-

Posts

857 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jond

-

Keith I continue to be inspired by the clean and crisp imagery of your build. Now watching you go through figuring out how the rigging works I love it even more. One of your comments was about tacking the topsail. I have read several different approaches. The 4 masted schooners used clew lines to gather up for top mast furling. It was thus a two step partial raising by clew line and the tack lines p&s transferred to allow tacking across the spring stays, lower gaffs and peak halyards etc. Bluenose has clew lines but the stories tell of a brave crew member staying aloft to pull the sail over and transfer the tack line while racing. If the topsail is raised from the deck . Perhaps having a double tack line would be enough to pull the sail up and let it flow over. Perhaps a lighter traveler line could have been rigged to pull up the tack ( opposite action of the jib down hauls) Anyway I love learning more about how these boats worked. And I love learning from logs like yours Thanks for sharing Jon

-

Fix the main boom lashing Now that I have the main boom available for my thumbs, I needed to remove the spiral lashing. Let’s see how it went. · Here we see an image of Bluenose ll main boom under sail. This is the image that I am trying for. A few exceptions however, as I have figured out this rigging is not identical to the original Bluenose. The lashing looks right however, so that is step one. · Here is a detail and it shows the lashes wrap under to a square knot and the ends then tuck through a single strand of the line on either side. You can also see the outer topping lift line passing forward to the pin on the port side jaw. Please remember this image when we move to lazy jacks. · Here the boom tackle gets tied up to avoid sagging. · Here you see on the model I had fixed the first lashes aft of the main sheet bale. · Here is the needle tucking the end through. Most lay perfectly parallel but some are stubborn. Wax helped, though I fear more fabric glue will do the trick. · Here is a challenge. Like previous models I had staggered the jaw holes. That is wrong, and I shall plug them and align them as I go. · Here we are with the lashing done and the mast re-stepped. Oh for the breakage…..chuckle Remember the little top mast extension. I chose not to stress either dowel or mast by using a brass pin. I used a tooth pick to pin it so that the tooth pick would be the weak link. I was right; even the weight of the light strings and the waving around was enough to break the tooth pick. So far so good. when i was moving the whole boat for cleaning up and the camera hit the for stays, this tooth pick broke again. It might be too weak a link, and I need to think about it, perhaps plastic tooth pick. For now though it's easy to fix and it causes no mast damage.[ I do not glue this connection] cheers jon

-

thanks Patrick It is hard though on the great fall days to blow leaves , set up firewood and come inside and be careful. oh well it is all fun cheers

-

Thank you all for your concerns regarding going back together after demasting. Before I posted the demasting, I completed several upgrades on the boom , installed what I call the mast boot and put her back. It works; yes with some breakage and other issues I shall share. It definitely is not for once a week but may let me set the detailed lines and things aside and then add simple masts and sails just for sailing. More on that as I work it through. At least I can transport her to the Owls Head Museum show next march, and now have a scheme to let her sail if only once. i chuckle to see insanity listed above as a suggestion of my mixing scale with sail. I am using a new word...analidity to describe some of my plans. But that is what this is all about. Anyway, each time I move stuff, something breaks. Today the camera tripod fell on the bow sprit and broke a clip holding stays. Fortunately the 'sailable' bottle style turnbuckles are strong and the replacement was a simple brass founding. anyway I am struggling on a few things today [ remaking the main sheet bands to be correct] and hope to update in a day or so. I plan to remove the foremast next week. cheers jond

