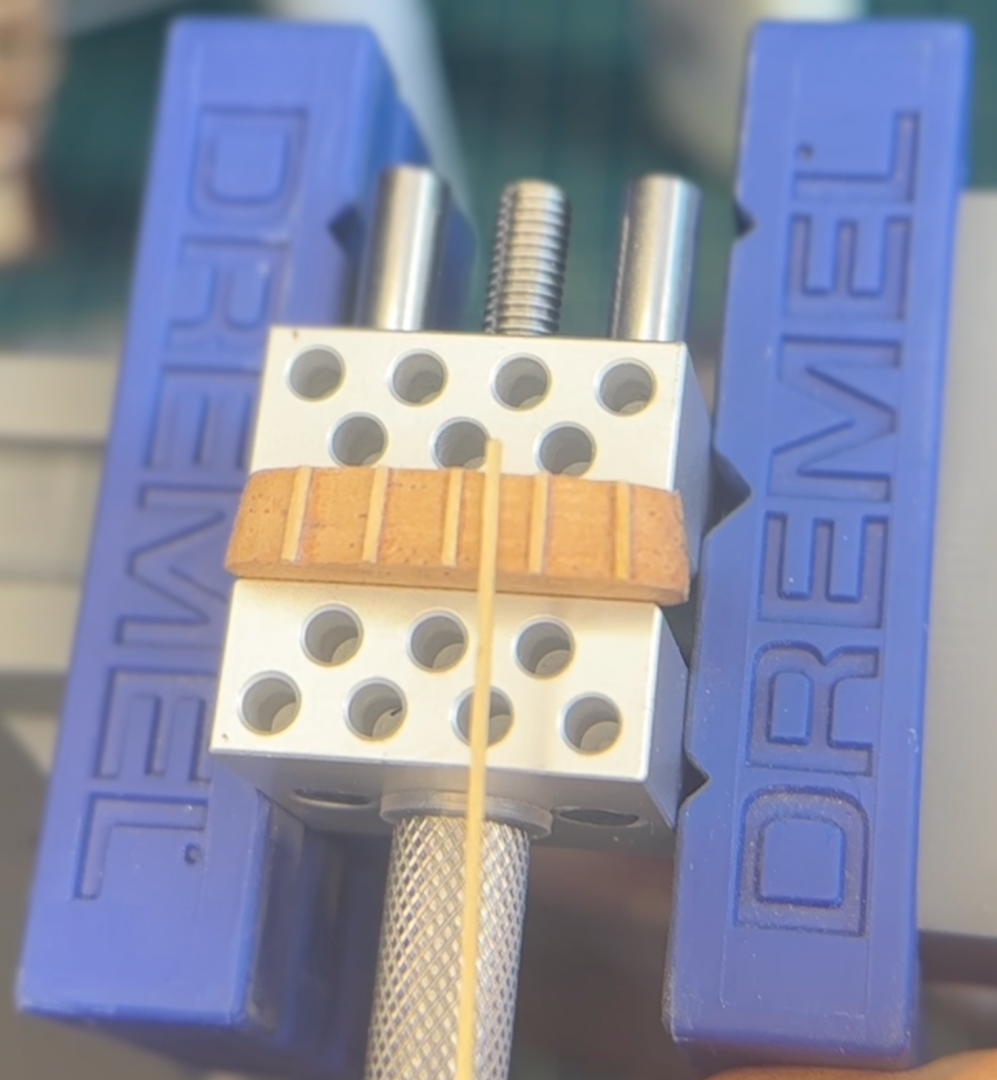

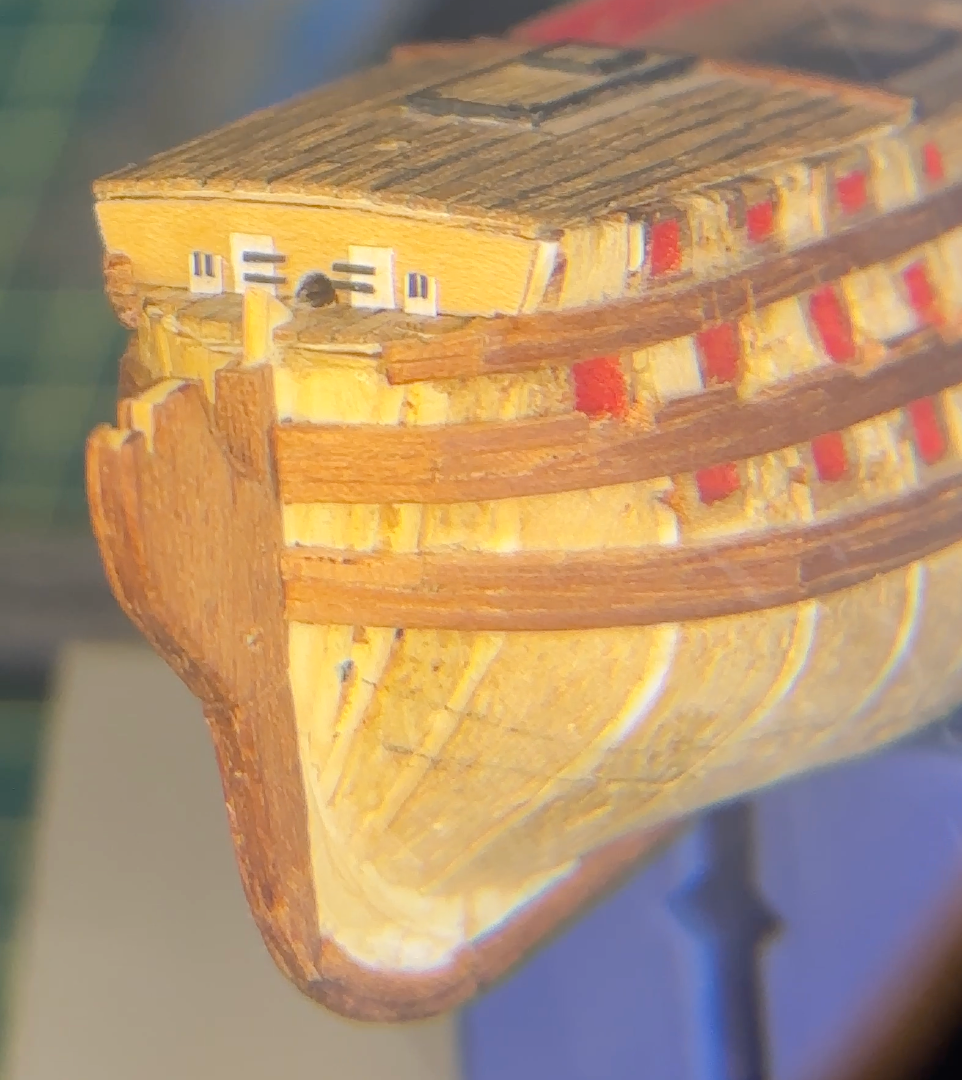

Ok, so after a few weeks with a persistent flu (as well as lot of work) here are the developments in the shipyard... I started the planking... and to be frank man is it difficult. I've purchased a few books on planking and read a lot of tutorials here in the forum but when push comes to shove you don't really know what you're doing (at least I didn't). I tried splitting each station in bands and calculating the width of each plank, but they are so small I couldn't do a proper job (perhaps when I buy my saws - still looking for some proxxon table and scroll saws). Each strake or plank is taking a lot of time because tiny imperfections ruin them (for instance, I start sanding one and then it gets on the grain and takes more material than supposed - ruined, and I have to start over...). I bought a dremel Stylo (which is weaker than a normal dremel) so I can sand but not so deeply... but it is still too strong. I also purchased two battery-powered micro sanders (rotating and going straight going) and I hope it is less harsh on the veneer, but customs have withheld them for inspections / tariffs . When they get here I'll use them and tell you if they are worth it or not. But mostly I've been using my handy, trustworthy homemade sanding block. But because they're so thin, the planks are giving me too much trouble, and I doubt they will look nice in the end. Good thing I intend to paint the hull as in the Paris Museum model, so even if they don't look super nice, paint will cover most defects... But it was nice to try my hand at drop planks and stealers (I had to compensate for my miscalculations / missanding of planks).. I got bored of the planking and also didn't know how to do the turn of the bilge properly so I stopped for a while to work on the upper sides. As I reported before, I would try a veneer panel with scoring to simulate planking but I had to get the pattern of the cannon windows... And after cutting them. I really regret not being attentive to simulating the curve of the decks and the cannon windows are really out of alignment. Well, next time I'll do it properly... Good thing that model is so small that the camera is unforgiving in the details but at naked eye you can't perceive most of these awful problems... I'll leave you with a picture of what it looks like right now: So, that's it for now... Thanks for being with me in this adventure! Bye from Brazil! -

