-

Posts

2,421 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by usedtosail

-

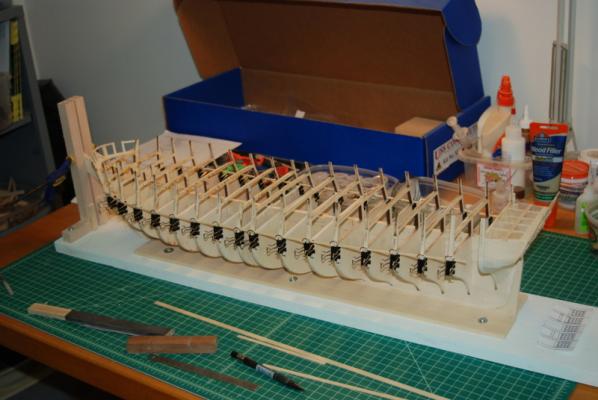

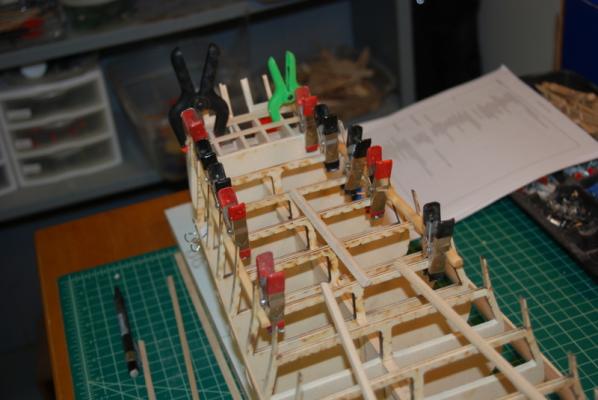

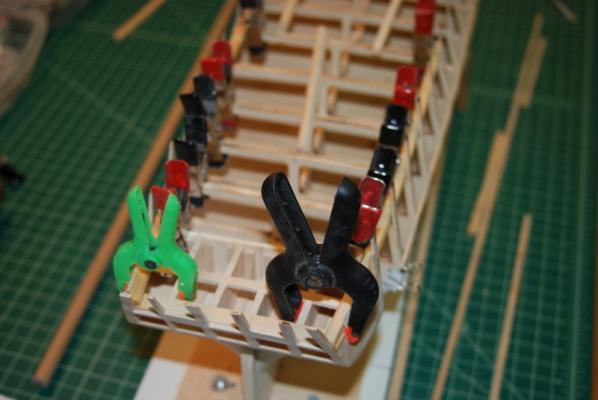

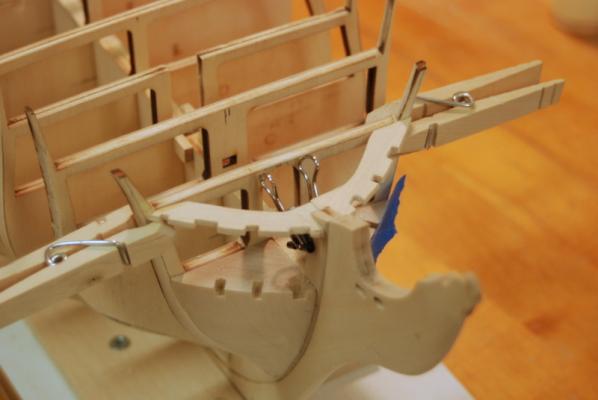

I finished up the stern framing by adding the bottoms to the chase ports. Since it will be a while before I will be planking the hull, I decided to add some battens to each side, to stabilize the bulkheads: I sanded the stern framing flush: Here is a view down the batten to check for fairness: I then started preparing the waterways. I used my disk sander to sand in the bevel along the bulwark supports: Then I put this crazy set up together to sand in the 45 degree bezel on the top and front of the waterway. It is the Dremel with a sanding drum in the Dremel workstation at a 45 degree angle, with the True Sander underneath so I could use it's fence. I put a finger board in there to hold the strip against the fence. All in all, I probably would have been better just to sand these by hand, but once I started putting stuff together it was fun to see if it would work. I didn't sand in the whole bevel, but enough to get it started. I then put the strip in my vice and set the vice to 45 degrees and planed and sanded it to the final bevel with a sanding block. This method worked but the Dremel put some pits in the face that I was able to sand out. That's why I didn't do the whole bevel this way. I made up the side waterways in two sections and I will connect them with a scrap joint, I think. I have enough overlap that if it doesn't work the first time, I can try again. I soaked the two back sections for about 30 minutes, then clamped them in place to dry. I need to add a post on the inside of the transom so I have an edge to connect these to, as well as the inside bulwark planking. There is nothing on the plans to indicate this, so I am not sure how the inside planking is otherwise supposed to end at the transom. You can't see it, but there is a small block of wood between those large clamps and the waterway to push them over, but I don't think it is enough yet. I may have to resoak and do this again. I'll see tonight how well these held the shape and how much more shaping they may need.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

