-

Posts

876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

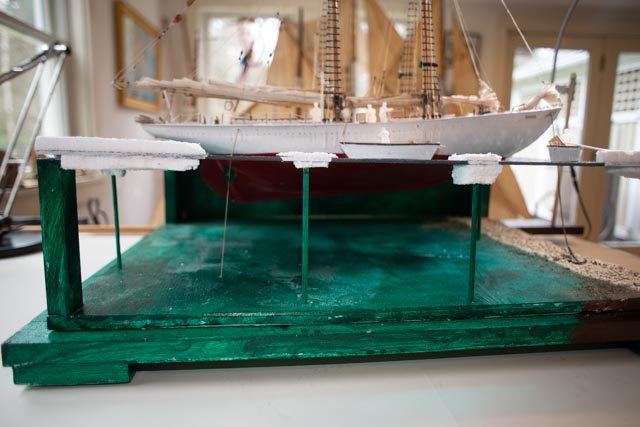

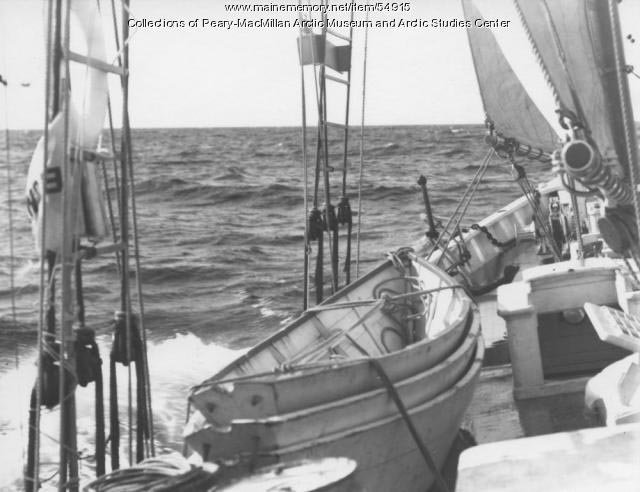

thank you guys for the thumbs up. we all know that is appreciated. here we are on our way to the museum store in Boothbay Harbor Post 37 We are ready to go 300 switching to the 90 mm lens to get some more detail. Our crew on board with the box needs to moved a bit forward. I suppose next time I need to cut out for dories too. 301 our waiting crew member finally stood up. A little white glue helped 302 I love the change in color of the water. I also have an extra anchor on the transom ready for use as they work their way out through the ice 303 here we are looking into the sun with the water sparkling 304 here we pick up and the sparkle fades and the shadows on the water stay. I like the sparkle reflection on the hull 305 looking down sun but lower to the water the water again comes alive……this fun though I really and just trying 306 glass box ion the car 307 Bowdoin in the car ready to go Cheers

