-

Posts

514 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Morgan

-

I’ll follow along, I’ve got this to start at some point and it’s useful to have more than just the YouTube videos to reference. Gary

- 28 replies

-

- Victory

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Dimension ‘A’ in Post #2 or ‘step’ between the Wales and the planking above and below were not that great, they would only be one to two inches (25 - 50mm). On Victory the Black Strakes, those planks above the Main Wale were two inches thinner, as were the Diminishing Strakes, those below the Main Wale, and so on. The higher up the ship the less noticeable the change in thickness with the subsequent strakes and Wales. At a maximum of 50mm difference step change in planking in the scales we generally work at we are talking only 0.5 - 1mm difference, or Dimension ‘A’ in post #2 above. Gary

-

Incredible Orkney Shipwreck https://www.bbc.co.uk/news/articles/crg447y13nzo

-

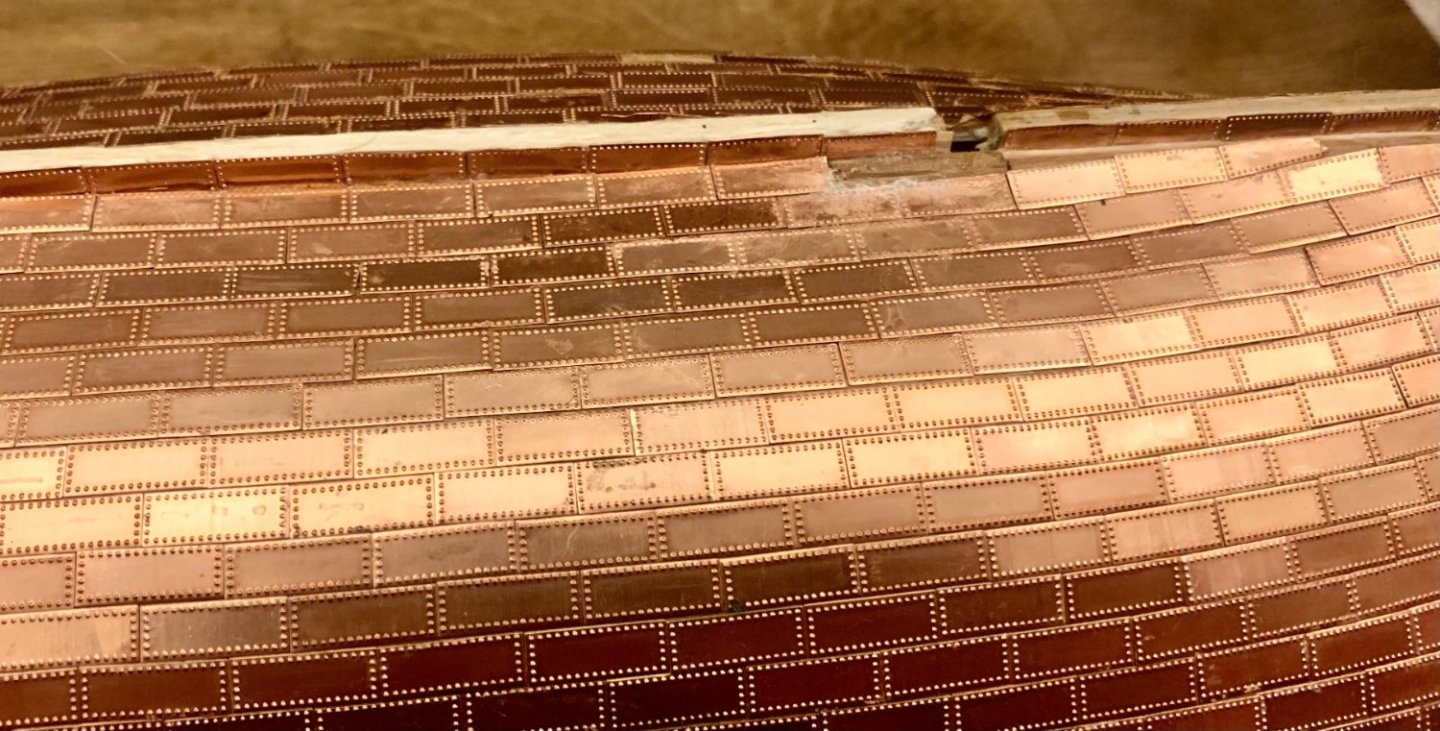

The reasoning for ‘Top down’ and ‘Stern to Bow’ is to negate the effect of friction on the plating. Consider the impact of friction as the ship moves through the water, this was enough to wear down the copper plating over time. The same forces will act on the seams of the copper plates. Forward facing seams would be more prone to opening up as friction has each individual seam to act upon. A rear facing seam allows the water to slip over the seam with a much reduced impact. The same applies with the horizontal seams, the effect of water on the ships hull is to constantly push it upwards, hence the seams were also upwards facing to mitigate this frictional force that would otherwise work its way much easier into those seams. Gary

-

This is certainly what Bugler says of Victory: ”The sheets were worked with laps, clinker fashion down, and butts, clinker fashion, aft. The strakes were run as far as practicable parallel to the waterline. At the fore end they were laid roughly parallel to the fore foot.” My reading is ‘Top Down’ and ‘Stern to Bow’ as the lay direction. Gary

-

Two points to consider. Firstly, drawings are not definitive when it comes to fixtures and fittings. And secondly, the contract only takes the ship to the point of handover to (usually) a Royal Dockyard for fitting out, tiles could be added during fit-out, the silence in the contract or drawings does not preclude this. I assume the addition of the stove itself was by the navy at the appointed Royal dockyard and not by the Contractor? Gary

-

Ships at Trafalgar - what kits are available?

