-

Posts

661 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by DaveRow

-

-

Hi Greg,

Just found your log, a went through every page.

Very inspirational and fantastic photo diary.

Lots of top ideas for us beginners to learn from, my Endeavour being a first time build, need all the ideas and tips as I can get I reckon.

Keep the spirit(bundy ?) up.

-

More blocks, more blocks and more blocks hey Greg. When will it end !

Looking really great.

Your Endeavour log will come in really handy when I get to the rigging etc.

I'm plodding along on the planking.

Keep the excellent work shipmate.

-

So I have been pondering on the Tree Nails on the hull - how to do them and to get a finish look I'd be happy with.

Made a test set of planks and glued a row of sharpened plain match sticks in. 0.7mm holes.

I'll see how they finish off when cut flush and test a few stains on the end grain to see how they come up.

-

I wasn't at all happy with the kit stern detail. 5 metal windows - no way.

Decided to build from scratch the stern including windows, Taffarel etc. based around the AOTS details.

Progress so far in the picture - with a lot more to do(scrolls, figurines etc)

I have made the 4 Dead-light window hatches as well(not fitted). I have made some hinges, but a wee bit too wide and plan to grid them narrower. Now that I put them on the hatch, looks like I'll be changing the pin angle?

-

Hi Shipmates,

Planking on hold for a bit, as my left shoulder muscles are traumatised heaps - lifting too much.

So added the Naval Hoods at the bow. That pushed me a bit with the arm problem.

I glued 2 planks, then bent to the bow shape, trimmed and glued in place.

I am not sure if I brought the bow high enough up, as the holes only just make it through to the deck, even drilled up a ~ 30deg. angle.

Too late to change - will live with it.

- rvchima, kiwiron and Captain Slog

-

3

3

-

Thanks fellow shipmates; Udok, Mirabell61 & shopaholic.

Trying my best to get those planks fitting snug. Wrapping and holding a plank in place around the bluff bow is a challenge. I actually did each as a 2 stage process.

First pre bend the plank to the shape of the hull line, glue it from the stem to frame 2, let it dry(Picture below)

Then glue the rest back to the rear. joint.

Takes time eh !

- kiwiron, maddog33, Captain Slog and 1 other

-

4

4

-

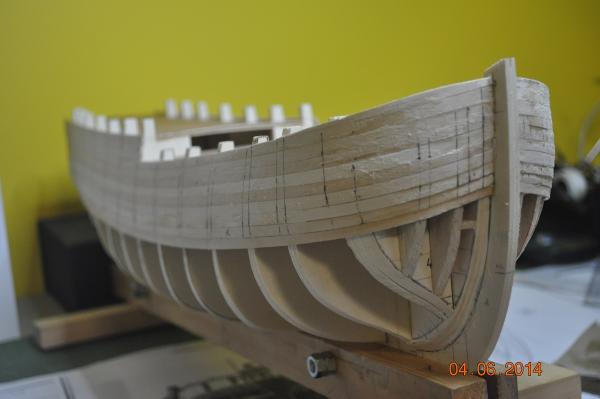

My boatyard has completed 2nd layer planking(1mm) down to the wales - both sides.

Picture - close up of the Starboard Bow is before a slight sand.

Picture - Starboard side after I lightly sanded the planking. Came up pretty good I thought considering. Didn't pay any attention to position of light or dark planks, random as they came out of the stock.

I did physically break each plank run at least once(1), and other breaks I will score the plank to indicate a join. Hope that is sufficient to indicate the joints. Joints bit add hock > at the start went a bit haywire, then started a 4 way pattern.

Next task is to add the wales !

1 x 1.5mm thick plank(thickstuff above the wales) then a series of 2mm to make up a 12mm wide band for the wales.

So this will provide a 2 steps on the top of the wale and 2mm to 1mm step below.

I've decided my boatyard will follow the AOTS by Marquardt as close as it can.