-

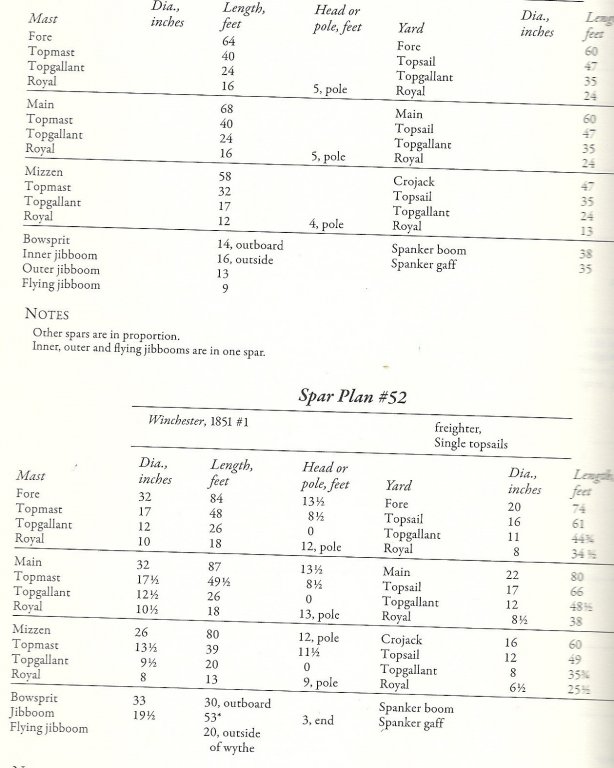

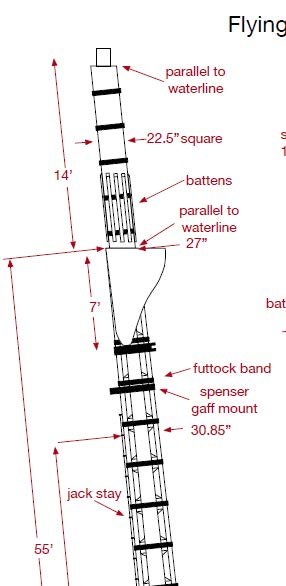

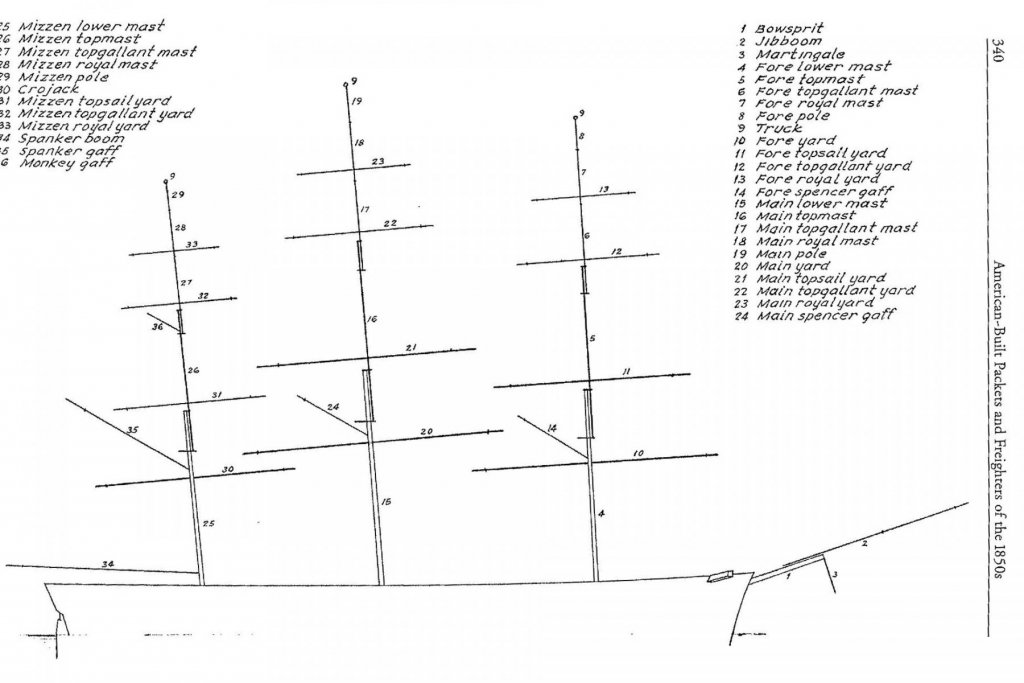

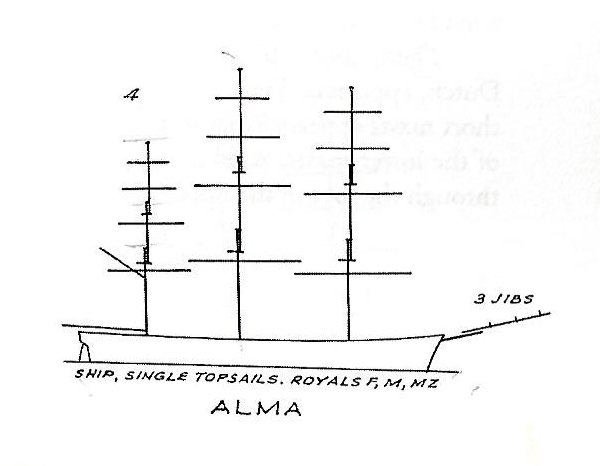

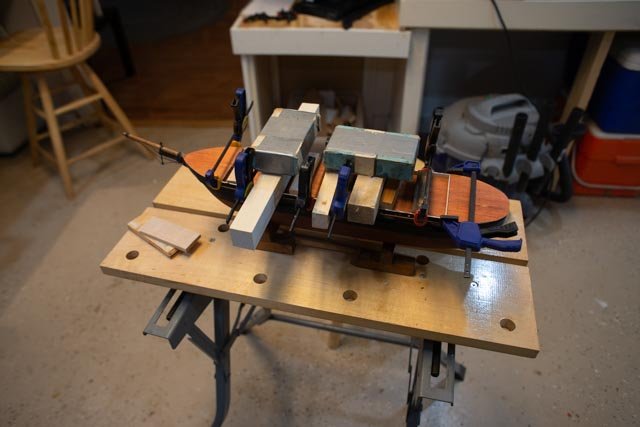

Post 11 More mast study….start to build I have been madly reading the Crothers books. I have also been scanning other builds of ships in this scale. Wow so much fun and so much to learn. I was thrilled to find others have picked up this masting information as well as other details I saw in these books. It suggests I may have fallen onto a good track reading these books. Anyway, I figured out my plan for the three lower masts so here I go. Foremast 1) Field measure of our model [ 147 foot} … 5.0” above deck with 1.125 doubling 2) Scaling off Crothers drawings of typical ship rigging plan including reference to Alma [ 153 foot]…5" above deck and 1.375 doubling. 3) New calculations based on the Crothers masting book….. a) [147’ length plus 30’ beam] /2 equals 88.5 feet total main mast. Then foremast = 8/9 of main=78.6. this is total mast, so we need to subtract the housing [ below weather deck] b) Ap-071 scaling from the Crothers cross section of two deck ship we get bottom of tenon. On the section it was conveniently 5 inches from the weather deck to bottom of keel and one inch up to bottom of tenon…thus 1:5. Measuring on the model the shear plank to bottom of keel is 3 inches, so the correction is almost 2-3/8 or 2.4 inches or roughly 19 feet. I would not pass a physics test with those measurements, but it is all about proportions. c) In the masting book, spar plan 51 is Alma, they show foremast to be 64 feet. Then we adjust. [ {153 ‘-147’}/2 =-3 feet as we are shorter than Alma. We subtract another 19 feet for the housing and have 64-3-19 =42 feet. 42/8=5.25 yippee ki yay or rather not bad, it almost agrees with our field measure and scaling of 5 inch. I plan to use 5.125 d) For the doubling we see in the notes that doubling was being reduced from .4 times top mast to .3 during this period. Looking at.3 x40-foot is 12 feet or 1.5” we find the scaled drawings from the earlier book we were 1.375”. for now, I am sitting on 1.375” [I did not want this to be greater than the mainmast] Main mast Same process. The model was 4.75 and 1.125 doubling. Scaled drawings and calculations supported 5.5 inches and 1.375…you will see as stated in the earlier measuring post that the top royal mast on this old model was 3/4 inch too tall, so this increase was expected. Mizzen Same process. The model was 4.36 and doubling 1 inch. The scale drawing and calculations both supported 4.5 and 1.125 doubling. I will reduce this to 4.0 length above the raised half poop deck. I have read the masts were typically made up and banded. The iron bands were spaced at 3 feet. The hounds were eight sided and ½ the length of the doubling. The doubling was square. Since they were 22 plus inches and the lower mast was banded, I assume these sections had bands, but I am still checking that one out. The whole mast was painted out. The lower yards were also painted out black. My plan is to now make up the three masts and lower yards and to check the bow sprit. While doing this I need to complete the cabins, pin rails and get ready to make other deck furniture and chain plates and lower mast tops. Cheers