Morgan replied to bruce d's topic in Wood ship model kits

Her sisters, Neptune & Dreadnaught were also at Trafalgar, so 3 for the price of one option. Gary -

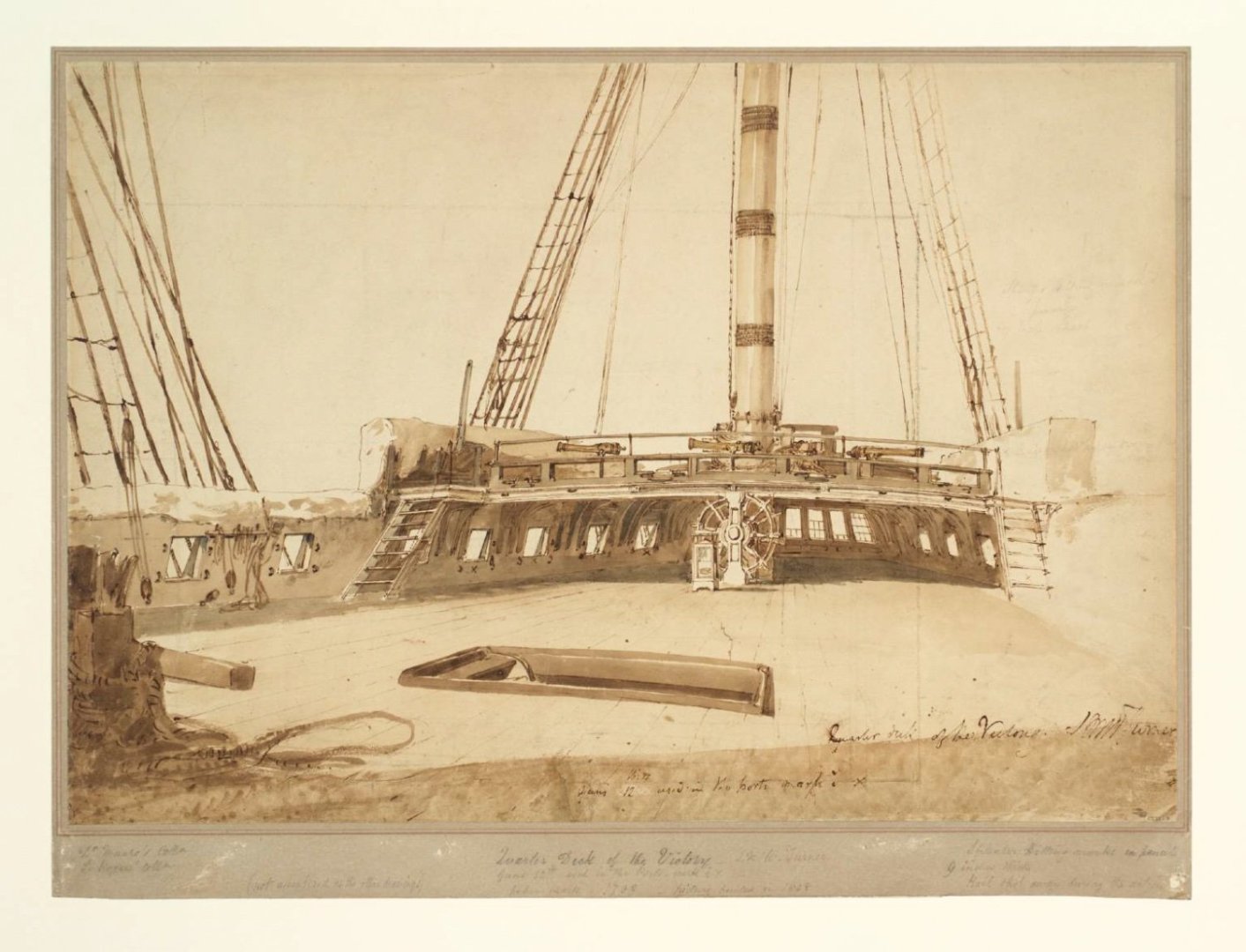

Hi cbill, In answer to your question, certainly as late as the Napoleonic wars First Rates carried swivel guns. There is strictly contemporary evidence of Victory having 3 swivel guns mounted on a rail at the break of the Poop Deck at Trafalgar, as evidenced by a watercolour made by JMW Turner in December 1805 (see below). This was somewhat unusual as they were normally mounted in the fighting tops, but Nelson did not like small arms fire in close proximity to the sails. In this instance it had been shot away during the battle but was subsequently reinstated at Gibraltar during temporary refitting. Although not First Rates there is also evidence of swivels at this time being mounted on capstans for example, so it seems almost any convenient place. Please do take the time out to introduce yourself in the ‘New Member Introductions’ section, and welcome to MSW. Gary

