Peta_V

Members-

Posts

351 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Peta_V

-

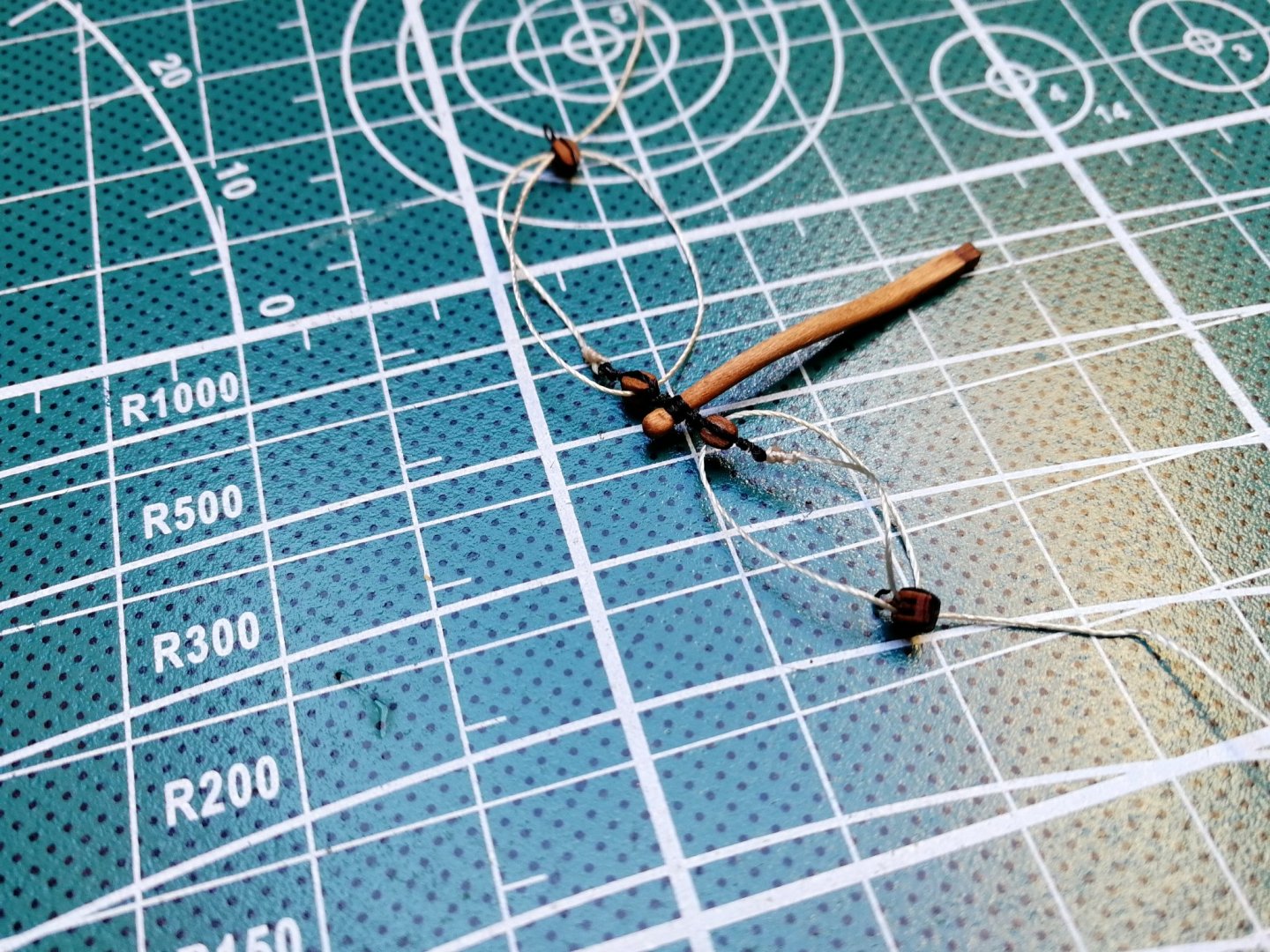

I have shaped the rudder tiller and did the tiller tackles. The end of the rope will end on the rudder tiller as well, this is just temporary fastening on the cleat as I'm not sure about the colour of the tackle. This thread is supplied with the kit. The quality is fine but I'm not a fan of that white and glossy colour. I'm thinking of replacing it by my own thread with matt tan colour.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

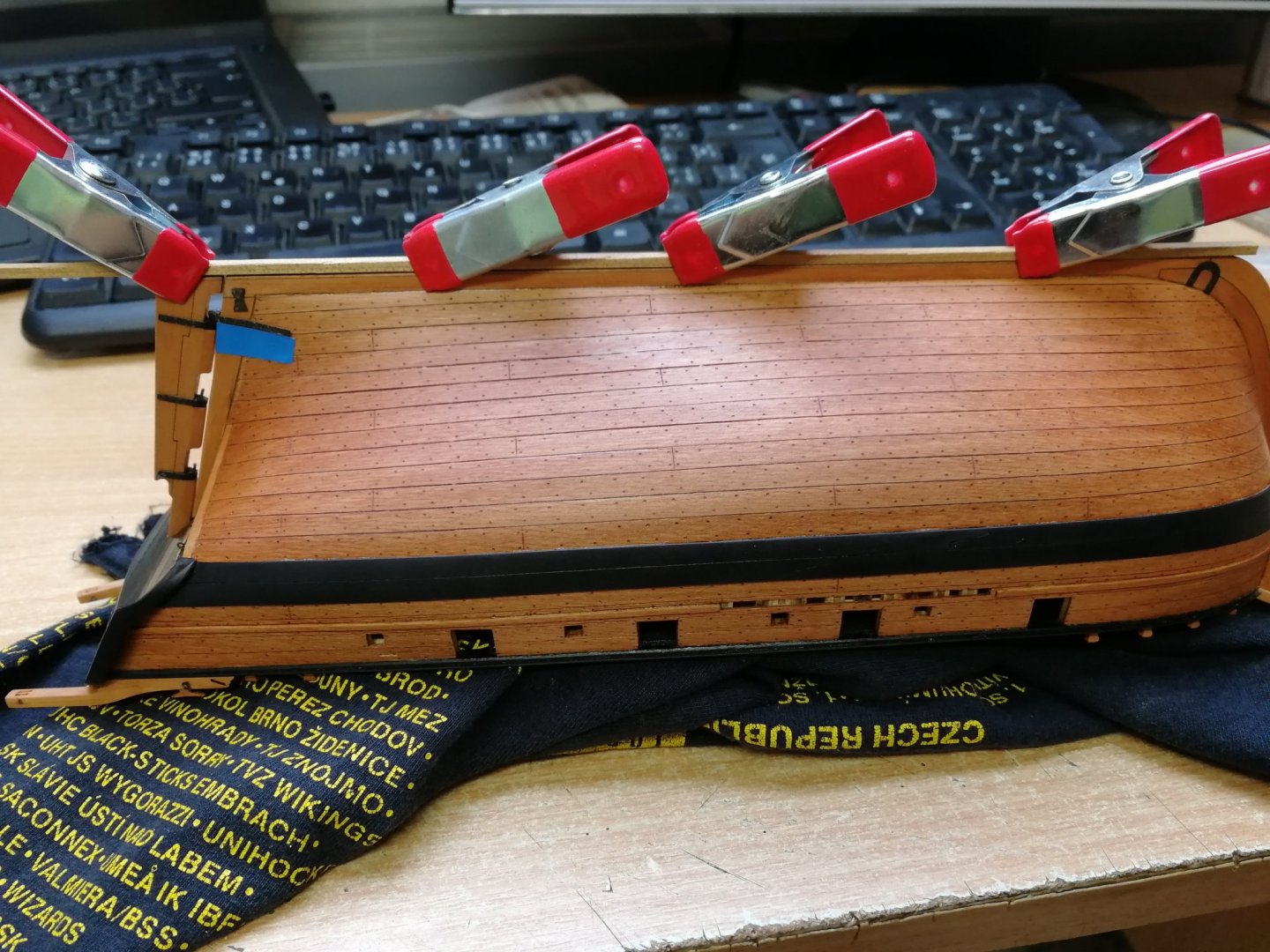

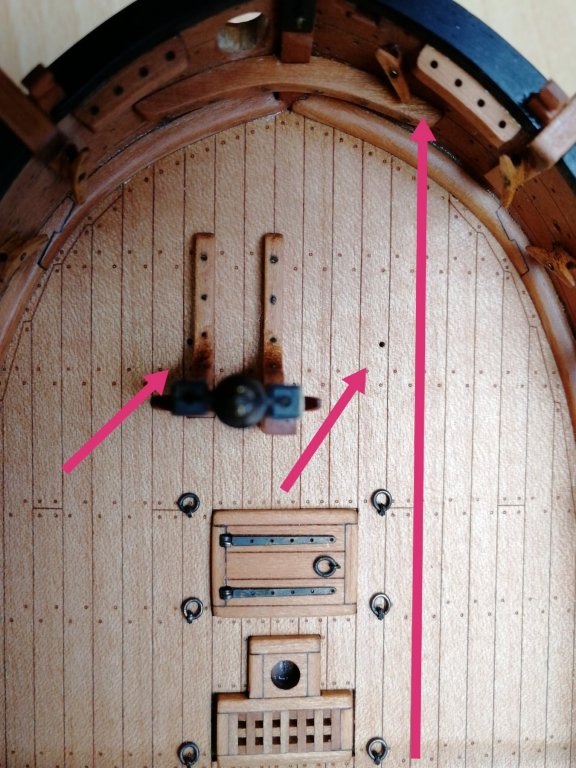

Instalation of the rudder braces to the hull. It took me while to figure out how to position it properly. At the end I clamped the plank to the keel which protrude to the stern and fix the rudder to the position. Once I was happy with the position of the brace I marked the position with the tape. Remove the rudder and glue the brace.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

