-

Posts

2,856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

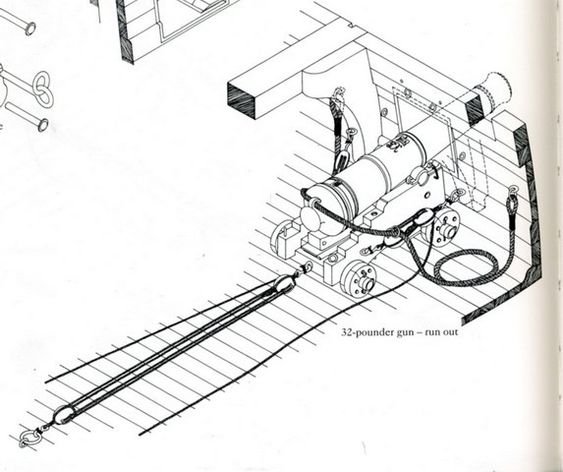

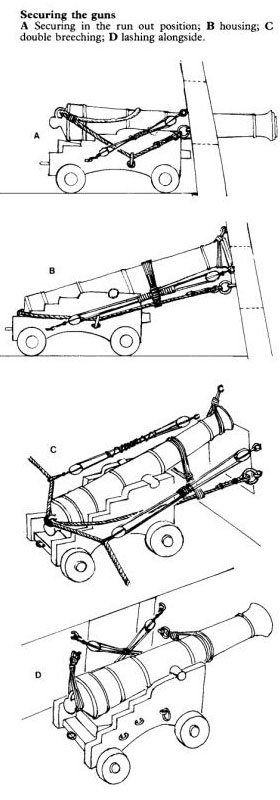

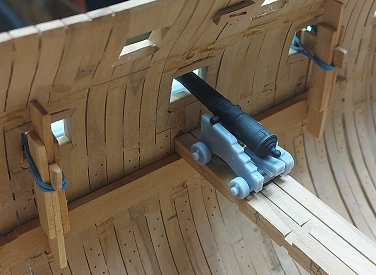

This one is a mish-mash. On both sides the breech rope is well to the outside eyebolts where as the gun tackle is in on the right side and out on the left side. Also they eyebolt location of the breech rope and guntackle are switch as other sources suggest the breech rope secures to the lower eyebolts. Two securing eyebolts above the gun port.

-

Below is an image reference to various methods of securing the guns. In all images only two eye bolts are shown to either side of the gun port, not three. Interestingly, both are quite high, adjacent to the actual gun port, none lower than the lower cill which some other references would suggest. In image "c" there is a single eyebolt above the port... but in the earlier photo I can see two eyebolts. It is all very confusing.

-

I was told to laminate tight bends with multiple thin strips. Make the pieces wider because they will wander. Steam and bend them as an assembly without glue. Allow for spring back. When dry, glue them together and clamp. When cured, sand the edges to proper width then assemble on the model.

