rcmdrvr

-

Posts

396 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by rcmdrvr

-

-

-

-

-

I am continuing to make progress with planking the hull. I am soaking each plank about 2 hours. My "soaker is a capped 1 inch PVC pipe filled with water. I have two so I can soak about 10 to 12 planks at a time. I live in So. California and it has been about 95F lately so I have to work quickly. The planks dry out in about 10 to 15 minutes.

- GrantGoodale, Elijah, EJ_L and 1 other

-

4

4

-

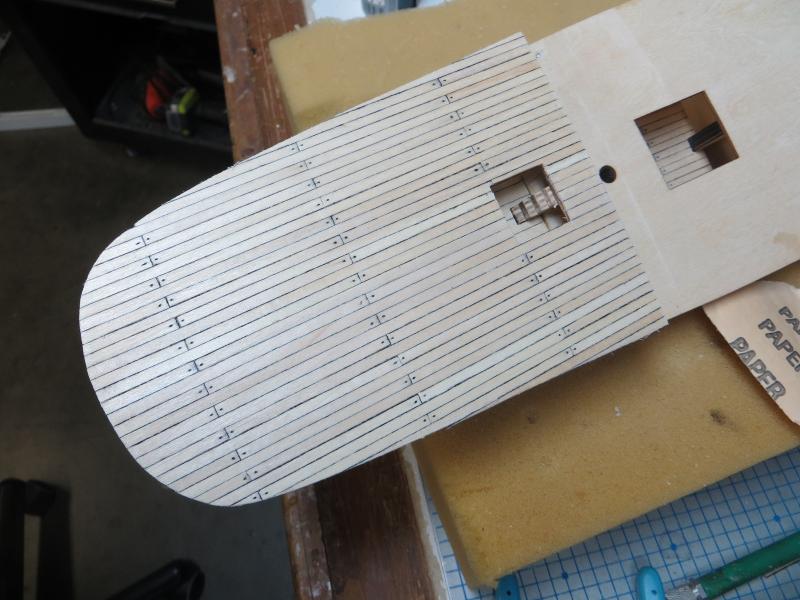

With the deck planking almost completed (I only have to simulate the tree nails); I move on the hull planking. The wood provided has a cross grain at about 30 degrees so it wants to splinter when bent. I am soaking for about an hour which gives me about 20 minutes work time. Since the hull will be painted and coppered; the planking does not have to be pretty.....just shaped correctly and smooth. I am using a CA gel to affix to the bulkheads.