- 57 replies

-

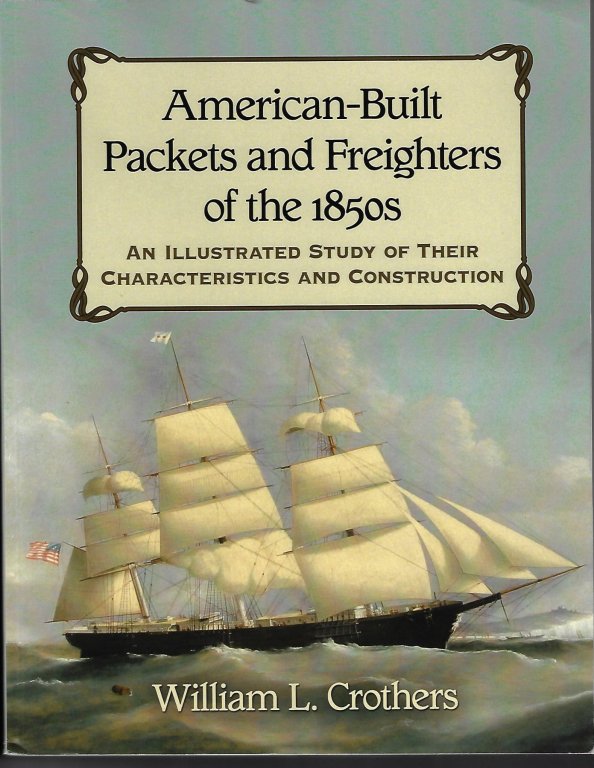

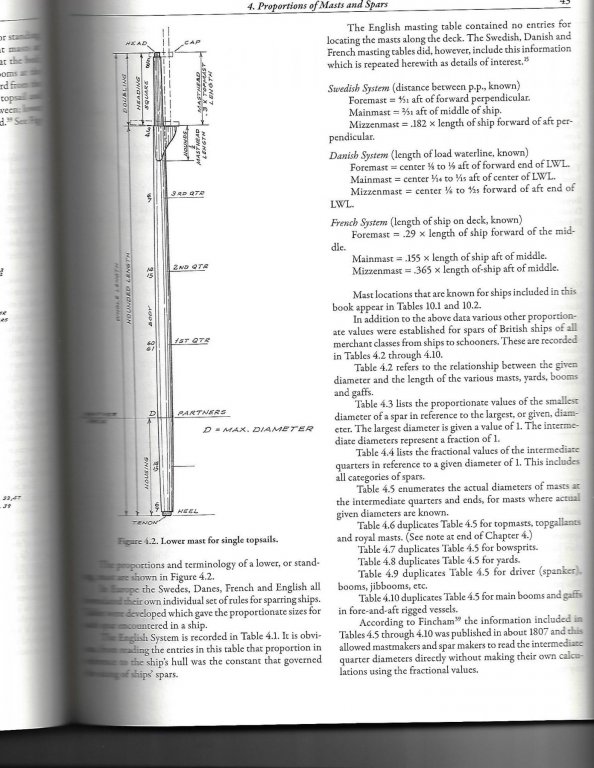

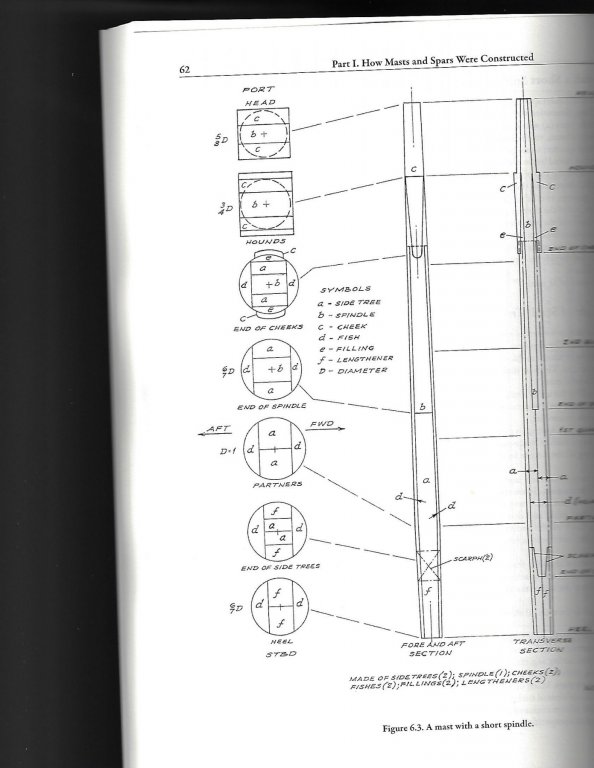

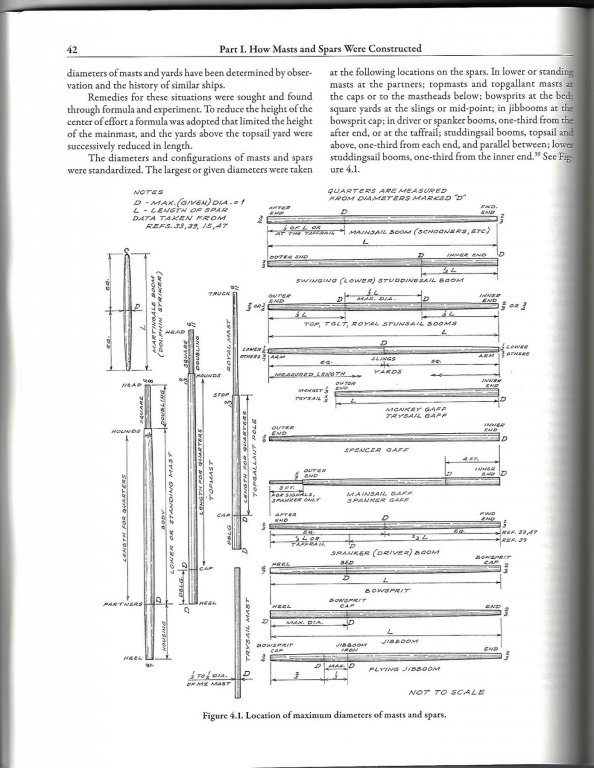

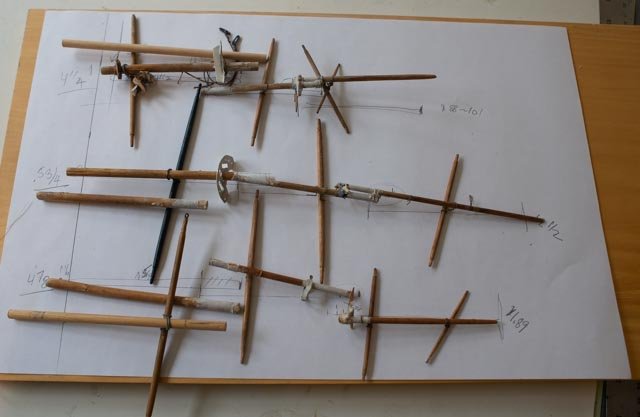

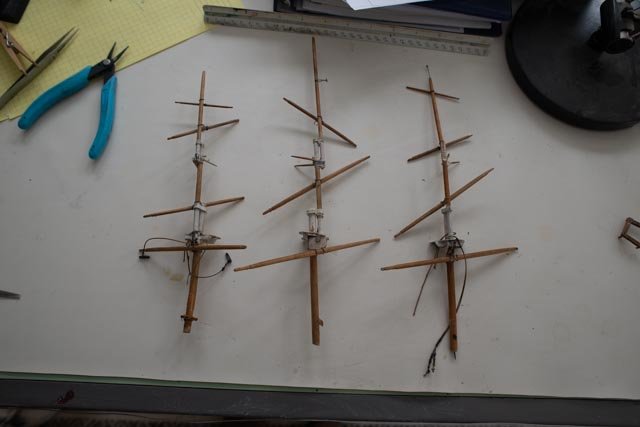

Post 10 Back to study of masts and yard 1850 ships One good thing about this build is the find of the great author William Crothers. Years ago I bought his clippership book and was awed. For this build I have bought the other two of his trilogy Ap 64 This book is amazing. It was reviewed in a post favorably and yes it costs $95 but as I said early, the hull was free. Everything I have done to date is based on the reading I continue to do in the this volume. Ap65 is a downloaded pdf from the internet of mast on the Flying Cloud by Bradner. Reading the notes, a bibliography came up and it was fun to go through. It lists not only the classic books but articles from both newspaper and NRJ. Bradner credits his details to three authors including Crothers and he cited another volume dedicated to mast construction. Ap66 here we are. Found it at Amazon. The third volume specifically on masts and spars. It is incredibly detailing and full of historical references and explanations on how things went together. A straight forward point that makes sense was that by 1850 the large trees that allowed single tree masts were mostly gone. Large masts and yard arms were being made of ‘sticks’ there is all kinds of information in this book. It seems that many were painted as in the cover painting and that squares with much marine art. I am still reading and gathering notes, but I believe in the end I shall replicate made up masts as they must have been the norm. As I recall in reading about the big schooners, large spars were floated in to Boothbay from Wiscassett. Much to learn Ap67 on this page from the Crothers mast book we see an example of the explanations. References to the tables completed the process and by matching the model to a relevant ship in a table [ our match is Alma from Sullivan Maine], we can be more confident of what we are building. There is interesting reading to come that I have not done yet explaining the calculations to establish the optimum heights of the masts and placement of the sails….as I said so much to learn Ap-068 here is one of several methods to make up a mast again from Crothers Ap-069 here is Crothers diagram discussing the maximum diameters and the locations of the tapers on masts and spars Ap070 here I have taken the masts apart, as I need to do this for rigging them one level at a time. I have already replaced the main lower mast and the broken yard. I have much to do before I get back to this and summer diversions are fast approaching. I believe I will choose built up lower masts, and they will be painted. I definitely will square up the heads and rebuild the cross trees. overall work I have just glued on the monkey rails and will try to get the hull cleaned up, pins installed and houses in before summer break. I will putter along reading and planning out the spars. Then depending on summer availability try to get them adjusted or remade. Fortunately, the deadline for this build is next year at this time, so all is good and we can slow down. Cheers jon

- 57 replies

-

Post 9 Finishing the upper waste shear planks and channels This step is to do the best I can with the pig’s ear old hull and decide to move on. There is also a funny oops. I need to complete the exterior shear planks and channels over the finally repaired hull. ap-58 here again I am soaking and bending thin strips to shape the outer edge of the main rail plank. At this small scale I am not attempting to have a groove. This step included three more passes of putty sand paint sand putty sand …it must be me as new pin holes kept showing up. I think not being able to use the spray filler primer, which fills in things like pin holes is one of my issues. I also don’t have a paint station, so I am brushing paint. I know I need to get over that, and go learn how to spray with a new toy or two. maybe next year? . ap-59 Here is the shear plank bending to shape. ap-60 Here we have the oops. Back in post 4 I was proudly copying the chnanels from the original model. The were 1/8 by 1/8 ……omg…that means a foot square channel???. Here I quickly made up planks to agree with the Crothers detail and we are on again. ap-61 Here I painted out using the satin finish to see how it looks and if the defects are reduced enough not to catch the eye. You can also see I have painted out the replacement yard satin black as per the Crothers note and I think for now I will stay with this look. The highlights of the channels I think are better than in the ink black. I will use the ink black for any iron work. Ap-62 here we see bow on. Ap-63 looking ahead we have 198 pins to install. I have taken small brass pins and cut them and tried them in the pin rail. I will need a rainy day to put all of them in. That is not a commitment to add 198 lines, however. i also chose a soft gray for the roofs. there are no notes on that point. the Alma was shown to have pearl and I am using ivory for the bulkhead and later on the house after making many little windows. Cheers

