-

Posts

1,723 -

Joined

-

Last visited

About scrubbyj427

- Birthday May 13

Profile Information

-

Gender

Male

-

Location

Bend Oregon, Portland Oregon

-

Interests

Model ships, classic cars and outdoors

Recent Profile Visitors

-

brunnels reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

brunnels reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

Chuck reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

Chuck reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

Chuck reacted to a post in a topic:

HMS Winchelsea 1764 by Kusawa2000 (Mike Draper)

Chuck reacted to a post in a topic:

HMS Winchelsea 1764 by Kusawa2000 (Mike Draper)

-

CaptMorgan reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

CaptMorgan reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

rcweir reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

rcweir reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

marsalv reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

scrubbyj427 reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

scrubbyj427 reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Absolutely beautiful work!!! -

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

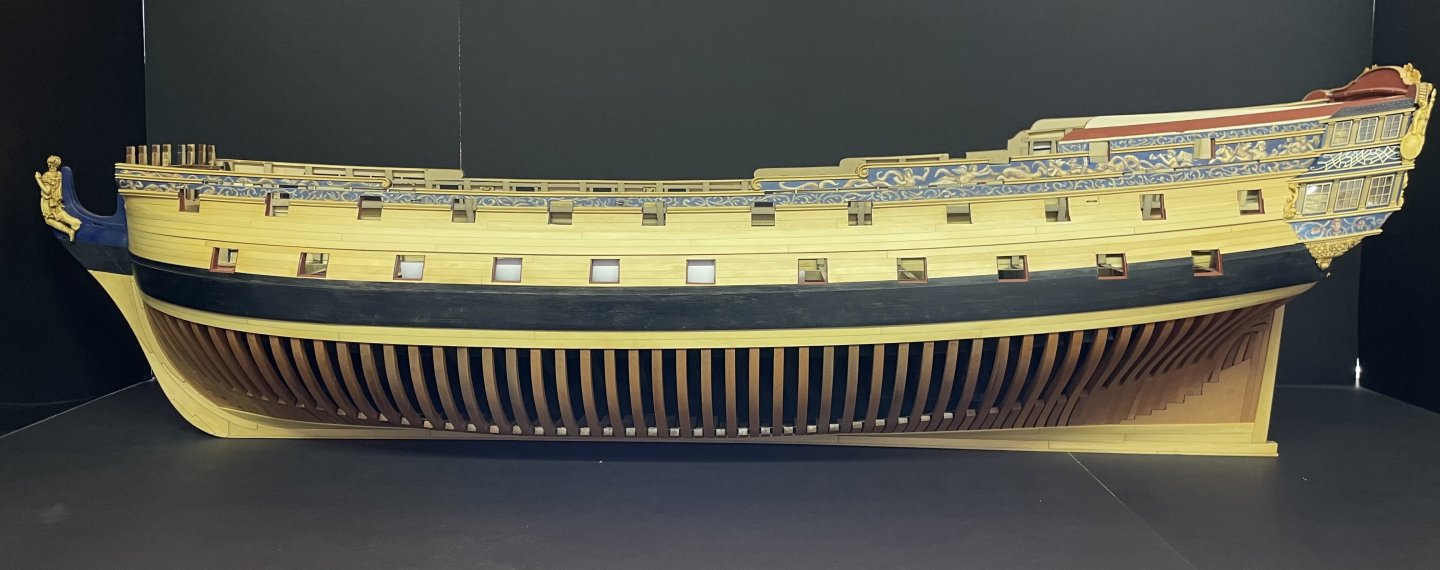

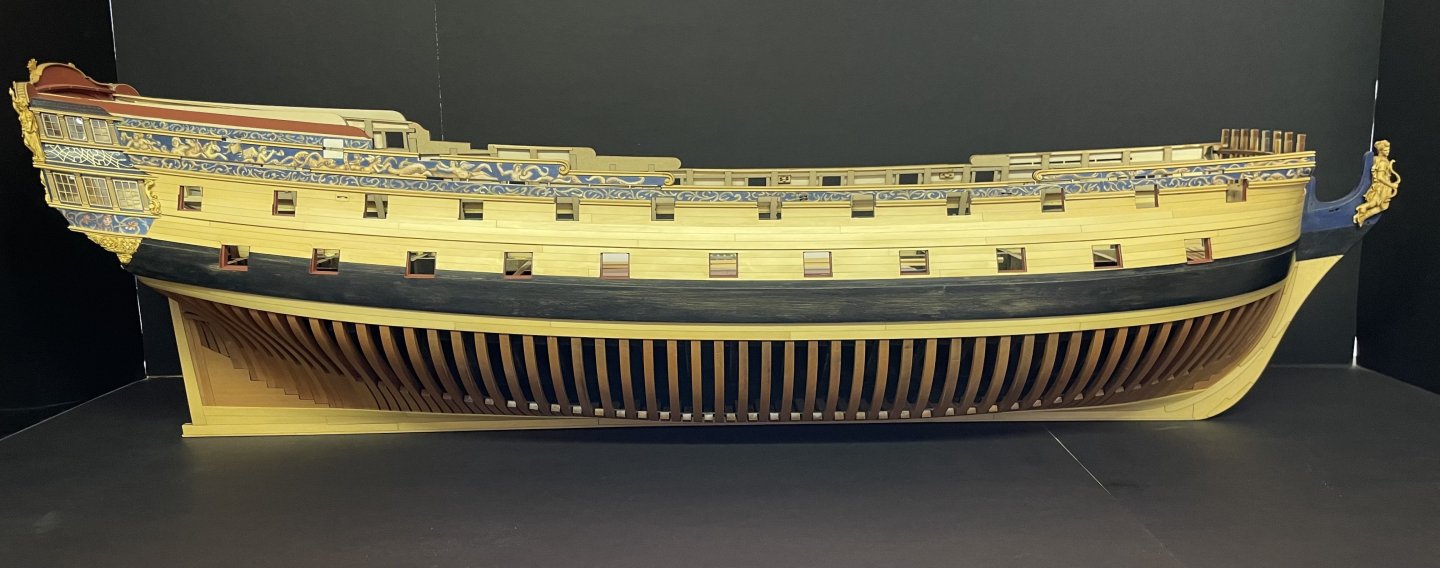

Chapter 3 concluded. I finished up by adding the small boxwood strip (.040x.040”) on the upper edge of the lower QG roof. These go between the columns and above the windows. Will begin chapter 4 in march which will be the main gundeck and fittings as well as spirketting for that level and I’m thinking possibly gun port doors.

-

Hey guys, Im going to be winding down at the shop today as I have to get back to work on Friday (I still have to maintain a real job), so not much production for 6 weeks. As of today I’ll have another Portland kit up (they take about 1.5-2 days to produce), I’m also going to try and crank out some Winnie chapters as well as a couple capstans if possible. I’ll be available while away and I’ll keep the store open but I won’t be making anything until I return in early march. JJ

-

Thank you Kenny, that was my goal from the beginning when I designed them. I think it worked.

-

Almost finished with Ch 3. Need to add some strips to the QGs, a smaller frieze on the QG roofline and the stbd side upper molding and scrolls.

-

Thanks Guys. It’s getting there. Gary, if there was ever a green light for ship modeling being displayed in the living room, Coming from the admiral that was certainly the best comment one could ever hope for!

-

Few more Portland updates. I’m getting closer to finishing the QG’s. tomorrow I’m going to work on the lower QG frieze work that goes on the lower roof along with the thin strip of molding, also i have some boxwood scrolls to add! Should be a fun one. JJ

-

Thank you Kenny. They are almost complete. Still some components to design and add. Updates soon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.