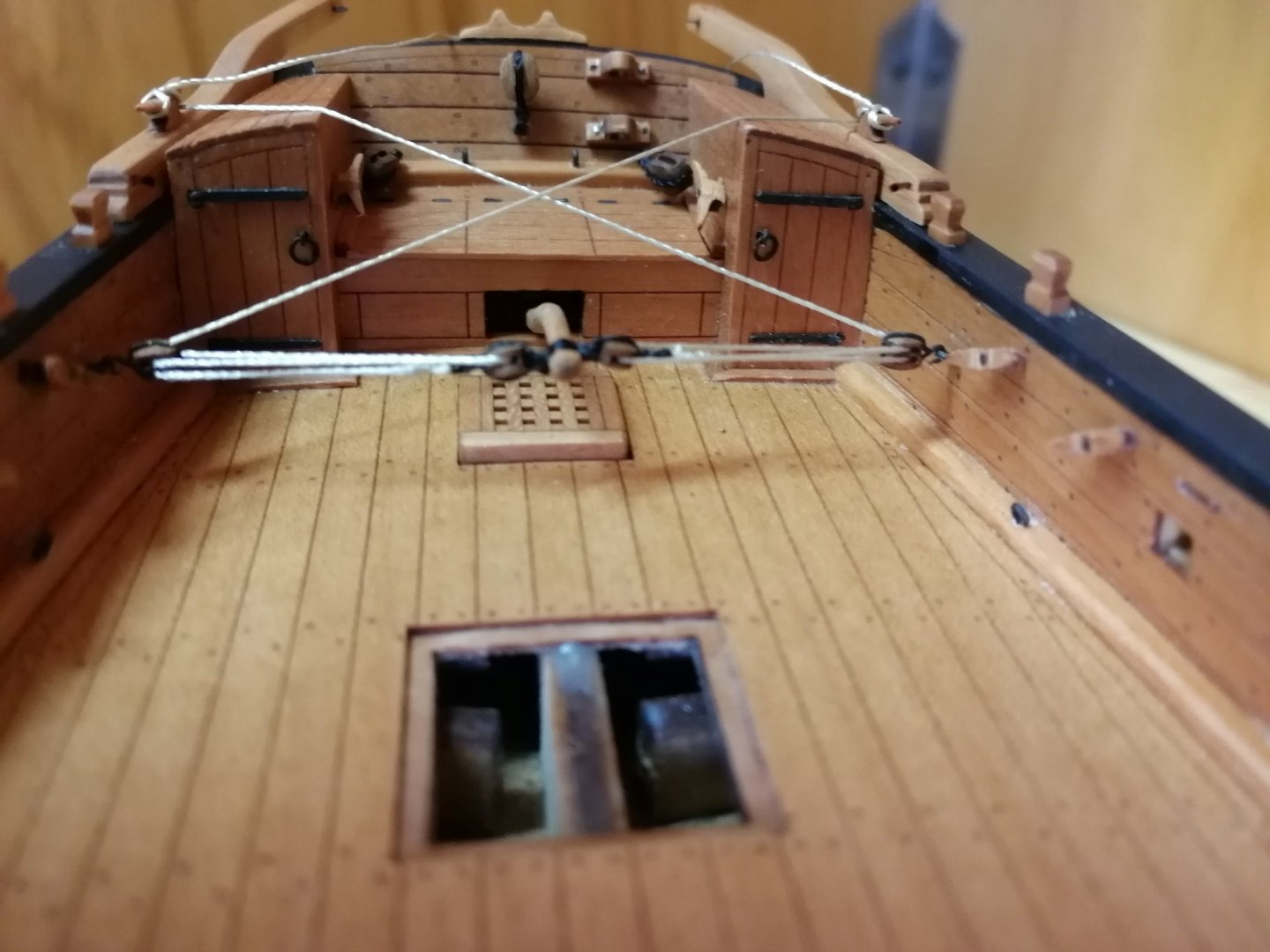

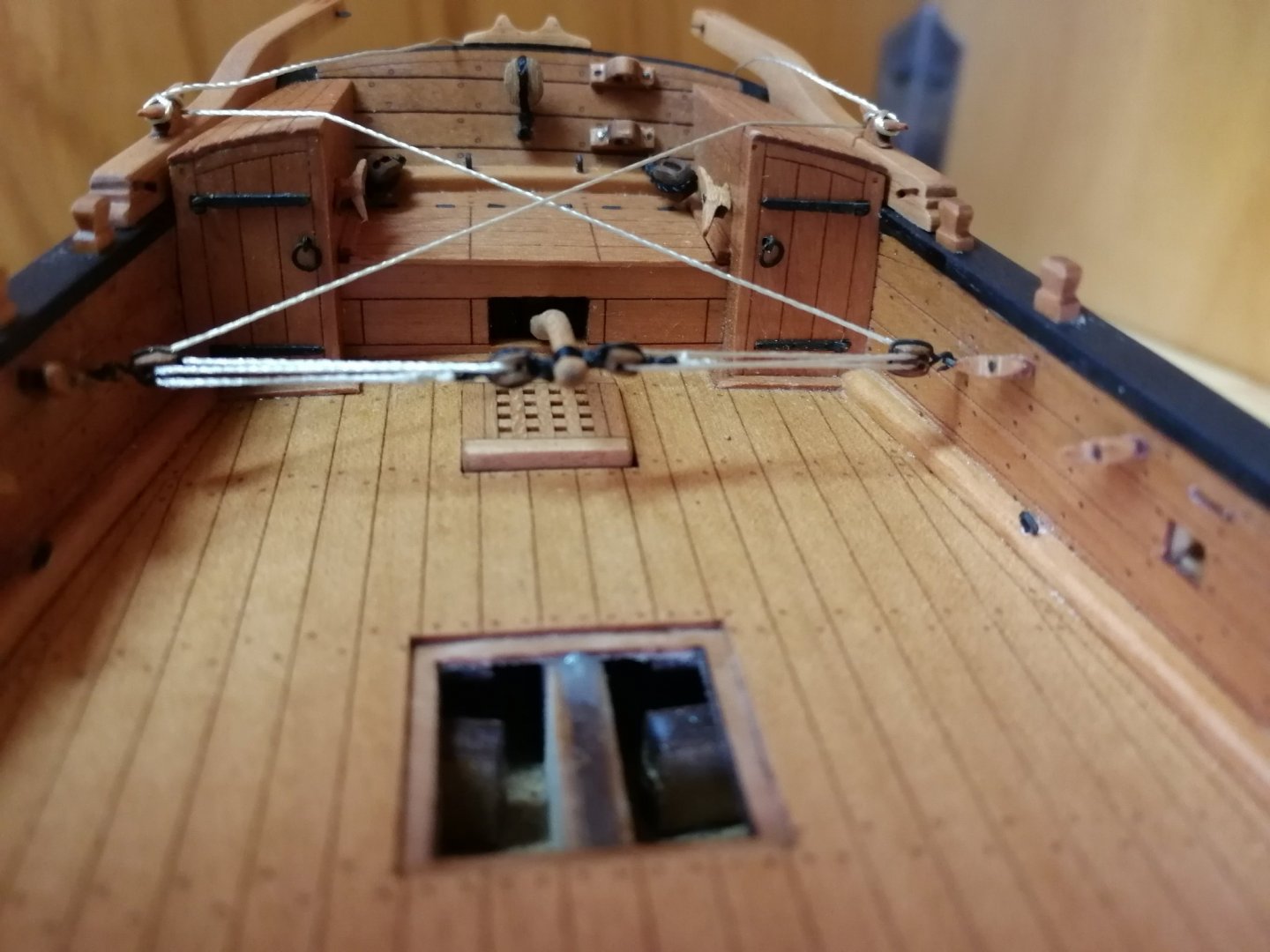

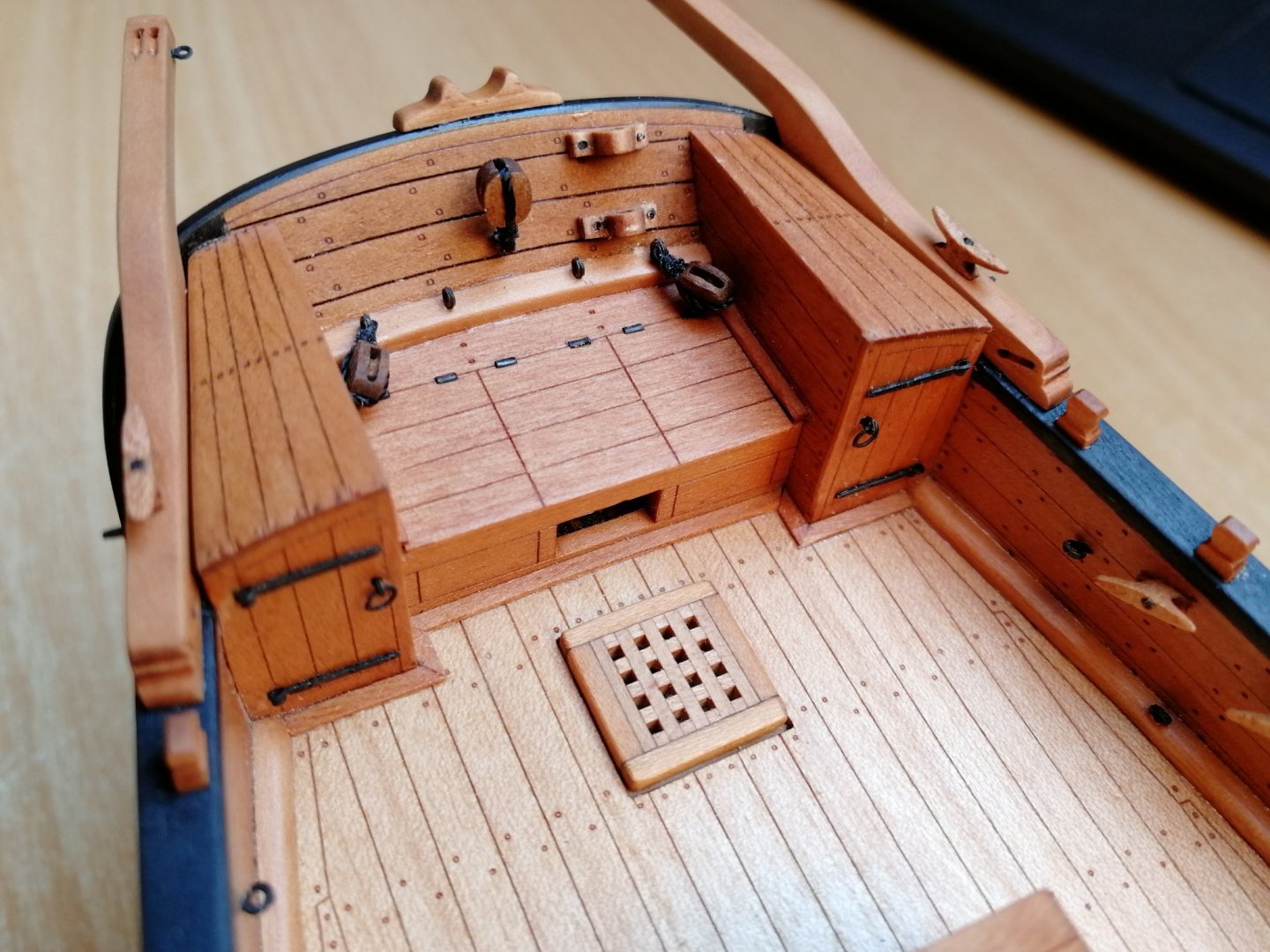

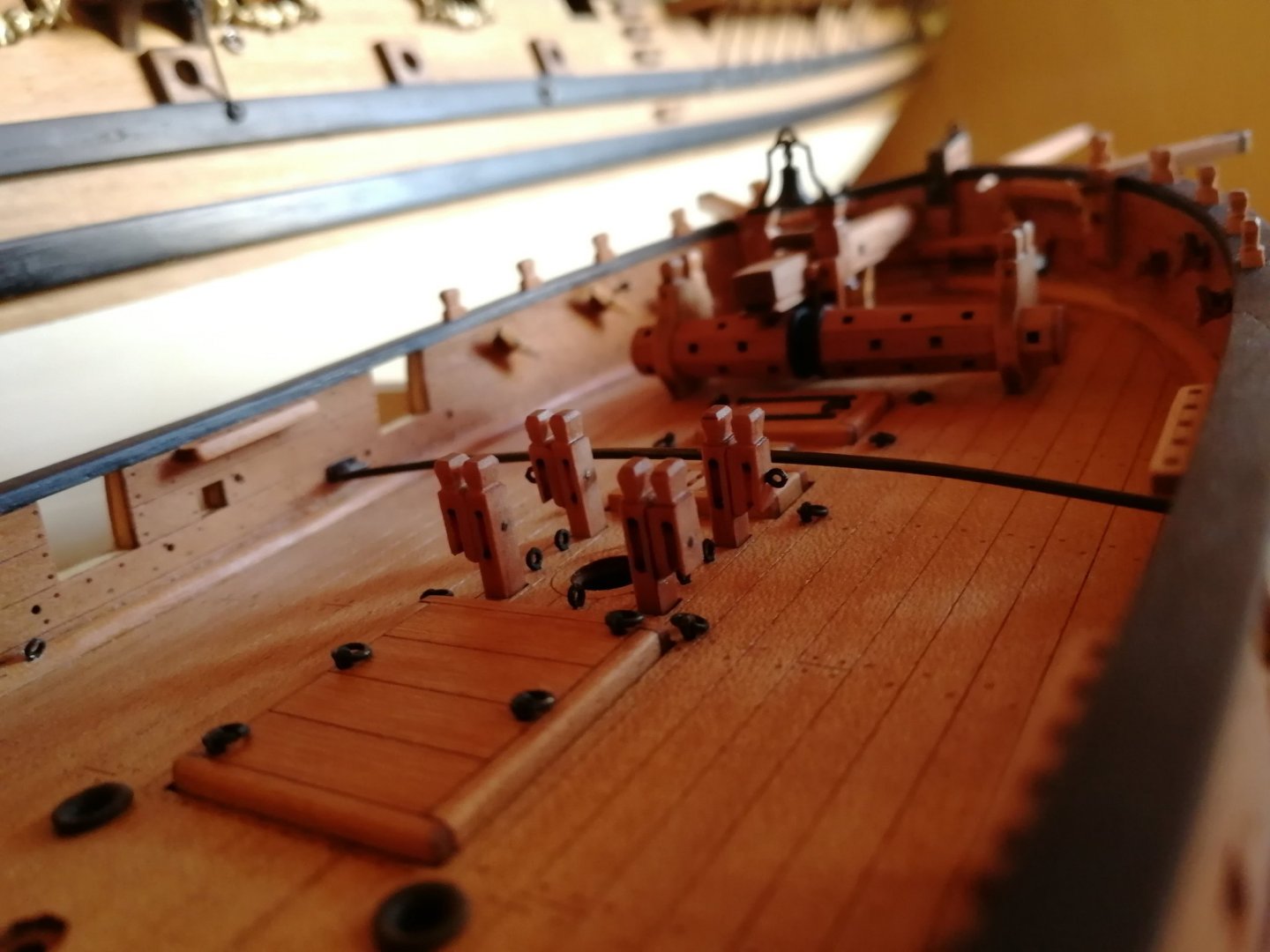

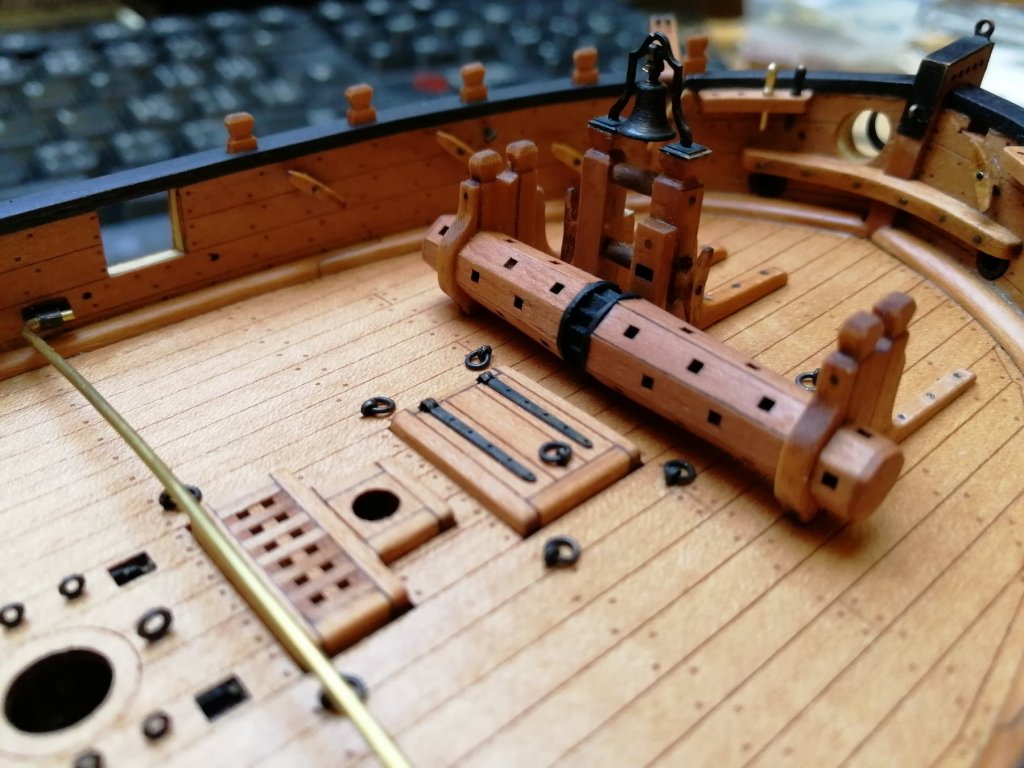

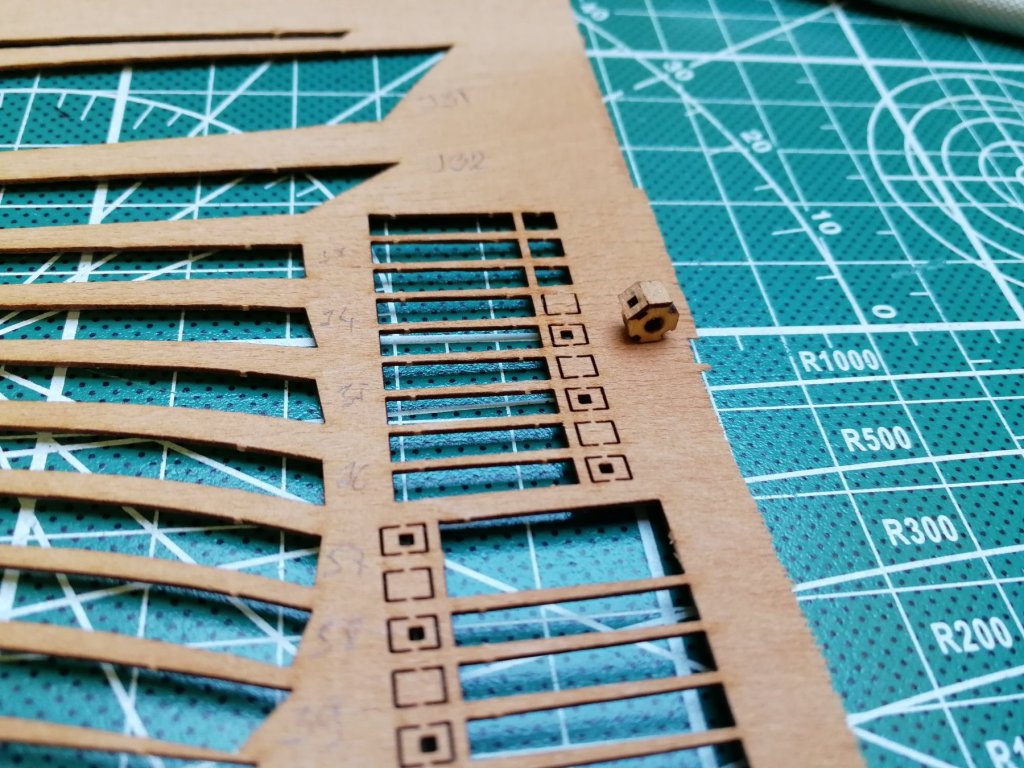