-

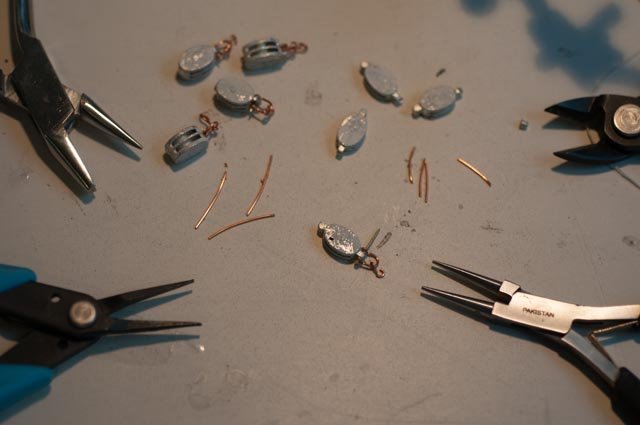

Take out masts I had an epiphany. If I improve the bolts on the chain plates and critical shackles, I could remove: · 20 bolts on shrouds · Three turn buckles on stays · Three sheets [ add bolts in shackles] · Cross stays above [ add bolts in shackles] · Jumbo boom gooseneck figure it out add bolt · Back stays two lines and deck blocks for each mast · Halyards, whips, boom lifts etc . say 20 lines now 30 lines later In maybe an hour or so I could remove the masts. I am not sure where this is going, but just to make some improvements on my current lists I need to get the masts out, so let’s try it. this could have been a big oops let's see how it went. I ordered more small bolts. i chose the 0-80 as they are a little more robust and if they are going to come out and go back that is important. I had snipped them to length. That crossed up the threads to help keep the nut in place, but that prohibits re-threading. In this photo you see I am trying new bolts at the right length. First on the left shroud is a new 1/4 in bolt...too short. The right shroud has a 3/8 bolt...too long Oh well I should have known no standard sizes would work here. Now i have two more bags of mini bolts. Here I have filed and chased the threads with a die so the right length bolt is ready to go Here i demonstrate the use of two mini bolt sockets that make this a reasonable option, especially if this is to be done and redone. You can see the black paint falls away from the brass, but that's no big deal as I am constantly going to be touching up if i choose to move this thing. here the first set is off and bolts saved in the plastic cup. yippee! I normally end up on the floor looking for that errant nut. Here I have untied and grabbed all the lines tight to the mast. simple masking tape to hold things from getting too messy. Now lets start working on upgrading those sheet blocks to see where a simple nut and bolt is all that is needed to disconnect. this is 0-90 bolt. Here is better view to the spaghetti taped to the mast. wish me luck on this one please. Now for all those cross braces. i like the idea of upgrading these shackles and ties through the bales to 0-90 bolts and nuts. I continue to use copper instead of brass for the bales because as here , I effectively chase threads into the copper as I install the bolt the first time. I suppose i could tab a bent loop if it were brass, but I find it too difficult to bend the brass as it is not fully annealed. Since I am painting it I currently stay with the copper. Well here we are finally ready.....Shall we lift the mast???? It came out...we'll discuss what happened when it's time to restep. not too serious, and if we made it, we should be able to fix it right?? cheers Jon

-

Nils i thank you for dropping in. You are just in time to here about my new idea of what to do with a model that is 7 feet long, six feet high etc. stand by jon

-

Keith Thank you for you encouraging words. It is your build that fills us all with awe. I have been inspired again thanks to you to try to use soldering and my late brothers Sherline to actually make a fitting. I need to have more bolted shackles connecting things as I am going to figure out how to remove and reset my masts for transportation. The copper wire bending only goes so far. I also note your use of brass wire for hooks. I struggle bending the brass but it would be stronger. Cheers Jon

-

Patrick you are too kind as usual. when I look at your interiors on you pages I am stunned at the patience and steady hand you have. an that is real detail. as to 1:24 scale detail, I am in the awe stage... possibly also known as the upper part of the Rabbit hole i have entered. Like do I need to redo the parrel through the front of the boom Jaw? anyway thanks for following jon

-

Derek. many times I cheat when bending planks with little to hold them. I soak the plank in ammonia water for a while ...not too long say an hour...then put a few in place with clips [ much less stress] and let them dry. they don't have to be perfectly fit as you are trying to get most of the bend into it. I come back the next day when they are dry and they glue up with much less fuss. I also bought long pins with little plastic ball tops at Joann's. I drill down through a part [ it could be rail I am bending or post and on occurrence a temporary laminated plank that gets removed afterward] then temporarily pin it in place. If it's stubborn, I CA the pin too.....then if too hard to remove pin, I cut it off and leave it in. I used this to build most of my waste planks, monkey rails etc. I know my model size is bigger and if i sail her strength is more important so some of my pins stay in for that purpose..... but it worked what your doing looks great....good luck getting through this step. I believe it is one of the tougher stages of this build and yes that often means twice. It sure did for me. I am redoing many things as i learn. cheers jon

