-

Posts

2,861 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

THE CABINS LOOK GREAT! I just watch a two short videos of the cori robotic knee replacement surgery... got my GDD (Google Doctor's degree!). I'm guessing it will be a quicker recovery with this procedure. Hoping all goes well and your back jogging in no time.

-

Sometimes I find the small restricted area fiddles with my mind to make it more difficult than it should be. I also find carving on end grain to be difficult. I find that if I take a slightly larger piece of thin stock and rubber glue that to a base piece of wood that is clamped, then pencil mark the shape, then start carving it is somewhat easier. Then I remove it from the base and take it to the table top disk sander and sand the edges to their margin lines.... but still the first one can take three attempts! But it gets easier.

- 1,127 replies

-

I get to 9:51 in the above video and it kicks me back to the beginning! I can pick just ahead of that and it loads and plays... not sure what I missed, assuming not much

- 1,127 replies

-

HMS ANSON 1781 by albert - 1/48 - 64 guns

AON replied to albert's topic in - Build logs for subjects built 1751 - 1800

There is nothing more satisfying than getting the last of those seemingly never ending frames done! BZ -

Was it the actual removal of the rubber cement or the paper template? If it was the rubber, what did you use? I use a crepe eraser to remove rubber cement residue. Thanks to David Antscherl who had taught me this. You can buy it at any tool shop that sells sand paper. It comes in a block and is used to clean the sand paper to get more life from them. I cut about a 1" slice off one end to use as my rubber cement residue eraser. Works like a charm!