- rowand, GrantGoodale, EJ_L and 2 others

-

5

5

-

-

-

- EJ_L, Elijah, Farbror Fartyg and 3 others

-

6

6

-

-

-

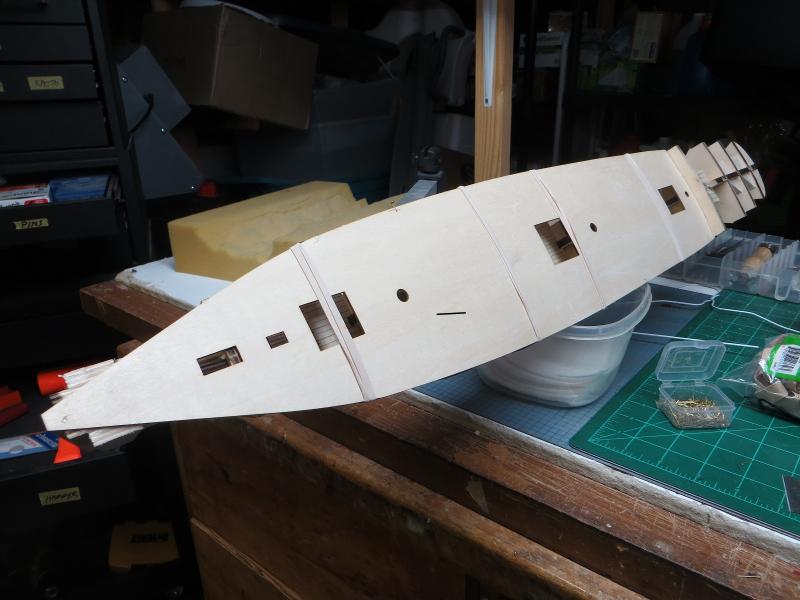

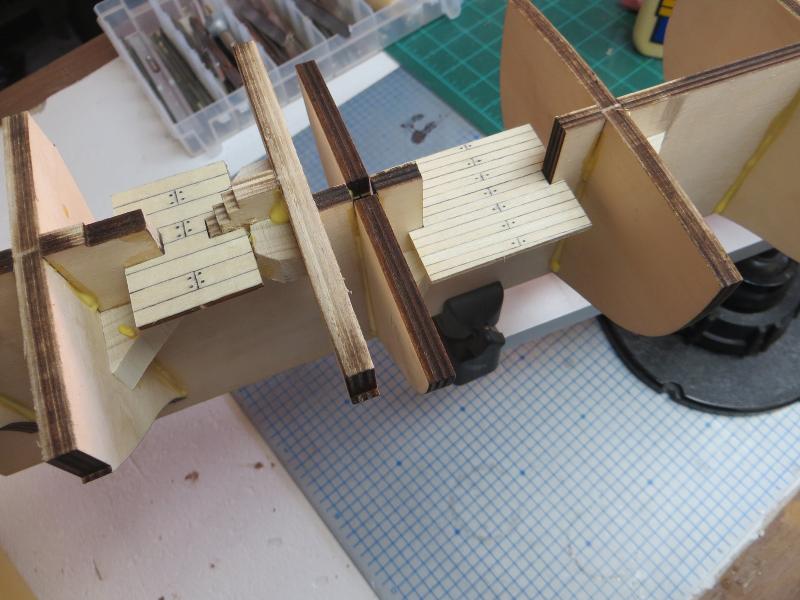

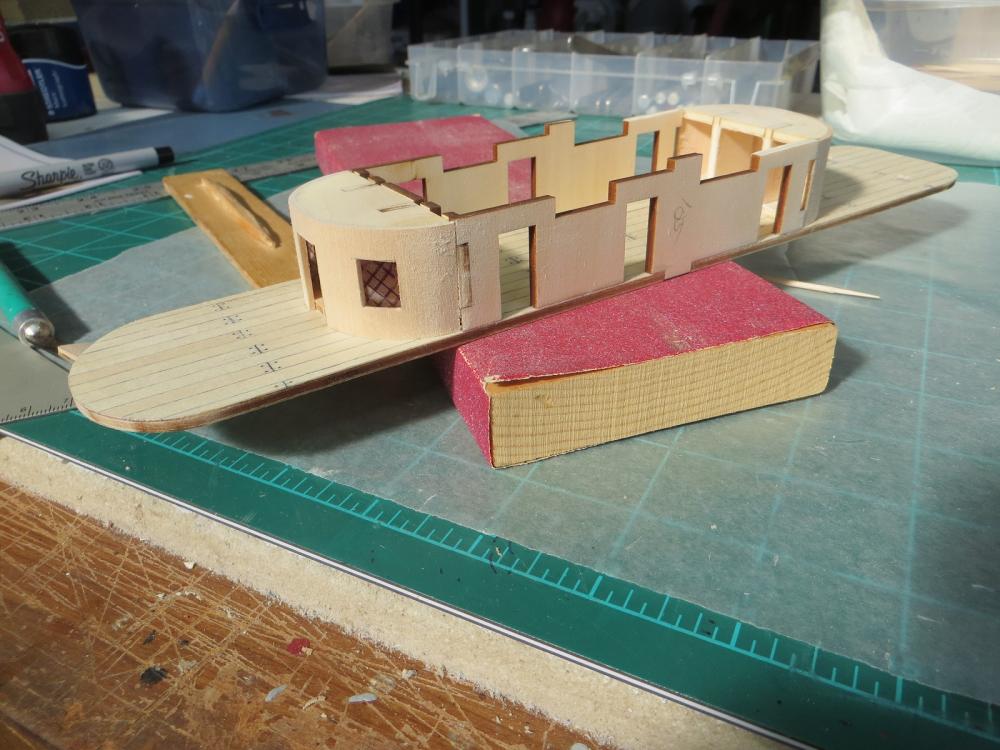

The following photos cover the first week of building. First is attaching all the bulkheads to the keel and getting everything lined up and straight. You notice that I cut a bunch of wood triangles which are into the structure to ensure that the bulkheads stay at 90 degrees to the keel.