-

Add back stays to rerun halyards on the main mast: I mentioned in an earlier post that I found in Lunenburg that most lines are a rich tan colored hemp traditional style. To replicate that I went to the Montreal hobby store and got several sizes of their tan lines. Rigging lines on board adds a challenge for making splices. · Here again I have set the spare hands on a stool and after running lines feed them out to allow splicing. I then pull them back through and make them off. · Here in order to make up blocks for the back stays I am adding both shackles and hooks to the Bluejacket blocks. I then paint the blocks white and the copper silver for the galvanized. There is some confusion in photos because the Bluenose ll chose for natural color on all blocks and black paint on all of the metal work. I have decided to take the forged rods on mast bales and the like and repaint them black but am keeping galvanized look for the fittings and bands as the lower deck photos hint that to be correct. This is a choice as there are not enough old photos especially with the rigging to clarify this point. Here for the record is a block from Bluenose peak halyards. It shows the white paint and light remaining galvanized roller bracket on top. The block would be upside down as the roller rode on the "wire bridles" as named by Jensen" lines spliced to the gaff. · Here we see on the rail the throat halyard whip and the back stay. I chose for now to have one back stay here and the port side in the aft position. That is important, so the lines are the right length. With the throat whip to starboard, the throat main halyard drops to a block on the deck on the port side. Here you can see the crew feeding the main throat halyard for the final step of raising the sail. The Black braided halyard went through the large deck block and ran forward to the winch [ capstan] port side. The peak Halyard ran forward similarly on the starboard side and you can see it on the deck past the mast. The gal standing at the right of vertical halyard has 'dogged' off the halyard with the lanyard. the hitches are just below her hands. The Lad is taking the halyard off the winch and making it fast to the forward pin. They then coil the halyard that had reached the forward capstan on the deck next to the mast while sailing. The white braided fore sheet on the port bitt. These deck blocks do not typically show on model plans. They are also used to raise the top mast. The fore mast is a little different and I will share that next time. I thought it to be reasonable to share a photo of the main competitor to the Bluenose in the 1933 and 1938 races, the Gertrude Thebaud…..Gerty, as she is displayed in Lunenburg. She has been moved and now lives close to the trophies honoring the races. Many details are similar, though she was smaller. It is a great model to study. cheers jon

-

I see reviewing this that the parrels project from the front of the jaws. oops I have to think about that one, maybe just a 45% hole? cheers jon

-

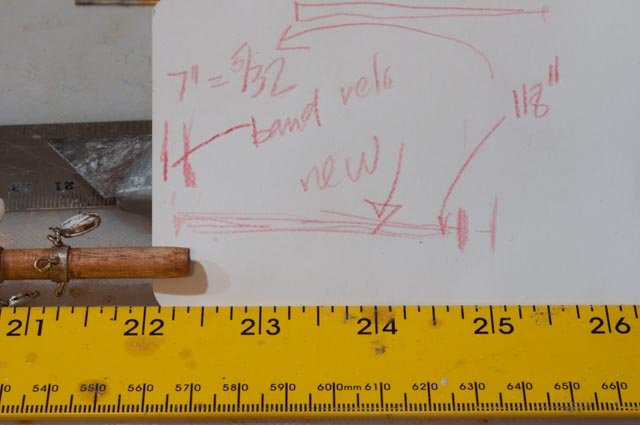

This posting is to record two more items on the list of corrections involving spars Jaws and parrels · Here one sees the correct dimensioning and counting. · The model plans had very long jaws. · Here you see the extension forward of the mast. The Jensen plan gave much tighter dimensions and the pencil mark is right. · Here you see the large beads I used for 7 balls on the parrel. The size and number for the main was smaller and 9 each. · Here is a the main fixed · Mid main boom topping lift. This goes lift up slightly forward of the main sheet band. Model drawings did not agree, some show common with the main sheet band. · Here we see the proper fitting for the mid topping lift on the main Boom. Note the two horizontal tabs and vertical bolt leaving a gap of about 3-4 inches. There is a bent figure eight ring angling upward to carry the spliced cable boom lift around this bolt. Behind the bolt the outer topping lift lead is fed on its way forward to a pin on the jaws.[ port side ] · See on this photo there are two becket cables wrapping the mast above the second band. Two small ears support the dead load before tensioning the lines. · Here we see the ring on the model based on not having enough information. I had two rings to pick up the lift. There is also confusion on the model drawings that the Jensen drawings correct as to where these lines go. · Here we see the corrected band with figure eight bent ring, shackle and spliced steel cable. Now I need to figure out the baggywrinkles. They are about 1-1/2 inches long and roughly a ¼ in diameter. · Here we see the just installed top blocks on beckets. The paint on the blocks is being touched up before I run the lines. onward we march cheers jon