I am having trouble with something that, to me, should be obvious. I am building the waterways for the Constitution and I don't know if I should add a section across the stern, at the inside of the transom. The plans don't show it there, but they also do not show the whole waterway anywhere, only a small section of waterway along the side. I went back through build logs and I find some models with it and some without. Of course, I could go into Charlestown this weekend and look for myself, but I thought I'd ask first, since we have so many Connie experts on this site. Since I am asking questions, here is another one. Is the waterway split under the bow sprit or does the bow sprit clear it so it can be one piece across the bow? Again, the plans don't show this anywhere, at least that I have found. I am hoping it is split as the clearance in this area is really tight. Thanks.

-

Mick, I had the same gap in the stern post.

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Patrick and Tim. Patrick - your Niagara looks great. I am so going to use that method for the flags on this one. I have never had much luck in the past getting realistic looking flags and that method with the aluminium foil looks good. Tim - Your cross section looks great too. I built the Santisima Trinidad cross section a few years ago, and it was a great introduction to planking and cannon rigging. I get a lot of comments from friends on that model still. I like all the details you have added to each of the decks.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Oh, one more thing. I saw one of these large cutting mats in Blue Ensign's build log and thought it was great. It is 36" by 24" and makes a nice flat surface., I found this one Thursday on Amazon for only $20 US, and it was here Saturday. I am so happy with it, I just had to share. Thanks BE for the info on it.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

