-

Posts

2,611 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

In addition to the grating, the sole also has a rower’s foot rest. This was made first cutting two channels into a 3/16” x 1/16” piece of boxwood and beveling the edges. Using the razor saw and miter, I sliced up twelve 1/64” thick foot rest supports. To use the miter’s stop, I had to use a piece of wood as an extension because I couldn’t set the stop to 1/64”.

-

I thought about how to reproduce these. The problem of course was scale. 1/76.8 is just too small, at least for me. The kit however provided a compromise. It provided a photo-etched mesh to use in lieu of creating one or just faking it. From what I have seen on other builds, the mesh was cut such that they ended up with a fine square cross-hatch pattern. I wanted to emulate the chevron pattern. First off, I made a pattern for the sole and then made the sole itself from 1/64” plywood and stained it mahogany. An opening was then cut matching the plans. Instead of just cutting out the mesh to the shape of the grating, I split the mesh such that when the two pieces were put together, the mesh holes were on an angle, more reminiscent of the actual grating. Looking at the plans, I also noticed that the grating did not have a frame around the edges due to the method the actual grating was made, so I deliberately made sure my cut mesh had ragged edges. The two pieces were aligned and CA’d into place over the sole opening.

-

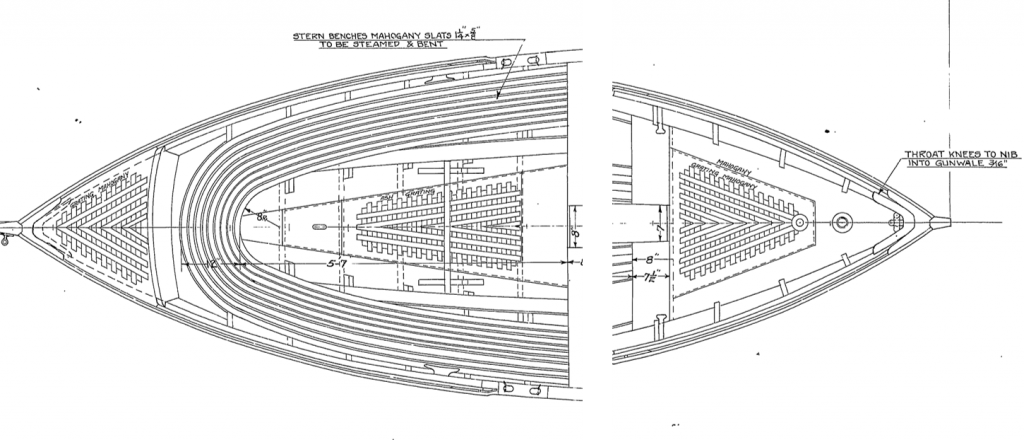

Gig The gig, when last worked on, only had the ribs and keelson installed. So now the question was, what to do next. The kit plans basically state, follow the plans and make the boats. The practicum does not put in all the detail I want to include. Other build logs don’t have the detailed step by step guidance I was looking for. So, after a number of false starts, I plunged ahead. Working from the bottom up, inside to outside progression, I decided that the sole at the stern was a good place to start. The sole has a unique grating. In fact the gig has three unique gratings. They look like chevrons instead of the typical square cross-hatch patterns…and they have very fine openings.

-

I like your sense of humor. Sometimes that's all you have to keep going 8-) Jon

- 67 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

When I wrote the above comment, I did check your log for the construction of the boat but didn't go back far enough. I had forgotten that you indicated that you followed my log in making the boat. Installing the boat requires that you first install the spare masts to support the boat which need to be lashed down first, and then the boat mounted and tied down on top of those. It's the tying of those lines which will become difficult as you add more rigging that may interfere with that process. I tried to work from the inside out, bottom to top. The boat is inside bottom. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

The tiller was made from boxwood to resemble the US Navy plans and inserted into the rudder stem where a hole had been previously drilled. An additional hole was added on the rudder where it jets out midway down. A final coat of Minwax Polycrylic was added to the whole model to protect the bare wood and add a little gloss to the painted sections as well. One down, three to go.