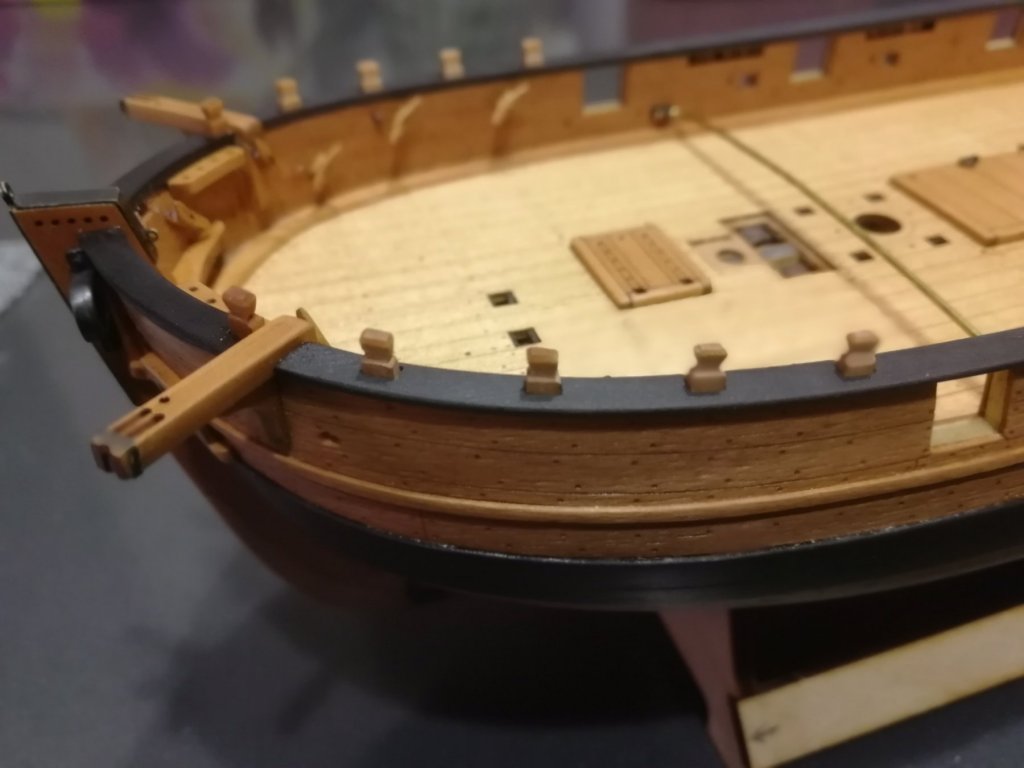

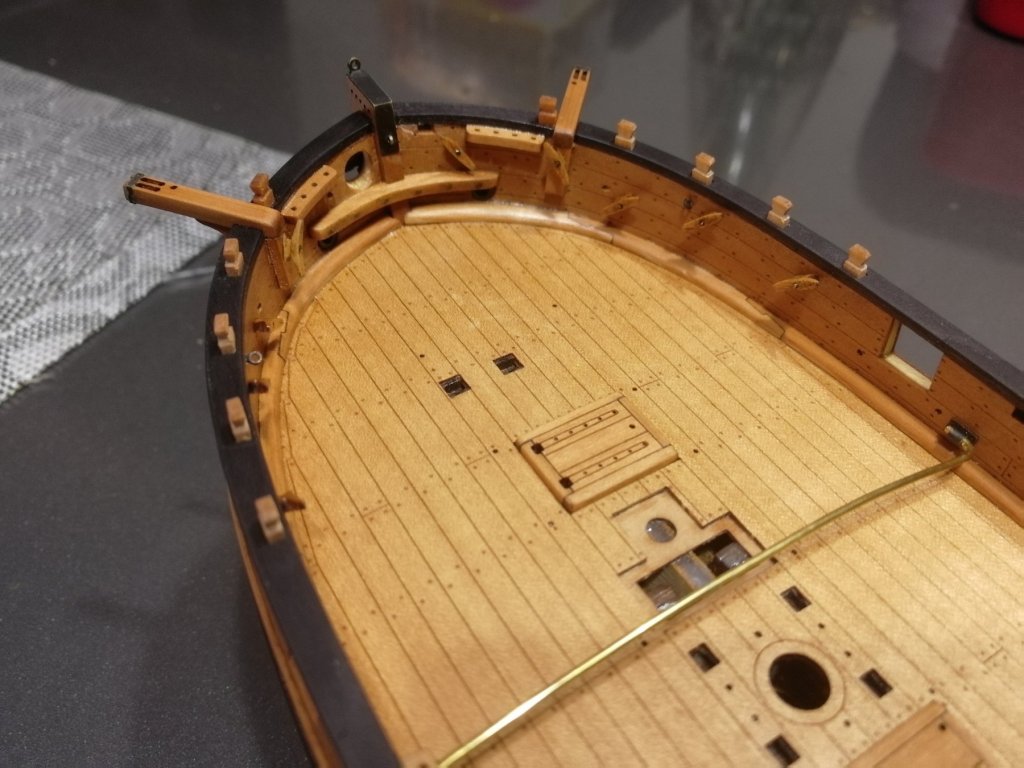

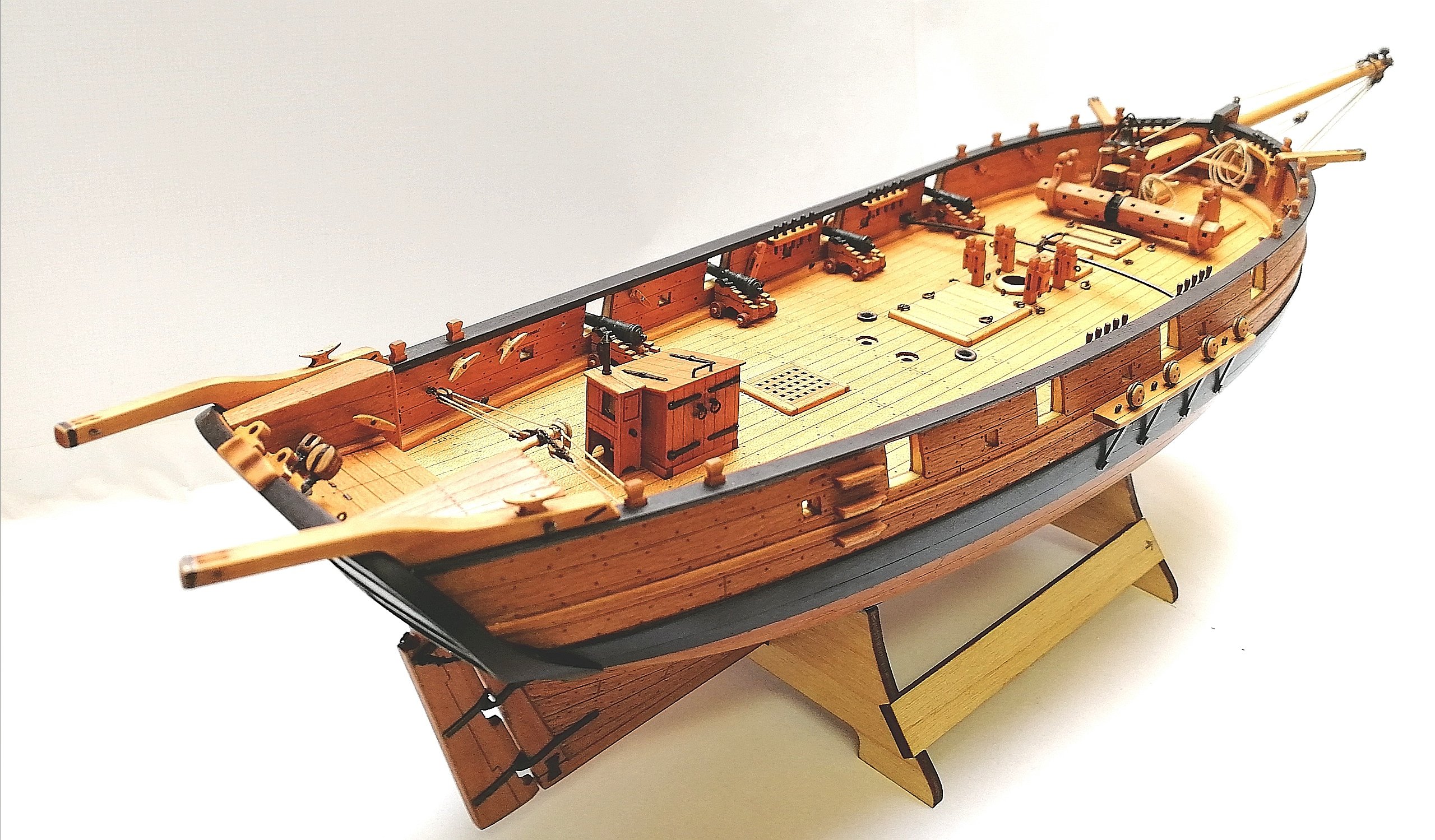

Next deck details....... Two last hatches, flagpole planks and sail boom pad. I have also started with fastening of the blocks in the eyes where hook is not used. It would be really tricky to do this on the ship so I decided to remove the eye, Fast the Block outside and put it back. Will do this for all eyes which holds block this way.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