-

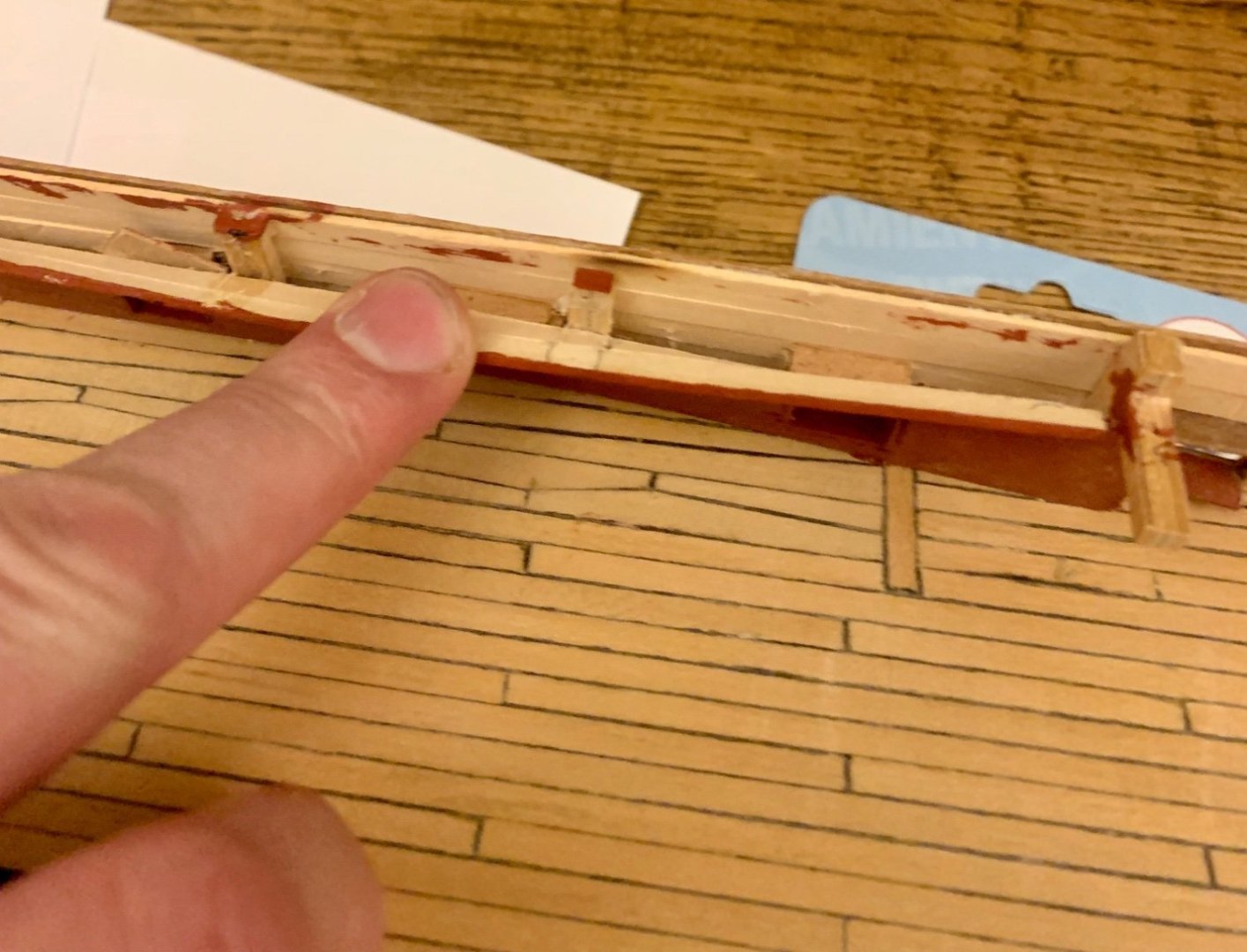

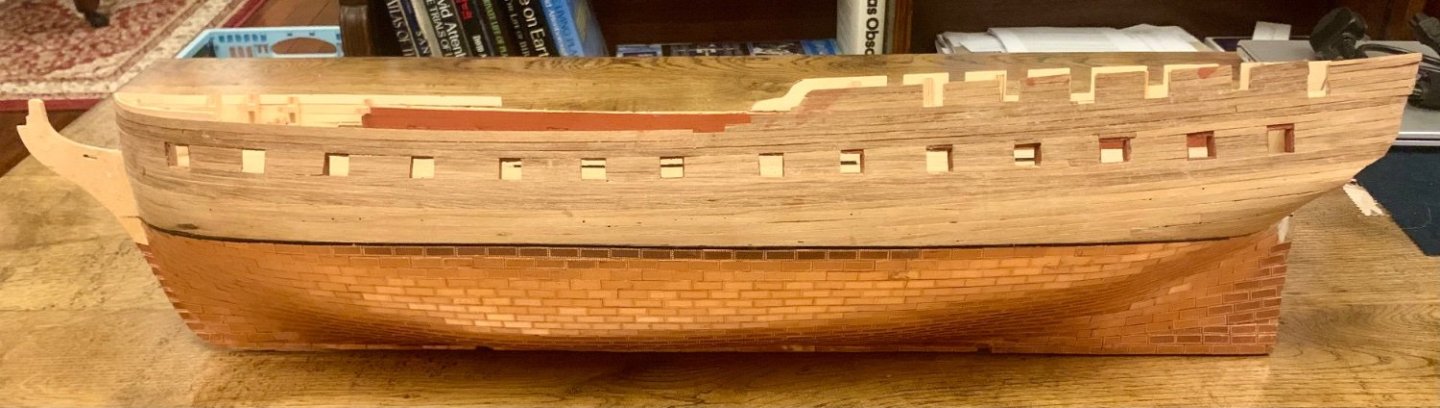

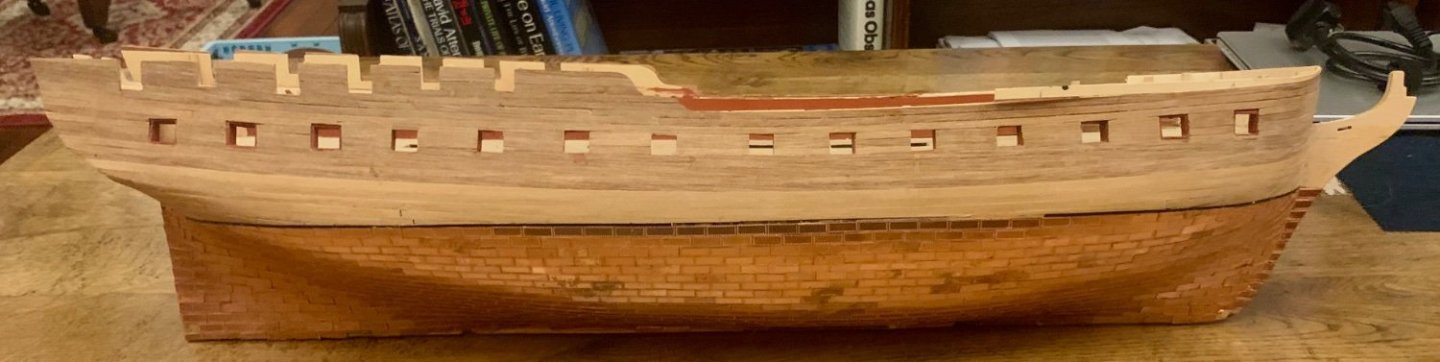

The removal of the copper plates has continued, leaving the glue residue to clean up. The heat from the removal process has left the glue residue brittle, making sanding removal fairly easy. The exposed hull leaves a couple of areas to address, also, the keel needs squaring off, it has lost its profile, I’ll add a false keel and fill up to this line and sand it back. The re-coppering will hide this. More of a problem is an area of planking that falls short of the sternpost under the counter, for now this is filled and sanded, but I have to address a more permanent solution. One possibility is to paint the hull below the Wales. As identified earlier the gunports needed realignment. The only way to do this is to remove them, but this necessitated removal of all internal and external planking down to deck level, so another case of moving backwards before continuing. The removal of the planking inevitability damaged some more of the upper extensions frames of the bulkheads. However, having stripped the hull back I can now been able to move forward with reconstruction. I have put in place some gunport framing and ‘splints’ to support the original structure and re-establish the profile ready for re-planking. None of this will be visible and is only to hang the planking on and for lining the gunports. It necessarily has to fit in with and between what is in place, which means it fits where it touches, but ‘pretty’ isn’t a consideration. There is some more fettling and levelling required. To aid this the lower plank of the inner bulwarks have been cut to the same height as the sills of the gunport frames, this is not yet glued in place as this will allow each port to be aligned / squared prior to fixing down. When positioning the inner bulwark lower plank the longitudinal ripple along the deck is obvious, but once a waterway is fixed this will obscure it, it won’t affect the cannon placement as it is limited to the outside of the deck, and most will be obscured by the weather decks. It seems that where the deck is not supported by the transverse bulkheads there is a tendency in places to have sunk, but no matter, onwards and upwards. Gary

-

Axminster 300 mm disc sander unboxing

Morgan replied to vaddoc's topic in Modeling tools and Workshop Equipment

Hi Vaddoc, I doubt you’ll go wrong with your sander. Axminster customer service is excellent, ans are their products. As a specialised woodworking supplier they know their business and what customers want from them. The Admiral has to place time limits on my store browsing when I visit, I could spend all day in there. Gary -

I would search for the likes of the commanders such as Howard of Effingham, Sir Francis Drake, Sir Walter Raleigh, or other commanders of the era. Include the names of their ships in the search as well, it may help narrow the search. I can’t guarantee you will find what you are looking for but it is as good a starting point as any, hopefully other here can suggest other contemporary sources. Good luck with the search. Gary

-

Have you tried studying paintings of sea officers from that era, I would imagine some would show themselves in their cabins which may also capture how the cabin is furnished. I certainly recall that such images from some of the leading figures of the Spanish Armada (on the Spanish side) are so painted (I can’t recall where) but possibly some may also exist of English officers. Bit of a long shot but they would certainly be contemporary. Gary