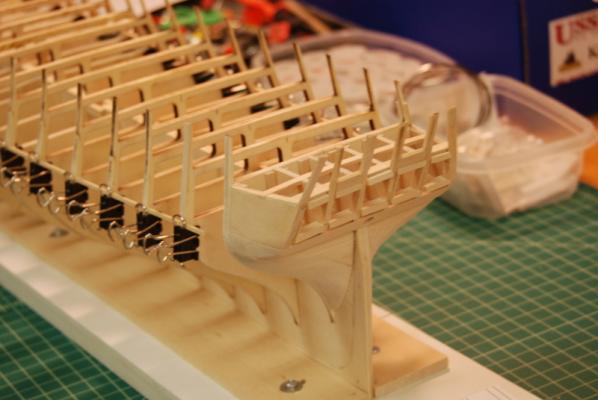

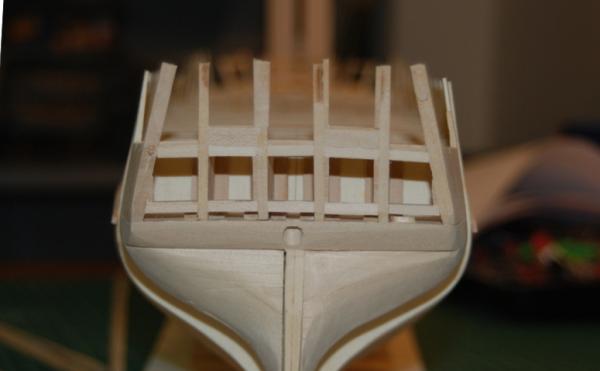

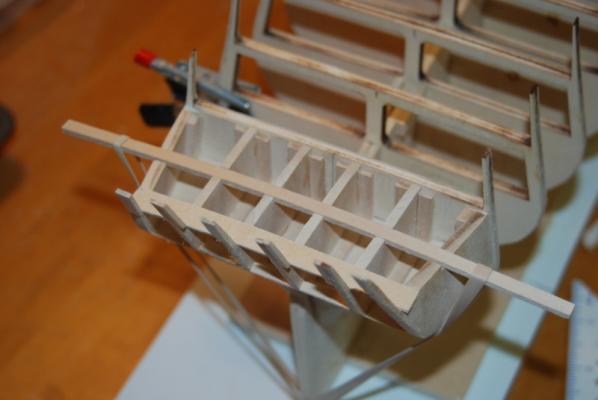

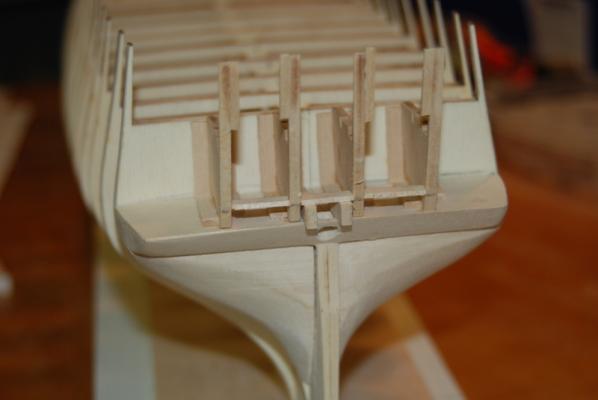

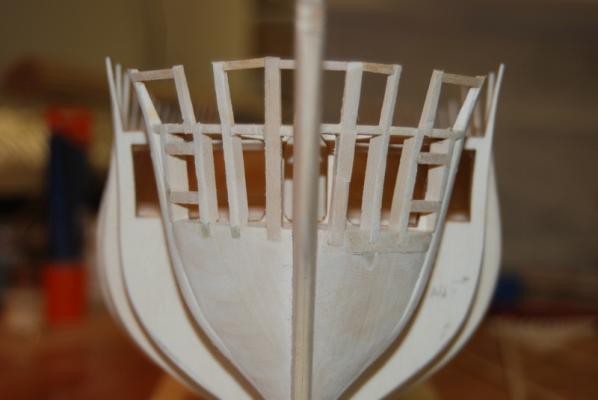

This week I have been working in the stern framing. I have the outer transom support pieces in and faired, and added the two deck beams. I left the middle one long so that I could hold it down to the curve of the deck using rubber bands (or as they say here in New England - elastics) I sanded these down to be flush with the support pieces, then started framing the stern windows. I added pieces for the top and bottom frames, then added the side frames. I first used thin (1/16" thick) pieces on the top and bottom frames, but since they were only edge glued to the supports they were not very sturdy (you can see a few of these in the above picture). I replaced them with thicker pieces that I could glue to the transom filler piece on the bottom, but the top pieces are still only edge glued, but the edge is bigger. In these pictures I have just glued in the side frames and they are all clamped and drying. The top frames can be seen above the clamps. You can see in this picture that I left the frames a little proud of the support pieces, so that I can sand them flush later. I will use the planking that will go onto the outside of the transom to make a recess around each window and then build the window frames to fit into those recesses. That's the current plan, anyway. I still have to add the bottom frames for the chase ports on the spar deck level. The top frame will be the taffrail. The windows are on the gun deck level.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Nice start so far Al. You'll have fun with this kit. As others have said, you want to edge glue the planks. But, be careful with the amount of glue you use. I found it difficult to get the excess glue off the inside of the planks after I took the hull out of the form. Luckily, I only had a few spots to deal with.

-

Proxxon Micro MBS 240/E Band Saw Review

usedtosail replied to Blue Ensign's topic in Modeling tools and Workshop Equipment

Hi BE. I have two questions, if you don't mind. 1. How tall of a piece can be cut, that is fit under the blade guide? It looks fairly tall. 2. Where did you get your desk cover? I have only seen those mats in 24" lengths or so. I would love to cover my work table like that, although I imagine that could be a little pricey. Thanks. -

Thanks for the review Jay. This looks like a great set up and I especially like your Bracket for the Dremel. I just wish I had an extra grand and a place to put the machine. Someday maybe... You asked about speed control. I know you can get a foot switch that will control the speed, but you are probably looking for something that will retain a constant speed.