- 57 replies

-

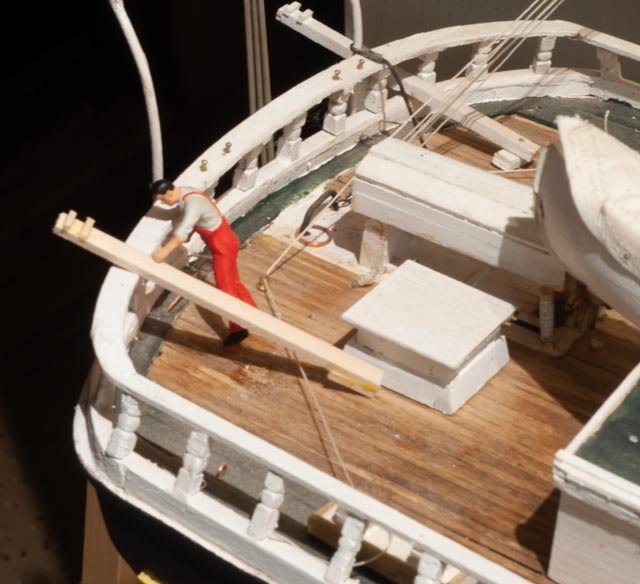

Post 36 get ready for final punch list before the showing Many of us need a little pressure before actually finishing a project. Since my last posting I have been working on 5 projects simultaneously. I got marching orders yesterday so two of the projects need to be ready for shipping to the museum store by next Friday. My third project is tiling the laundry and the rear admiral says we are done at the same time…oh!. The forth project is Charles Notman summer lecture which means I need to finish the model. I have most of ratlines done. Fifth is Aphrodite the first ship built in Boothbay is now an active log. For the museum I am doing Bowdoin and project two is repairing two old schooners. One is a large-scale Bluenose like my project from last year and a sister schooner the Herman Zwicker. I will have a posting on my Bluenose log to cover that work which has been fun. To the Bowdoin. We are getting there! b 284 I took the model out of the diorama so I could complete the stand and get it already to sit on a table. I then needed to figure out the scene detailing and work on the last few lines and things. b-285 turning around I found the safety line missing and I needed to tie off the 3rd dory. I also had to wet and coil some lines a bit better. I am still an amateur at that process, so I hope the crew’s grandchildren will forgive me. I first soak them with diluted white glue but they dry stiff. I find using a paint brush with water softens the glue and I can press and pull a bit. b-286 I noticed while reviewing these photos the white surround for the Bowdoin bow sign is too white. I need to address that….it never really ends does it?? b-287 Once a year we all should clear off our desk. I moved the diorama into this area as the light is much better. I am done to the real punch list now. Looking from this angle, the water is similar throughout. b-288 Here you see what I see. Beyond Bowdoin are the two models I am fixing up for the same dead line. b-289 Here again as we move aft, the water comes alive and the shadows extend aft on the deck. b-290 I find this interesting as the water under the stern is a beautiful green. I also like the strong shadows on deck. b-291 In this view the water is all the same. the light coming form behind picks up many highlights. This is opening my eyes to a whole new are of exhibiting models. Lighting can make a big difference. b-292 I love this view as it depicts exactly what I am trying to show. I n the July 1 1924 photo form the mountain top they had used ash to melt the ice around the hull. b293 Here you can see the completed diorama stand. the added layer below was painted out to match. The glass sits on lower ledge. The light stand remains outside the glass. b-296 Here we see a better view of the underwater beach and anchor b-297 Here is a fun bow on view. We see the bright light on the port side. Very different from the starboard side b298 For all submariners, this view shows the fun of supporting a model on 1/8th inch acrylic. We get to see the bottom. Note the stern anchor line that goes on down through the water. Please don't ask me to sut out for the dories. I suppose i should but not now please. next time!! B299 I leave this post with this overall view. We see 5 of the 6 crew. Perhaps I should add the 6th figure so nobody counts. I wish I could get some dogs and a sled All these views were taken with my 24 mm. I am fixing up a few oops and taking more pictures using the 90 mm/ macro. Then the final shots will be at the museum store in May. All for now jon

-

Nick thank you for you r comments and support to the figures. I am putting together the final imaging and have posting to day of the updated diorama. I still plan to get up that way this season. My knee is almost back to normal so it should be soon. regards jon

-

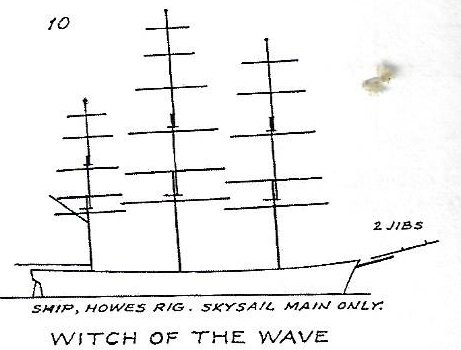

Post 8 First Study of masts and yards It was fun to read the chapter on the mast and yard design in Crothers book. It was this period of the 1850’s when the introduction of the split topsails [ renamed gallants at least in american trade I think] came to pass. Part of this study is to confirm if the existing model spars can be used. The short answer we shall get to is…. yes with some help sort of maybe.....sound familiar? Ap-50 this scan from the Crothers Book shows the basic consensus design of a an American merchant ship of the time. The chapter goes to explain the influence first of Captain Robert Bennett Forbes. The evolution of then top sails grew, due to their power, to be 60 feet wide and high. They drew well but in any wet weather became unmanageable. He was the first to split them in 1844. Part of his experiment was to “fid” the top mast "abaft" of the lower mast. He felt this approach improved the sailing function. Another fun fact is it was he who first popularized these topsails as Gallants in his pamphlets. In the 1850’s Forbes design was much debated. It was a ship builder/ captain named Frederic Howe who while building the clippership Climax in Medford, Ma., made two improvements. He realigned the huge top sail yard and fixed it to the cap of the lower mast. The sail was shorter. He then had a new upper top sail yard hung on the top mast and extended it clew past and behind of the lower yard , filling the previous gap in these two sails. Looking into more clipper ship plans I find this upper yard became known as the top gallant yard as per the Forbes pamphlets. This is all fun, but for our build we have to respect that Alma was not shown to have any of these newer rigs. Ap-52 this scan from Crothers book shows the understood rig of Alma that I shall use for the contemporary Maine built ship. ap-52 scan from Crothers book shows the Forbes Howe change on a clipper of the time That is all good stuff, but we need to move on to our build and check the existing model by measuring it against the designs of the time.. The measurements The first job was to take the scan above in ap51 and measure the components. I then measure the hull to get a scaling factor to bring them up to the model scale of 1:96. The second job was to measure the model components. One yard, the boom and gaff are missing, and one yard is clearly broken. The mast tops were all made and glued and I hope not to damage all of that. I will save that for possible use. { maybe} So, this post is for the planning of the reconditioning. I have a full excel sheet where I take the Crothers dimensions and’ scale them. Against each number I post the measurement for the existing spar. I won’t post all that here but the results as a list were amazingly good. Ap-053 Here we see the foremast . The lower mast is crocked with a splice and it is obvious looking at this photo, I have to disassemble the masts to install the standing rigging……. Ap-054 here is the Main mast. It is overall about ½ low. Lower mast needs to be increased in length by 1.25. [definitely replace]. Top gallant mast to be lowered about ¾ inch. Ap-055 Mizzen masts….very close over all variation about 1/8…clean and reusable…..maybe??? Ap-056 here I have disassembled the fore mast. ….if the 30 inch diameter mast was composite, does a simple dowel reflect how it was made. I must really think about this one. Ap-057 here I am making the missing yard. As to the measurements, the model yards were consistently a bit longer. The shoulder and tips were quite visible, so I may work to reduce that a bit There is more study to be had. One reason is I am reading in the Flying Cloud documents so I can best assist a friend on the model, I am finding 30-inch masts were composites with bands and all kinds of things. More of that in another post because I am quickly sliding down a rabbit hole. I just ordered Crothers Book on masting. $$ again. I am glad it is the journey. At least the book shelf will look good. Cheers jon

- 57 replies

-

thanks Keith. I am finding I have much more to read and that is part of what I love in this work. I am trying to come to a set aside point because my other project all just got deadlines. any onward we go. I want to get the hull sort of done and masts figured out. jon