-

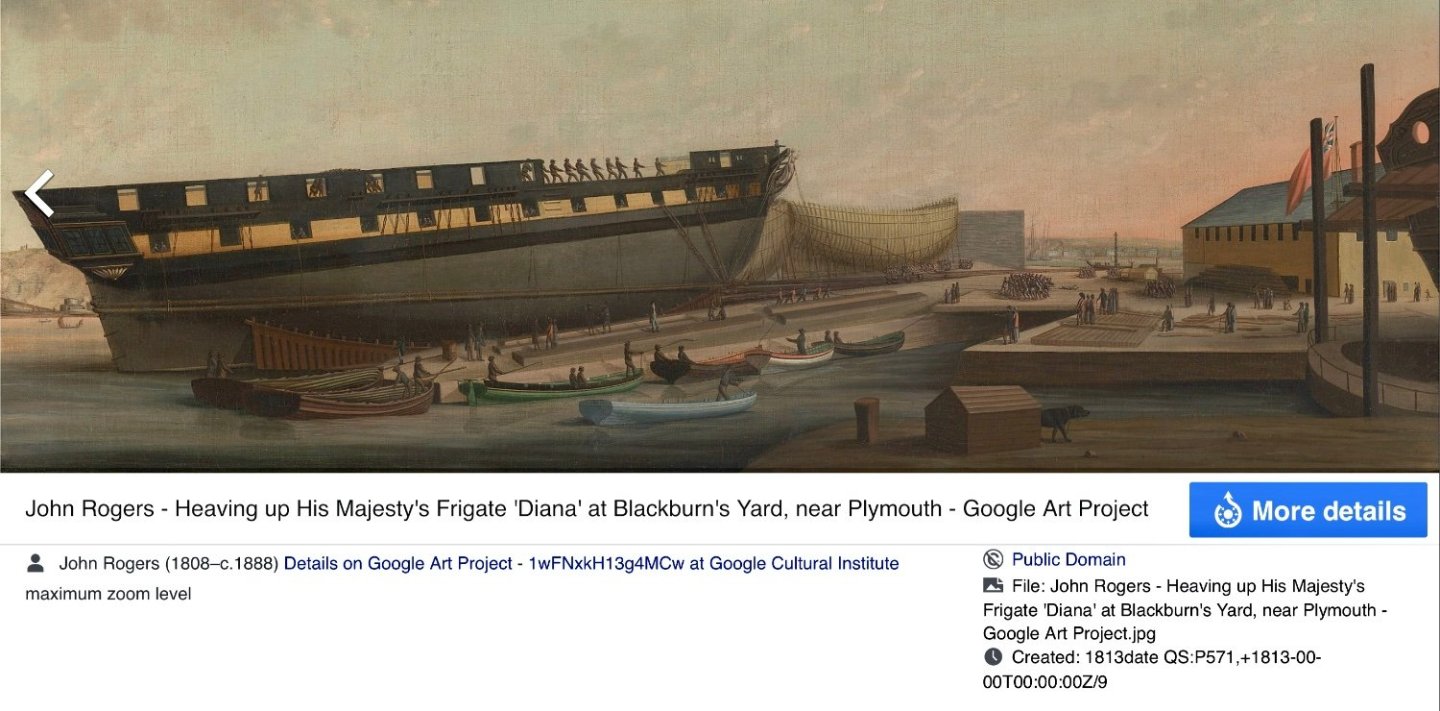

Hi Sizzolo, Just a heads up, in 1806 Diana would have carried a built-up forecatle this was an Admiralty directive (I can dig out the reference), she still carried this in 1813 as per the photo below. Not as aesthetically pleasing in my view. Also note 8 QD ports. Obviously your build and decisions, just adds to the mix of info. Glad your National Archives visits are finally bearing fruit. Gary