- kiwiron, Captain Slog, CaptainSteve and 3 others

-

6

6

-

-

I bet you're glad that's done and dusted Greg.

Going to look great on the model.

-

Hi Greg,

Fantastic workmanship.

Your attention to details astounds me.

Something for us all to aspire too.

For me, back to the 2nd layer of planking on the Endeavour, very, very long way to go...

-

Looking good Udo.

I am also building the Endeavour.

I am onto the 2nd layer planks, above the wales.

My first layer - had several planks that split when bending at the bow.

I'll keep on eye on your log.

Cheers Dave

-

-

A couple of members have asked whether this is my first wooden ship build. Honestly it is. However, I am a design draftsman, attention to detail is part of my trade. I also spent nearly 30 years sailing on many types of sailing vessels, fixing and modifying many of them. I have also completely rebuilt our family house - and yes it is out of timber. See where I get it from... !!

Hi Pat,

Yes I plan to add the tree nails and pins - good idea me think, all to lock in the 2nd plank layer to substrata. Have been reading up on how it make them tree nails, and install(wow something to test out for me - a while off to get something working).

Thanks for the tip on the capping strips, I plan to construct new channels as the kit ones have too many holes along the length and from ply ? I prefer to us solid timber for these. or I could glue on a slightly thicker capping strip around the edges ? fake it ? something to mull over.

Back to planking ! slow going down to the Wales. I think I should of started from the wales and went upwards. !

- Mirabell61 and CaptainSteve

-

2

2

-

Research Materials:

I managed to source and purchase a First Edition 1997 including all 15 plans of "H.M. Bark Endeavour: her Place in Australian History" by Ray Parkin.

Thanks Pat for guiding me to find this book.

Need to set some time aside to do some reading.

-

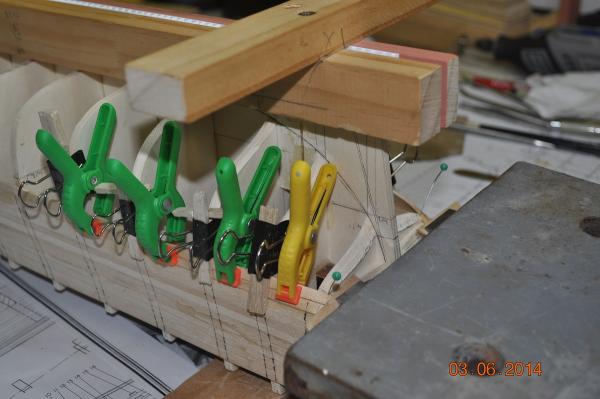

Planking update - this will seem to go on forever.

Second layer:

Now I have not done a lot of research to how to add plans onto a first layer. At the moment I am getting away with gluing and holding each on the side with drawing pins. On the bends is another matter and I either use my contraption(that help hold the cramps in place) or craps to hold the plank in place while the glue dries.

Speaking of glue; I am using a 2 part Epoxy called "Compset 121 Gel". Gives me a 30min wet time then goes off semi-hard in 1 hour, but fully rigid in ~12 hours. I got it from a boat builder mate who uses it on full size boats. Works very well and the whole boat to date is glued/held with this glue.

A pic. of how I use a small length of plank below a glued plank joint to get a good line for the next row below.

Channel Slots:

I created 3 slots in the Sheer Strake(rail) for the side channels. Picture below of how each will slide in. When glued each should hold really well.

It works for me !!

- Zarkon, The Sailor, kiwiron and 7 others

-

10

10

-

Thank you all for your kind words.

I have had a good look and the logs on some of your builds, the details you guys go too ! Wow it encourages me to do great things.

Planking 2nd Layer Pic:

Progress to date, slow going on these, trying my best to get no gaps and no chines (ha, very hard). Thank god for sandpaper.

An hour or so a day, usually enough to fit a plank and glue in place, leave 12hrs to dry.