-

Ah, she who must be obeyed. I know it will look great whatever color you end up with.

- 420 replies

-

Thanks Evan. That is a great tutorial for getting a nice wood effect.

- 446 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

Welcome Nick and Tim, Thanks for following. I attached the two side supports and have started to sand them into shape. While I am doing that, I am also sanding back the transom filler piece, which you can see in the last picture I posted that it is a little long.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Patrick. This is a tough decision because historical accuracy is important, too. In the end though, aesthetics to me are going to win out. Some progress this weekend on the stern framing. I transferred the support piece outlines to the last bulkhead and the transom filler block. I glued some small tabs along one side of these lines and let them dry some I then glued in the supports and the tabs on the other side and slid them up to the first tabs. I checked the alignment of the stern ends using a divider to make sure they were all parallel to each other I started beveling the two outside support pieces but quickly saw that if I hold them flush to the last bulkhead, the deck beam notches are too far forward and don't align with the inner support notches, and the stern uprights are also too far forward. So, I glued some extra wood to the front of these two pieces, which I will bevel to match the angles and put these pieces in the right place. I'll have pictures of that process later. In the mean time, I started to frame the windows. As you can see, I used two small piece of wood that were the same height as the bottom window frames to align them parallel to the transom filler block and with each other to be all the same height. I also made sure that these frames stand a little proud of the support pieces so they will get faired along with the support pieces when I sand the supports before planking. A lot more work to do on the stern, but it is nice having a start.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

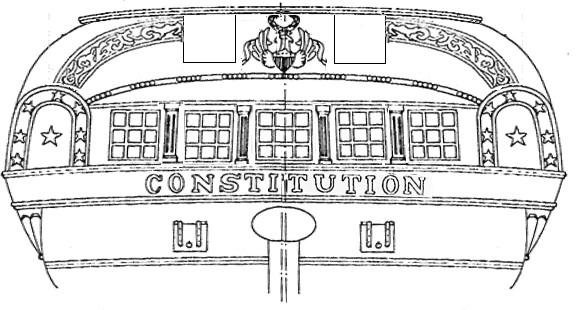

Thanks dragzz. Russ, thanks for the tip. I have been looking at both the Hull model and the Corne painting of the period for a while too. There are some major differences, like the number of windows, and as others have discussed in their build logs there is really no good source. As you suggest the Hull model may be the best reference since is was made by the crew, but I am not crazy about that stern configuration. The Corne painting is better and does have some of the elements I like, but may have some inaccuracies because it was painted at a later time. That is one of the reasons i am calling this an 1812-ish build.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Happy to help. I am certainly using ideas I have seen here too, so that helps a lot. Hopefully this will all work the way I see it in my head. Or, it may just turn out to be another "learning experience".

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Rich. I have gotten in trouble in the past when not paying attention to these support pieces, so I am being careful now. I will still have problems later, but like you said, that is life and solving problems (up to a point) is actually one of the things that I really like about this hobby. I hope your stern problems get resolved satisfactorily. As I mention at the end of my last post, before I can tackle the stern framing I had some design decisions to make. Since I am shooting for an 1812-ish version, the first decision was the height of the bulwarks and taffrail. I had already decided to eliminate the bulwarks in the waist area and replace them with some stanchions and painted cloth panels. For the rest of the bulwarks, I am going to build them only as high as the top of the main rail, so there will be no top gallant rail and the top of the spar deck gun ports will be just under the main rail. I am going by these pictures from before the 1927 restoration. It was after the restoration that a topG rail was added. I am also going to make the top rail out of one wide piece instead of three glued together laterally, and thicker as in these pictures than what is on the plans (3/32" instead of 1/8"). There were some other design decisions that came out of this one, like the placement of the hammock boards and their height and the bow rail details, but I'll show you those as I get to them. The major design piece that I needed for the transom was the height of the main rail where it intersects with the taffrail, so now that I have established that height I can design the transom. I am going with a modified five window design from the Constitution Anatomy of the Ship (AOS) book, which shows a possible transom design in 1812. I scanned this design along with the transom plans from the kit, and using Paint and PowerPoint, I was able to get them to the same scale and start merging the two. The AOS design when scaled to the height of the top rail was too narrow, so I stretched it out to the width of the kit. The AOS design also shows the taffrail above the main rail height, so I moved it down to meet the ends of the main rail. This meant having to move the decorations down to meet the sides of the chase ports, but I think that still looks OK. Since I am going with the five window configuration for the stern, and the kit has four inner supports for the transom, I wanted to make sure that none of the windows had supports behind them, since I plan to use acetate in the panes and would like some depth behind them. Since these supports are all the exact same, I figured I could move them laterally a bit without causing problems later, so I came up with a framing plan that has these supports moved and used to frame some of the windows and the two chase ports. I will add other framing as shown in the plan for the other sides, top, and bottom of the windows and chase ports. So, working from this plan I am currently adding the side supports for the windows and chase ports to the transom support pieces before I glue them in. This way I can shape them to conform to the shape of the supports before I glue the supports in, which appear to be only edge glued to the transom filler block and last bulkhead. I will probably add some small blocks of wood along the joints to support them better when I glue them in.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