-

Thank you Johann we are trying and learning so much, but I have so much more to do. I looked at your video and found them so inspiring; the crispness of the metal work ... wow. thanks for looking in and thanks for your sharing jon

-

Thanks for these last black smith lessons. The way you support pieces as they are set for braising makes good sense. It inspired me to try harder. Thanks Jon

-

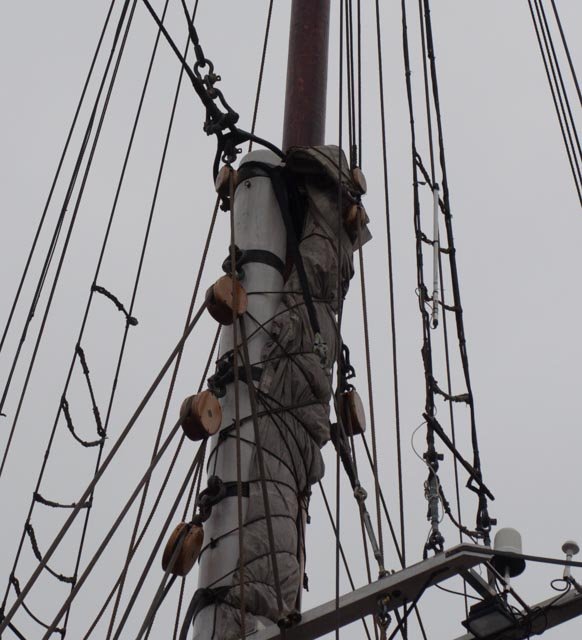

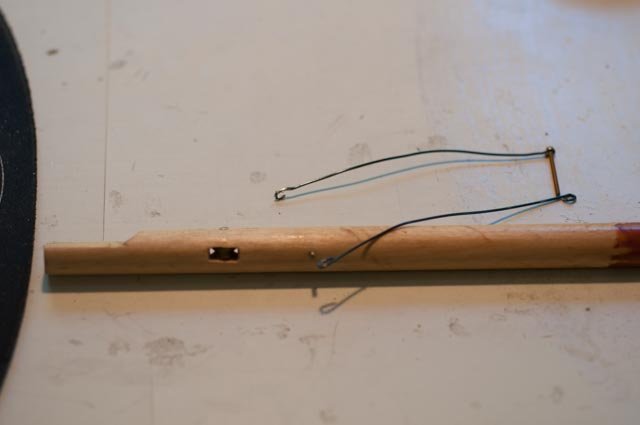

It has been a few weeks and I have used the old trial and error method more than once. I also went to Arizona and road on a mule along the south rim of Grand Canyon. please believe me; that was not my idea. It was pay back for her going with me to Lunenburg. Today I want to record the several items entailed in my effort to bring the masts up to snuff regarding the need to be close to true detailing at this large scale. This post affects the top masts. First lets look at Bluenose ll and refer to the newly aquired Jensen plans · Here is a cropped photo taken in 2014 of the fore top mast from the port side. The black clips forward of the top mast for furling the topsail are clearly shown here and on the Jensen drawings. The drawings show seven, but the photo shows six. One can also see the black rod that grabs a through bolt carrying the top mast load up to the mast cap. On my model I had attached that rod to the second to top band as had others in the Lunenburg models I saw while there in 2014. A very small detail I learned while talking to the Bluenose ll captain the night we arrived. The small blackened hole at the bottom of the top mast, just below the bolted rod is the Canadian style fid. It is a drilled hole slightly chamfered and blackened with a hot iron so the boom hoisting line will run through. The American schooners inserted a sheave at this point to facilitate raising the top mast. A becket cable [ double ended spliced cable] with two blocks are draped over the mast cap to carry that line when the masts are set or lowered. · Here is the same top mast in 2017 from starboard side with the top sail furled. The furling favors the starboard side. There is also more clarity in this shot of the iron work holding the jumper stay and main topmast stay to the mast cap assembly. also note the rings holding hooks on the large peak halyard blocks. · Here we see a cropped photo of the main top mast. There is a significant shoulder in the mast. Here they painted the top section white and the top ball gold. Looking at the Jensen plans I learned the disk at the top of this section holds port and starboard sheaves for flags. The flag is on its own spar and run up to the disk. · Here we see the fore top mast. A similar detail with a 5-foot extension above the shoulder. On both masts, all for the stays and shrouds are spiced loops draped on the shoulder. · Here we find the jumper and top mast stays are each made of two pieces joined at a fixed block. I did not get an explanation why as they are made up as the mast is raised. The main fore stay by example is made fast before the top mast reaches its peak position. · Here we find a cropped detail of the gate holding the top mast in place. The whole thing is very tight, and I need some work if I want the top mast to come out for travel. Now let’s look at the model and see what I had and the fixes · Here is the fore top mast. Based on the modeling plans small iron bands and many eyes are placed at the top to carry stays and shrouds, halyards, clewlines flags etc. oops · Here is the main top mast note the lack