-

Pinnace Rudder The last major piece of the pinnace is the rudder. As in my previous part fabrications, I made a template from the US Navy plans and cut out the part from some boxwood stock. So far everything was going smooth…too smooth as it turned out. To my surprise, when I placed the newly cutout rudder part next to the stern of the pinnace, something was wrong…very wrong. The part matched exactly the shape and size in the plans as all my other parts had done except in this case IT WAS TOO SMALL for the boat. What was going on? The length of the boat was correct, so was the width, but not the height. I never measured the height of the hull once it was carved. I never thought to check that dimension since the hull was formed using the pre-cut pieces that made up the bread and butter sandwich method construction. Subconsciously I just assumed the carved hull was correct for outside dimensions. For some reason(s), either accumulative measuring errors, I didn’t remove enough material during the carving process, or whatever, the hull was too tall. I was not about to shelve this little model and start over. To salvage the model, I decided to just go with it and only I, God, and the readers of this log would know. I got on the computer, brought up the image of the US Nay plan of pinnace (reduced to scale) and stretched the image vertically to reflect the actual build height. That image was printed, a new template was made, and a new part made. In the photo below you can see the difference.

-

Beautiful looking model. I noticed that you haven't documented the building of the ship's boat. Have you made it yet? You might want to think about installing it soon before you have too many lines interfering with a clean installation. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Pinnace Fender The last thing to install on the hull (excluding the rudder) was the half round fender. Per the US Navy plans, the fender 2½” x 1¼”. This translated to 1/32” x 1/64” at scale which matched the kit’s instructions. Now that is one fragile strip of wood. I chose to use 1/32” x 1/32” because wanted the extra strength as I pulled it through a scraper to create the half-round profile. When I was done, I needed my magnifying headset to actual see the roundness and to be sure I was gluing the proper side to the hull. In other words, nobody but me would know I had even bothered to shape the fender Initially when I was pulling the strips through the scraper, the fine strip would curl 90-degrees towards the scraped side, opposite of what I would have liked. Dipping my fingers in water and pulling the strips through my fingers removed the curl as the water seeped into the wood. To ensure the strips didn’t re-curl as they dried, I hung them with a clothes pin as a weight to keep them straight.

-

Thanks for the tip Glen. Unfortunately I thought of the same thing after I had made them all. Hindsight is 20-20 as they say. I got the razor saw and mitre box at one of the NRG conventions from a company called UMM According to the box, their website is umm-usa.com. I believe Micro-Mark sells the saw; l don't know about the mitre box.

-

I'm in awe!! I have never seen anyone make yards in multiple parts before. That is a nice bit of craftsmanship. Is there a reason you chose to take this route as opposed to making the yards in one piece? Having never made jackstay before, does the rod running the length of the yard pass through a very fine eyebolt? Jonathan

-

The practicum would have you glue in place the rails with the required spacing to create openings for the rowlocks. Then it would have you custom fit cut styrene flat pieces to create the locks. I did it differently. Because the rowlock had to be in specific positions, I installed the first set beginning at the bow end. The rails at the bow were pre-bent to the required curve and custom fitted between the stem and the first rowlock. The next set was done the same way; install the lock first, then the rail till the final rail was installed reaching the transom.

-

Pinnace Rail and Rowlocks The 14 rowlocks were fabricated from a 1/8” x 1/16” piece of basswood stock to match the rail height of 1/16”. A channel was cut along the length of the stock by making multiple passes with my Byrnes Saw. The piece of channeled wood was then sliced to 3/64” lengths like a loaf of bread with a razor saw and its miter accessory. Then one side was filed to a 45-degree angle to mimic the actual rowlock. This was the hardest part because trying to hold these tiny pieces secure enough so I could perform the actions required as well as seeing what I was doing was a real pain in the… fingers. Finally, they were all painted black as directed by the kit’s instructions.

-

The Mamoli Rattlesnake, my first build; and I jumped in with both feet doing the complete Hunt kit-bash. Now I'm doing the USS Constitution. What I have learned from the Hunt's practicums, is first, I could not have done the Rattlesnake without his guidance. The second thing I learned was that I relied too heavily on his instructions rather than read the kit instructions on the plans and make my own judgement calls. I would also make a suggestion as to the kit's plans - transcribe them to notebook paper. I found they were very difficult to read (for me at least) due to the small print and inconsistent contrast. In a notebook, it's much easier to make notations. I did the same thing with the rigging charts, and parts list. The parts list to have to translate yourself. I look forward to following you on this endeavor. Jonathan

- 67 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The Stem and Keel Before I move onto the rail and the rowlocks, I wanted to add the stem and keel to the outside of the boat. The rail needs to attach to stem. The stem was made in two pieces: the rounded bow and the straight upright portion of the stem. Trying to edge bend the 1/8” x 1/16” stock was near impossible. Once the stem assembly was fabricated and installed, the keel was added with lots of overhang. The keel widens as it follows the shape of the up to the transom. I made a card template to get the shape, and transferred it to some stock wood. The piece was then fitted and glued into place. All of these pieces, including the knees described above were glued with PVC glue to aid in adjusting the parts. The stem and keel were then painted (not shown).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.