First I fitted all the bulkheads to the keel and made sure that they would slide into the pre-cut slots.

-

Well I took the plunge and purchased the Cutty Sark by AL. This looks like a very complicated build so I am hoping that I am not getting in over my head. The materials in the kit look very good but I will update everyone further as I go along.

I am going to head over to Amazon and see if there are any books about the Cutty Sark with lots of good pictures. I visited the museum website and they offer a book; but it might take a few weeks to reach me from from the UK.

I want to put down my "building philosophy" so you can better understand some of the decisions I will make as I move along. First....have fun. I love working with my hands and this looks like a lot of hand work will be involved. Two....I will never reach the skill level to build "museum quality". This model will end up in my house and the quality I look for is enough to make me happy and get my guests oooh and aah. Three....have fun.

First photo, the box and its contents.

-

-

Thank you for your complements

-

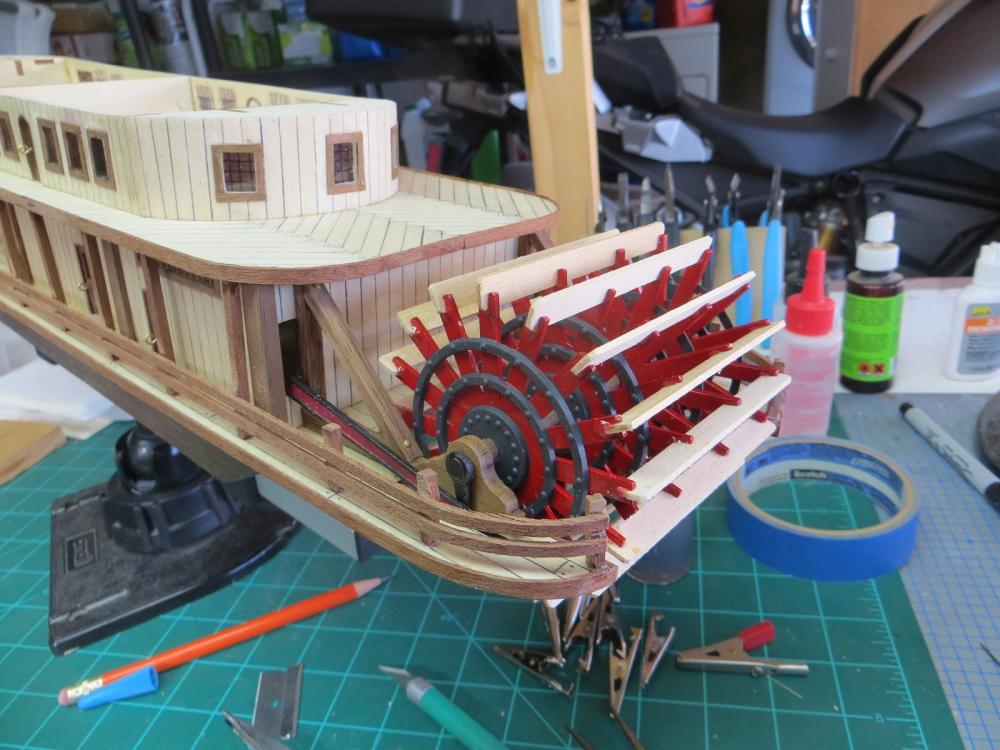

Completed. After three month of work I declared the project completed. I know that this has not been a detailed log of construction steps but I am pround that I brought this log to its completion. If anyone has any questions, please feel free to send me email.