of significant shoulder needed for looped shrouds · For the first fix, before removing things as I was still dithering on how much to undo, I made up the three small cable connector blocks. · Here the first one is connected at the desk top · Here is the first one in place · Here all three are done and in place……oops too early as I finally decided to do much more. · As part of this process I got out the serving machine and started finally to us it. I seized about three inches of each top mast pair of shrouds and then made the loop and over wrapped to make the slice. It’s a good detail, but I do not think very visible at the top of the redone masts. It was however fun to learn to do. The first ones are sort of OK like everything else it takes time to get them good. I also just read an article suggesting using varnish instead of fabric glue. I want to try that Now the top masts. They needed to be rebuilt. The Jensen drawings gave me much more detail. And I needed to remove damage from have installed sheaves. · Here you see the bottom of the main top mast. The sheave is there and the rods that held to the band on the main mast. · Here is the top with all those blocks. Note there is no real shoulder and reduced top section nor a disc below the ball. · Here I did a measurement and decided that the top 5-foot section could best be attached. It is to be a pinned dowel. That better reflects the shoulder that was not evident in my current mast. · This decision allowed me to cut off the offending bottom · This is the new shaped top section of the mast. The Bluenose ll is painted white. I will not paint it but leave is natural like the bottom of the main mast that is visible in the old photos This is the point of decision. I have been convinced for some time that if I could make the top masts removable I could figure out how to transport the 4-foot-high model. Perhaps even display the main top mast being erected. · So here is the possible set up with the main top mast being lifted. · Here is closer shot where the shoulder is holding the new shrouds in place. There are still two blocks, forward for the fisherman staysail and aft for the top sail. The topsail clewline block is sewn onto the sail, and the two flag lines use the sheave in the disk. The disk is a copper washer with holes drilled. I have yet decided but as of now no gold paint is going on the ball. · This is the same picture just in the early morning with the bright Maine sunlight pouring into the shop. The Jensen plans show the furling clips on both masts. I have a 2014 photo where they were not on the BN ll main mast. With the topsail furled in 2017 I can’t tell. I decided to keep them based on the redrawn plans All for now cheers jon

-

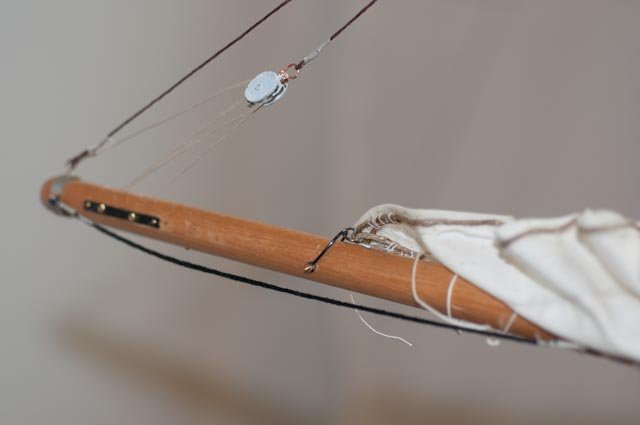

I couldn't stand it...I must be nuts I went ahead and rebuilt the boom end topping lift band with top tabs and ring and added the shackle as I upgraded the line to a tan twisted line for the outer boom lift. I also started replacing the sail lashes with the first three also using a tan line. The ends are spliced through using a fid so I simply sewed them on either side and left them loose. It will be really hard to do the rest now the boom is in place. Other than the more beat up color of the Bluenose ll boom, the brass fittings needing black or silver paint and the over sized bolt rope, this photo now almost looks like the real thing. I need to move on or I will be remaking the sails.....argh I also need to get back to figuring out how to do the baggy wrinkles at this large scale. cheers jon