- 57 replies

-

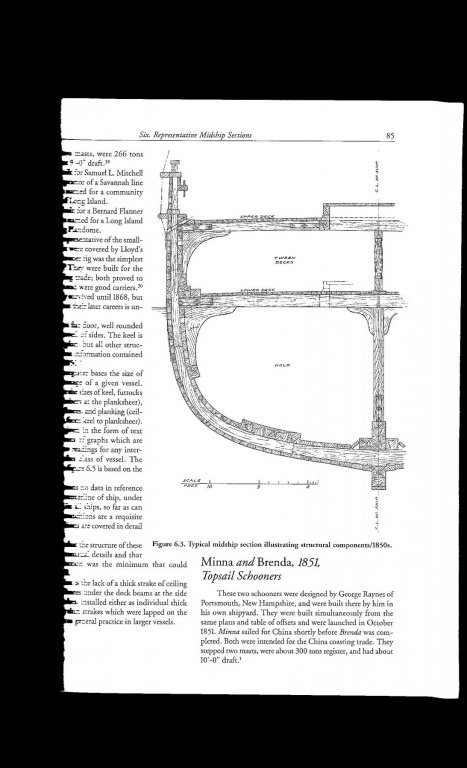

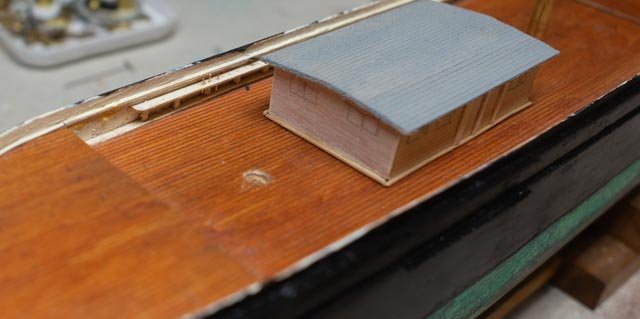

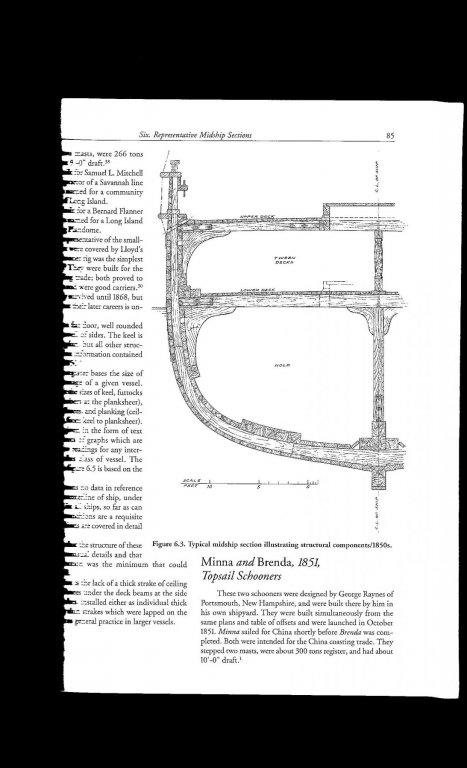

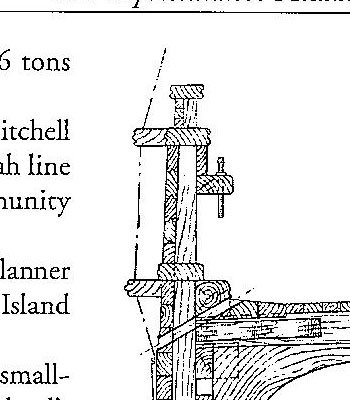

Post 7 Upper bulkhead shear planks and rails part 1 It is time to rectify the bulwarks and see that what we end up with is close enough to show the real thing. I started off by reading the chapters on the related items. In summary let’s look at two sketches Ap-40 This page, from Crothers’s book, shows the midsection of the hull. What I am after is the relationship on the side from waterline to monkey rail. By taking measurements from the drawing and scaling them slightly to fit the model, we find the issue I have mentioned of the deck being a little high. Not enough at say 1/16” to worry about. Ap 41 This view is the cropped bulwark for my planning. Here we see that above the pin rail there is an inner plank over the top of the stanchions [ bulwark clamp in nomenclature]. This made my use of a solid horizontal strip in this section show both dimensional separation of the pin rails and provide more solidity to the construction of the model. My next activity will be to build up the monkey rail. As per Crothers index of ships, we are trying to get to 4’-6”or 9/16” to copy information on Alna I will get to ½” due to the slightly high deck to focsle deck, so that is close enough for me especially as the dimension is a bit of conjecture. Ap-42 the shear plank is an extension of the main deck elevation and should thus be the ½ inch below the top of the top rail. In this photo we see the remnant of the old shear plank first too wide at 1/8” and too low. I have since carved it off and shall install a proper 1/16 strip at the right height. This also reinforces the previous decision to remove and replace the channels that were at the same level as this rail. Ap-43 Here we have an issue. This is the soaked future monkey rail stanchion that I set at the plank shear elevation to check out the problem of the too rounded stern. If I had cut out one inch fore and aft and ½ down, replaced it with a block and carved the stern, I could have earned a few more broom handles but ended up with a more proper termination of the shear plank. I will solve this one later Ap-44 here we see the first of three rings of styrene 30x30 to form the extreme curved water way. This is a short cut for this type model where everything is painted out. I would other wise have cut out the waterway from wider strips. I hope I am forgiven. Ap-45 I glue a little bit then bend a little more and work around the waterway. The first outer one is hard, and the inner ones are easier. At the same time, we have the wet future monkey rail stanchion bending to conform to the stern. Ap-46 here we are on the focsle deck. There is a sharp bend at the bow. We also have the monkey rail stanchion waiting for the stern to take shape. Ap-47 Here we continue by cutting to rough length, presoaking the bow section of the monkey rail stanchion, and bending them to conform. Ap-48 Just for fun, I have some progress on the deck houses, and it is fun to see how were coming along. Ap 49 Here we are gluing the first aft section of the monkey rail stanchion. I am using scrap shims to hold it to the center of the main rail, the bow or stern water way. We are away for a while and spring is coming, I just want to get the bulwarks and main houses done before the slow down for summer. I am still working on the other projects with summer dead lines. this model is for next summer Cheers Jon

- 57 replies

-

Keith It is such a joy to sit down with a cup of coffee and read the next few pages of your build. I just learned all about options to finish wood at this scale , to turn portholes and to punch acrylic so they look real. This last image showing the hull should make the team rooting for paint pause.....if only briefly. It is gorgeous. I can't wait to find out what you decide to do. Jon

-

Mark Thankyou for the tip. I typed in U S Constitution in dry dock and got dozens of photos. They show several variations. What is interesting is they are the opposite of my results. The inside curve near the stern had large areas where the copper color stayed. Perhaps movement of water. On the other hand, the U S Constitution does not move very much so what that might mean is out there. The process of seeing them makes me feel better. To the real modeler I may have strayed into folk-art, but I am ok with that. Cheers Jon

- 57 replies

-

Kieth there are two types ...one is two part and very hard etc and the second that I love, is one part and forgiving. It is called Glazing Putty Bondo...Glazing & spot putty it is red cheers

- 57 replies

-

Post 6 Copper Hull experiment…the patina part 2 I think I ‘m going to proceed. I can always come back and change. Here is my rationalization. Ap-33 I turned her around and tried the other side. This image shows we are on side two with coat two ready for treatment. Ap-34 here we have the same issue as the other side. I only did two coats so three coats as an issue is eliminated. I was very careful on application, and the bare spots still came up. They are consistent on the roundest part. Before removing the masking tape, I did a second application. There is improvement but some green is getting too green. Ap-35 another issue is which black to use. I started with this coat as an experiment. It needs another cycle of filler sanding and another coat anyway. This trial is the ink black that is so perfect for flat iron work. It is flat, I mean really flat. The debate is ..was paint in 1853 ink black or oil and other pigment. Should one use flat or satin. I just don’t know the evolution of paint. If tar it is a bit shinny and I like to use ebony stain for that of ratline slats and things. All the books say is black. I will do each side different and then decide. As to the look …….I mean when the model will be displayed how does this patina and paint look… Ap36…This image fairly shows it will be low and not under bright light on the lower hull. As to the message…. I am trying to depict what things were, how they worked and focus more on that. I am not the fine workmen to focus on the beauty of the wood or the skill in finish and carving and the like. Ap37 a glance of the hull at eye level as one walks by… I want one to look at the model and sure like what they see, but also understand from the glance what things are made of. That bottom says I AM MADE OF COPPER AND I TURNED MOSTLY GREEN. The green paint did not. Ap 38… I have read the copper plates under water did not change to all the same green. The copper near the water line that saw air was the greenest, some boats saw more time in dry dock, Some areas where fast water kept the copper hue longer[ maybe??]. All these things are perceptions. And we have no copper in our lifetime to look at. Ap-39 I went ahead and painted the opposite side with the satin finish black. In the write ups on 1850 paint, Crothers discusses the mix of ink black with red lead and “paint Oil” [ other reference said linseed oil]. If they were painting yards black, they added turpentine to the brew as it... "gave a gloss". [ Therefore, without adding turpentine it may have been flat. I have a different issue. This hull is caved spruce. Despite three treatments of putty and sanding the satin finish highlights every little defect and takes the eye the wrong way as to scale. The spruce grain that I have filled and sanded three times is still there and ruins the concept that one inch of model is eight feet in life. On the flat iron side, there are defects that I can eliminate with another round of fill sand and paint to the result of the back ground is non discernible. That is the look I need for this repair. Once I replace the plank sheer and the channels, I want them to be what is seen not the grain that despite my effort lives on. Conclusion…that is better said my conclusion What I have may be out of scale and to some will be awful. Perhaps I should do copper plate and then acid etc. This test shows my attempt to clearly explain the bottom is copper patina. I spent only $40 on material and having used just 10% of it means that supply could do many more models. I feel it is better to use on the larger hulls meant for RC sailing and someday I shall treat my large 1853 Pilot schooner, I showed in the last posting, that is currently just green paint. I have a friend building a 6-foot Flying Cloud and maybe he will like it. I believe the results are better than green spray paint. ..The option to install thin Copper plates to this hull would have been easily $100++. The market plates are meant, I believe, for larger scale 3/16" and up, so I am not sure what to do. Then I still would have the issue of how to treat to get patina. As to scale with the tape option…..would one punch the nail holes at 1:96? I think not……and unpunched tape just is not worth the effort to prepare the hull. Regardless there is always so much to learn. Years from now, I may laugh at this conclusion. This model is not a fine piece to have any great value. It is chance to salvage an old model and end up with a decent replication of a ship built at the time, so people can see what was built in our harbor. With that logic or at least opinion, it is time for me to move forward. I will do more touch up on the Dixie Bell copper, as handling will cause some damage and I need to address the “too green” spots. I also need to do the rudder. I tried sanding with 400 grit, and it improved the look by removing the roughness and blending colors some. That helped reduce the scale issue. I will use the Ink Black super flat paint for the hull and then a satin when I get to the painted yards. I will re address this when we are really done with the hull. on to the bulk head Cheers

