-

Posts

6,126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Unknown Royal Yacht kit.

James H replied to Lucius Molchany's topic in - Kit build logs for subjects built from 1751 - 1800

No. Only if they are rip off copies of legitimate designs. Please don't spread that misinformation here. There are legitimate Chinese kits, and as you have that wrong belief, I assume you have gained that information on different shores to MSW. -

That was a hell of a save! Congrats on the sale too. Well deserved.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That is stunning, beyond words. If I'd built that, I'd retire my tools. Simply gorgeous.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

-

That's exactly what it is.

-

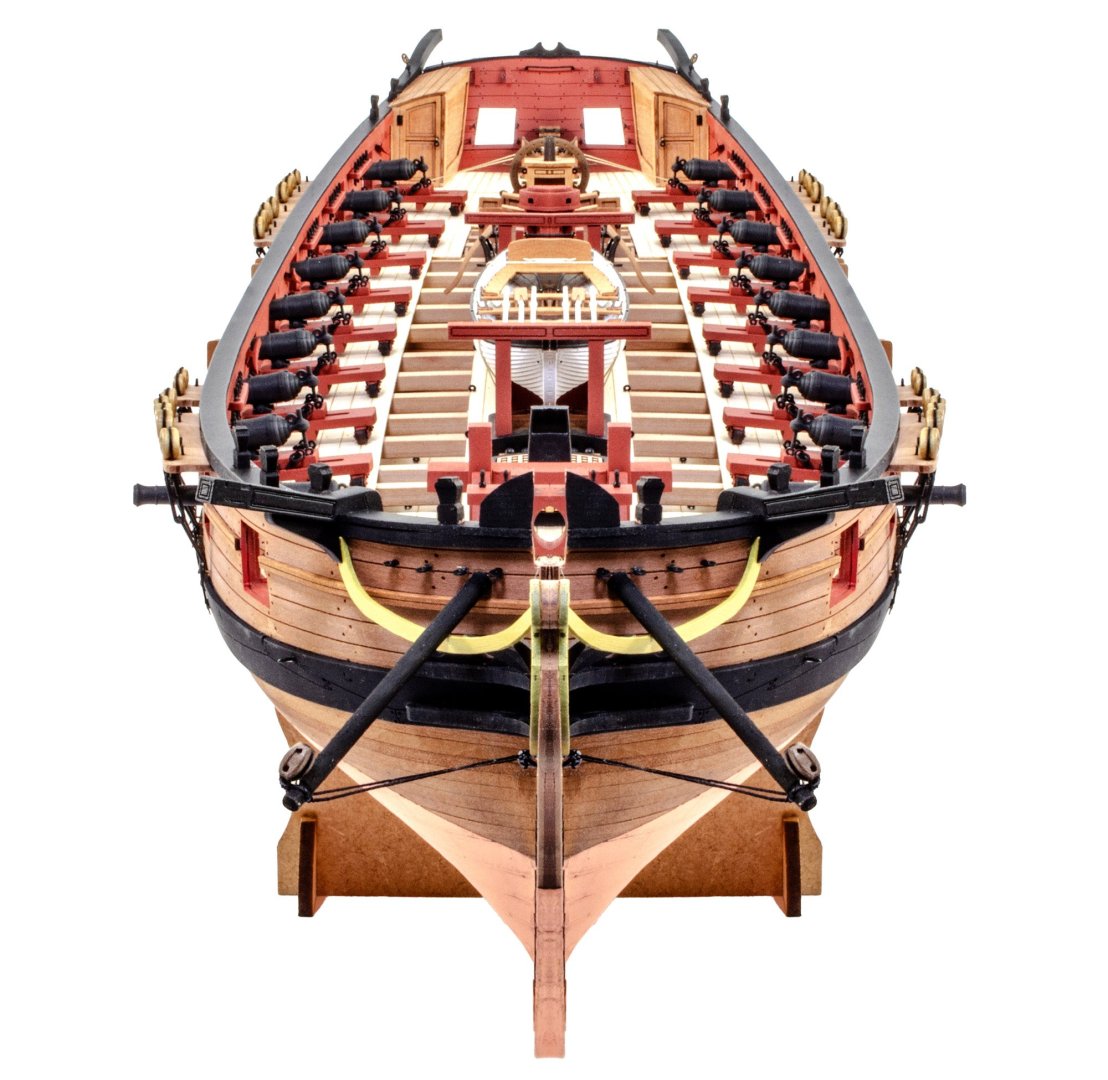

Remember that this kit will have been developed at the same time as another Vic kit from this year. That isn't the fault of any company. AL seem to be offering something akin to the original cutaway Bounty kit they once did, but on steroids. Fair play. If it appeals, then give it a try. Choice is good.