-

Here is the first in a series of clarifications or corrections made based on the recent trip to Lunenburg. I shall post them as i complete them. Both plans by Fischer and Eisnor are vague at best about the outer boom lift, mid boom lift and lazy jacks. They both indicate a sheave to be side mounted on the boom. Eisnor shows no outer boom lift. The photos I took in 2014 did not go that far aft on the boom and the archive photos are not clear on the rig at all. Another detail is the clew of the mainsail connection. it is not clear on any of the plans or photos. The fisher plans did show the outer boom lift with side sheave leading to cleat perhaps 20 feet forward. They also show a reef tackle line cleated near the end of the boom. Here one can see my progress on the model included a side sheave that I have temporarily used as an out haul for the main sail. this approach is wrong. Here is the detail on Bluenose ll. It's interesting for a few reasons. Note there is only one through bolt holding the forward sheave. Also there is a shadow suggesting a larger diameter hole through the boom at the aft sheave. That suggests a through pin welded internally and possible installation of that sheave first in sequence through the side. There is also a bolted bail holding the mainsail clew at a fixed point. In the larger photo all the remaining aspect of the outer boom lift is shown with the large line shackled and the smaller line spliced directly to 6 inch ring held by a pin through the vertical band tabs. Also there is no evidence of the reef tackle being rigged either here or in other photos while under sail. They did have an effective down haul on the gaff head used as well for the flags, and that was cleated to the boom. They pulled on it while lowering the sails... more on that later. Here is my solution. I show two through bolts for the sheaves. I have used a temporary ivory colored line through the block and sheaves and it goes to the pin in the boom jaw port side. The boom tackle line I needed to move over to the starboard side jaw pin. i have ordered more tan lines to upgrade this installation. I am debating if i need to modify the end band to have two vertical tabs to house the pinned ring as on the BN ll. maybe later . I did use new #90 thread bolt to hold the bail for the sail clew. I now know that I have to un lash the main sail from the boom and retie individual lashings using tan lines....a future punch list item. cheers jon

-

Dave Sometimes the trip also confuses. I love your choice of more heart like upper "dead eyes." Bluenose ll has them. I also like the fact you made them. I chose to use the Walnut premade ones for strength. They are round. I keep looking at the old photo and can't tell for sure if they were round. The bn ll folks also seized the whole wrap and painted it white. I am going to an exodic wood dealer in northern Maine for other projects in the next month and try to get some walnut blanks. I may try. It is an item on the list I may get too. Cheers

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Dave I just caught up and wow you really did a great job on fittings and rigging. i chuckled to see .... yes 100 days off....good for you. summer is over and it's great to be back in the shop. cheers jon