-

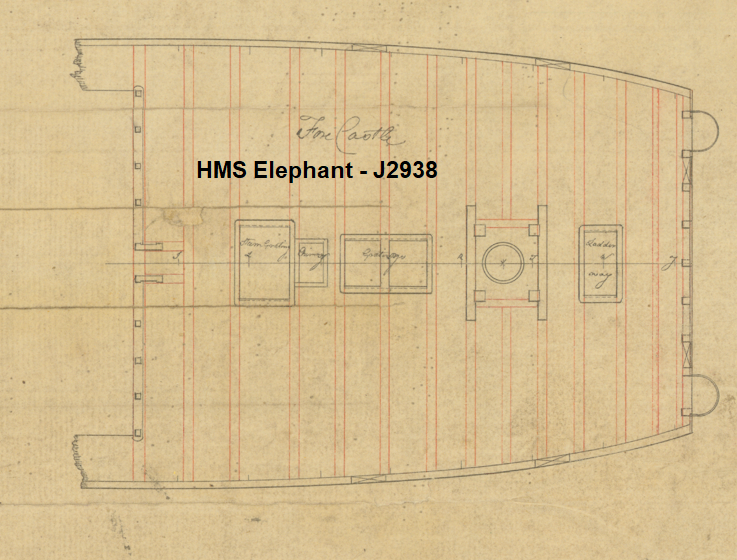

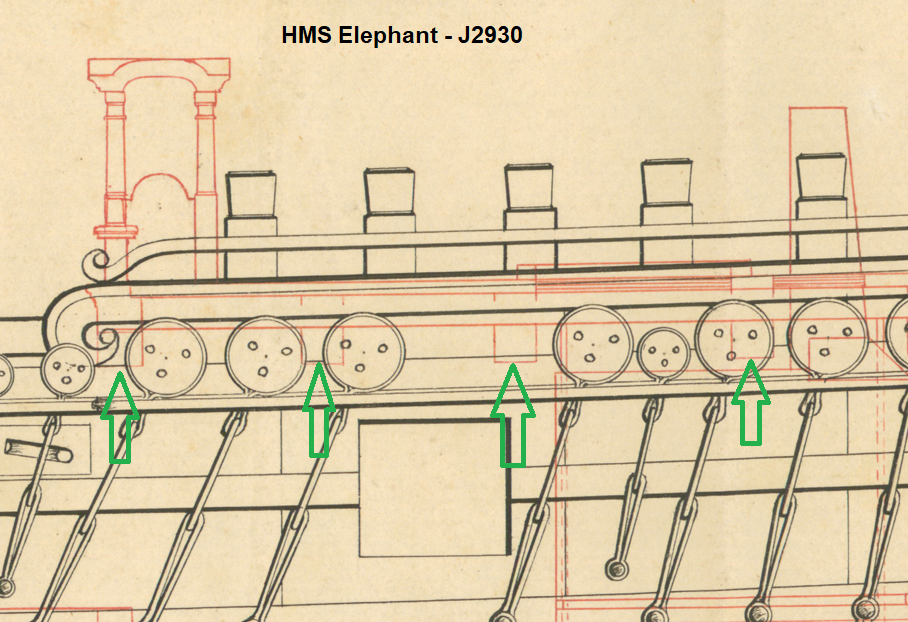

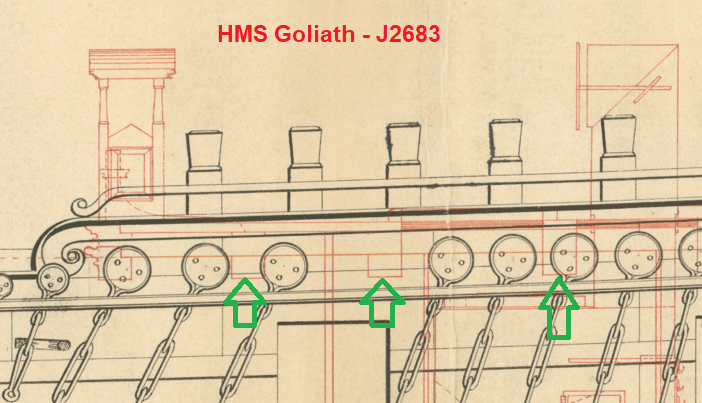

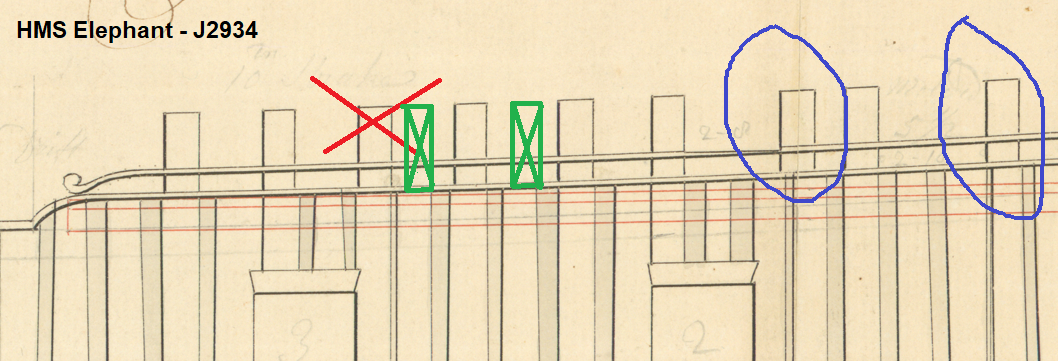

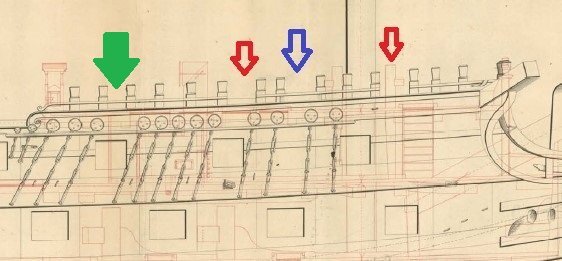

Good morning Druxey. You can see in the images below for HMS Elephant and HMS Goliath that removal of the third timberhead from the left offers a wider opening location clear of the shrouds and there is a deck beam in that location that would be similarly located to the original two gun port locations which can be seen on the Elephant deck plan. If the third timberhead from the left was cut down, would they have had install a short timberhead (as can be seen at the far right in framing drawing J2934) between the third and fourth or the fourth and fifth? I'm guessing between the third and fourth (move the original over one to the right) as it is behind a deadeye and should clear all rigging and doesn't seem out of place.

-

This is what I understand the classes to be and include Third rates of 74 guns (two-deckers) Bellona class (Slade) Bellona 74 (1760) – broken up 1814 Dragon 74 (1760) – sold 1784 Superb 74 (1760) – wrecked 1783 Kent 74 (1762) – sold 1784 Defence 74 (1763) – wrecked 1811 Third rates of 74 guns (two-deckers) Arrogant class (Slade) – modified Bellona class Arrogant 74 (1761) – broken up 1810 Cornwall 74 (1761) – scuttled/burnt 1780 Edgar 74 (1779) – broken up 1835 Goliath 74 (1781) – razéed to 58 guns 1813, broken up 1815 Zealous 74 (1785) – broken up 1816 Audacious 74 (1785) – broken up 1815 Elephant 74 (1786) – razéed to 58 guns 1818, broken up 1830 Bellerophon 74 (1786) – sold 1836 Saturn 74 (1786) – razéed to 58 guns 1813, broken up 1868 Vanguard 74 (1787) – broken up 1821 Excellent 74 (1787) – razéed to 58 guns 1820, broken up 1835 Illustrious 74 (1789) – wrecked 1795 Fourth rates of 60 guns (two-deckers) Edgar class (Slade) Edgar 60/64 (1758) – scuttled 1774 Panther 60 (1758) – broken up 1813 Firm 60 (1759) – sold 1791

-

It is a well worn path we've all walked... and some still are ( like myself). As George Bernard Shaw said: A life spent making mistakes is not only more honorable but more useful than a life spent doing nothing. Keeping moving forward. You will get better at every challenge.

- 69 replies

-

- Miss Adventure

- Model Shipways

-

(and 2 more)

Tagged with:

-

Chapman: I thought both Vanguard and Edgar were Arrogant class ships. Druxey: You've also confused me. Are you addressing PQLear who reopened this thread with a question about Vanguard at the Battle of the Nile where Brian Lavery wrote she had 4 carronades and 2 long guns on the forecastle, or are you addressing me and my Bellerophon where an eyewitness, the son of the ship's gunner who both signed on with the first crew claimed she had 2 carronades and 4 x 9 pdrs on the forecastle?

-

Check RMG for armada class 74's and 9 drawings popped up with only 3 having images and these showed forcastle gun ports far forward. Checked Harold Underhill's drawings of a 74 dated 1813 and the gunports from sheet to sheet do not seem to agree or relate to each other but the one deck plan does seem to agree with my arrows above.

-

Just attended a Zoom meeting with the Society of Model Shipwrights (UK) this afternoon and an image of the forcastle of HMS Indefatigable filled my screen showing six guns. The two forward most were cannons and the four aft were carronades. What was of most interest was that the four forward were where guns should have been (red arrows) and the aft most gun was located one step aft from my green arrow in the image below. If a carronade were put on a 74 gun ship in that location it would blow out the rigging... the green arrow location misses the rigging but the rail needs to be cut out similar to the other locations. Problem solved!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.4267f044b2b4ccd791ffb52039777240.jpg)