-

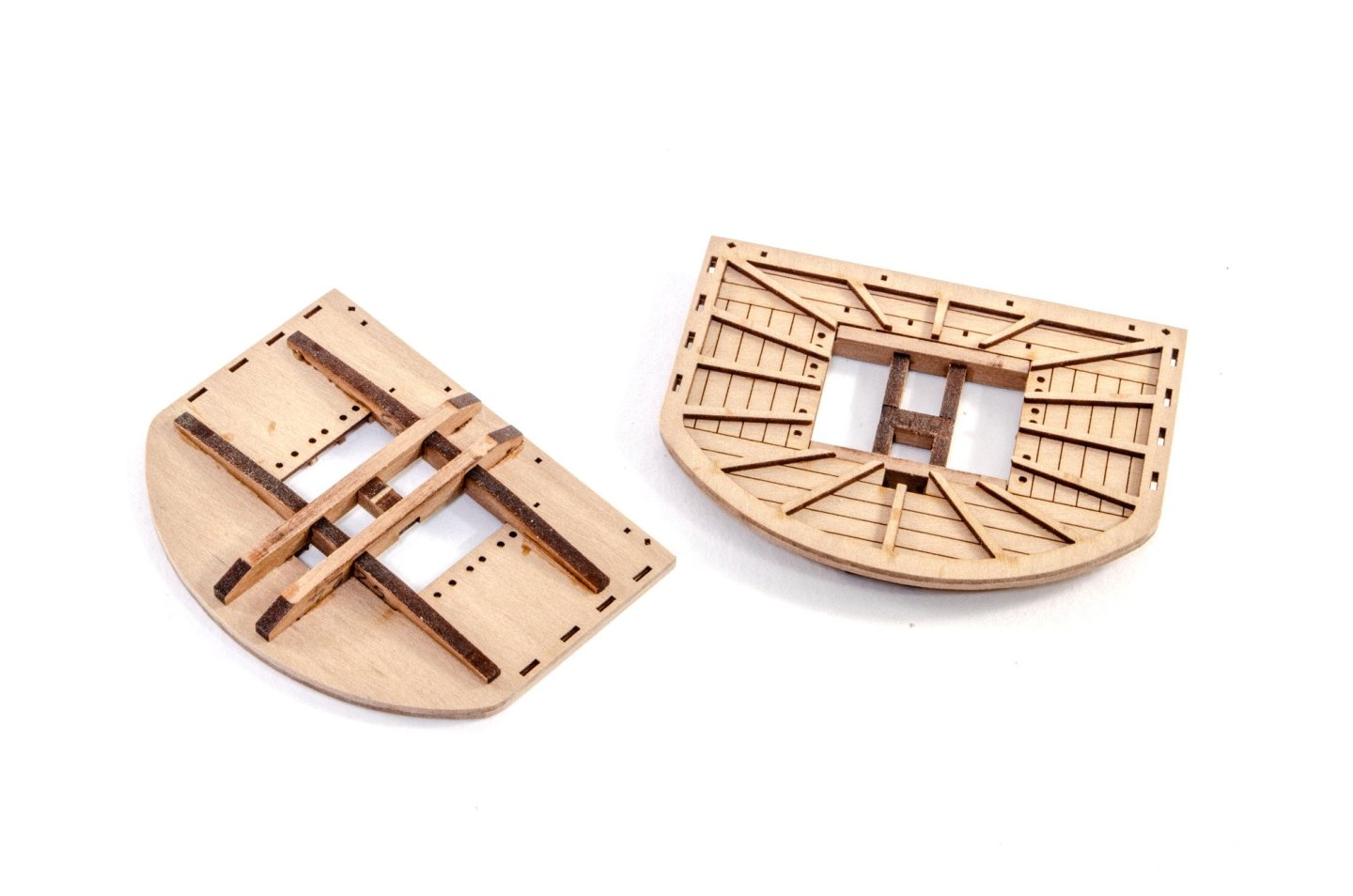

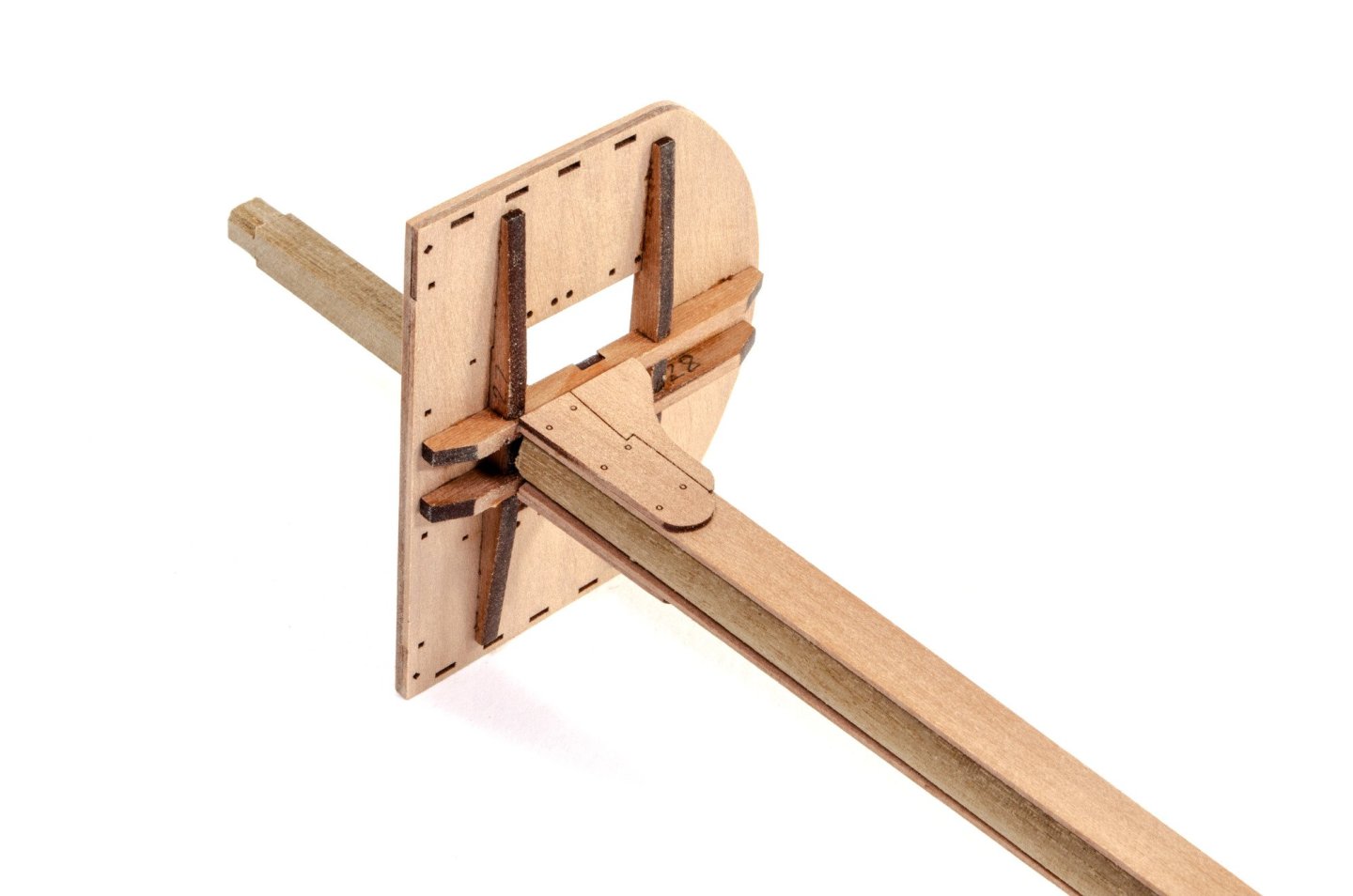

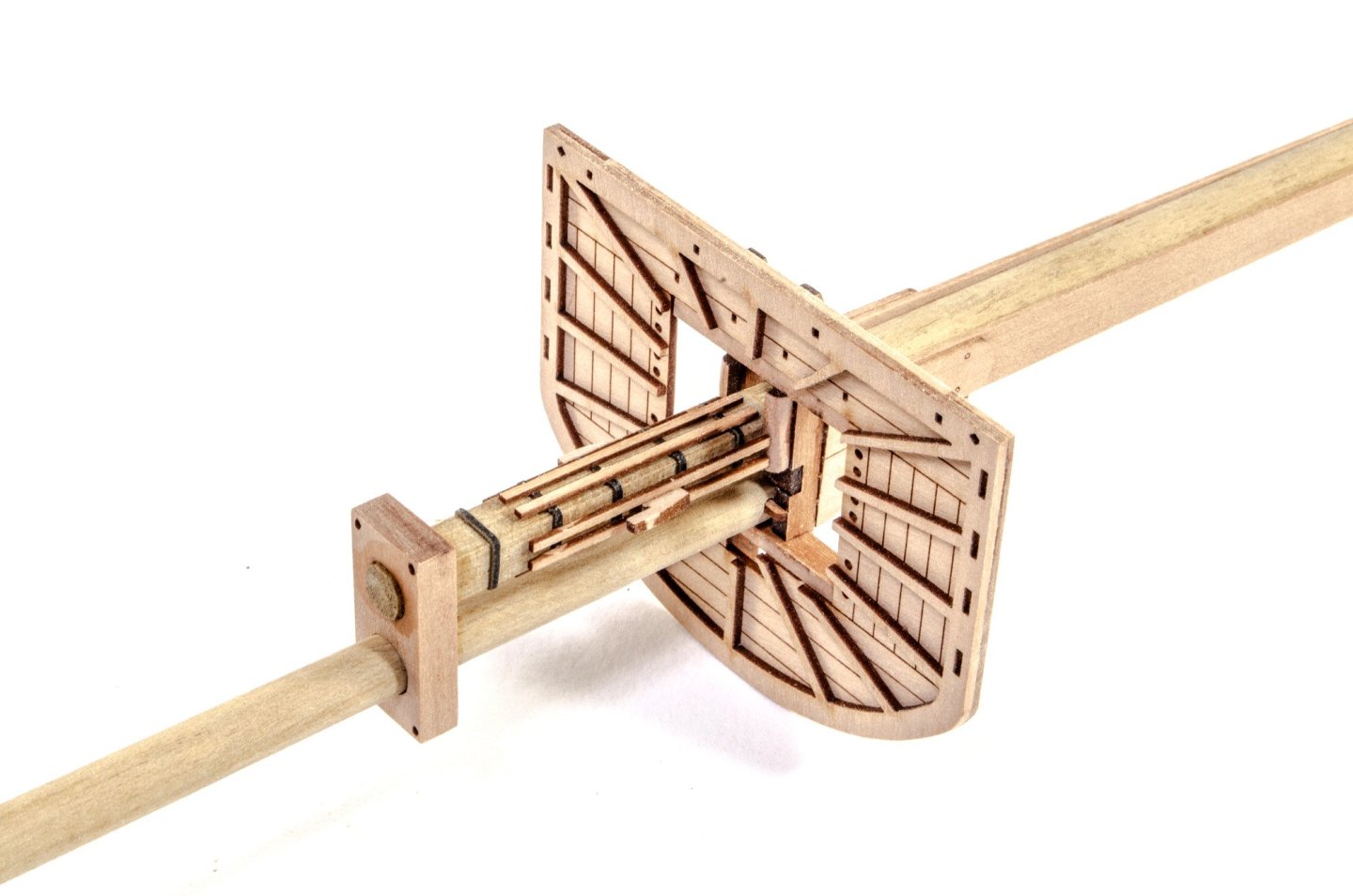

This is likely to be my penultimate update as the next one should show this rigged and finished. That'll be a nice way to conclude this, so until this, these are a few photos of Harpy's masting, including some photos of the yards, gaff, boom, spritsail yard and the completed bowsprit. I've concluded this with a photo of Harpy as she currently looks. No text is really needed for this as the photos are self-explanatory and perfectly follow the convention you've seen in other VM build logs. Hope you like the results so far. ]