-

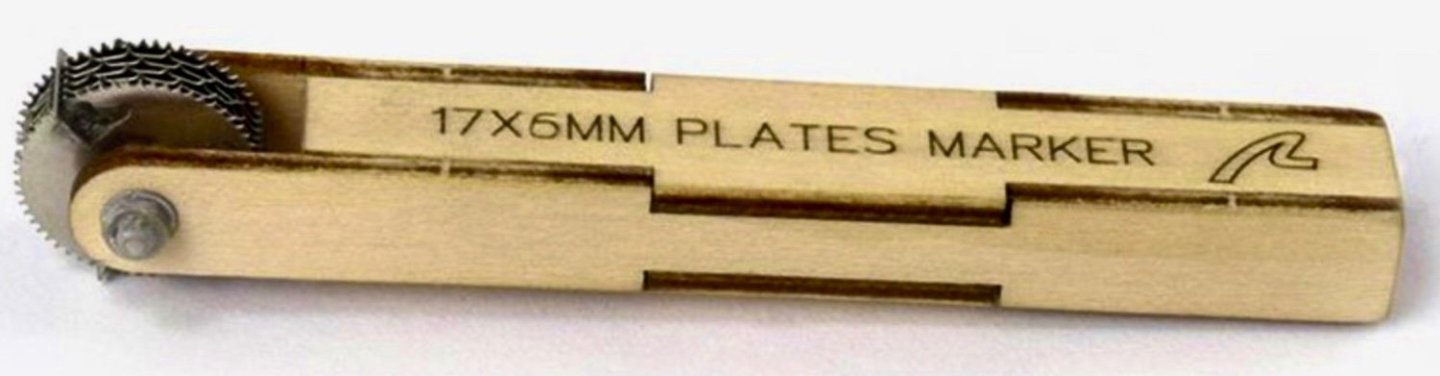

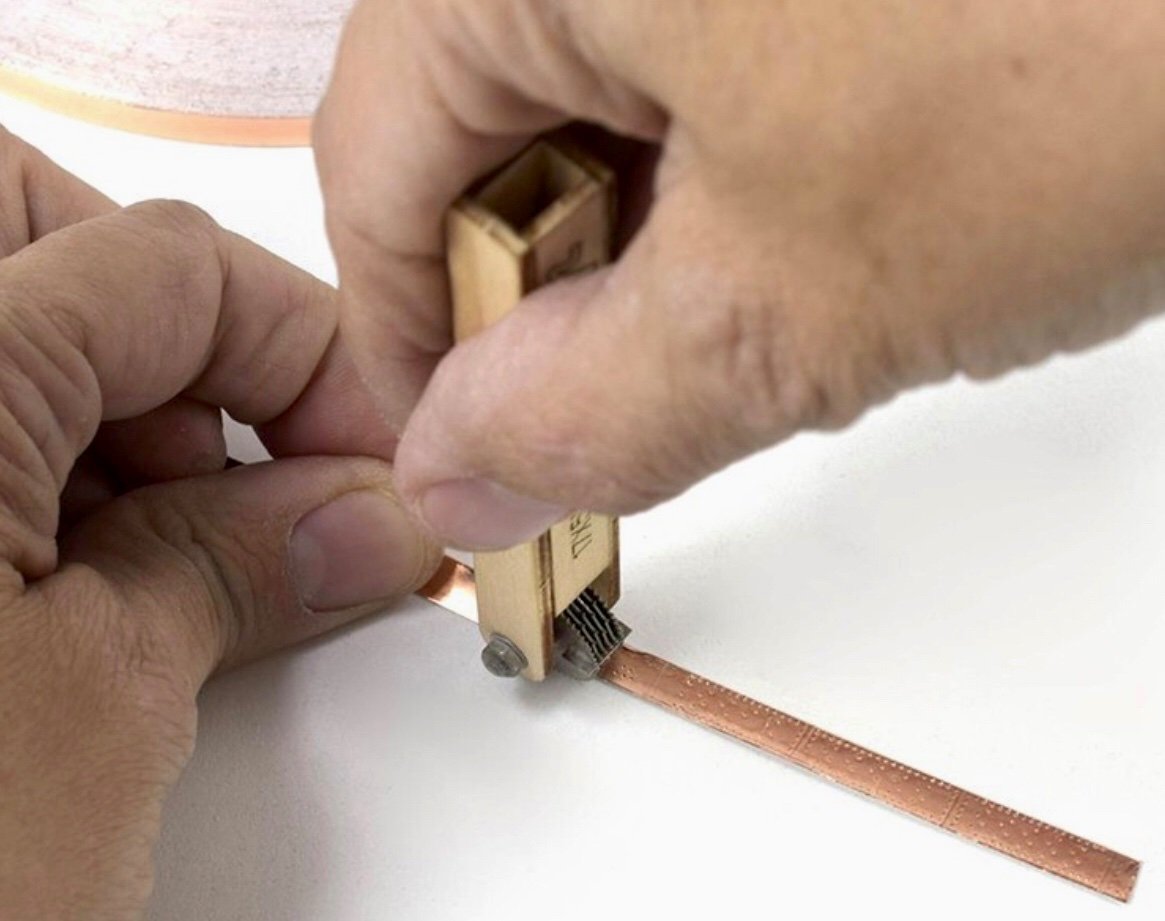

If you account for the overlap the effective plate size is 46.5” x 13.5”, at a scale of 1:72 and converting to metric then 16.4mm x 4.8mm, so the 16 x 5 AL version works, so I can use this on my Victory build, but for 1:64 scale, as for Diana, then 18.5mm x 5.4mm is required, however, if you use standard copper tape widths then using 5mm and 6mm respectively would probably work. All near enough, and as you say, tweaking the spacers would probably be near enough at these scales as the width is important not the length. Gary

-

Hi Allan, I’ve also seen the single edge approach and agree it looks good. Artesania Latina market two PE rivet tools, I’m thinking one of these could be modified to produce a single edge pattern, their multi wheel approach also allows for the infill nails to be simulated, the rivet points on the inner and outer wheels are at separate pitches allowing the different nail patterns to be produced. I may need to buy 2 to get the number wheels I would need, but I’ll see. Photos below. I’ve also trialed using heat to de-bond both copper plates and planking, and initial trials are good, which is a positive for future modifications. Gary

-

Hi Allan, There is very little on copper plating, obviously sizes and plate gauge are known, but as to lay-patterns, nothing unfortunately. I agree on the scale issue of copper plates, I am going to experiment with the new AL plate parking tool, but getting the representation right will be difficult. Just getting the overlap of plates at scale without creating an obvious clunky series of ridges is almost impossible, the plates would have to be as thin as tissue paper. There are plenty of photos to draw from, I have many from the Victory and Trincomalee so do have the visual template, simulating it 🤔 Gary

-

The information is in the PDF, but a brief overview: The history of Victory’s restoration to her Trafalgar condition has for the last century been hampered by financial constraints, the placing of pre-conceptions over evidence, politics, and domination by strong characters. This has always resulted in compromises that leads us to where we are today. When her great restoration began 101 years ago Great Britain was gripped by post war economic constraints, so very little money was forthcoming from the Admiralty, the Society for Nautical Research had stepped in and raised funds to finance for the restoration, and appointed an advisory technical committee to oversee this. Unfortunately this committee had two differing schools of thought, one side wanted to see her restored essentially to the ‘beauty’ of her as-launched condition, the other side went with the records available, these sides couldn’t be reconciled. In essence we ended up with something similar to her Trafalgar Stern, and something similar to her as-launched bow, but with a near representation of her Trafalgar figurehead. Everything in between was a similar mix. Money was also a factor, and when reopened to the public in 1928 the ship was fairly bare of fittings, however, the ship had been saved, and that is the main benefit. Unfortunately the 1920’s restoration essential locked-in place the major elements of the ship, and that continues to influence subsequent works. Several cycles of poor restoration, WW2 bomb damage, and many decades of death watch beetle infestation have soaked up vast amounts of money just to keep the structure in place, but this money may otherwise have gone to research and interpretation. I am hopeful the current restoration will arrest some of these issues, but I don’t see any structural changes to the form of the ship, they would be too intrusive and costly. Gary