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

By the way, I'm thinking about purchasing a scroll saw for future projects. I have two options in mind - a Dremel moto saw and a Proxxon small table scroll saw. From what I gather, there are advantages to both products, but since I will use it mostly with hobbies in small scales I am leaning towards the Proxxon because it seems sturdier and more precise. I've crossed off my list other products because I live in an apartment and these are the smallest I could find (if you happen to know even smaller ones, please let me know!). But the Dremel sure is versatile as it is usable as a hand saw... Does anyone have any experience in this? I'd sure appreciate your input. -

JacquesCousteau reacted to a post in a topic:

Royal Louis by fmartins - multi-media

JacquesCousteau reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

catopower reacted to a post in a topic:

Royal Louis by fmartins - multi-media

catopower reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

catopower reacted to a post in a topic:

Royal Louis by fmartins - multi-media

catopower reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

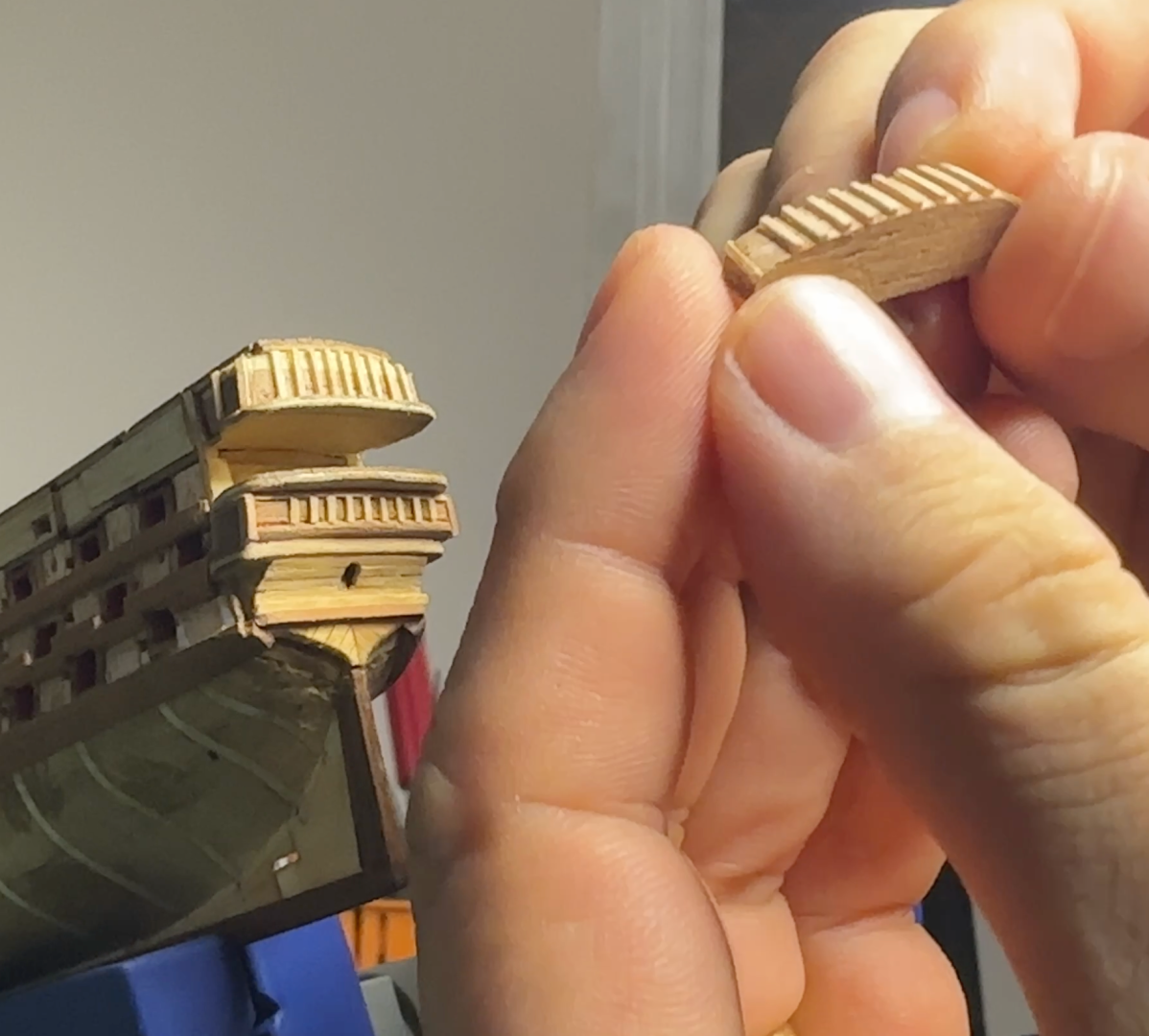

Ok, so I've kept working on the transom area. I kept adding plank up, and I had a piece of balsa wood to fill that I've cut away (balsa is too soft). The planks were sanded flush later (to the naked eye but with a close picture you can still see some level issues). I tried adding a harder wood (brazilian pink cedar, which is what I had around). Then I sanded these little filler pieces for hours until I had the geometry right (the angle close to the balconies, the side areas, etc). By the way I made two holes by mistake, plugged them but they will be on a canon hole, so no problem... Then I started adding the "columns" where the windows and doors sit: I still have no idea how to make the windows / window frames etc, because it is very small (windows have a width space, the framing and all at 1.1mm, 0.0433071 inches according to dear uncle Google). By the way these pictures are taken through a magnifying glass... To be frank I wish I could go back and make it at least twice as big. It is incredibly difficult to my poor skills to work on such a scale... For reference: These three fillers are not glued to the ship yet, because