- 57 replies

-

Posting 5 Copper hull experiment I always like to try something new. It does not always work. I am setting myself up for big oops, so let’s follow the bouncing ball, as I attempt a craft approach to copper patina paint. Ap-25 the secret supplies arrive. On the net I found many choices but was most intrigued with the Dixie Bell paint procedures. Here I have chosen the copper patina paint [ in the jar] and the green [ vs optional blue] patina spray. They show applications to vary from the spray to sponge. The sample on the left I did not like. It was too much liquid which over treated the paint and retained a chartreuse green. On the right we have the second sample. One paints a copper layer and lets it dry. One then applys a second coat and added the liquid to the wet paint so like blackening agent for copper and brass fittings, the metal particles suspended in the still wet paint can turn color. Ap-26 here the second sample looks ok Ap-27 the test. Setting the second sample over the green hull I decide to go for it. Ap-28 first coat per instructions….let it dry Ap 29 I was not satisfied with the cover of one coat over the green so I added a second coat….maybe oops. Ap-30 Here as the third wet coat gets sponged, I am optimistic! Ap 31 hours later I am perplexed. Why so different than the flat surface. This may be great results for life size plaster bust that I want to look like old brass but for the scale it may be wrong. Ap-32 here if you compare closely I have put dabs on where the copper showed the most and added more treatment. It’s better but the green if hit twice seems to get too green. What to do. Stand by I am trying side two Jon

- 57 replies

-

Thank you Keith Now I am ready for some real comments on my next two posts.

- 57 replies

-

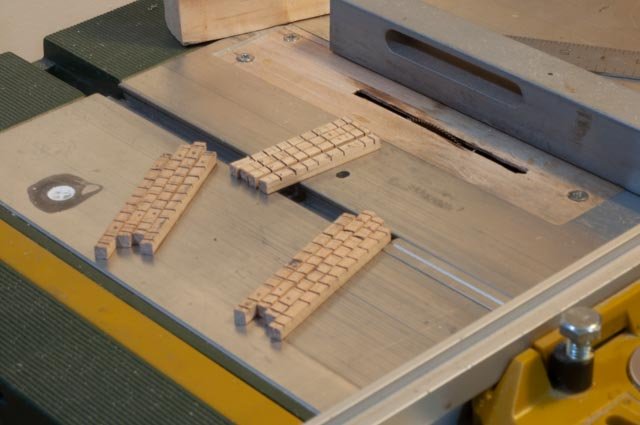

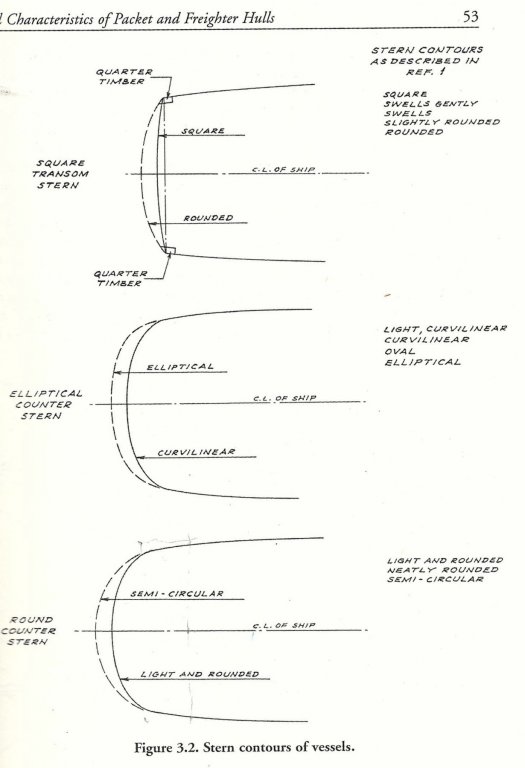

Post 4 Hull part 2 Ok it is time to move under water line. This carved hull of spruce had large grain, two knots etc. That is fine if I strip it and varnish it as a novelty. I am trying however to depict what a ship was like that was indeed build here, and not what the model is made o. Therefore a crisper cleaner look is needed in this area. The process is routine, the issue becomes do we do three times through or keep going. How are we going to depict the copper? Ap-018 this view is after the first full cycle of bondo, sand 220 grit, putty, sand prime and sand 400. Ap-019 second time we delete bondo and go with smoother glazing putty. Then gray auto filler primer. Sand that 400 grit and spray the green finish. Now we add more glazing putty and sand…yes a mess but we all know it well. Ap-020 the transom. Here is the discussion on different transoms at the time. Alna was the bottom one, Lightly rounded as per this scan from Crothers book. Well our model is defiantly a semi-circle. Looking back to the photo ap-015 we see that if I cut the transom to the right shape shown as pencil on masking tape, I would uncover the rudder. The other alternative would be to cut out a block and set a larger one in its place. Then I would need to carve the transom to extend cheeks and create the correct “lightly curved” profile. I decided to leave as it is and simply record the finding. Ap-021 in this photo one sees the first sailing schooner I built. It is large scale and meant more to sail than to replicate any details. I used rattle can soft green paint to replicate the copper bottom. This is my starting point Ap-022 well here we are as we stand if this level is good enough. This is the third green paint cycle of paint and patch and repaint. As a sign, the can ran dry, so perhaps it’s a signal that we reached enough. Stand by because I am going to try an experiment before leaving the process as is [ loose interpretation of patina] material is on its way. In between coats and other jobs I found a need to rebuilt the standing rigging channels. Ap-023 Here I use the mini saw to try to make them the same length. I found some scrap hard wood similar in color to maple. I find bass wood to"frayey" if there is such a word for this type work. I have a big block of pear someone gave me to mill down but that is a winter project in itself. Ap-024 here I sliced out the groves, again to make them look a like. After this step, they were filed with triangle to get to a groove. I chose to make the lengths and slices based on the Crothers plan which was a little different that the old model. i will be doing the standing rigging on this plan so the groove count will match up. Cheers Jon

- 57 replies

-

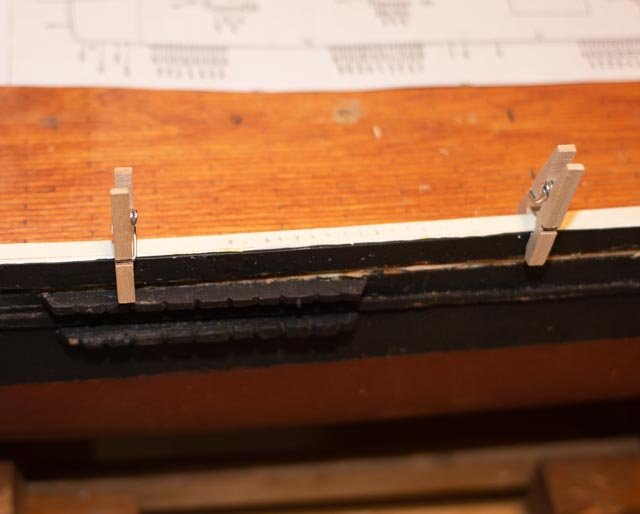

Post 3 How about those channels I studied the drawings for building the bulkheads and pin rails. First up I decided was to cut and place the stanchions. Because of the tight scale, I decided to cut them short [3/16”] to come under the pin rail. I then added a 1/16” x 1/16” strip to increase the height properly to the main rail. I want the main rail to end and tied to the waterway on both the focsle deck and half poop deck to follow the Crothers drawing. I have some compromises here. As I said before the focsle is a good 1/16"+ low and I chose not to raise it. I am trying to replicate 4’6” total rail as per Alna but I won’t quite get there. We’ll see. Ap-011 here we are holding down the main rails for the shear. Ap-011a I scanned this page for Crothers book just to show the slippery slope of models ships. This is the pin layout and there are 198 pins…….OK maybe on the next one. Ap-012 I cut it out and looked to see how the existing channels are located. Surprisingly after finding he masts correct, I was surprised to see how poorly they are located. Ap-013 Here is the foremast. I have light pencil lines where the pins go, and the channel location is way off. Ap-014 Here on the main mast we see they are off and awful looking I am happy I get to replace them as it will make fixing up the hull much easier than to try to work around them. Ap-015 here is the mizzen. I also found I need to raise the half poop deck to meet the main rail 1/16". I like this as there was small damage to the first applied deck sheet. The tape and pencil line on the transom I will discuss in the next posting; they represent the proper shape of the stern. Ap-016 So for fun here I have stuck the old masts in to take a look. I have started the hull rebuilding above the water line. About three times through the filler, sand and cleaning process. I want to get this done before working below the water line, but also before the more delicate monkey rails. I need to think about how much rigging so I can plan on pins. I assume at this small scale they are about 5/32”… I guess I set up and cut a bunch of coper wire with black coating to contrast with the ivory [ off white] color scheme of the bulkheads. Ap-017 I love to play with side and back lighting when planning a display. All for now Cheers