- 2 replies

-

- HMS Victory

- Caldercraft

-

(and 1 more)

Tagged with:

-

Somewhile back ‘Shipyard Sid’, aka Dave, found himself in the position of having to look for someone to take over the build of his HMS Diana for reasons he has already stated on this site elsewhere. Looking back at the relevant posts I had obviously missed these at the time, however, living only a mile or so away Dave recently asked me if I would like to take on the model. Diana has been on my wish list but wasn’t in my immediate contemplation. I have my Victory research which I just completed and have undertaken to publish on this site and have also very recently commenced the associated build of the Victory based on Caldercraft’s 1:72 scale kit, alongside the recently released Artesania Latina Cross Section of the same scale as a complementary pair (build log imminent). I also have a backlog of completing my scratch 1:64 HMS Trincomalee and Chuck’s Winnie also begging for a start as well, so no shortage of projects. So, what’s one more to add to the collection😊. I must admit that this hobby is getting like the Admiral’s DIY list which out-competes model building for my time, it seems only to get longer the more I do! But who wants to be bored. I think I will try to complete this simultaneously with the Victory but may take a few weeks to get up and running – that DIY list is pressing apparently, seems there is some artificial need to have completed certain milestones by Xmas, I have never understood that link, but it may be why DIY stores stock Xmas decorations. Happy for someone to explain the causal link between the two, but I undertake to wilfully remain sceptical of the whatever wafer-thin explanation someone can dream up! Back to Diana, obviously I have said yes. It is a shame Dave feels he can’t complete the Diana to the standard he desires, when I picked up the model, I also got to see his Caldercraft Victory he completed some years back and it is a wonderful example to behold, which he should be rightly proud off. I’ve enclosed below some photos of where Dave had got to with the Diana. As he pointed out to me, there is the need to do some remedial work, primarily to the copper plating, and on a cursory examination some of the gunports also need some attention. Some of the copper plates have come off, and some others are in the process of exfoliating themselves, bearing in mind Dave hasn’t touched tis for at least 2 years. In terms of the main deck gunports some of these need realigning. I think I will start with the copper plating, remove any damaged and loose plates and those that require some realignment. Dave fastened these to the ship with Evo Stick, so hopefully a combination of acetone and heat (not at the same time!) should loosen these. I’ll just see where the process takes me. For the planking I plan on removing all the inner planking and then establishing the high and low points of the all the gunports relative to the deck for the outer planking so as to determine how many strakes are involved in the realignment process. Hopefully I can just remove the planks within those limits, re-establish the gunport openings and make good the planking. Gary