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

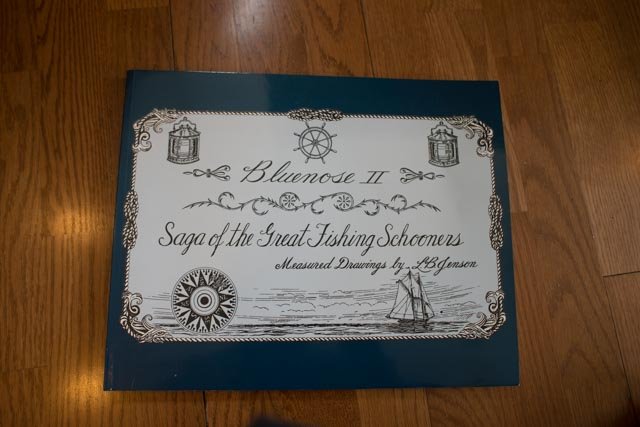

This posting ends a long phase of my work and introduces me to a whole new era.....I hope anyway. To all those lovers of big schooners like Bluenose, Gertrude Thebaud and the rest all I can say is two trips to Lunenburg is a must. I mentioned early in this log that we made a visit there in 2014 as I was getting going. We saw the Bluenose ll that had recently arrived at the dock after her 2012 rebuild. The team was still working out items to get ready to be recertified and then resume sailing. We then saw all the wonderful models in the museum, bought a few books and I was prepared I thought to get into this build when I resumed it last year. Over the past several months as I dug deeper I found the Nova Scotia archive photos of the real thing or my photos of models or BN ll from 2014 were lacking in many details. I also did not understand the synergies between the original Bluenose 1921 and the replica built in 1962 as it applied to the rigging. I learned early this year that they offer 2-hour sails and wow was I in for that. I started detailing questions and needs for new photo research. This September we went and had a great stay in that beautiful town. Our sailing day was to have been the 28th. We learned a bad weather day was coming so fortunately we bought extra tickets for the 29th. We arrived on sept 27 in the evening and learned the sailing was already cancelled for the next day. Walking down to the dock after dinner, we met Captain Phil Watson the skipper and had a great dialogue. example he explained that to lower the top mast they string a cable becket over the mast cap with two blocks. then the 'fid' the hole through the mast is drilled and burned with hot iron into a curve so the lines feed through. This detail he explained is the Canadian solution. The American schooners inserted sheaves.....My mistake 1 of 21 was to have already installed little brass sheaves...oops I need to repair and will record. Captain Watson then confirmed that yes of course the old Bluenose as well as other boats this big all use their gas engines to lift and drop the big sails and the top masts. Those lines of men in the photos are hauling up topsails not the big ones. he agreed with me the top mast shrouds were moved forward and a sixth shroud added due to coast guard requirements; thus, BN ll is not rigged exactly like plans for Bluenose...yeh I got that one right. Overall, he said I would not find other variances as they are serious about maintaining those items. Example: the aft toping lift sheaves are in the boom and not on the side as shown on Eisnor plans and invisible in the archive photos. more importantly to me, the crew on duty saw me talking with captain Watson, so I could ask them anything. I must say they are a great bunch and study or no they make it a wonderful outing. One lad was happy to demonstrate up close how the lanyards are used to dog off the halyards to hold them while they are removed from the windless capstan and made off to their bitt or pin. the next morning, I came down early before the rain started and spent an hour on the dock taking many photos of what I did not get in 2014. I then went on board and spent another hour. Several of the crew were great confirming how they rig the fisherman stay sail, topsails and identifying a mystery extra line just for lifting things on deck.. The Blocks made to staples on the deck for several lines do not show an any plans, the chains and cables used on jib and jib topsail sheets were great to see as they are stowed. The sails all furled and secured is how I plan to do the model so this was extremely useful. Who new…the Jumbo hanks are lashed to separate rings on the fore stay….more rework for me. I was able to photo everything and label them in note books. I could never have done this with 65 passangers and 18 crew sailing so I was very lucky for this rain day. the rain then came and we were off to the museum for great research and lunch three people on board and in the museum, all recommended I buy the book by LB Jensen. I chose not to in 2014 simply because it said Bluenose ll. When one reads it it explains the level of care that was used to make Bluenose ll a real replica so all the measured drawings and details are real. This book is a real need for a scratch builder wanting to focus on rigging and really understand how these boats worked. It is available either through the museum store or the Bluenose ll store on line. I bought several other books too as each one seemed to have additional photos and insight to the life and beauty of sailing. The next morning wow wow wow Time to raise sails What can one say! Sailing out from Lunenburg Captain Phil Watson giving sail down orders Nine crew members furling the main So what is the next phase of this build The short version is I listed 27 items where either the plans did not explain, or in a few instances disagreed with the real thing. Again, the plans I refer too were drawn for either a 1:64 or Eisnor 1:48 scale model. My effort at 1:24 needs to get a lot more of the rigging right. I will write up many of the items, showing what I thought or where I was stumped, what saw or learned on this trip, and ultimately what I do in my efforts going forward with the model. I have so much to learn and it is so much fun. cheers Jon

-

Patrick thanks for your kind words. as you will see in upcoming posts I went to Canada to ride on Bluenose ll and learned so much about the boat. I am thinking more and more about being sure about making the rigging work. also to be able to move it around I have chosen to furl the sails. thy are full size and it is possible to unfurl and raise them and go for it and I may do that some day. But weather is cooling down, so we are back in the shop more and look forward to learning to make more parts. here we are last week sailing in Lunenburg in almost 20 knot breeze cheers jon

-

Derek I just enjoyed going through your build. I too have run into many similar issues with kits. I broke many stanchions and also chose to cut them off and start over. I put in enough to run one or two planks. Then I used the planks to help align the stanchions. Then it went quite quickly. Also a drilled hole with pin vise locates the scuppers from the inside then a square small file makes the holes line up from the outside. It is fun to follow along. The seizing looked great! I have not mastered Chuck's machine yet..you have inspired me to try again Cheers Jon

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.