- 76 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

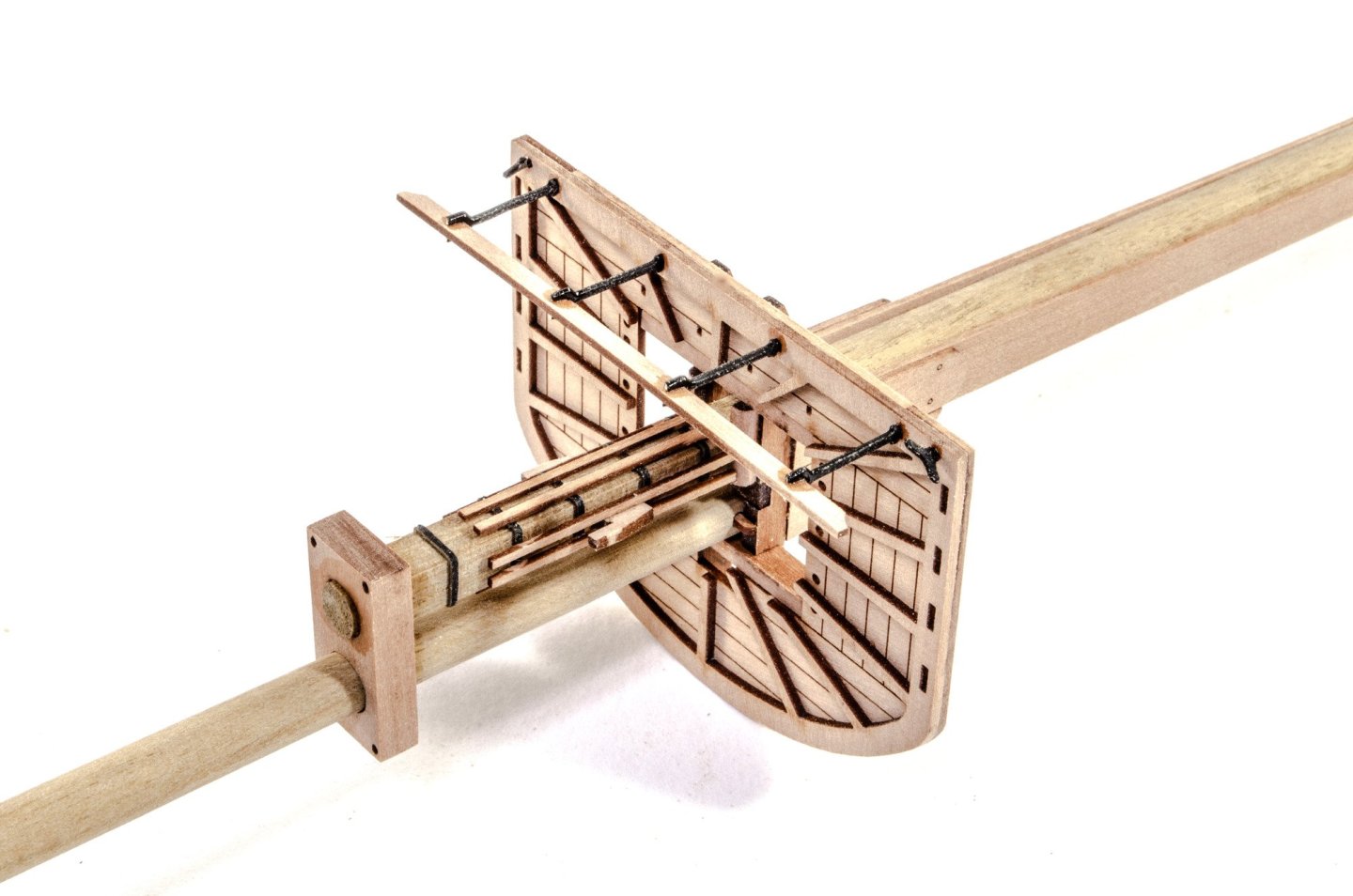

A pin pusher isn't a precision tool. It's just for slapping in brass pins anywhere along the place where the joint is. There's a knack to using one quickly so you get the pins roughly where you need them. The Modelcraft pin pusher works real well and of course you can set it so it doesn't push all the way into the wood. Quite neat.

-

That’s the exact same one I use.

-

It does seem very cut and dried with those hints!

-

I couldn't let those dusty photos remain, so I gave Harpy a blast of canned air tonight, and some delicate brushing. Here are some new pics.

- 76 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.