This is my first wooden model build. As a kid I remember assembling dozens of plastic model kits. Dabbled in some real size boat building somewhat during my yachting days(some time ago now).

I'll hunt the Ray Parkin's book down. Thanks for that tip Pat.

- Piet, kiwiron and Captain Slog

-

3

3

-

Fixing errors:

I extended the 2nd planking through to provide the cover to the Quarterdeck steps.

I am going slow. I check between the kit plans(and build notes) and the detailed diagrams in Marquardt's Endeavour book. The more I delve into the Anatomy book, I realise I will be building the Endeavour to Marquardt's details. Much better than the Corel plans and basic details.

-

- Captain Slog, Ponto, Piet and 4 others

-

7

7

-

- Ian B, The Sailor, Beef Wellington and 5 others

-

8

8

-

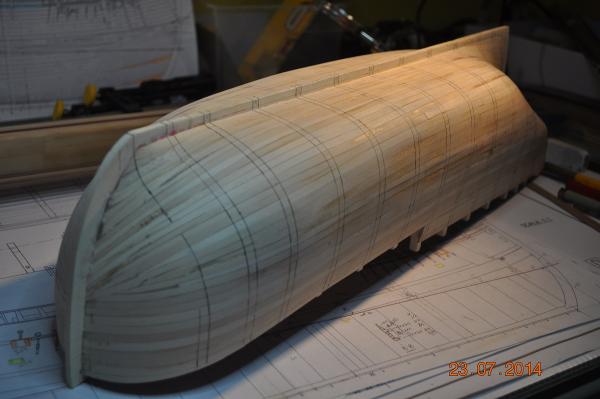

1st Planking:

All 1st planks glued onto the framing, sanded smooth ready for the 2nd planking. Fun begins on the more important, and visual planks.

I learnt a lot fitting the first layer. Found some information on "planking rules" which I practiced on some of the final planks.

I was pretty happy that I got a fair shape in the end. A few mistakes on the way, but hey got to learn.

- edmay, hamilton, Captain Slog and 6 others

-

9

9

-

-

-

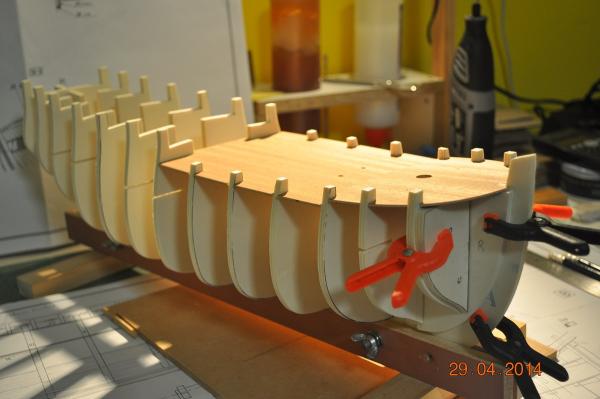

This is my first build of a model wooden ship.

I chose the Endeavour as it is part of our nations discovery, and plenty of others being built to see gather tips and trips for the build.

I am using 2 pack epoxy glue(no nails) for all the timber to timber joining.

From what I have seen, the build may take years, and just as well I have started now, plenty of time to finish in retirement - when it comes.

Enough waffle, some pictures and see where this goes.

-

Hi Greg,

I am envious of your workmanship and hope I can produce the detail as you have.

I have been planking my Endeavour(Amati Kit) for 3 months now, and just getting the 2nd layer going.

A lot of the supplied fittings are going by way of the bin - not happy with them at all.

I have a question if you do not mind.

The hinges for various hatches - did you make them all ? or purchase ?

I have looked a few options, but not happy with any to date.

HMB Endeavour by RGL -FINISHED - Artesania Latina

in - Kit build logs for subjects built from 1751 - 1800

Posted

Great looking ship there Greg.

Looks good with the sun on her.

Dave