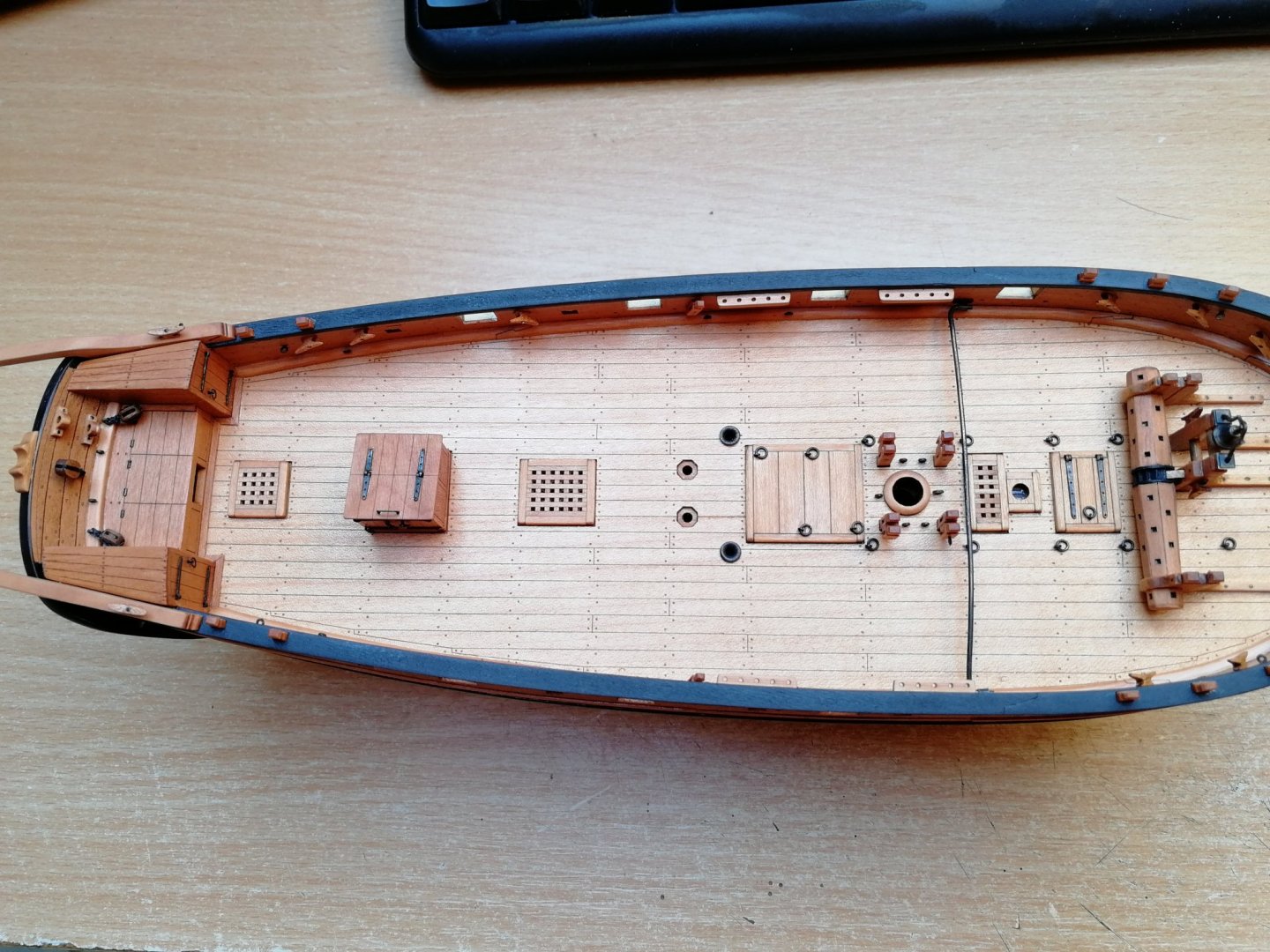

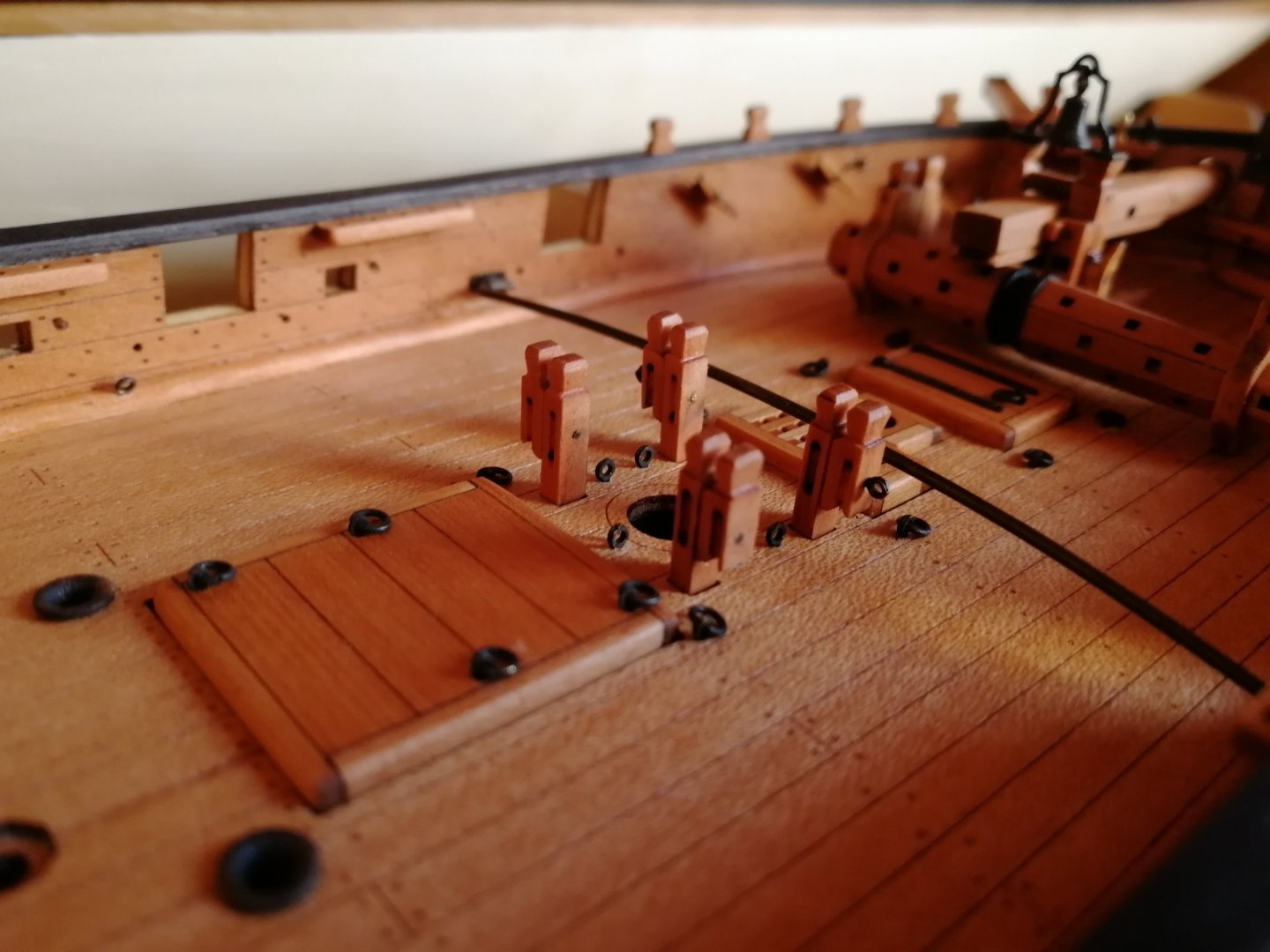

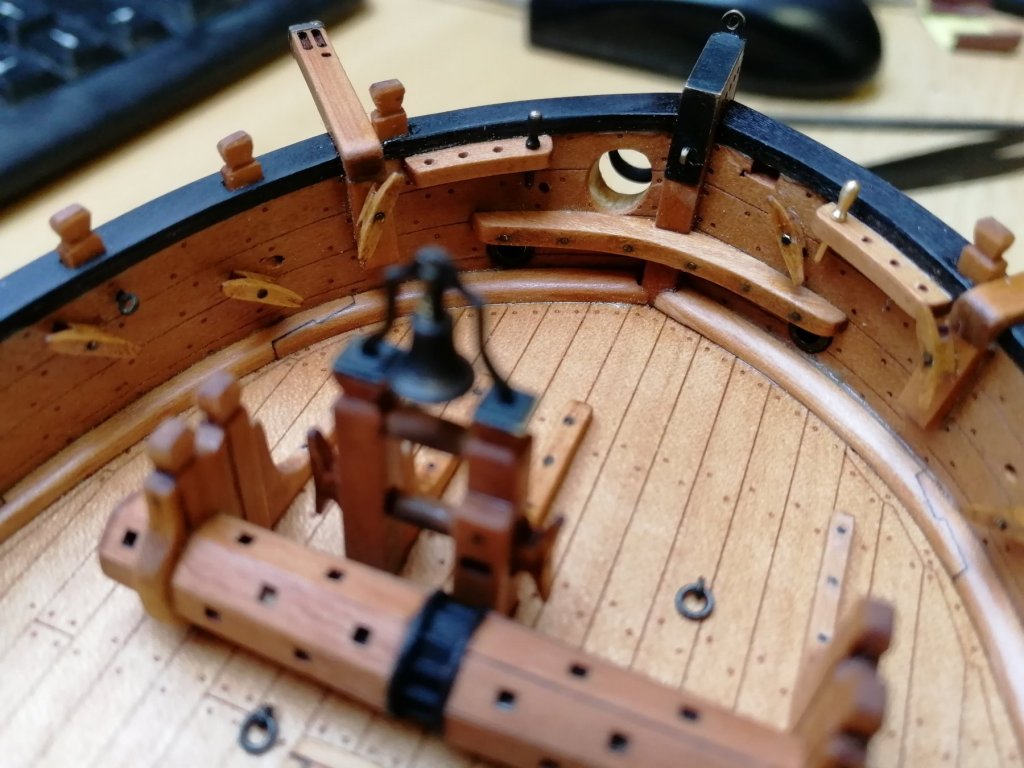

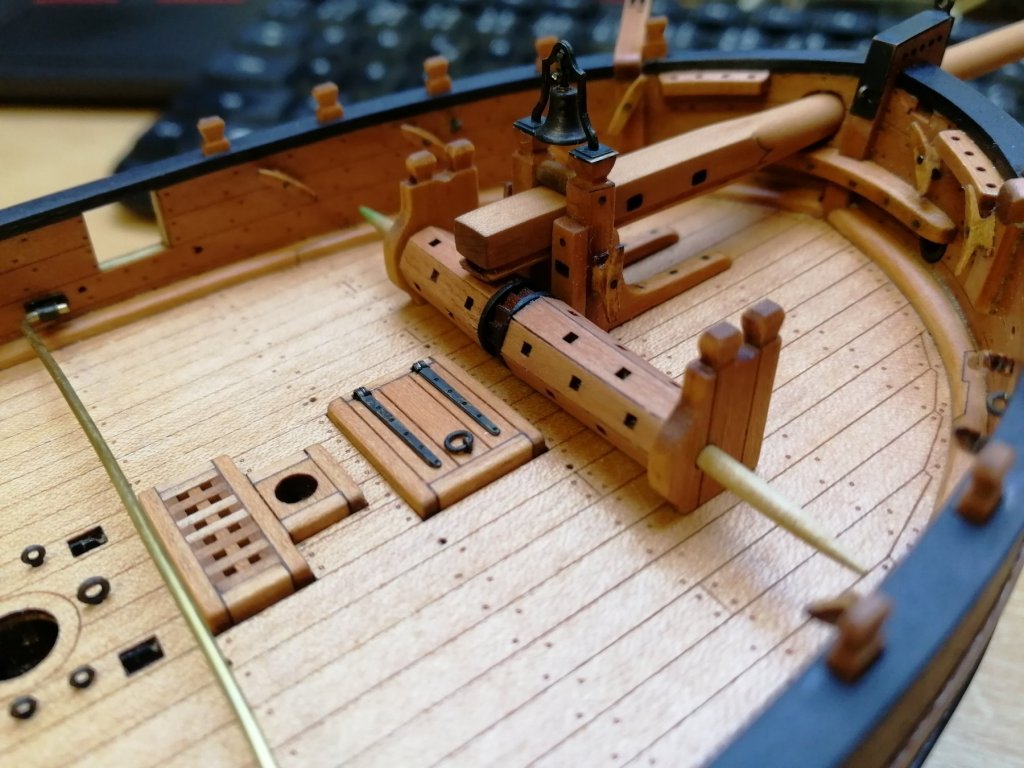

Few more deck details. Irons on the latrine doors, cleats, bitts on the bulwark rail, pawl in windlass and mast coat.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