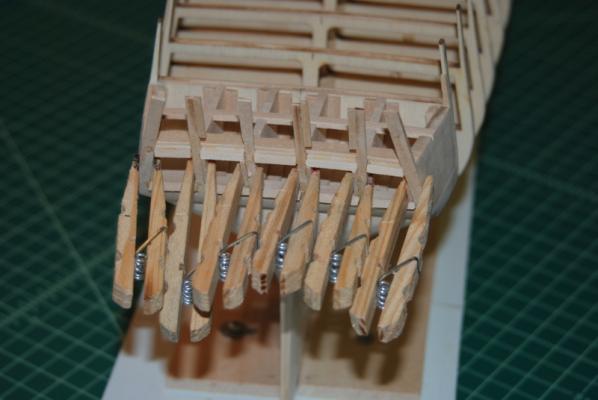

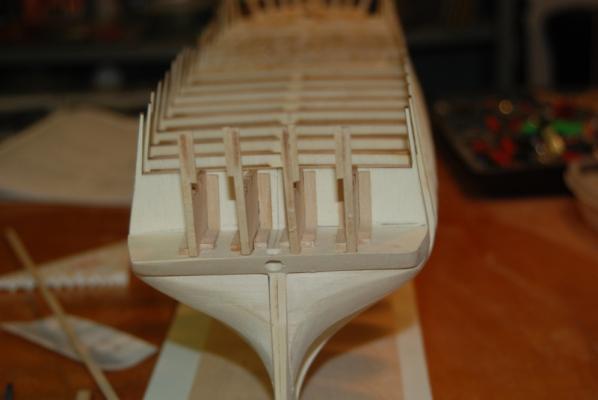

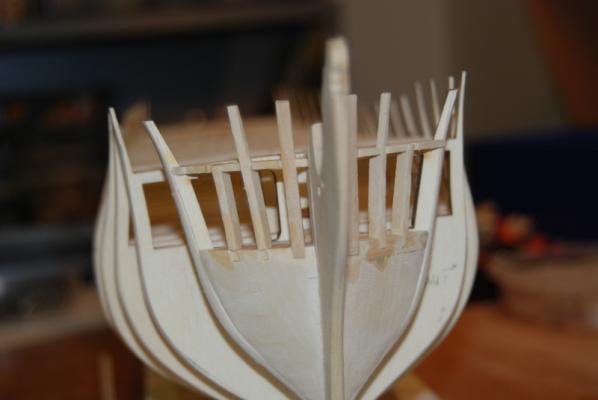

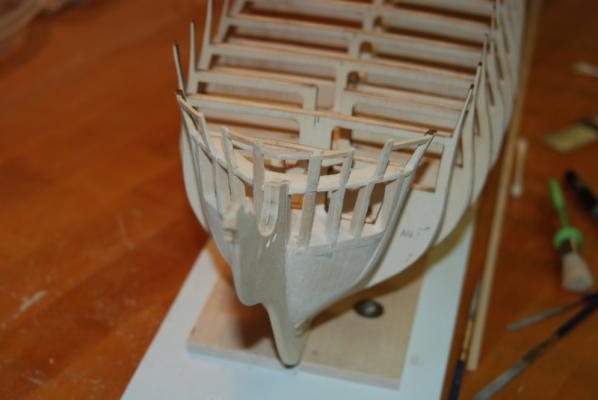

I faired the hull from the keel up to about the wale, then turned the hull over and faired the rest of the way up. I then started framing the bow. I first cut out the main frame pieces, after gluing up three strips of wood for the knightheads. The timberheads I could make out of a single piece of wood. One thing I did was to hold the pieces together to make sure the notches all lined up at the same height then sanded the bottoms flat. When I was satisfied with these, I fit them into the bow filler block notches and cut out the stiffener pieces that go between them. This took a couple of tries because these pieces as shown on the plans are too short and don't reach all the way to the rabbet. I modified the new pieces to end at the rabbet, then glued them to the stem and the first bulkhead, using clothes pins and a binder clip to hold them at the right height. I then added the upper piece that forms one side of the head entry. I clipped a batten between the adjacent pieces to get the correct location for the top of this piece. If you look closely at the picture before the last one, you can see that the port knighthead was curved too far back at the top and didn't make a nice curve with the timberheads on this side. Instead of replacing it, I added some wood to the front and removed some from the back to get it into the right shape. I added the side pieces for the bridle ports and the upper support pieces Then the top and bottom of the bridle ports. I faired it all and here is how it came out. I have some more design work to do before I can tackle the stern framing, but that is next.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

I have used copper tape to good results. For preparation, I give the hull a coat of primer and a good final sanding afterwards. I cut a length of tape, then score the individual plates, so that I am applying them one plate at a time. This way I can overlap the ends as well as the sides. The trick is to just score the copper, not cut through the paper, so you can remove each plate with tweezers from the long strip. I have not tried using a ponce wheel to simulate the nails, but I am going to try that on my current build.