I still need to think about how to have windows there... Then I started working on the bow - the doors and hinges are made of paper. I got a white-ish paper for the door as the paint will cover but the "hinges" are from black paper so the paint will not cover them entirely. I tried adding a video so you can see the size of one of those hinges. I have no idea how many of those I lost before I could glue to the door... IMG_0058.MOV Here is the finished procedure (there are two latrines but they ate glued to the grating - which I also have no idea how to make at this scale - and two stairs, but these are attached to the catheads further along the road): First coat of paint: To finish, I painted the stairs as in the french museum model: Next steps: - Figure out what to do for the windows --- I tried using black paper and adding the window framing on paper glued to it but it is too small <-- given up --- trying homemade low cost photoetching? --- print the windows in "wood" paper to simulate? --- I accept suggestions! - Start planning/doing the planking (spilling? spiling? spoiling? I heard these three terms and I infer they are the same thing) Ah, by the way under the admiral's guidance I started a Youtube channel for this build. It is supposed to make me commit to the build on a regular basis according to her... I'm not sure there are rules for that but I can assure you it is not commercial (https://www.youtube.com/@ModelismoCaseiro), please someone let me know it this goes against any rules here. See you next update! -

fmartins reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

fmartins reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

I have just found your log and I'm amazed at your craftsmanship! This truly awesome! Wow, no words, really! What woods are you using? I'm asking that because I'm thinking about building a similar ship in the future and I'm research woods... Again, congrats! I'll follow it along now on

-

fmartins reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

fmartins reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

fmartins reacted to a post in a topic:

Spilling (very long) planks

fmartins reacted to a post in a topic:

Spilling (very long) planks

-

fmartins reacted to a post in a topic:

Royal Louis by fmartins - multi-media

fmartins reacted to a post in a topic:

Royal Louis by fmartins - multi-media

-

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

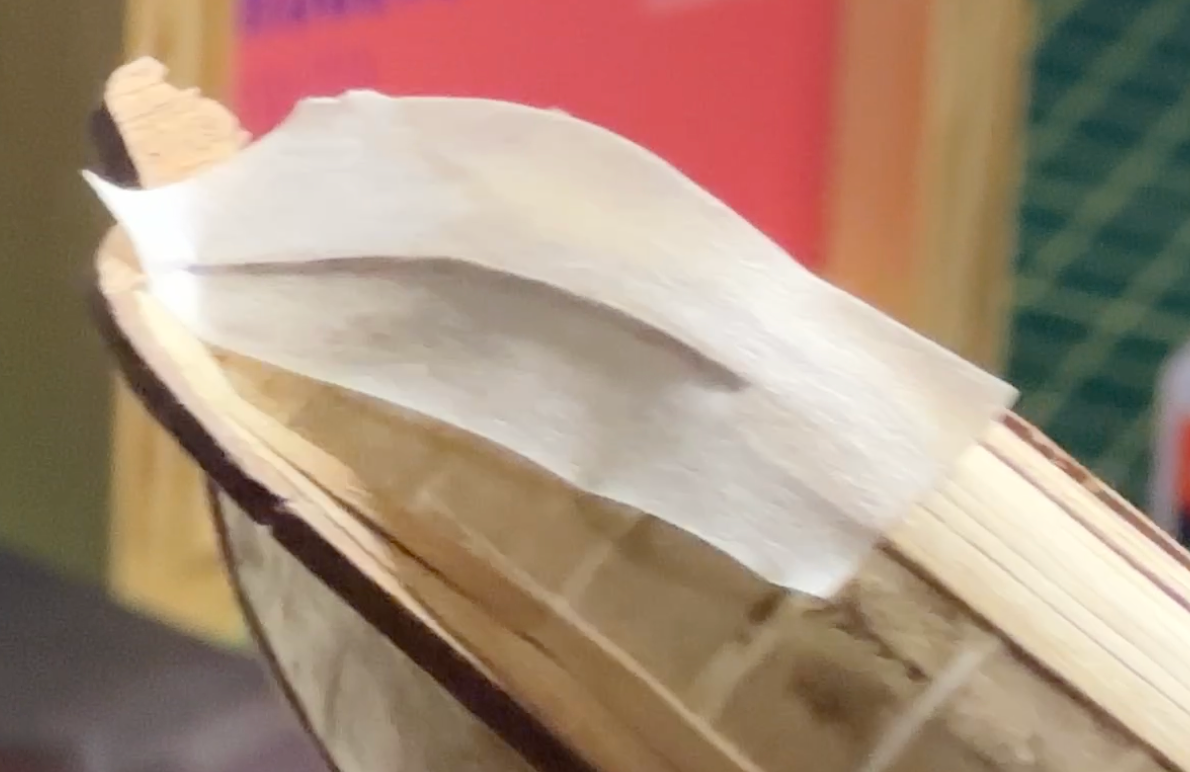

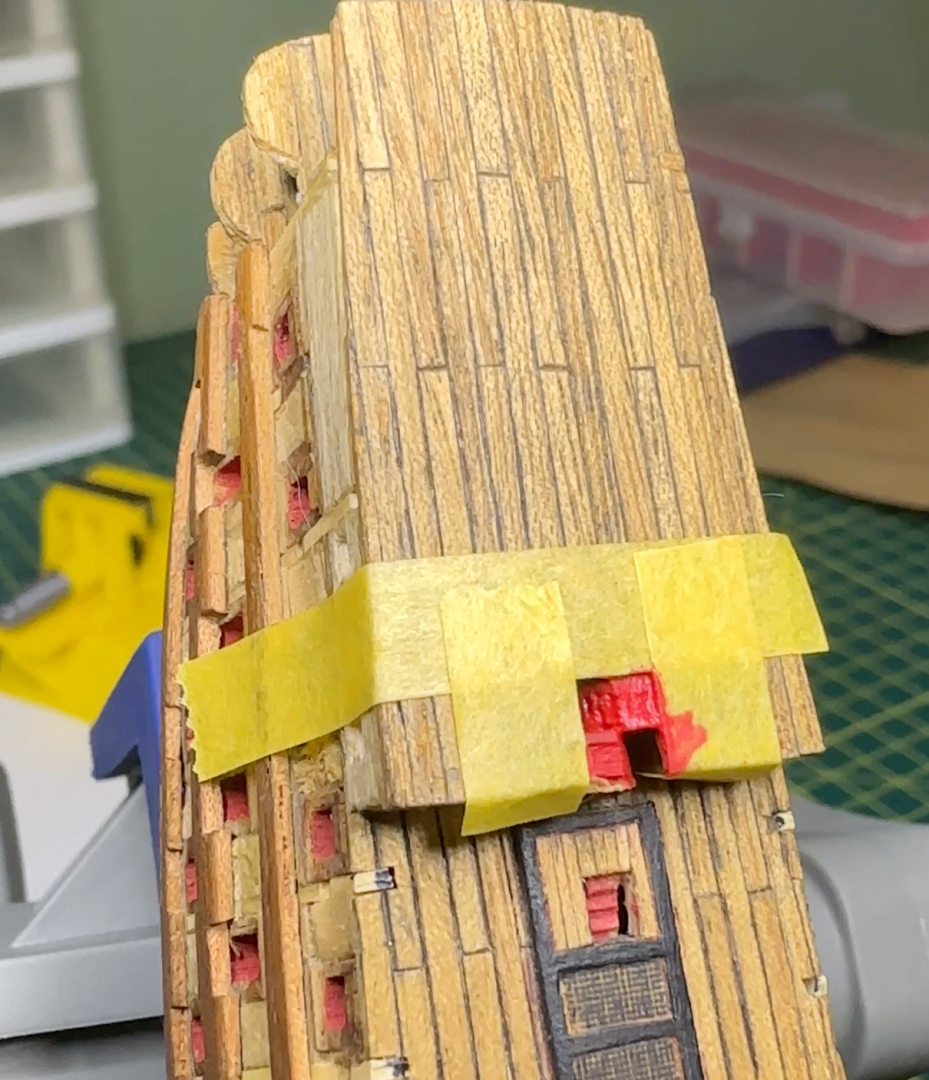

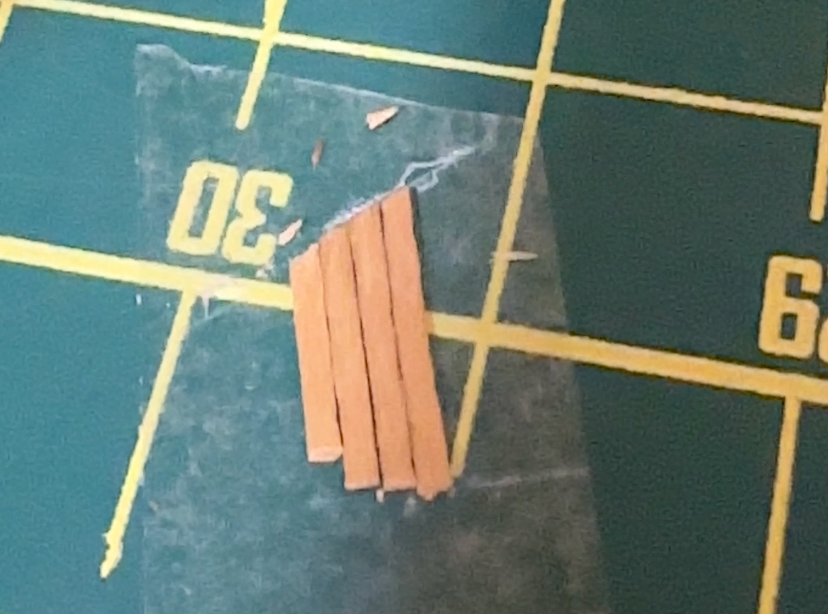

Well well well look who's back? It's a-me! Almost eight years later, I'm back to the shop! Last time I posted I was in the final stages of my PhD (last post was in June 2017 and I got my PhD in August 2017). Lots of stuff happened in between - started working full time as a professor, finished a post doc fellowship, got married, Covid-19 and all that nightmare, started another PhD, got a rabbit to join our cat, changed universities, and here I am. All this time I never really stopped thinking about the small ship tucked away in a drawer... I just needed a push and my wife always asked me "when are you going back to your little boat?" (either she really likes my "skills" [pun] or the wants me off her back so she watch her soap operas in peace). I'm in a new apartment and I have less space now, but I'll make do. In the meantime, I never stopped watching videos and reading about model boat building and now I can see so many mistakes in this build. But I won't abandon it and simply start anew. I kinda owe it to the model hidden away all these years that kept staring at me... So, let's go back at it. The transom in the Parisian Museum is curved almost round with planks bending at the back, and I should've seen it but it is too late. So I found two commercial kits (a wooden one and a plastic one) and both of them have a flush part at the back. I tried the same. Here's my attempt. I ended up poking my finger with a scalpel (so many years without using one!), but it's the price to pay. Now I can say I bled for this ship heheheh Here's my process: First I tried gluing planks but in such a small dimension it didn't work (who am I kidding?). Then I thought about it for a second and I found a "solution" - Use