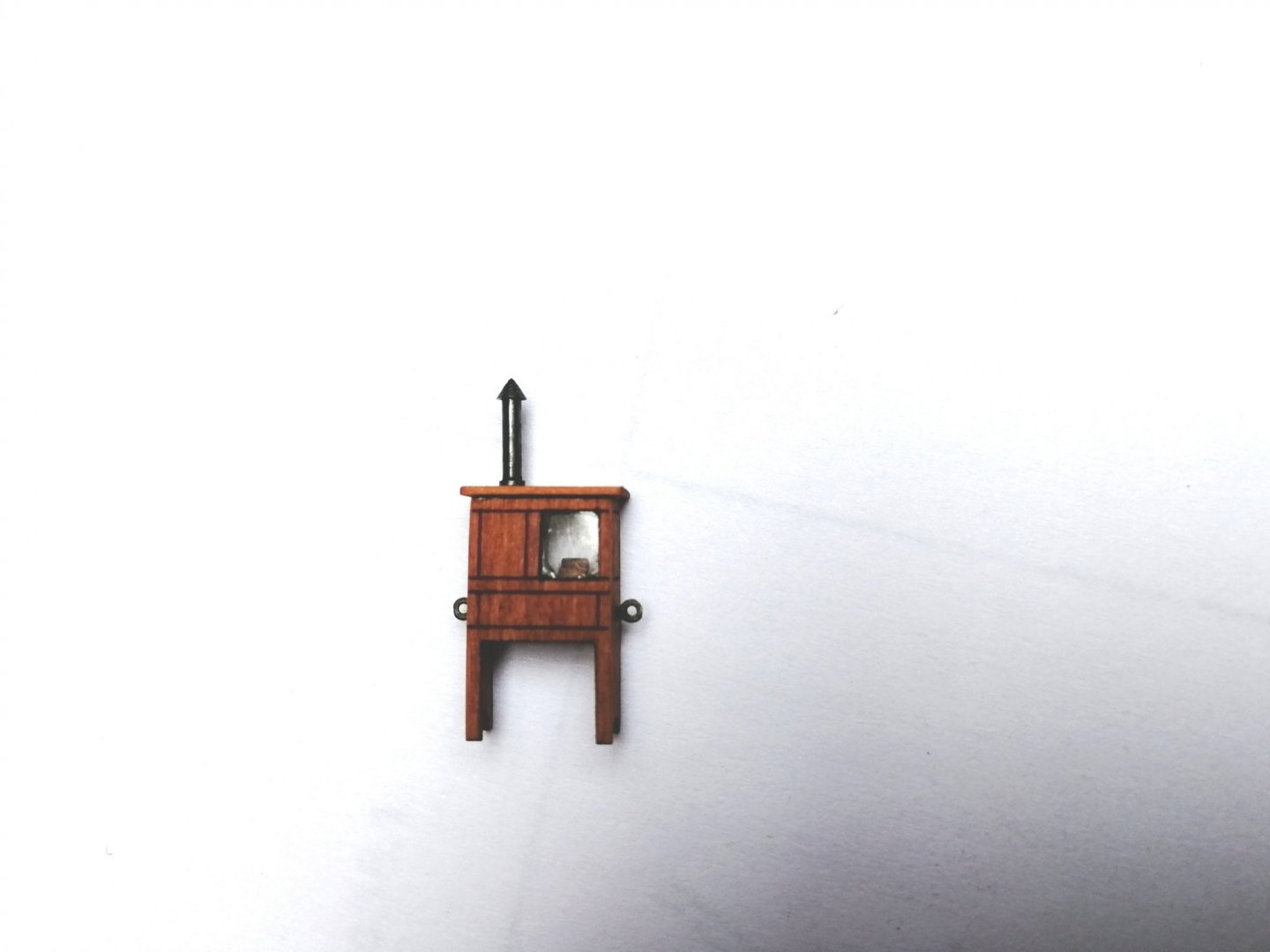

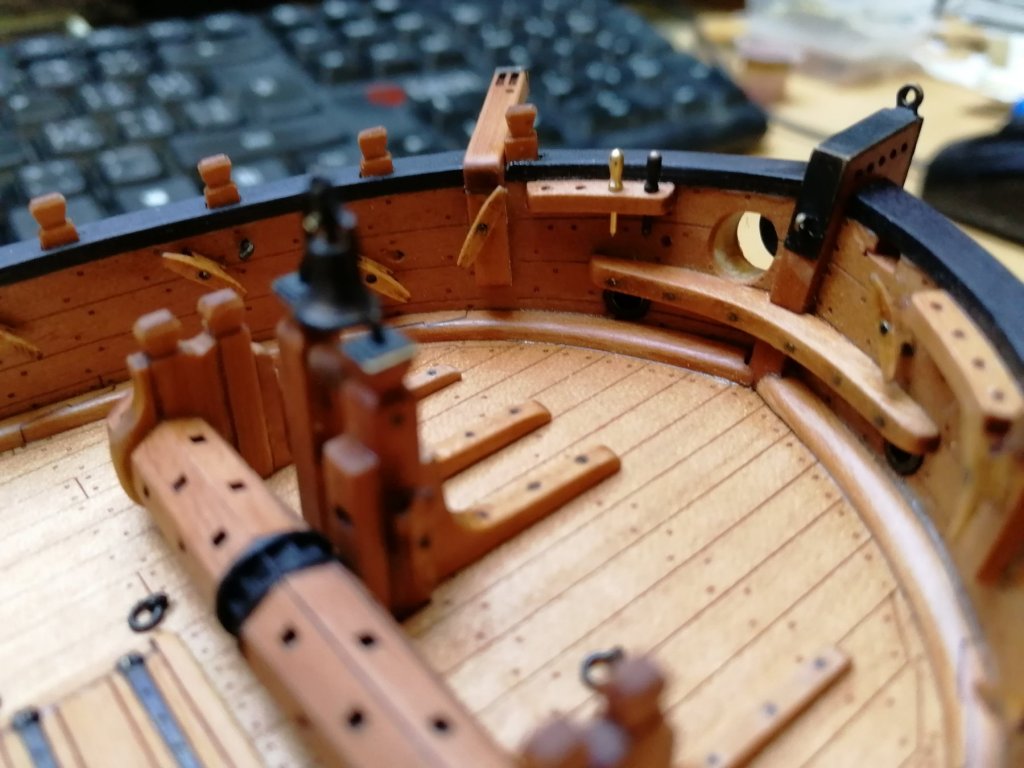

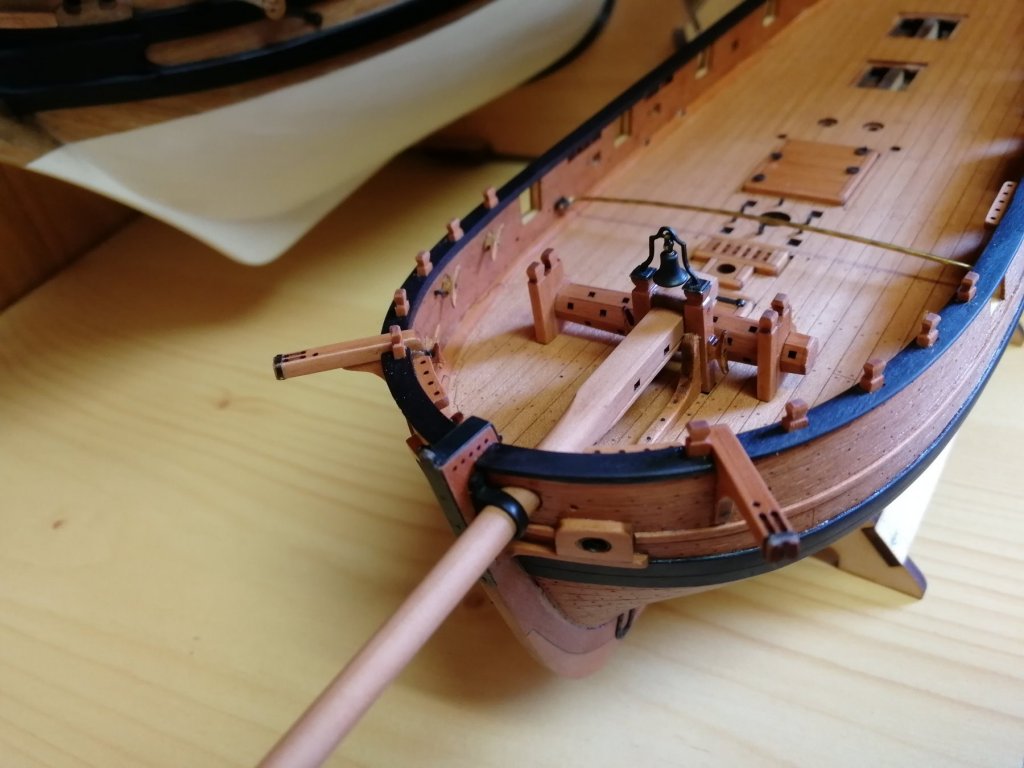

I have finished the rest of the mast bitts. Horse has been blackend and add some Iron details to the companionway.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

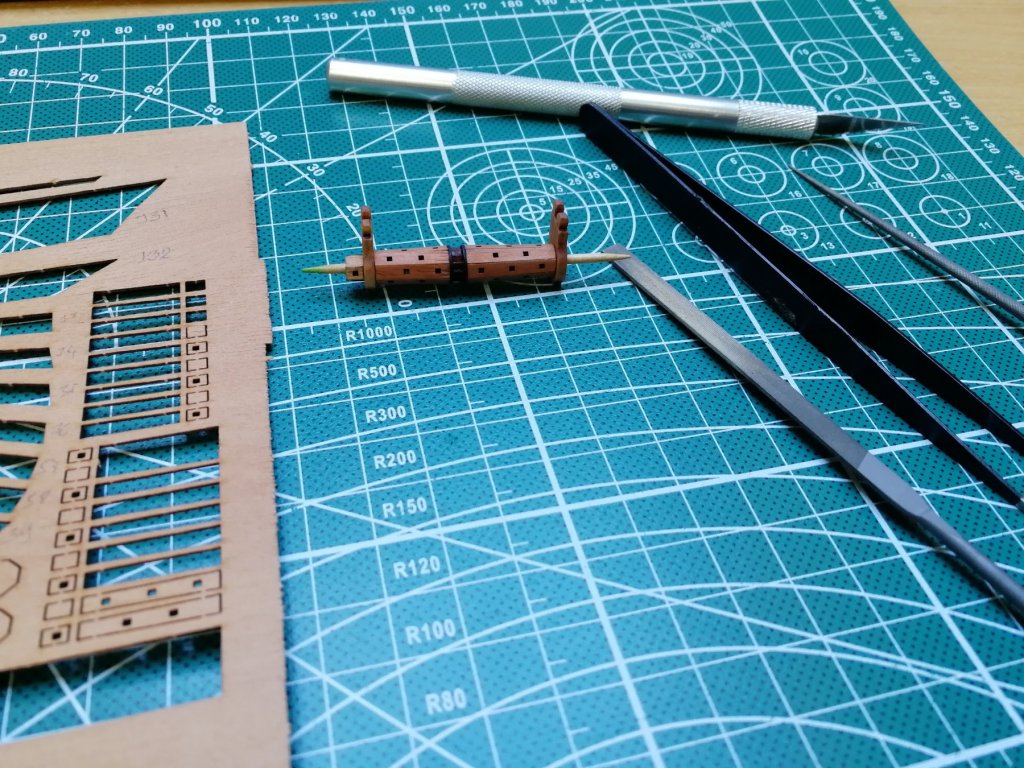

Thanks Jim. Next are the mast bitts. It is time consuming due to the sending off the char and processing the head and sheaves. It is very small so fun work. 2 already prepared, 2 more to go.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

Boat davits. I'm leaving them in pear wood instead of black colour. I like it more in natural wood. I'm going to simulate the iron bands at the end of each davit once I receive Copper tape. Simulation with a yawl And in its full (almost) lenght

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

Thanks a lot for all likes and kind comments. Love it! @Katoom and @Dubz thank you for your opinion, I share the same one as well. I took other 2 or 20 looks at it and black goes much better with other details. I try to avoid the brass fittings which is the next reason for black 👍