-

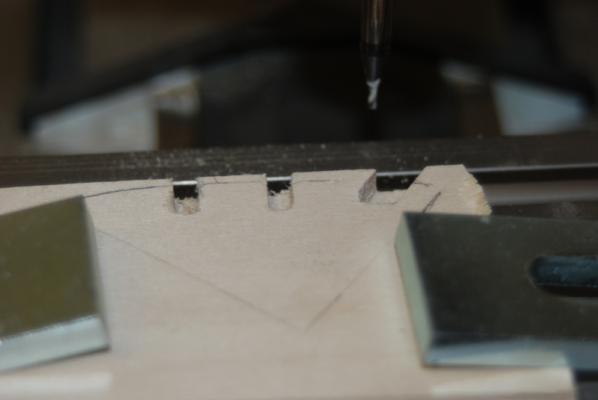

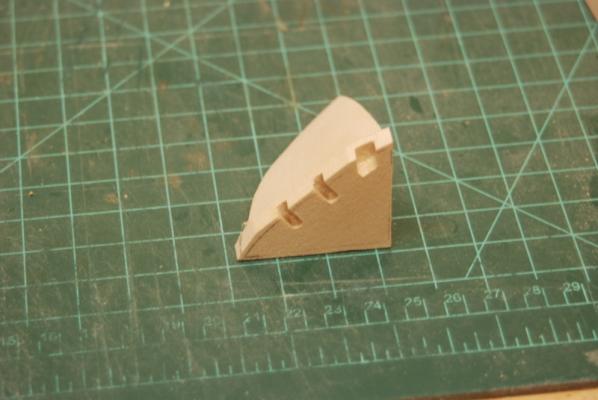

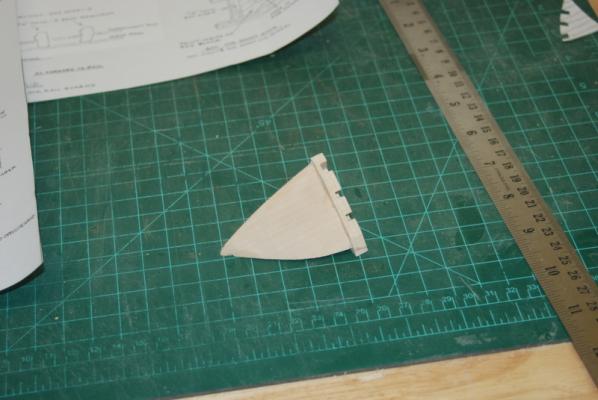

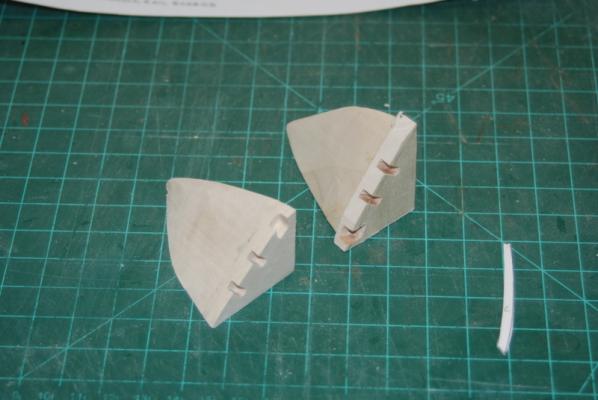

First, an update on the stern filler blocks. I ended up spending over an hour fairing these even more, once I started running a plank strip across them. They have a much nicer flow and a better transition from the rest of the stern bulkheads. The little shelf for the ends of the planks at the transom filler is now even on both sides. These are also now glued into place. After making the stern filler blocks, it was time to make the bow filler blocks. Piece of cake, I thought. These have a much flatter profile than the stern so there shouldn't be so much sanding. Ha! I had not counted on the little notches, which made this a harder job than I thought. OK, to start, I cut out the blanks for each filler block from the supplied block, cut out the rough shape with the hand saw, and sanded in the final shape using the disk and belt sander, just like the stern blocks. These both came out pretty well, so it was time to carve the slots. I marked them on the top of the blocks using the cut out piece from the plans as a template. I cut a slot on each side using a razor saw and started removing the material in the slots with some small chisels. Well, these came out pretty rough as you can see in these pictures: I slept on this but decided the next day that they were not acceptable. I had bought a few end mill bits to use in the drill press, and I figured this was the job for them. I had to figure out how to hold these odd shaped pieces in the vice I had and then it hit me. I could reuse most of the pieces I already had by cutting off the top 1/4" and mill a 1/4" piece of basswood sheet to replace it. The sheet I could hold flat on the XY table that I have under the vice on the drill press. So that is what I did. I used the table saw to cut most of the tops off, then