- 57 replies

-

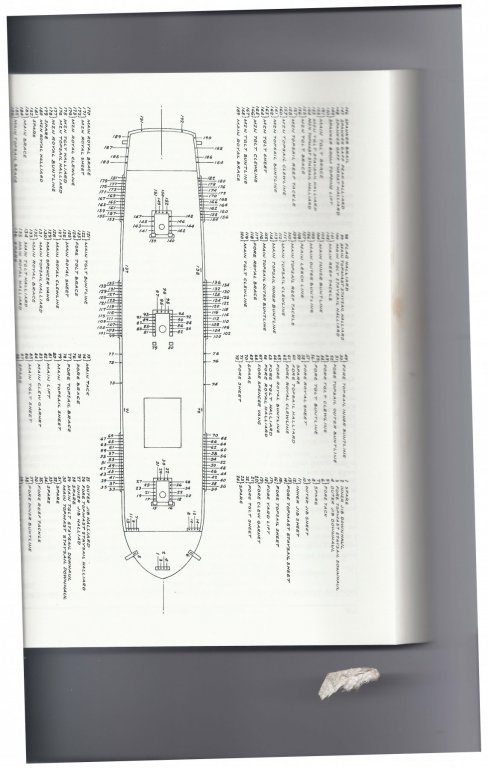

Post 2 The hull part 1 I am feeling my way here so I am not sure how far we may go. There is a lot this hull needs but if I go crazy one might ask….as Roger already did ask…..why am I using this old hull, it seems more work than carving a new one........I can attest Roger is right. So let’s try better to stay with the basics Easy ones The red paint must go! Then the decision to add either yellow metal / copper plate as was in vogue according to Crothers on most ships / freighters of the time. He also said that some yards sent them out painted and the owner then added plating and other items in dry dock before her first outing. We shall try to do more research on whether copper was part of the Boothbay Scope, but for now I have no reason not to include it. So for the choices, we will first clean up the rough spruce log look and paint a simple light green to simulate patina copper/ yellow metal [ contained more tin I read] I will share a fun experiment that I thought I might try when it comes. The teaser! lets look a a little progress on the hull Ap-006 So the first thing I did was to cap off the hull with a simple sheet stock decking. I hemmed and hawed about stain colors and ended up with gunstock. A bit too red for some but with sheet stock the grain comes through and blows the scale, so I went dark. I then after one coat of poly added pencil lines on the joints and cut all planks to be 12 feet on three alternating rows. I say all this hoping someone says right or wrong. Please note the added 1/2 poop deck that matched up with e focsle deck on height. The block cut outs are for cladding the deck houses again as per the Alna deck layout plan Ap-007 The second thing is to get the masts laid out and drilled. I want to try to reuse the old ones and their methods was a minor countersink [ 1/16”] at full diameter and a pin. Here I laid out the rake per Crothers on the yellow graph paper and aligned/ shimmed the drill and hull to be square for the pin hole. Ap-008 Here is the first bulkhead. It is ¼[ 2 feet] with waterway inboard. That is 1/16 too low but here I am compromising to fit the preordained low focsle deck. More on that later Ap-009 I had to use lead weights to bend the bulkhead to the existing shear. i wanted to get it in place before fixing the hull...that has several problems Ap-010 just as an import glance I want to share the existing spars that we need to study. I want to rescue them but there are a few dimensional issues. The good news is when I took Crothers dimensions to locate them, the fore and Main mast feel in the same hole almost perfectly. The mizzen was a bit aft but that makes perfect sense as there was no poop deck on the original model, and the rake of the mizzen mast moves the opening on the poop deck right back to the right place. this is good news. All for now Jon

- 57 replies

-

Thank you guys for putting a great perspective on this build....the broom handle I mean. It is going slow right now as i just have a few too many things going and yes I just ordered copper paint patina kits to experiment with......oh my cheers . jon

- 57 replies

-

Thanks Tim Bertha Downs is incredible . Please consider buying the very complete book on the anatomy of that wonderful schooner One might note that more than 10 days to reply shows I have too many irons in the fire. here I am trying to keep a pace of slats per day. i will get there but 15 a day is tough as there are to many o days. I am also fixing up two schooners, and completing the Bowdoin diorama all for may. then I started another ship! i must be nuts...spring clean up is around the corner and we need to get so much done cheers jon

-

Thanks for the comments. first to Roger.........Thanks for the question because to answer it helps me form my rationalizations and think ahead. This old model was being thrown out by the Maine Maritime Museum. I am trying to give it new life and along with other builds refocusing all to replicate what was built here in Boothbay. I agree that there are several issues with this hull like: the shape of the stern. It should be a "round counter stern' per Crothers. I did some minor sanding to reshape to simulate but not yet achieve even a symmetric curve . I am considering using my oscillating belt to also bring in the end to achieve the counter, but it will not be perfect. The rest of the hull however looked good to me other than two bulges at the bow that I knocked down. the height of the focsle deck is definitely too low. It is only a few feet up and I believe it should be a bit more. the data says the top of the combined bulkhead should be 4'-6".. I will be pushing the monkey rail to get to 4 feet. I want the main rail to tie into the water way for the upper decks as that seems to be the way in the Crothers drawings. the monkey rail then just flows all around. I chose to build up the half poop to match the low focsle, so it comes together in the rails. The cabin I built is therefor also low on the main deck. the correction might have been to carve main deck down, but I felt I am recusing a model and need to relax a bit. my intent is to openly declare what I determine is wrong. I plan to try to breath new life into he model and help a friend who owns it. I also have much to learn from the build and that is big for me. I will spend a few months learning how to work at a new scale for me 1:96 and to do square rigging. I am truly a schooner guy but a little ship learning could help. thanks for following and please help me when you see stuff i miss Kieth i appreciate the help i have gotten following you builds and the few exchanges on upper sails. I have a pair of Canadian 5 foot schooner models in my shop for repairs for our little museum store opening in May. One is Bluenose and the other the Zwicker [ formerly of Boothbay ], both built in Lunenburg. I will post some views , likely on the Bluenose log, for fun and it's a place for me to record them. Like this model they are "Folk art like" cheers jon