transparent double sided tape, taped to my cutting mat and put the veneer planks side by side. This has two goals - 1, stopping them from moving while they are being glued; and 2, protecting one side from the glue. Since the veneer planks are 0.4 mm (0.015748 inches? sorry I don't know American units), I had to use CA. I tried first 4 planks to see if they would hold after ungluing the set from the cutting mat and it worked fine (a bit fragile but it went well). I then made a paper template and used it set all planks. A bit of careful filing and sanding later: Here's the final result: It took me a huge amount of time to do such a simple task, I poked badly my finger with a scalpel (it will take i believe 2 weeks until it is well again), but man am I happy to be doing this again. I can see so many defects and problems with this ship but I do love it so much. I'll try to work on the transom area and start planking from the bottom (garboard up). See you soon! -

I have found your thread only today and I have spent most of my day catchint up with it. I am impressed with your technique, precision and creativity!! I have no words to describe how impressed I am by your work. I have a very small ship that I haven't worked on for a while (my job's falt) but seeing your work makes me want to go back to the table right away and work tirelessly on it!! And I was in Czech republic for work for 2 weeks (came back home last week)… If I had known your work by then I'd make sure to arrange a visit and be amazed by seeing your work first hand… 👏👏👏👏👏👏👏👏👏

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Le Soleil Royal by Nek0 - 1/72 - Marc Yeu

fmartins replied to Nek0's topic in - Build logs for subjects built 1501 - 1750

👏👏👏👏👏 incredible build, man! I'm absolutely impressed!!- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

At this point I'm not even caring about rewards and stuff I just want it all to be through hehehe -