-

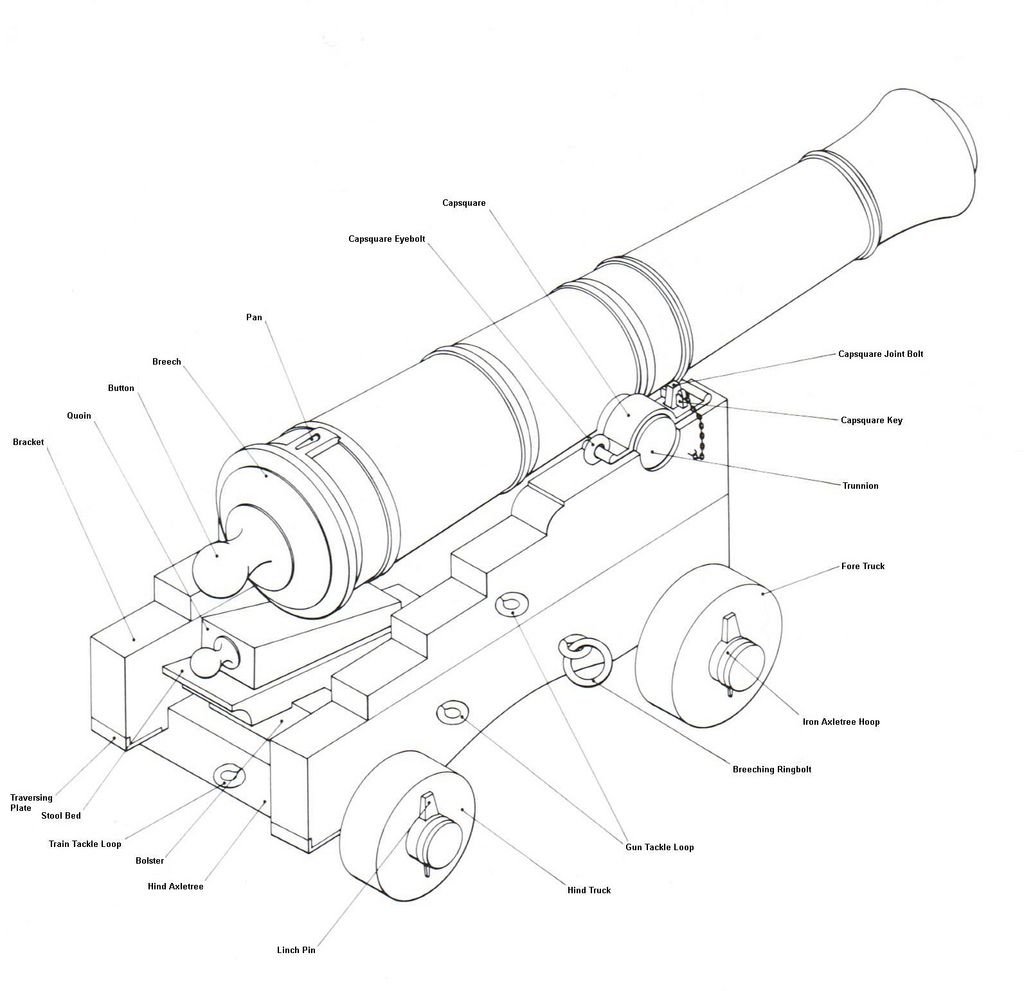

I offer the two images below showing the end face of the steps were square to the bracket and not to the centerline of the carriage assembly. On the Victory photo, the end face of the step would not be seen if it was square to the centerline, so it must be square to the bracket face. the carriage construction photo... square to the bracket face. I suspect the carriage drawings were simply easier to complete square to the centerline with a tee square... but easier to cut square to the bracket face. They would have enough of a necessary challenge cutting the cannon pivot trunnion and the axle pockets square to the centerline so why make things more difficult then they need be. ?????