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

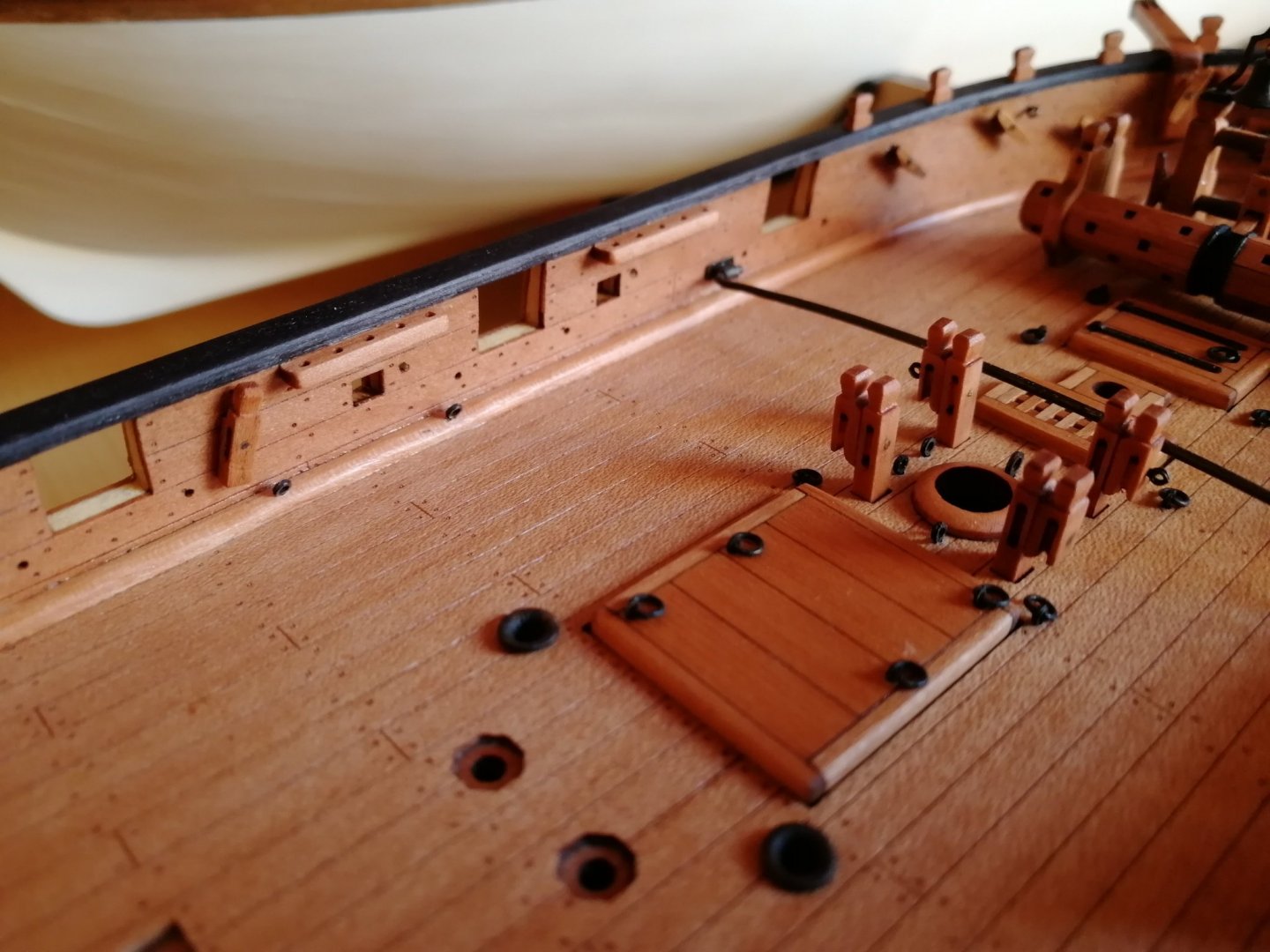

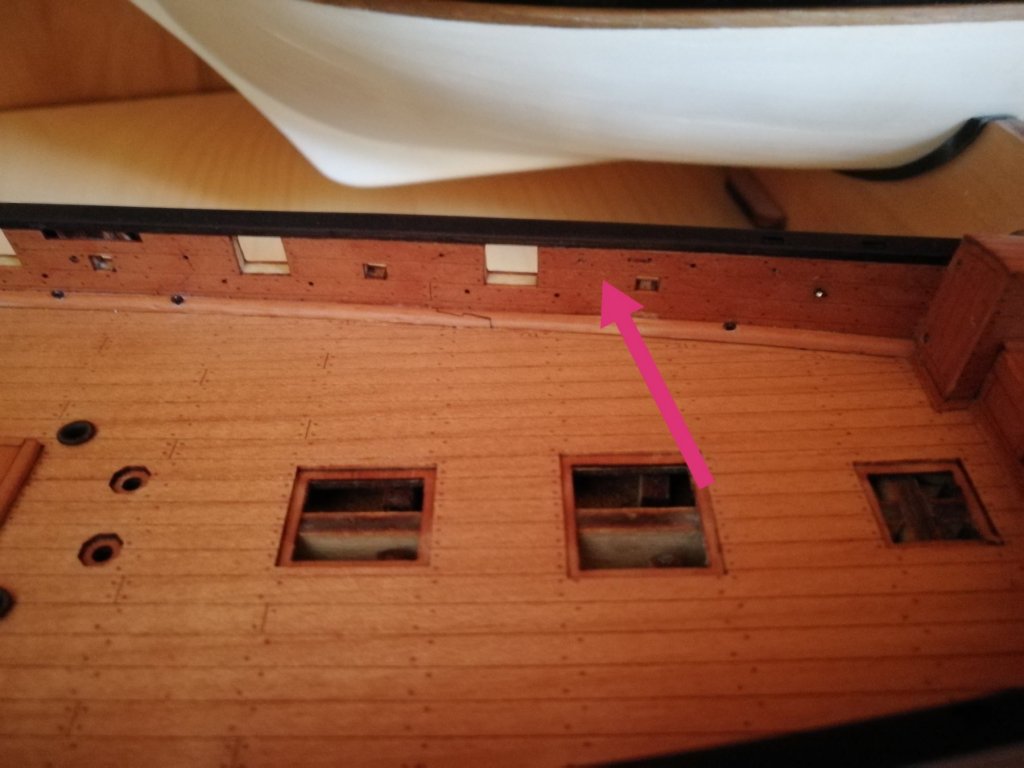

Back in the workshop with some small progress. I have added another pair of the secure rings @DPK's advice. Thanks again. I have finish few final touches on the windlass and secured it on the deck. I have experimented with the belaying pins. Luckily There are few spare so I could blacken one to se how it looks on the ship. Still not sure what I will use, if clean brass or black (leaning little bit more for black version). Here is the comparison. What do you think??

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

That is very nice! 👏

- 103 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Perfect, thanks a lot @DPK I will do 2 more rings and go with ladders👍

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

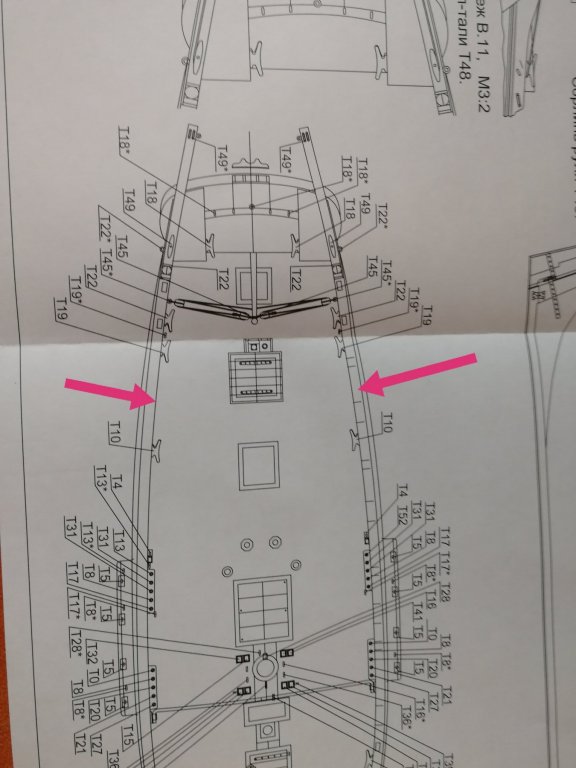

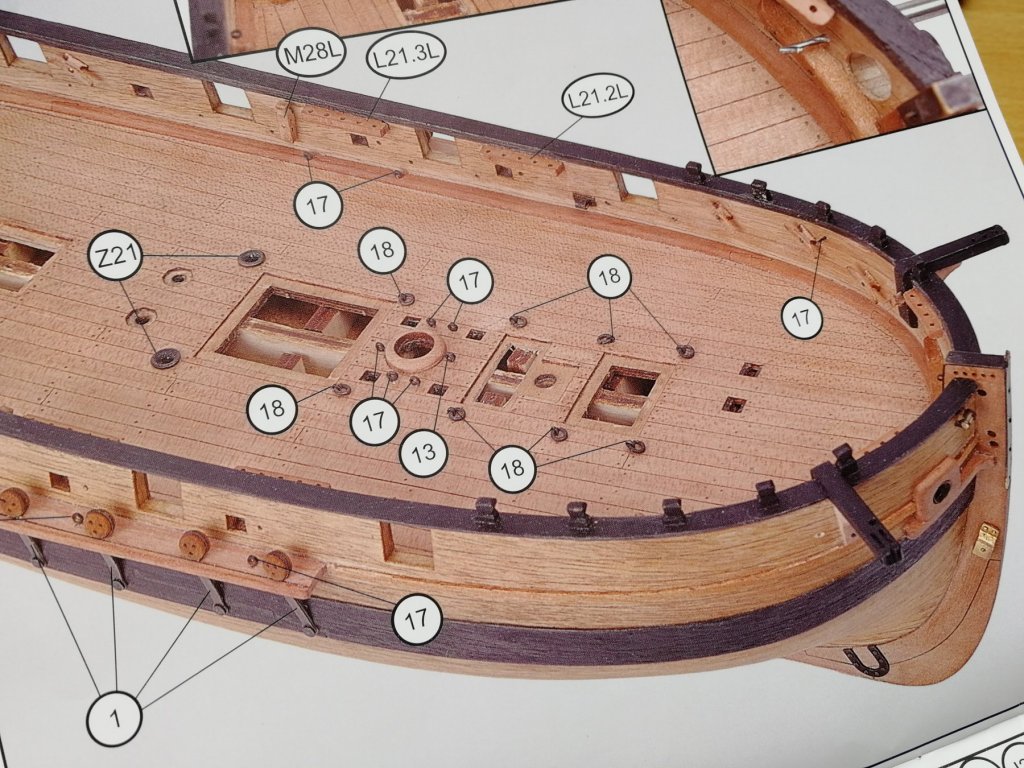

Preparation of the route for anchor cable. @DPK @greenstone can I ask you guys for advice? There are two pre-drilled holes in the deck forward to the bow from the bell in the same line with other rings for securing the cable. I guess There should be another pair of rings? But it is not in instructions so I do not know if I can use 2 more photo etched parts #18 (are there some spare or the count is exactly for the model?) or should I produce my own? Thanks a lot!

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

Ohh god, I feel so bad now (I scrolled Down this thread) and see the stage where I stopped. But I really needed rest from rigging. Unfortunately/fortunately AVOS cought me so deeply that I can't go back to RC right now BUT I PROMISE I'm GOING TO FINISH THIS PROJECT!! please Just be patient. Thanks to all followers and all who likes what I am doing. In case you would like to see the ship I'm working on right now..... It is a lovely kit. So much fun building it! PetaV

- 128 replies

-

- panart

- anatomy of the ship

-

(and 1 more)

Tagged with:

-

Thank you Greenstone. It is my personal choice.I found it distracting leave it in brass when all other irons are black. I do not like colourfull models so that is the reason. Not sure what I do with belaying pins🤔