To any one thinking of building this kit. The die cut parts fit. The wood is in good shape (but they have it measured down to the last inch so be careful with your cuts). When done it makes a really neat conversation piece.

-

-

This is an interesting thread. I think one of the success resources this site provides is the log. I allows the experts to make their posts and show us beginners how many aspects of the build are accomplished. It also allows us beginners to make our posts and seek advice on the model shipbuilding process. As I research my future subjects on this site I find that some builders attract very little attention to their logs while others become rather lengthy with many builders "pulling up a chair to follow along". How do these logs become so attractive. I guess I am asking is what does a log require in order to attract attention and the resulting comments. Put another way, what constitutes a good log.

-

Next came the smoke stacks. These were tougher to build than I though. First the painting. I sanded, prime and sanded again. Then the coat of black paint. Looked pretty good until I went to install the brass rings. The radius of the smoke stack dowel exceed the radius of the brass rings. I had to cut the rings and "slip" them down the dowel. They scratched the black paint. I glued them in position and then repainted. The bracing between the smokestacks and the tops took a little filing and priming before painting. All-in-all, I think this model is beginning to shape up. Now it is on the railing.

- Snoepert, Jeff-E, Mike Dowling and 2 others

-

5

5

-

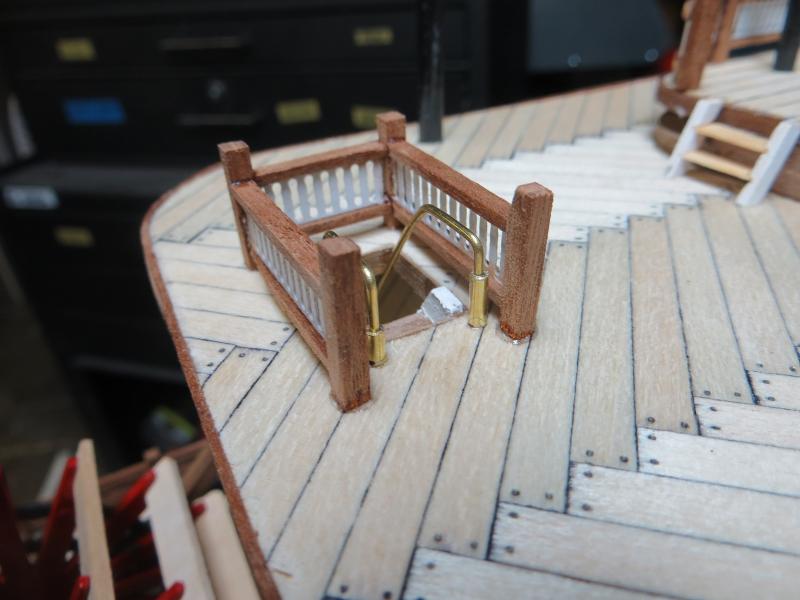

It has been a couple of weeks since I last posted to this build log. I have now added the wheel house to the model. The wheel house itself was quite straight-forward. Build a box, plank and stain. The windows and doors took a little effort; but turned out alright.

The ramps leading out of the wheel house to the 3rd deck were a bit of a challenge but I think they turned out OK. The kit supplied 3 scalloped brass strips to form a border around the 3rd deck. For some reason, mine did not reach fully around and left a 3 inch gap which I could not figure out how to hide with the ramps. In frustration I tossed the brass strips and built a wooden railing around the 3rd deck. Not "scale" but I think still adds to the model.

- Jeff-E, John Allen, Cathead and 1 other

-

4

4

-

- WackoWolf, Mike Dowling, Jeff-E and 2 others

-

5

5

-

-

- Cathead, Jeff-E, Mike Dowling and 4 others

-

7

7

-

- hof00, Mike Dowling, WackoWolf and 2 others

-

5

5

-

Cutty Sark 1869 by rcmdrvr - Artesania Latina

in - Kit build logs for subjects built from 1851 - 1900

Posted

Here is one side almost complete.