-

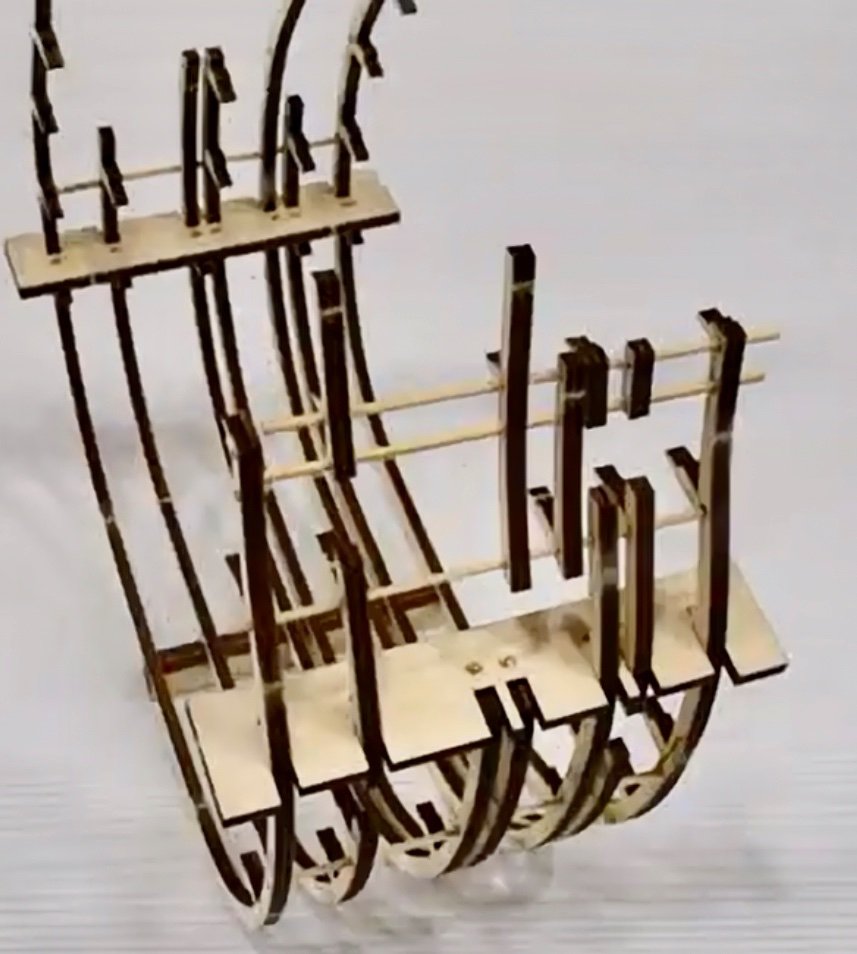

At the time of commencing this build log (November 2023) I have already been working on Part 1 of the project since 2015, which amounted to researching the ship herself and what Victory really looked like at Trafalgar. Now I know people will point to the Victory herself in Portsmouth and say that’s what she looked like, after all they have been restoring her off and on for a century so you would think they (NMRN) of all people would know, but actually no, it isn’t what she looked like. It may be that is how they label her, and that it has been the objective of her restoration since the 1920’s, and has been ongoing ever since. It was clear to me back in 2015 that the present Victory did not look like some of the strictly contemporary images I had recently been viewing, this is described in the attachments, and of course you will need to read the work for the background and results. You will see I use the term ‘strictly contemporary’ throughout the paper, and this is important, it both highlights and describes primary sources of works of evidential value from 1801 to 1806. Art Works and other records of Victory first produced at a later date, of which there are many, especially after 1814/16 when the ship was radically altered, are voluminous whilst passingly informative, do not carry the same provenance when considering her Trafalgar guise. Unfortunately, a substantive body of the Nelsonic art works, including images of the Victory, grew in preponderance in the 19th Century, and these works continue to dominate the visual record. Accordingly, there is a lot of myth that surrounds Victory, much of this grew up in the century after Trafalgar, especially with the Victorians recasting Nelson, Trafalgar and HMS Victory to reflect the values of their time. Much of this ‘doe-eyed romanticism’ hung over into the early 20th Century and made its way into the restored Victory and Nelsonic cannon of the time. The accompanying volume to this build-log looks back to the records before this dreamy rose-tinted time, but I also draw on the modern research that can be validated. I deliberately caveat my references to modern studies, as even some of today’s authors, including some of the biggest of names in maritime history, are not beyond repeating the hyperbole and mistakes of their Victorian antecedents. Neither are they beyond repeating the ‘findings’ of others, which upon examination of the historic archive do not hold up to scrutiny. I have labelled the result of my research ‘Nelson’s Victory Revealed’, my intention is to release that work in PDF format in conjunction with this build log. Included in this first part is the first instalment, principally the contents, introduction and review of the background research materials. I’ve also enclosed numerically the final 2 parts, the Bibliography and End Notes as they will be needed throughout for cross reference purposes (parts 12 & 13). There is a separate dedicated thread for the Research under ‘Discussions for ships plans and Project Research ….. etc.’, I’ll also post these over there as well. So, after enough waffle, on to ‘Part 2’, of the project - the build! Whilst I would have liked to have built the Victory in 1:64 scale utilising the prospective Amati Victory as a basis with the ability to detail all decks, it is not available at this time, and I am keen to make a start so waiting isn’t an option. So, I have purchased the Caldercraft 1:72 version from Jotika. I had considered scratch building, but I am being realistic about my abilities. I have scratch built HMS Trincomalee in 1:64 plank on bulkhead, or rather more correctly, part built – I’ve completed fitting out the Gundeck, but a First Rate is an entirely different proposition. I had though initially about opening up the Caldercraft Middle Gun Deck and detailing it, however, it just happens that Artesania Latina have also just released a 1:72 scale Main Mast Cross-section, timing couldn’t be better. I’m going to build this in tandem with the Caldercraft kit, or more accurately slightly ahead of it. This will allow me to detail items such as the double height chain pumps, Riders to all decks, pump well and multiple shot lockers, and multiple gun patterns. In terms of reference material, well there is that small volume I’ve already mentioned, and I have also collected in pursuit of my research a substantial volume of reference material, all of which is listed in the Bibliography. Then there are also in 1:48 scale all available Victory draughts and plans from the NMM, together with those of the Boyne. In addition, I have Bugler’s 1:48 plans and a set of John McKay’s drawings in 1:64 – so no shortage conflicting materials to draw from! Then there are the prints I have also obtained from the NMM, including both Turner and Stanfield’s Trafalgar works, as well as those of EW Cooke and Pocock. Some of these are now framed and adorn the library by kind permission of the Admiral, I’ll get around to posting a few photo’s of these. I claim they are for inspiration, but truth is sat in front of an open fire next to a decanter of Talisker Whisky there is collectively more of a soporific effect (cue Master and Commander on the iPad and miss the end of the