-

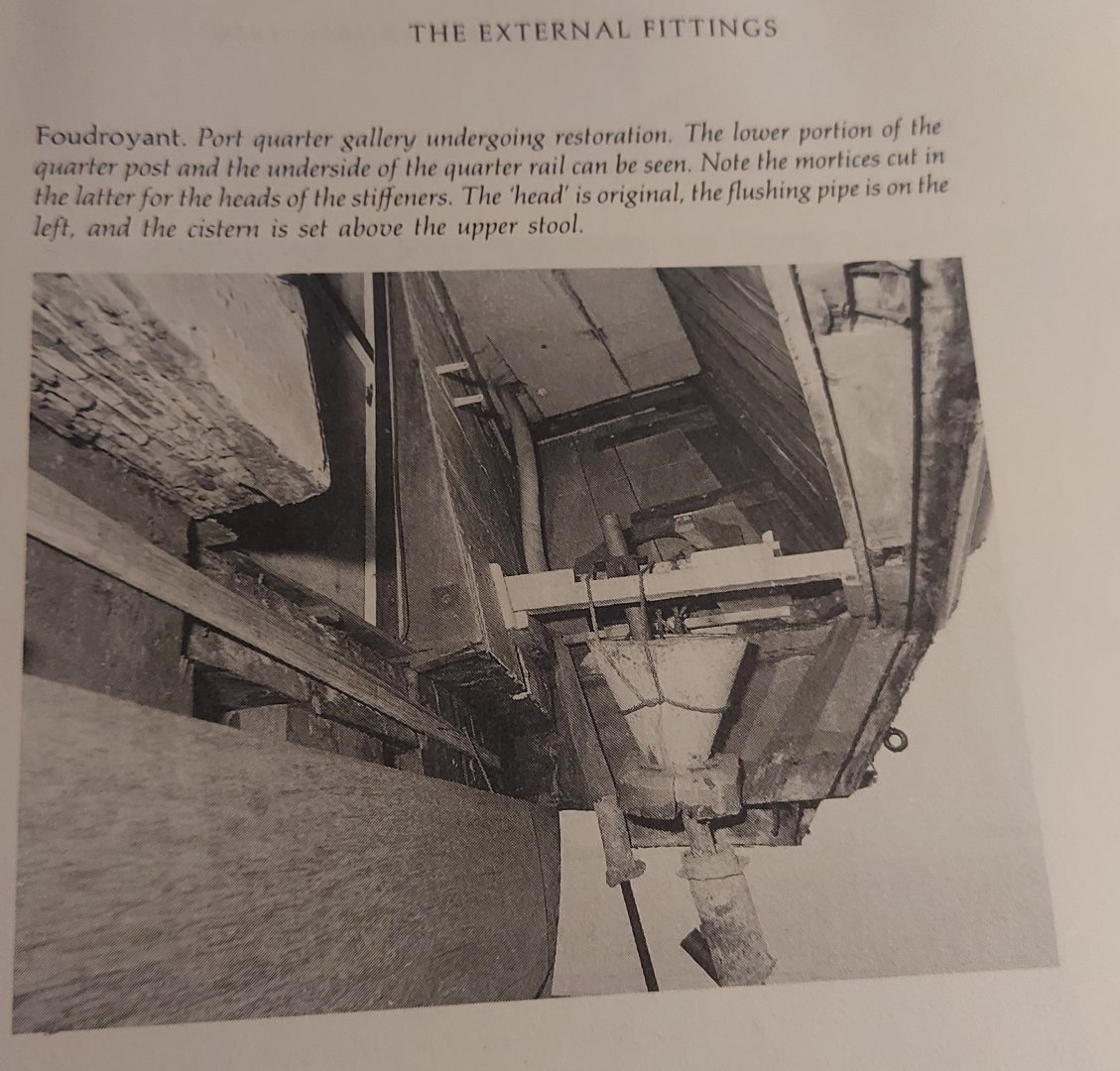

I am reading in Those Vulgar Tubes ( by Joe J. Simmons III) that when two or three levels were involved the seats were offset and by the late 1700's they had a flushing mechanism utilizing a water tub located on top of the quarter gallery. They do not describe or show how the soil tubes were run or located. Goodwin's Sailing Man of War, pg 199 has a photograph of the Foudroyant port quarter under gallery restoration and you can see the "flushing pipe" and "cistern" but doesn't seem to discuss it at all in the text on pgs 199-203.

-

Excellant work! I believe the officers seats of ease had a discharge tube connection running down to the pointy ornate bit on the underside of the quarter gallery Dumping directly into the water. I remember reading about gawkers getting too close to the Bellerophon When Napoleon was held onboard and getting a surprise.

-

I would prefer to learn from someone else's mistakes except I just don't seem to remember them as well as those I make myself. Since I told one person (and the cat is out of the bag), I have gotten past my damaged pride and so can tell everyone. I got to a point where I could actually put a gun on the gun beam and see it poke through the gun port. The problem was it didn't. The deck was too high. (note the past tense) I double checked my scale on the 3D gun models and compared to the 3D printed guns. Perfect. I double checked the dimensions of the model to the reference material dimensions. Perfect. I checked the height of the deck.... and there it was. I had measured from the underside of the keel to the top of the deck beam, not the underside. This made my clamp location too high, hence the deck being too high. I tore out the gun deck, and since lowering the gun deck makes the gap to the orlop deck too small... I tore it out also. Sanded everything yesterday and recalculated and proved the new deck height today. Orlop and gun deck clamps going back in today, then I get a "do over". Up side: I guess I am not a novice in this area of the build anymore so my results should be more pleasing to the eye. Now I am away until after my "new" anchor cable riding bitts are installed.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.