sanding the rest off in the disk sander. I milled two piece of 1/4" sheet, using a 1/8" end mill bit for most of the slot, and a 1 mm end mill bit to clean out the corners. These came out so much better, I was rather excited. I carefully glued the milled pieces to the rest of the filler blocks, making sure the slots were in the right place in relation to the rest of the filler block. The next day, I sanded one of them down and it fit like it was supposed to. I started sanding down the second one and managed to round over the top so it was ruined. OK, I thought. If I can do this once I can do it again. So off came the top, another sheet was milled and glued on. When I sanded this one it looked good, but when I fit to the stem, it was too small. Apparently in all the sanding, I was removing little bits of the original section and in the end it came out too small. Another lesson learned. So it was time to start over with the second bow filler block. I had a couple of scrap pieces that I glued together to form a blank. I sanded one end flat for the top and milled the slots first, while I still had a nice rectangular block that I could hold in the vice: After that, it was just a matter to cut out the rough shape and sand it to the final shape. And here is the result of a week of work: They are just glued on and there will be some fairing left to do, but I am relieved that they are finished. While the glue was drying on various pieces this week, I also did some fairing of the bulkheads. I glued some sand paper to this sanding stick and used it to fair down the bulkheads. As I noted in a previous post, some of the bulkheads were not wide enough in some places, so in these areas I glued some thin basswood strips to build them up, then sand down to meet their neighbors. After the bow filler blocks dry, I will do more fairing then start the bow and stern framing. Thanks for watching.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.