film again 😊). I will also need to capture some side profiles early for the later fabrication of the many fenders, and the head chutes. At some time there is the stern and quarter gallery shapes to confront and reconfigure, but this will be an iterative process as these can only be done when the hull is at a stage that the quarter gallery patterns can be fitted and shaped., which in turn help establish the stern shape. The kit will be augmented with an authentic mix of Blomefield and Armstrong-Frederick guns – spoiler alert, Victory did not carry a uniform pattern of guns throughout at Trafalgar, like much of the British Fleet there was a fair bit of mix and match. Also, forget 104 guns, there were 96 + 2 Carronades, speaking of which, there will be some bashing of carronades to get something akin to the prevailing pattern in the early 1790’s when Victory’s were probably cast, rather than the poorly formed replicas we see aboard the ship today. The Upper Deck will get its steam trunking, sick berth, and internal galley chimney. There will be more supplements to the kit as the build progresses. Painting will be in the new colours as I’m a believer in the science and the research undertaken to establish these, particularly when combined with the Rase Mark analysis on the ship. There will be some tonal adjustments to the palette to account for the optics at scale. She will also get the pattern extending around the stem, NO black gunport lids – that is wrong, and lower white masts with the hoops painted out and white underside fighting tops as were worn at Trafalgar. I’m not going to do an un-boxing, there are enough of these around already. What I do need to sort is either a building board or cradle of some form, but I think I’ll address that when I’ve got the skeleton assembled and have more of a feel for handling the model in the space available. Below is a photo of progress to date, first up were modifications to the stem. The kit provided stem reflects the present Victory, but is both too short and low for 1805. This necessitated some amputation and the insertion of a filler piece to throw the head further forward and upwards. There was some additional shaping and profiling with the horizontal bow filler pieces to obtain the necessary profile, which itself was thinned down from the stempost forwards and from where the third cheek down to where it is affixed to the keel. A sacrificial profile or template for the placement of the bearding line at the bow was added at this point, this follows the correct profile and will require further refinement as the work progresses. I also took the time to replace the kit keel which as supplied is a uniform 5mm x 10mm. Based on the Bugler midship section it needs to be 7mm x 11.5mm plus a false keel strip. In addition, it needs reducing in width at each end tapering down from 63mm out to fair-in with the stern and stem posts. Elements of the keel were pre-rabbeted to match the bearding lines. All of this will be covered in copper plates anyway. A new stern post was fabricated using the kit version as a template, instead of a uniform 5mm the correct width at the top is 8.5mm tapering down to match the keel. This will be fitted after planking. Brass rod is used throughout to strengthen the joints of these pieces, much of which is capped over with pear strip. I have also blasted the dummy gunport liners and cabin spaces with some rattle can paints, these areas won’t be seen directly, but I felt some appropriate colouration wouldn’t hurt. For those who haven’t seen the AL cross section yet I’ve attached two images below, one shows the frame they are using to build up the cross section, and the other is of their finished product. That’s it for now. Gary Nelson's Victory Revealed Pt. 1 Background Materials.pdf Nelson's Victory Revealed Pt. 13 References Endnotes.pdf Nelson's Victory Revealed Pt. 12 Bibliography.pdf

- 2 replies

-

- HMS Victory

- Caldercraft

-

(and 1 more)

Tagged with:

-

Kit review 1:84 Santisima Trinidad – Trafalgar 1805 by Artesanía Latina

Morgan replied to James H's topic in REVIEWS: Model kits

Thanks for the review James. I like the novel approach to their current kits, I recently picked up their Victory cross section (also just released) and they take a new approach with built-up frames (whole and part) threaded onto dowels with pre-formed spacers to construct the hull. Definitely some original thought being applied by AL. Gary -

Of course cash has nothing to do with this offering, it’s all about the ‘experience’ of building your Victory. Only 999 kits available, so that is anticipated sales values of GB£1.2m, US$1.6m or €1.4m. Given the plethora of Victory kits on the market I do have to wonder what the driver for this one is 🤣 Gary

-

I don’t understand why they have notched the frames, it is so wrong and is an immediate turn off! Given the laser cutting used (and price) it would have been more authentic to provide integrated beams and knees which would have been far more authentic. Those with the skill could have built on this and fully detailed the an authentic deck structure, those less inclined could have gone with the ‘cut and stick’ infill approach. Gary

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.