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

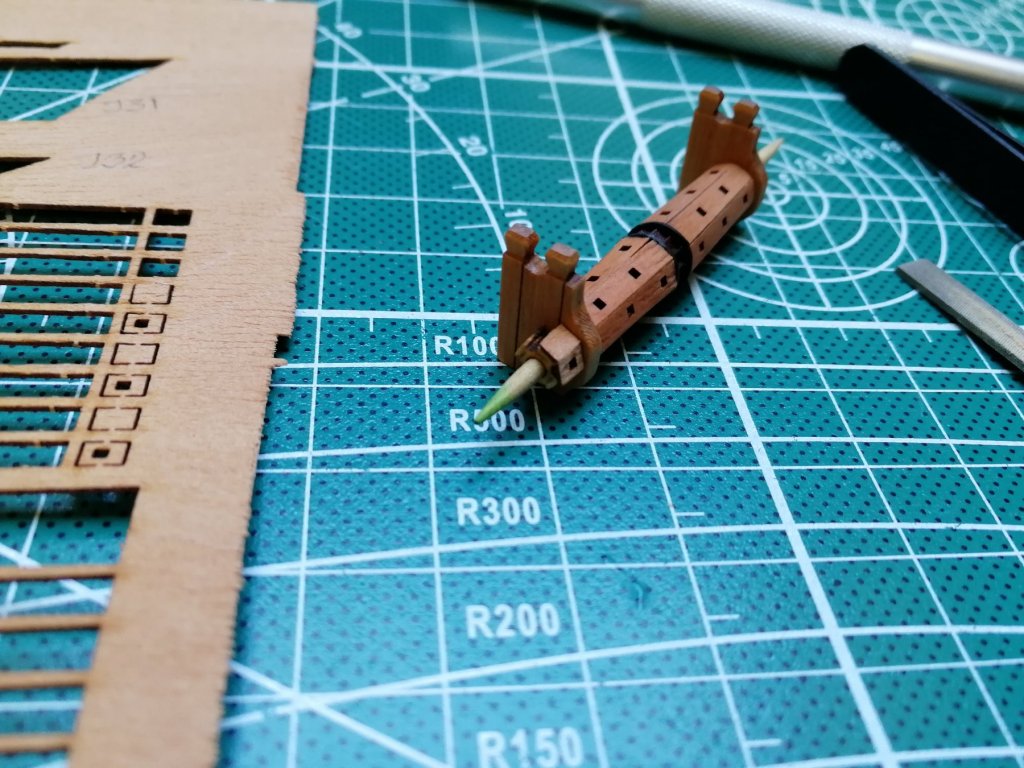

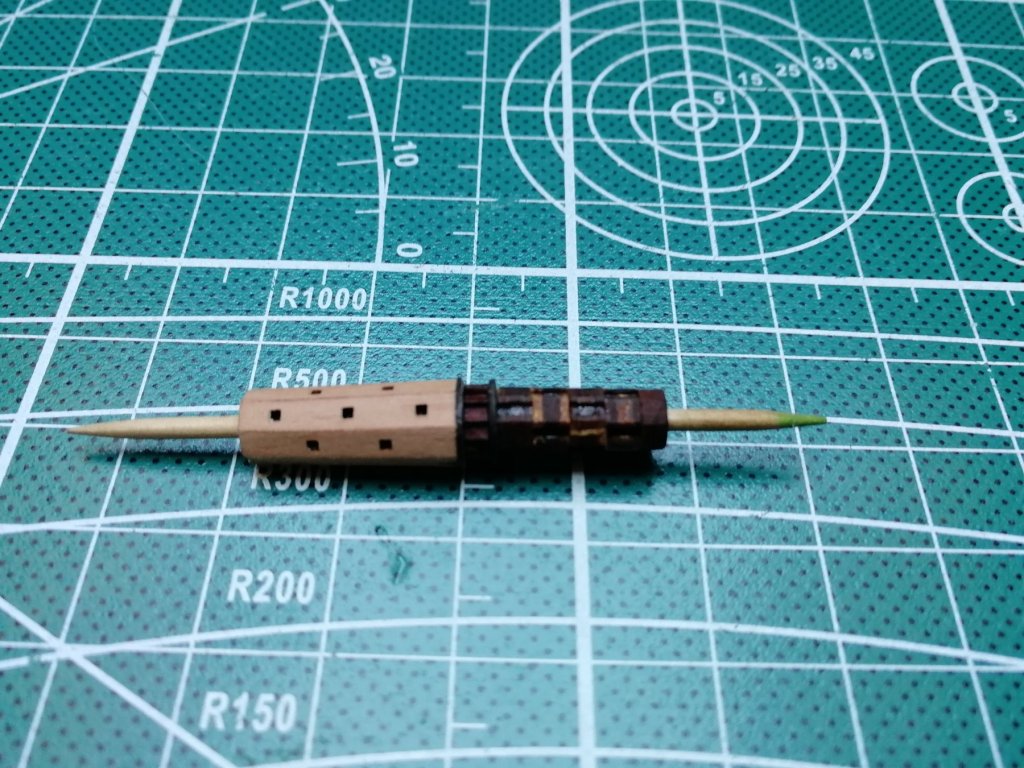

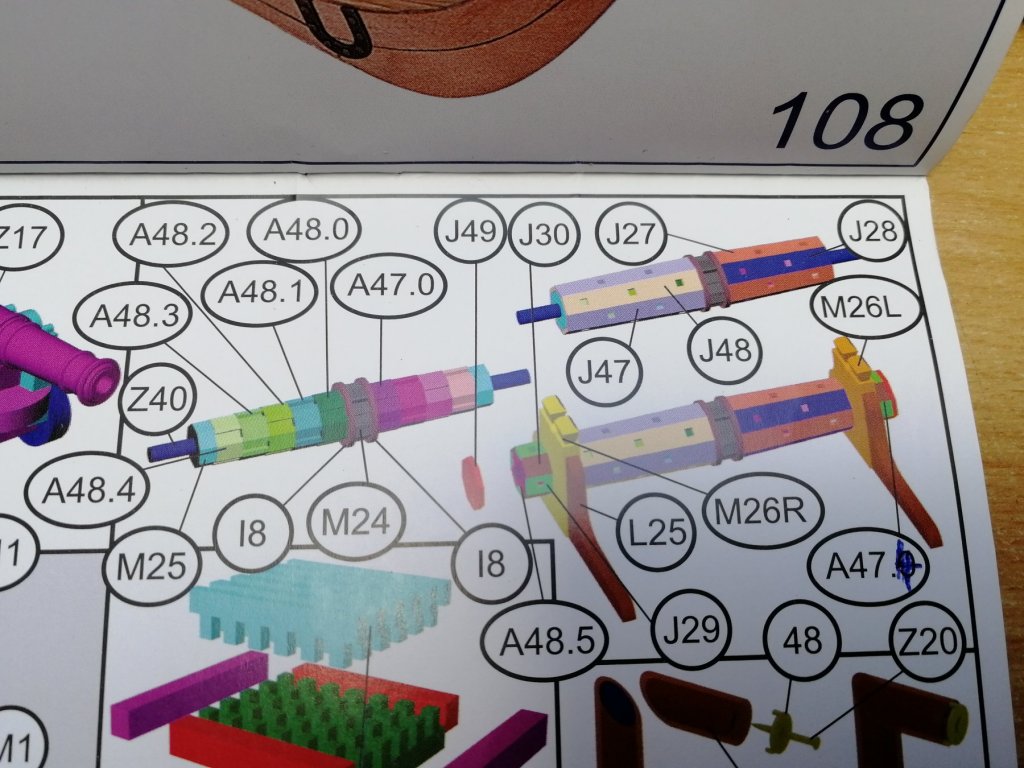

Windlas part2. Everything went fine to this stage. Time consuming as there are lot of pieces but smooth process. Until this small detail came. It is so tiny and will be made from 10pieces. Nice test for the nerves

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

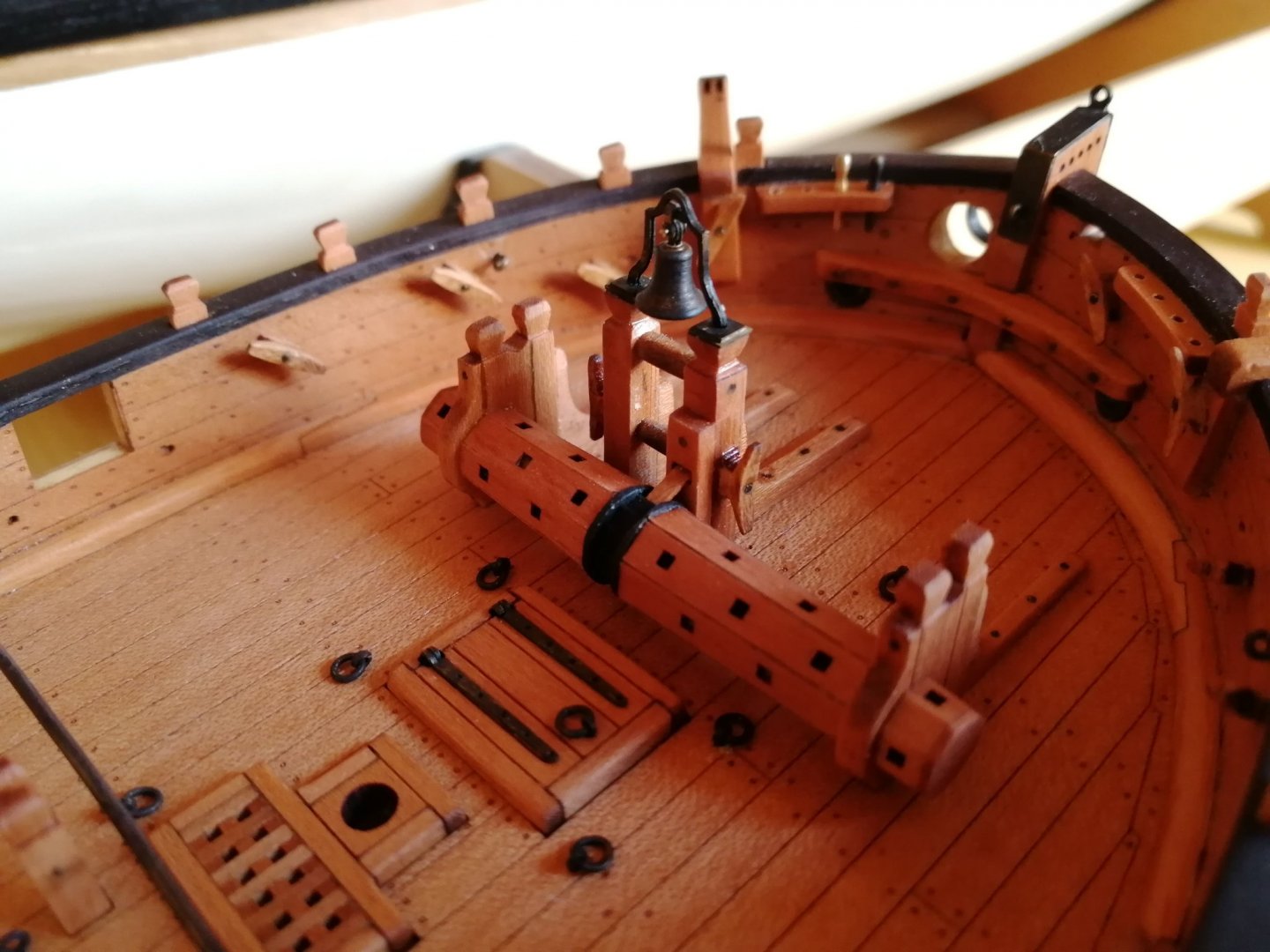

Windlas assembly. It has pretty complex shape but it is cut to "hundereds" small pieces that creates all the details which makes the assembly much more friendly then carve it from one piece of wood.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

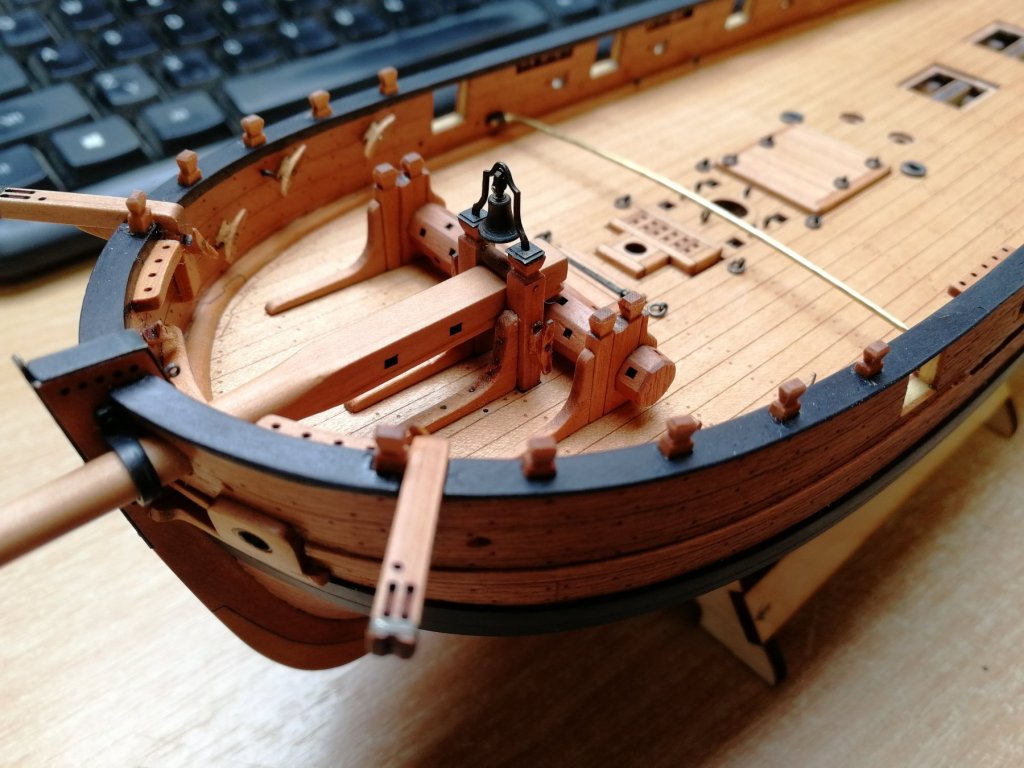

Continueing with the deck details. I added some hatches with Iron work. I have also placed many eyelets but it is still not all. I have also added the supporting knees to the belfry and glue it in the pkacd

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

-

What a ship! Congrats for finishing her. It is a Master piece! 🥳

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

Thank you! But half of the work came from you guys! I did only assembly.

- 315 replies

-

- master korabel

- avos

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.