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

Man, I had no idea what I was doing when I decided to go for a doctor's degree... That sh*t is crazy... At least with a doctor's degree I can try for a position in a public university here in Brazil. That would be very good - it is pretty much the same as getting tenure in an US university. Nice salary, only teaching 8 hours a week and that's it... plenty of time for model ship building hehehehehe -

Royal Louis by fmartins - multi-media

fmartins replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

Well, it's been a while I haven't posted here... If you're following this thread, know that it's not because I don't want to, or abandoned the project... The thing is I'm on the last phase of my doctoral degree, and it'll be all finished by june/july... until there, my focus has to be on my life-long dream of becoming a full time researcher. But, as soon as I'm done with my dissertation I'll certainly have more time, and I'll happily post more often... Don't give up on following my build... It is something that really makes me happy. I hope in the end it will turn out alright... Thanks everyone! -

PRINS WILLEM by juzek

fmartins replied to juzek's topic in - Build logs for subjects built 1501 - 1750

Wow Juzek, what an accident! Fortunately for a master such as yourself it's nothing, it looks even better now... as for the tips, thanks a lot! I looked around and found some linseed oil, I'm going to give it a try! Do you apply it on top of the paint, or use the oil first and then paint over it? Do you use any stains before linseed oil? I'll think about the veneer strips, I think this might help!! Thanks a lot! -

fmartins reacted to a post in a topic:

MORDAUNT 1681 by NMBROOK - Euromodel - 1:60 - Beyond Bashed

fmartins reacted to a post in a topic:

MORDAUNT 1681 by NMBROOK - Euromodel - 1:60 - Beyond Bashed

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.