- 57 replies

-

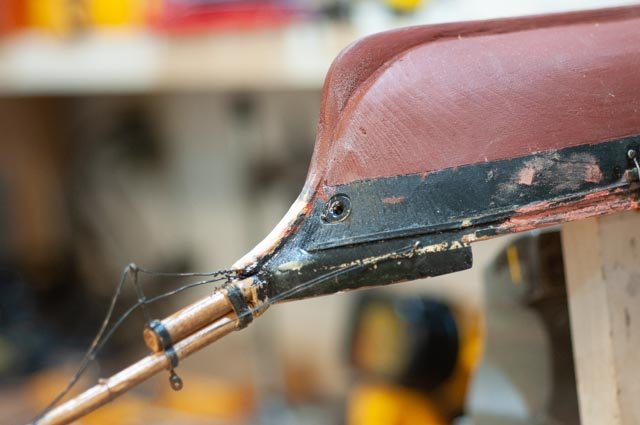

Boothbay Maine 1853 ship Aphrodite 1:96 Post 1 The beginning A friend has been rebuilding his Bluenose schooner in my shop for three years. The other day he came over with a broken-down old ship model given away by the Maine Maritime Museum. So it stayed on a shelf since last fall. Now that we are on a quest to build up models of the schooners and ships built in Boothbay, I got an idea. Do some research and come up with a Boothbay ship or bark that in a known scale would be the same size as this model. There is a wonderful book called Shipping days of Old Boothbay. It is available at the Boothbay Region Historical Society. Not only does is follow families that sailed out of the harbor it lists in several sections much about interesting ships, barks and schooners built here. On the chapter about barks there was one candidate that at 800 tons could have worked. It was however not typical. Of the 6 barks built in the main period of the 1850’s listed in the book 5 were all 400 tons or less. The Charles Lewis was 745 tons and built in 1875. She had a long life too…maybe next time On the chapter about ships, again there are about 6. The first one, built in 1853 was the Aphrodite. She was 680 tons and 147 long, 31 wide and 15 deeps. She was built by a well-known builder Stephen Sargent. She sailed far a way and then was lost off the Azores. Perfect size as we took the measurements and found a match with our derelict hull at 1:96 Next up is to find some design. I was very impressed years ago buying a book by William Crothers on Clipper ships. After a little search I found he published a book…American Built Packets and Freighters of the 1850’s How perfect!! Oops it was pricey, but the hull was free so why not. I am so glad I got it…wow what would you like to know. In the index they identify Alna a ship of the same size built in Maine in the same year. So why not that is my data base. So off we go. This will not be a long build but a fun learning experience. We shall reuse what we can, but I suspect most above the deck will be new. Unfortunately, we forgot to take a picture of as is. Trust me it was ugly. The hull is a carved soft wood with minor applications. The cabins were just blocking and the rails 1/8th thick, so as the queen said, off with their heads. Here you see the dead eyes wire loops were wrapped with like No 17 brads. The figure head was a large clown…yes a clown… goneso. The record of Alna only listed the carved and gilded Billethead. so I will thicken the stem to form a billet and add some stick on tape with gold filligree The stern was sort of round. Looking through Crother's book, there is a rounded stern that was typical of the era and listed to be on Alna. Also there was no poop deck. So after days of reading and thinking, we are adding a ½ poop deck based on Crothers findings. Here we have removed most everything and are cleaning up an under-deck. You can see the crudeness of the remaining bow and taft rails removed after this photo Here a little of the glazing putty to try to smooth out an under deck. there are at least 40 toothpick tips glued into old large brad holes to be sanded as well. When I laid out Alna masts, two matched perfectly an the mizzen within a 1/16. adding the half poop pushes the hole aft so we match there too. the fore deck extends aft and that is good because we gain an overhang All for now jon

- 57 replies

-

It's time to bring Charlie out again. I plan to record this as the final chapter in Charlies build and use. Maybe then I will say...completely finished This summer I plan to give a few lectures on the four masted schooners of Boothbay. Although Charlie was built in Bath in 1894 she is right there as to the size of the last several large schooners built here. The boom years were 1919-1921. During that spell, 10 Schooners were built right here. Next fall and winter I plan for trying to organize a diorama showing one of the yards and two of the schooners. We shall be celebrating 100 years since the launching. That yard has been a great lobster wharf for many years. i will start that as a new post later this year and hope to get other folks to build buildings and the lay out. Here I will update the repairs and completion activities to get Charles Notman ready to show off, and some of the highlights of the history of these schooners here in the harbor. If you go back to the first few posts in this log, i built Charlie to be a prototype. I had hoped to build two sailing versions and get them to sail in the harbor. The problem is they really do not sail well as RC. Therefore I will move on and try to get some normal two masted schooners to sail as there are many examples of the success they have in RC. Boothbay had many pinky schooners and a large sardine and off shore fishing fleet to chose from My punch list consists of the need to: complete the starboard side shrouds.here i am splicing the first two of six to go. complete starboard ratlines..ugh lots of them repair yawl boat and its broken support clean and clean.. wow the dust try to coil and hang lines. add a few missing windows and cabin details repair several lose lines and broken chains figure out transport. complete some graphics for the display complete power point lecture In conclusion I will include a few visuals of a few schooners i am fixing up for the new museum store. I believe just a little each day and it will be OK . I need to complete all by May cheers jon

-

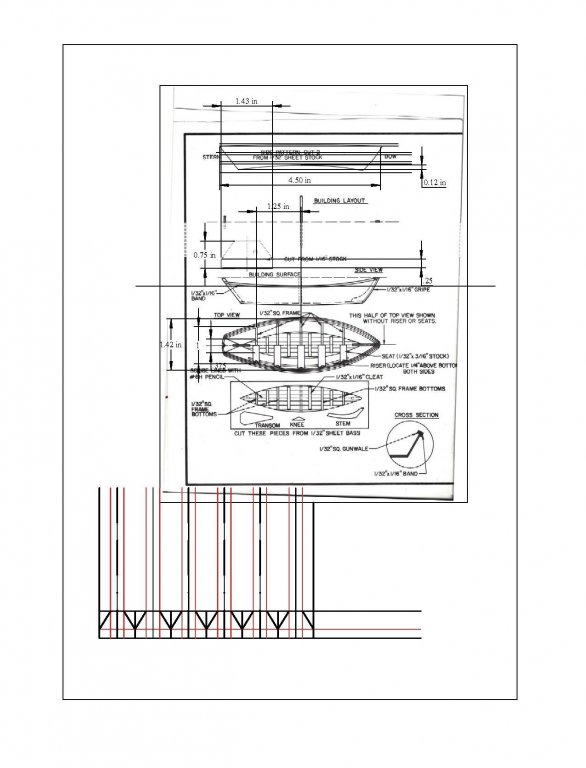

post 35 dories part 2 I was determined to succeed where I have failed so many times before. Or better said ... I wanted to get the dories closer to what they should be. I remember being told by a master modeler that each time we start a new venture, we should expect to need to make 14 tries before getting a keeper. I am somewhere in the middle of that, so I do ask for some slack. The goal here is to spile some thin enough planks to bend at this small scale to make 16 foot [4 inch] non lapstrake dories. Let’s see how I did. First of all, we look at the boat yard where the first dories in part one were made. We need to complete them for at least a stacking opportunity on another schooner. Second, we need to work around the shop to find planks that are thin enough to bend. the bass wood cut in this photo is just too stiff. Here we see a friendly BRHS archive cropped photo showing clearly the later 1920’s dories. They were smooth and white with dark gunnels. So back to turbo cad to lay out both midpoint molds and to figure out the spiling curves as best as I could. The third point molds ended up being simple dimensions to make up. I printed out a strip on the bottom of the sheet to lay out on a ¾ inch strip to make them all at once. All the horizontal lines on the top gave me a clew to figure out how to get planks just more than ¼” wide that would work. As I laid out all the molds, I added gunnels to the old dories and made up new bottoms and parts. I used 1/16” plywood to make them strong. Here I am gluing up the transoms and stems as the gunnels set up on the old dories. To make the proper flare we need to force the lower planks around the molds. Glue on the bow and let it set , then bend it around. After setting two planks, I learned to remove the partially build dory from the molds [ this time using masking tape to allow breakaway. Then using every kind of clamp, I could work the top planks keeping the flare and making up the smooth[ish] joints. Here we glue to the bow stem before the bend Another clamped third plank. After glazing putty and sanding and setting the four ribs on the insides, we get a coat for gray for priming. Then more light sanding. The first one gets its first coat of white. Diorama I have added a second dory under way to bring the last of the winter gear back aboard as we are a day or so at most from sailing. My figures only stand so I am figuring how to make his action reasonable. I am thinking of either a small line and anchor on the ice or just use the oar to hold position. Here I have re staged the offloading of boxes and added two more figures. as of now i am not going to attempt to paint the figures. One reason not to paint them is their costumes are the correct period, but they are not sealskin, bear skin etc. I hope to encourage more support for opportunities like figure for the next diorama. There were 6 crew plus the Greenland and Labrador Inuit and dogs all getting ready to sail. There is more cleanup and punch lists to do, lines to coil and hang and surely repairs between now and the show in May. I am already working on three other projects…so the beat goes on. I will add a few more posts as we go to the show and I prepare the inevitable lecture. There will be some tours and review down at the Bowdoin college campus, where the MacMillan arctic museum display is always available. I still plan to visit the John Gardner model at Maine maritime and will add photos here. Finally i want to get the skipper over here and then find a way to ride on Bowdoin next summer. Next up is back to an old build…Charles Notman to get ready for other summer shows. All for now cheers

-

Andrew I love the look of the finished sheathing. The paint job is really crisp. Cheers

- 106 replies

-

- bowdoin

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.